Production method for bis-(2-hydroxyl isopropyl)benzene

A technology of hydroxyisopropyl and production method, which is applied in the production field of di-benzene, can solve the problems affecting the oxidation reaction speed, etc., and achieve the effect of increasing the speed and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

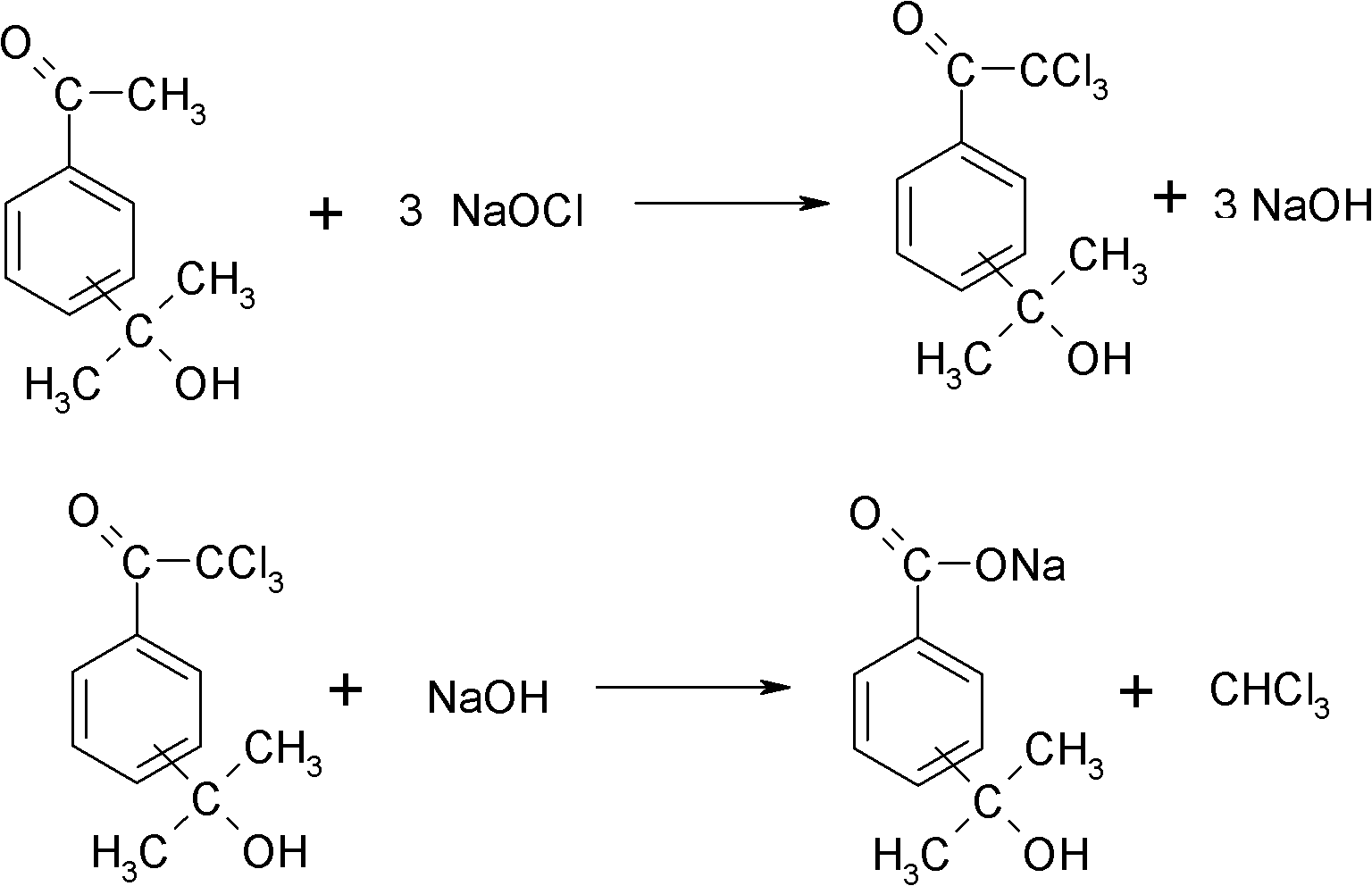

Method used

Image

Examples

Embodiment 1~7

[0024] The recycled dicumene stream III containing KC is fully contacted with the sodium hypochlorite solution, and the water phase is excluded after standing for stratification to obtain the dicumyl stream I meeting the requirements. Wherein, the weight percentage concentration of sodium hypochlorite solution is 10%. Contact temperature, contact time, weight ratio of dicumyl benzene stream III to hypochlorite solution, content of KC in dicumyl benzene stream III before treatment, and removal rate are specifically shown in Table 1.

[0025] Table 1

[0026]

Embodiment 8

[0032] The recycled dicumyl benzene from which KC has been removed and treated in [Example 4] is oxidized with air, and then reduced with a reducing agent to obtain bis-(2-hydroxyisopropyl)benzene.

[0033] Wherein, the oxidation reaction temperature is 100° C., the reaction pressure is 0.25 MPa, the reaction time is 24 hours, and the weight ratio of dicumyl to air is 3:1. The reduction reaction temperature is 65° C., the reaction pressure is normal pressure, the reaction time is 6 hours, and the molar ratio of reducing agent to MHP is 4.60:1.

[0034] The initial MHP content was 2%, and after 24 hours of oxidation reaction, the MHP content was 30.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com