Ozone oxidative decomposition treatment method for vocs and/or gaseous inorganic reducing compounds in gas

A technology for ozone oxidation and decomposition treatment, which is applied in gas treatment, inorganic chemistry, separation methods, etc., and can solve the problems of slow ozone oxidation reaction, unrealized practical application, and complicated treatment of unreacted ozone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

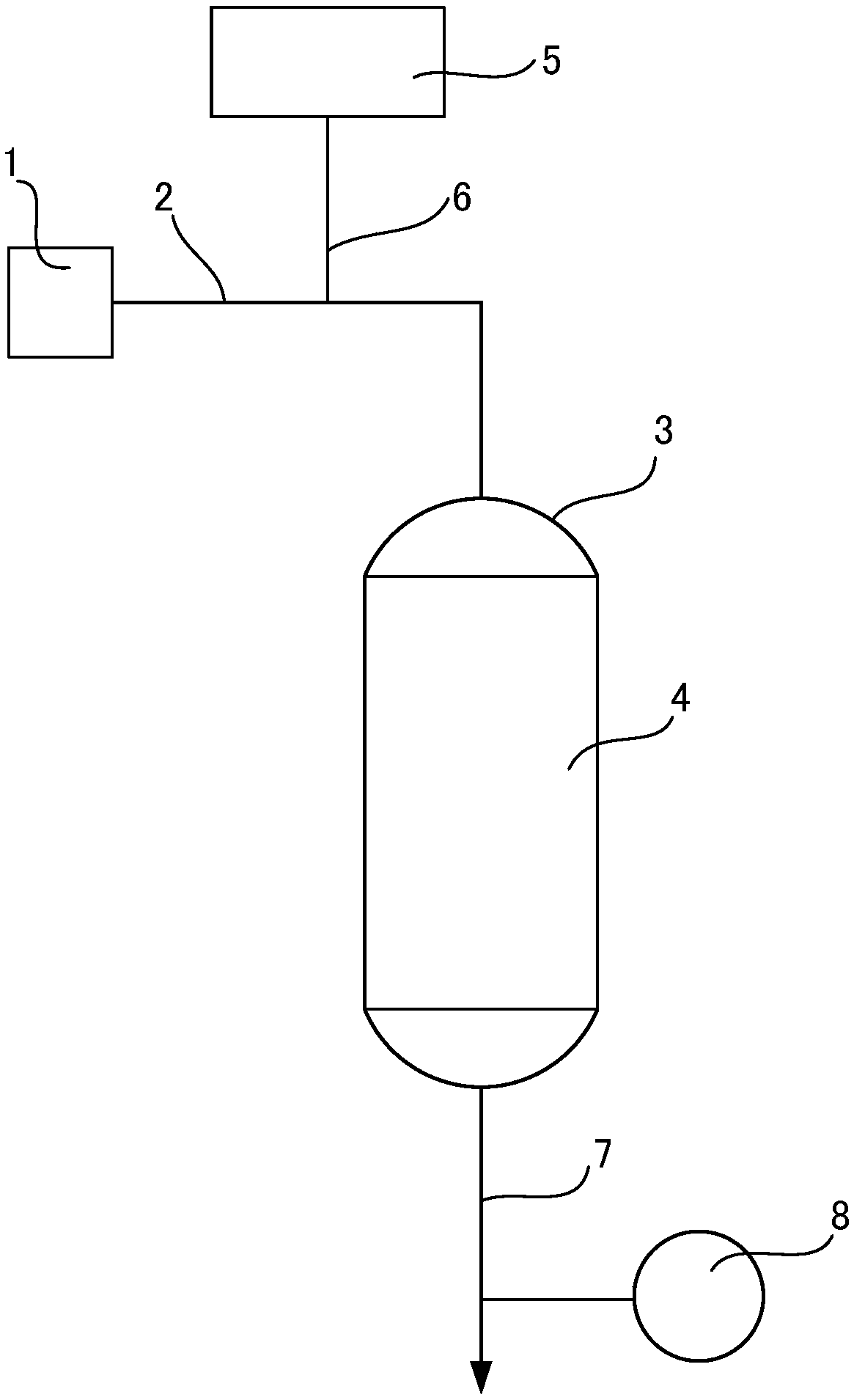

Image

Examples

Embodiment

[0028] Hereinafter, examples and comparative examples are given and the present invention will be described in more detail, but the present invention is not limited to the examples at all.

[0029] (processing equipment and processing conditions)

[0030] As VOC, exhaust gas containing 25 ppm, 2.5 ppm, and 0.25 ppm of MEK was used, and supplied to the packed tower 3 through the flow path 2 . Furthermore, at this time, a desired amount of ozone gas was injected into the flow path 2 and mixed with the exhaust gas, and oxidation decomposition treatment by ozone was performed in the packed tower. As the base material of the packing material to be filled in the packed tower 3, a material having a corrugated cardboard structure made of silica zeolite which is a porous body of the above-mentioned form was used. As silicalite, use SiO 2 / Al 2 o 3 Ultrastable Y zeolite (USY) with a ratio of 100.

[0031] In addition, for the transition metal oxide-containing fine particle powder s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com