Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid deep oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

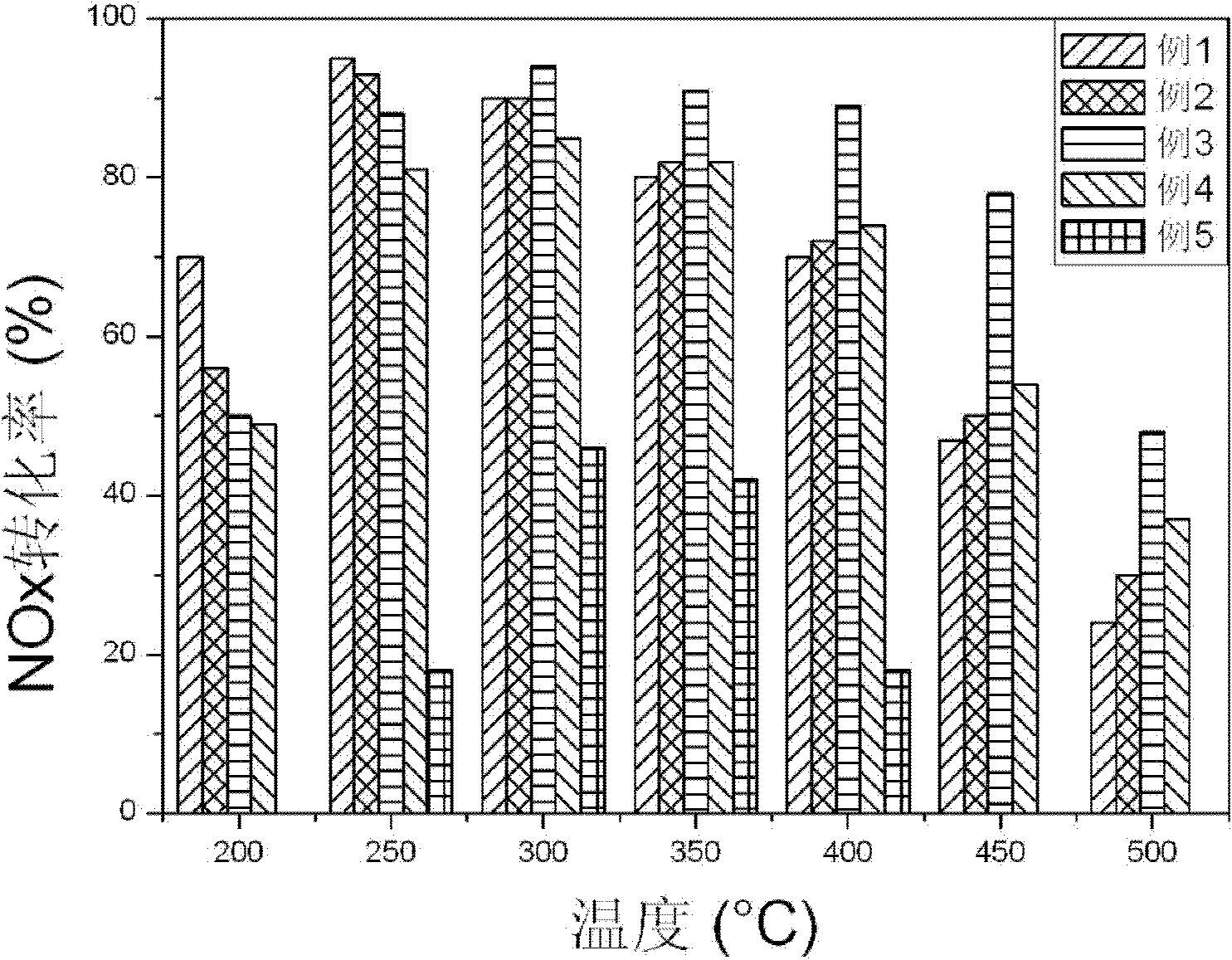

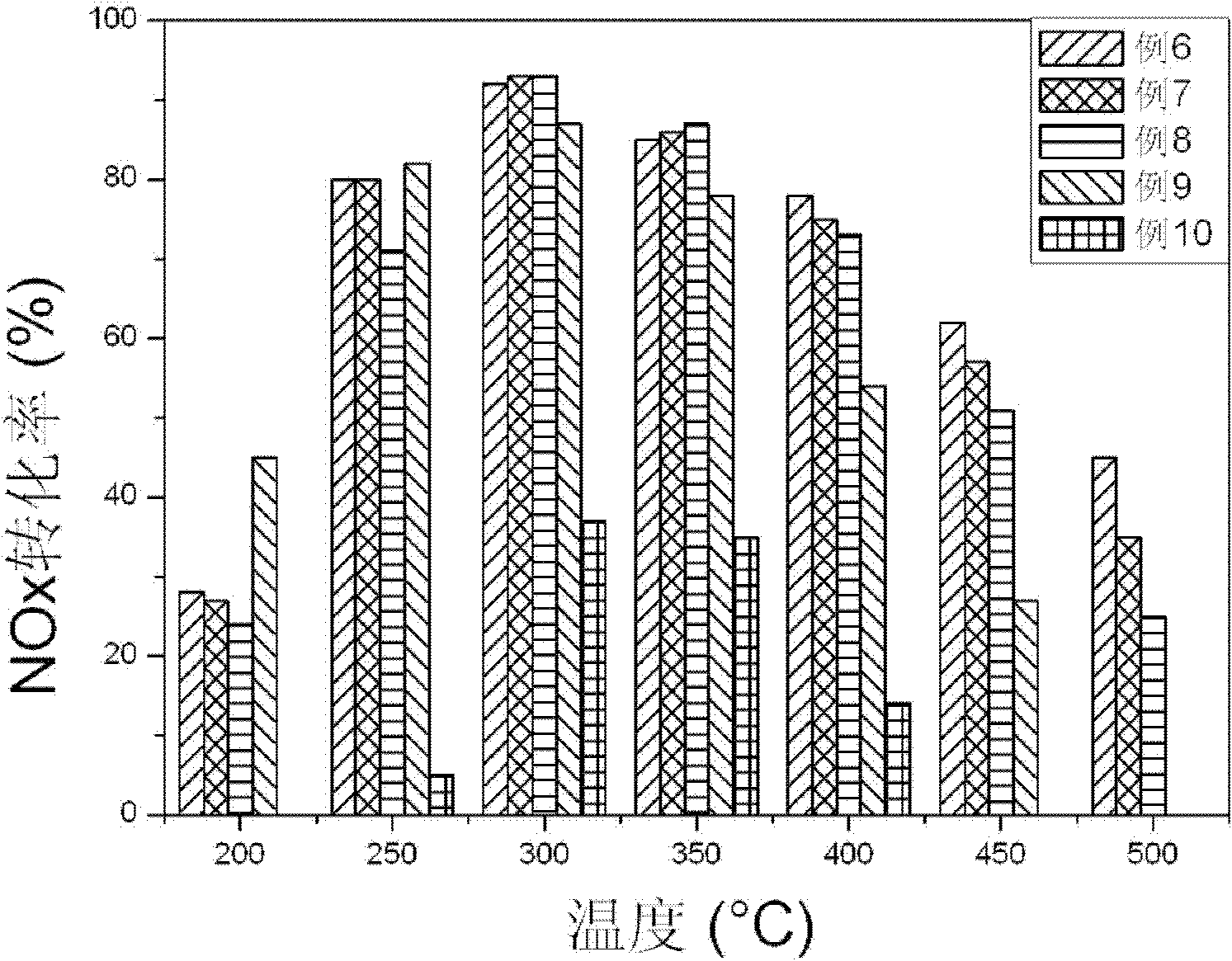

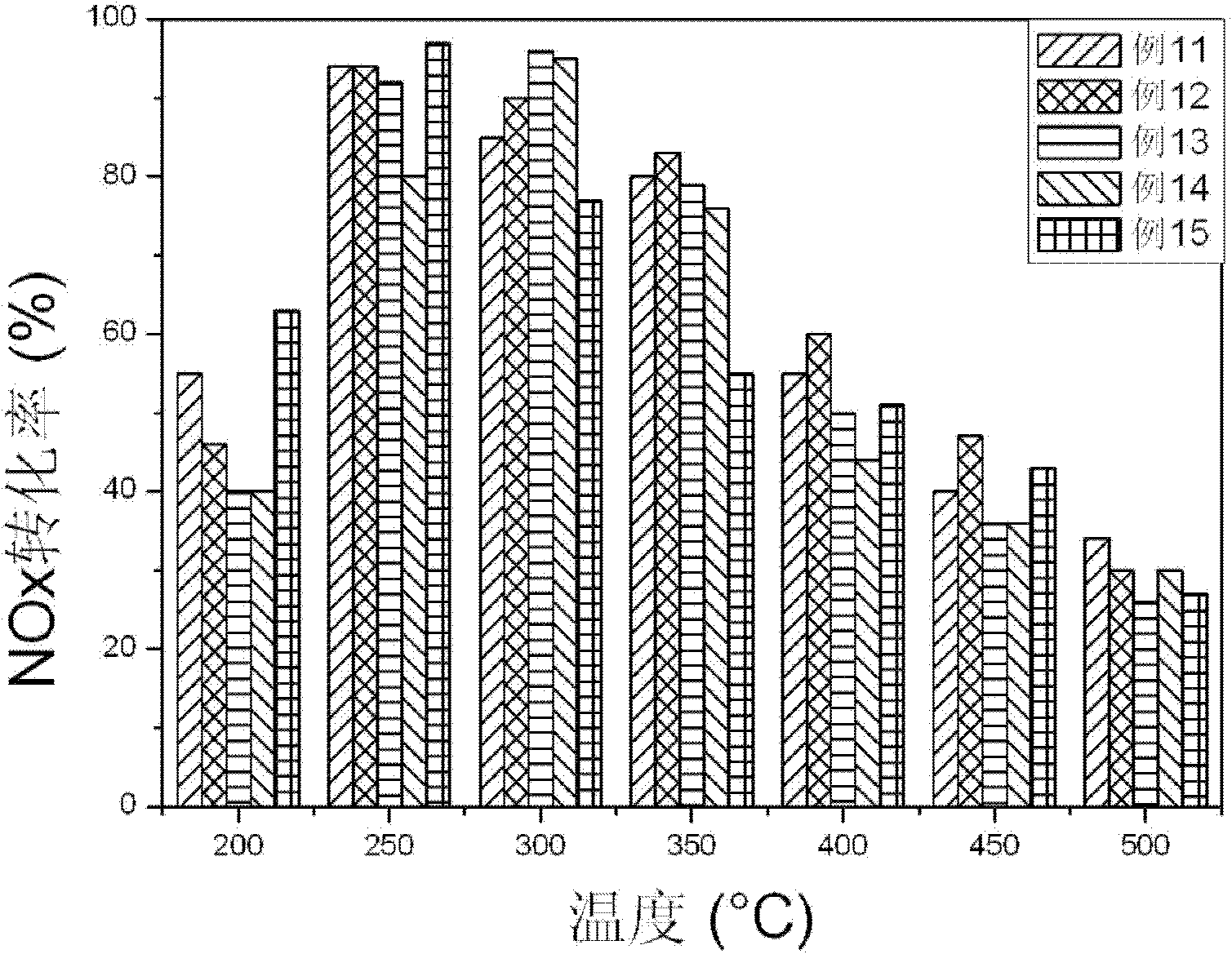

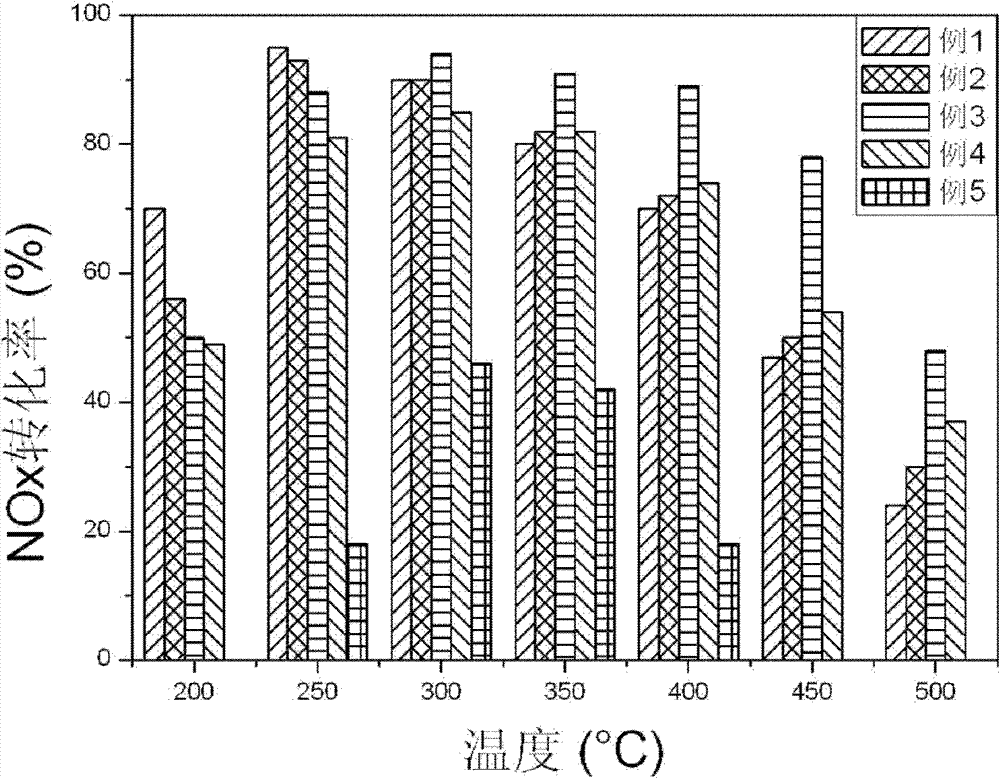

ActiveCN102240543AImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

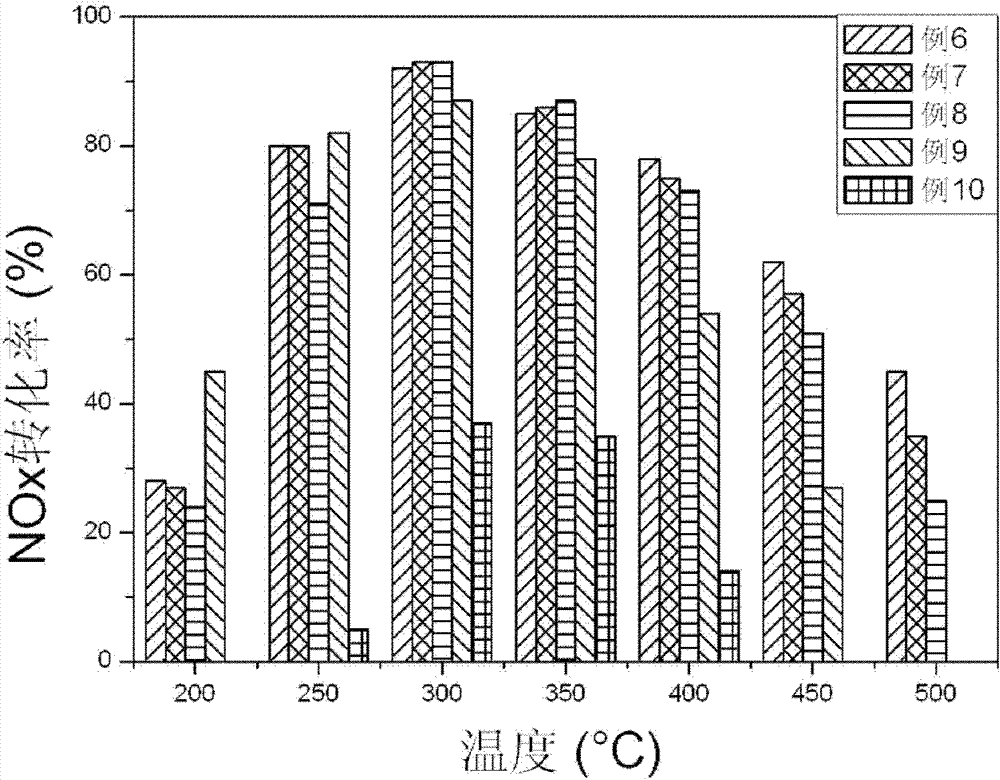

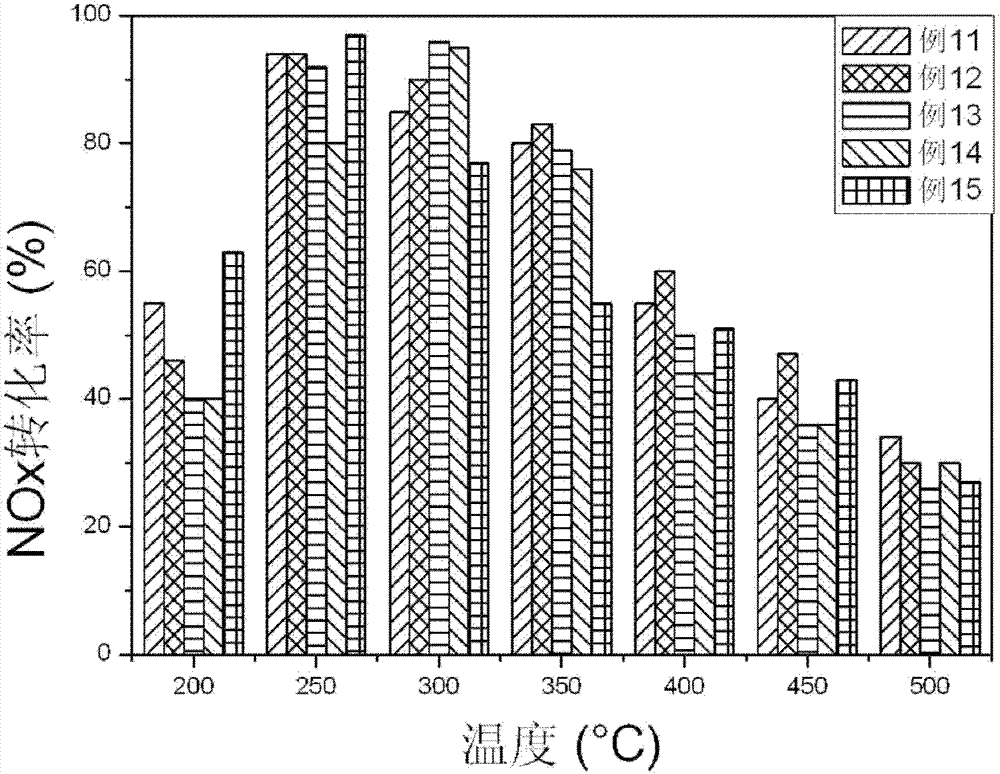

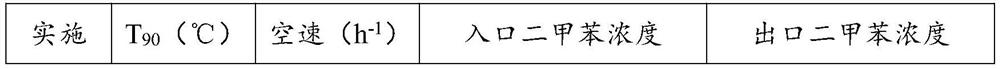

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

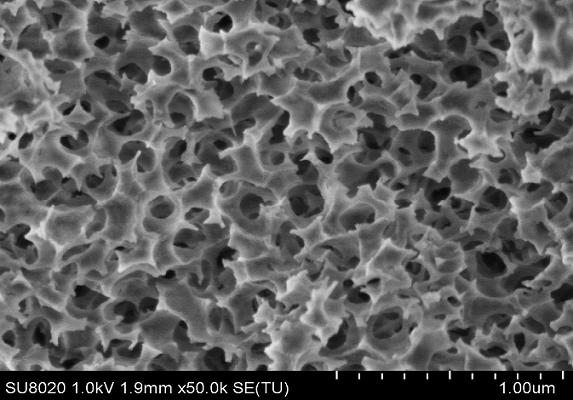

Mesoporous carbon-supported composite metal oxide catalyst and preparation method thereof

InactiveCN102485331AIncrease surface areaLarge apertureHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsMesoporous carbonCarbon deposition

The invention discloses a mesoporous carbon-supported composite metal oxide catalyst and a preparation method thereof. Compared with the prior art, the mesoporous carbon-supported composite metal oxide catalyst has a high specific surface area and a large aperture size, is conducive to rapid diffusion of reactants and products in an aperture channel, avoids deep oxidation, coking and carbon deposition, and has good catalyst activity and a long catalyst life.

Owner:CHINA PETROLEUM & CHEM CORP +1

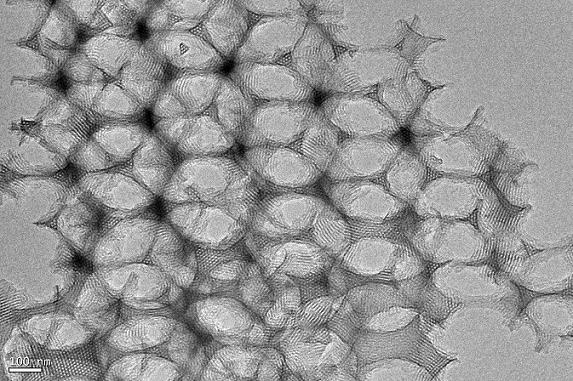

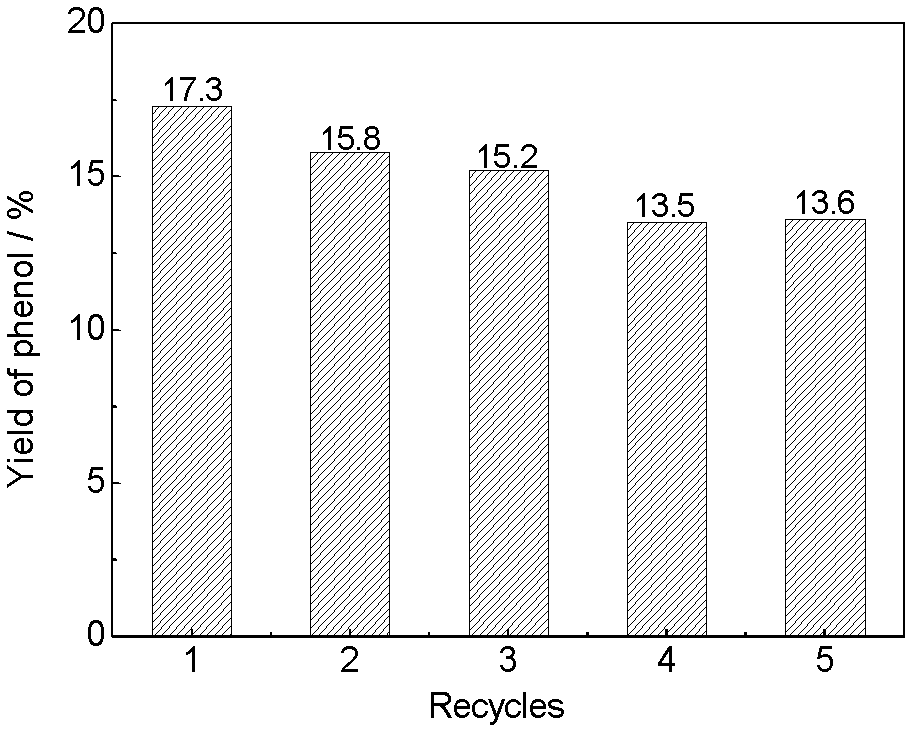

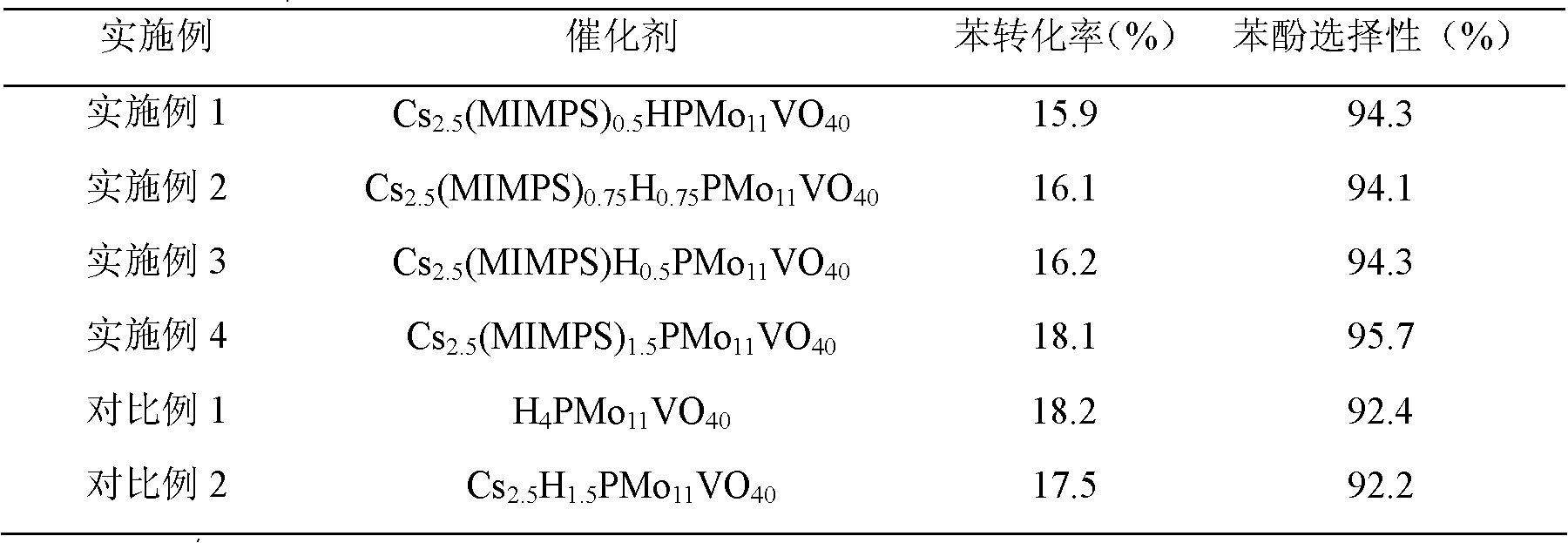

Catalyst and preparation method for benzene hydroxylation to phenol

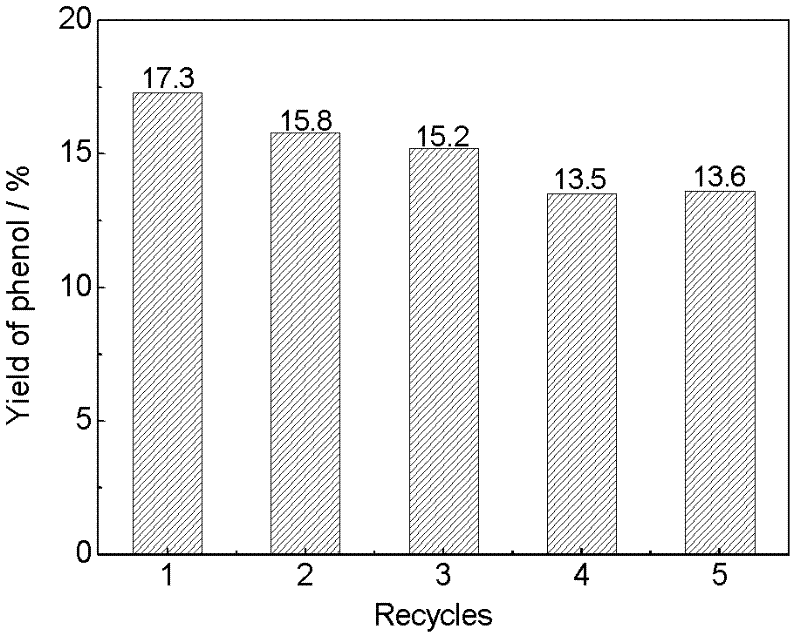

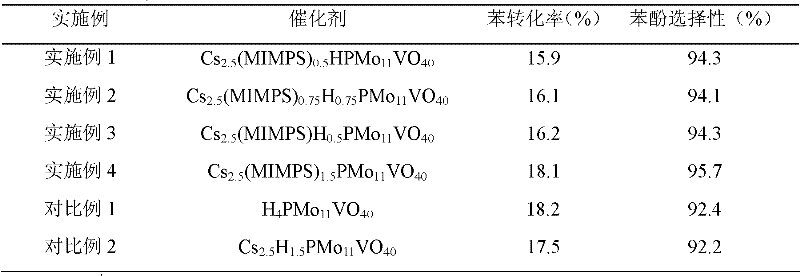

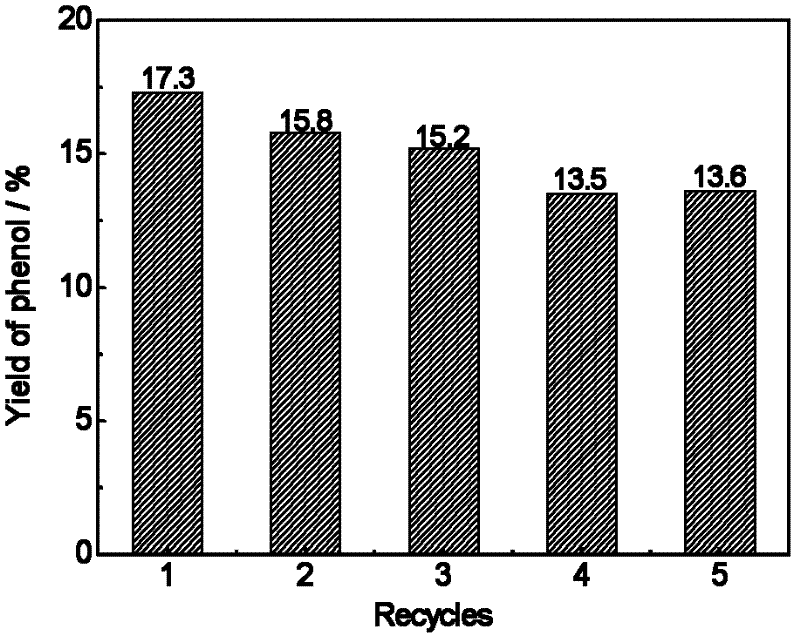

InactiveCN102294272AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationBenzeneSolvent

The invention relates to a catalyst for preparing phenol by hydroxylation of benzene and a preparation method thereof. The component expression of the catalyst provided by the invention is Cs2.5(MIMPS)nH1.5-nPMo11VO40, wherein MIMPS indicates [N-(3-sulfonic)propyl-imidazolium] and n equals to 0.5-1.5. The preparation method provided by the invention comprises the following steps of: (1) preparingpure vanadium substituted heteropolymolybdates; (2) mixing the pure vanadium substituted heteropolymolybdates obtained from the step (1) with deionized water, adding dropwisely an inorganic cesium salt solution into the above solution with stirring, followed by a reaction, removing water from a suspending liquid obtained after the reaction so as to obtain a solid, drying to obtain a heteropolyacid inorganic cesium salt; (3) mixing the heteropolyacid inorganic cesium salt obtained from the step (2) with deionized water, adding dropwisely an MIMPS aqueous solution with stirring, followed by a reaction, removing the solvent from a suspending liquid obtained after the reaction so as to obtain a solid, and drying to obtain the catalyst for preparing phenol by hydroxylation of benzene. By the adoption of the catalyst provided by the invention, the yield of phenol can be obviously raised; in addition, the catalyst is easy to recover and convenient to repeatedly use.

Owner:ZHEJIANG NORMAL UNIVERSITY

Method for preparing styrene through oxidative dehydrogenation of ethylbenzene

ActiveCN107285979AMild oxidation capacityPromote activationCatalystsHydrocarbon preparation catalystsDehydrogenationNitrous oxide

The invention relates to a method for preparing styrene through oxidative dehydrogenation of ethylbenzene and aims at solving the problem that the selectivity is poor when styrene is prepared through oxidative dehydrogenation of the ethylbenzene at an oxygen gas atmosphere in the prior art. According to the technical scheme, the method for preparing the styrene through oxidative dehydrogenation of the ethylbenzene comprises the following step: by taking a carbon nonmaterial as a catalyst, nitrous oxide as an oxidant and gas which is inert to reaction as a diluent, preparing the styrene through oxidative dehydrogenation of the ethylbenzene, so that the method relatively well solves the technical problems and can be used for industrial production of the styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Green synthetic method for phenol by directly hydroxylating benzene

InactiveCN101100415AAvoid deep oxidationHigh selectivityOrganic chemistryOrganic compound preparationChemical reactionCorona discharge

A green synthesis of phenol by benzene hydroxylation directly is carried out by apply DC high-voltage 10-30 kV onto plasma reactor to generate corona, discharging, keeping temperature of plasma reactor between 50-80 deg. C, inducing into raw material containing benzene and oxidant into reactor in proportion of 1:1-6 mol, keeping for 5-10 mins and oxidizing into phenol. It's simple and convenient, has short flow path, less consumption, more yield and no environmental pollution.

Owner:HARBIN UNIV OF SCI & TECH

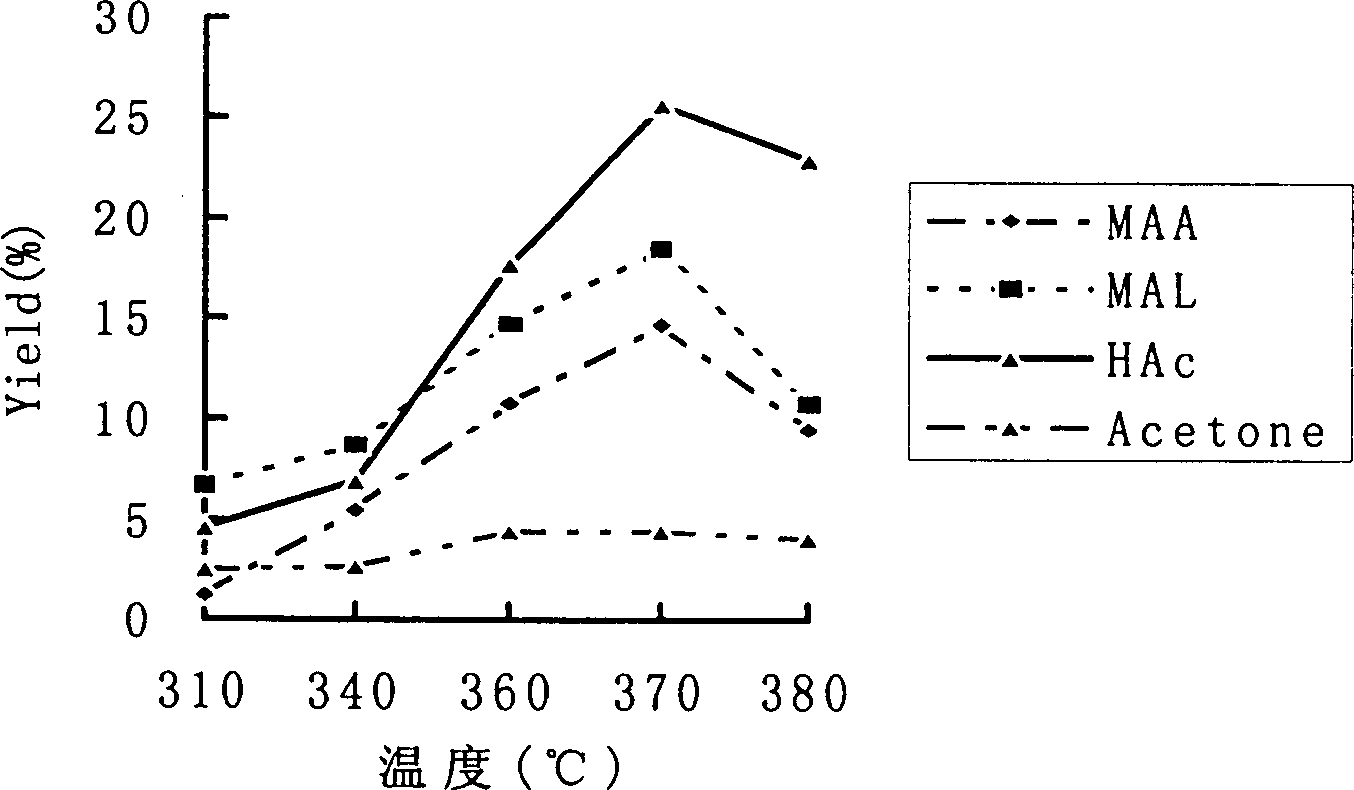

Method for synthesizing vanillin

InactiveCN102030625AAvoiding Explosion HazardsAvoid deep oxidationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSlurry reactorVanillin synthesis

The invention relates to a method for synthesizing vanillin, comprising the following steps of: carrying out material thermal pretreatment by adopting a pressured reaction axe, and then pouring the materials into a cannular slurry reactor for vanillin synthetic oxidation reaction; and by using 4-methyl-2-metoxyphenol as a raw material, using ethylene glycol monomethyl ether or ethylene glycol monoethyl ether as a solvent and using oxygen as an oxidant, carrying out the oxidation reaction for synthesizing vanillin in a way of intermittently feeding oxygen. The conversion rate of the 4-methyl-2-metoxyphenol as the raw material reaches more than 99%, the selectivity of the vanillin reaches more than 93%, and the separation yield reaches about 82%. The oxidation test carried out in the cannular slurry reactor proves that the oxidation reaction of the 4-methyl-2-metoxyphenol can be successfully carried out in the reactor under a milder condition to synthesize vanillin, and the method avoids a danger of easy explosion of the traditional axe type oxidation technology process for synthesizing vanillin by using methanol as the reaction solvent and has the advantages of environmental-protection process and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

Rare earth flame resistance magnesium alloy and preparation method thereof

The invention provides a rare earth flame resistance magnesium alloy and a preparation method thereof and relates to a magnesium-based alloy adopting rare earth metal as main component; and the atom percentage of the elements of the alloy is Mg96.0-98.19Y0.31-0.5Dy1.5-3.5. The preparation method comprises the following steps: first weighting three raw materials, namely pure magnesium, Mg-Y preliminary alloy containing 29.05% of Y and Mg-Dy preliminary alloy containing 29.025% of Dy according to the weight percent of the elements of the alloy, heating and smelting at 600-720 DEG C, intermittently injecting mixed protective gases containing 99.5vol.% of CO2 and 0.5vol.% of SF6 at about 600 DEG C, 650 DEG C and 720 DEG C, and finally casting to obtain Mg96.0-98.19Y0.31-0.5Dy1.5-3.5 flame resistance magnesium alloy product. The product has very high purity and higher flame resistance property.

Owner:HEBEI UNIV OF TECH

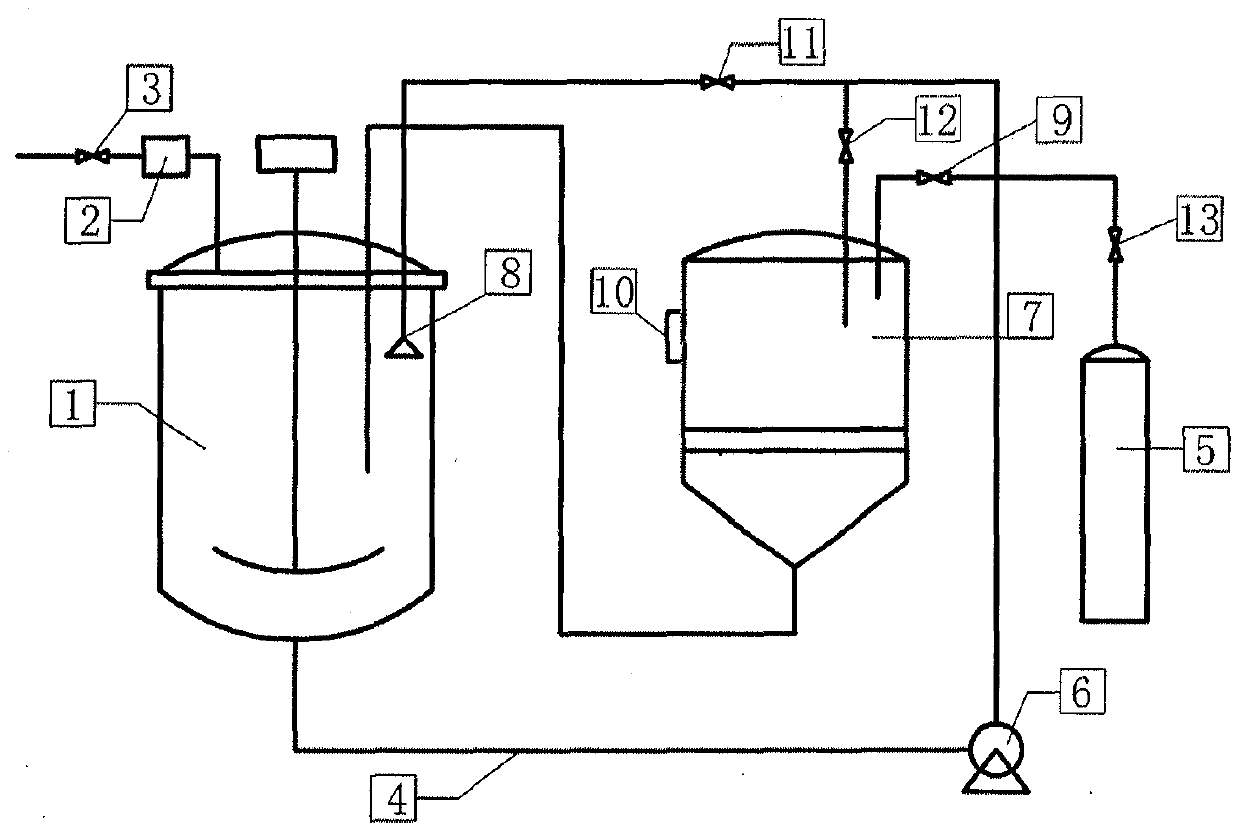

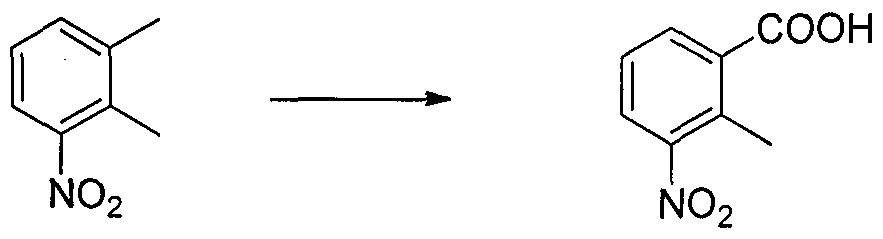

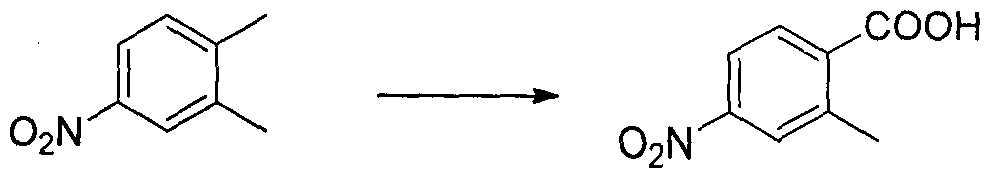

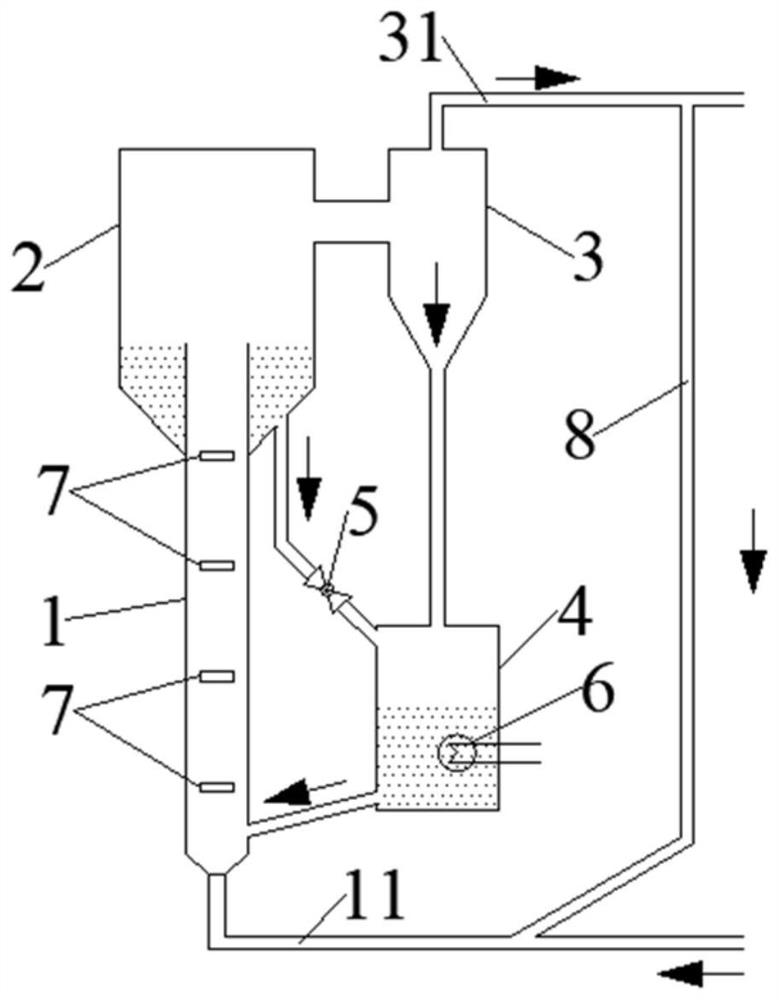

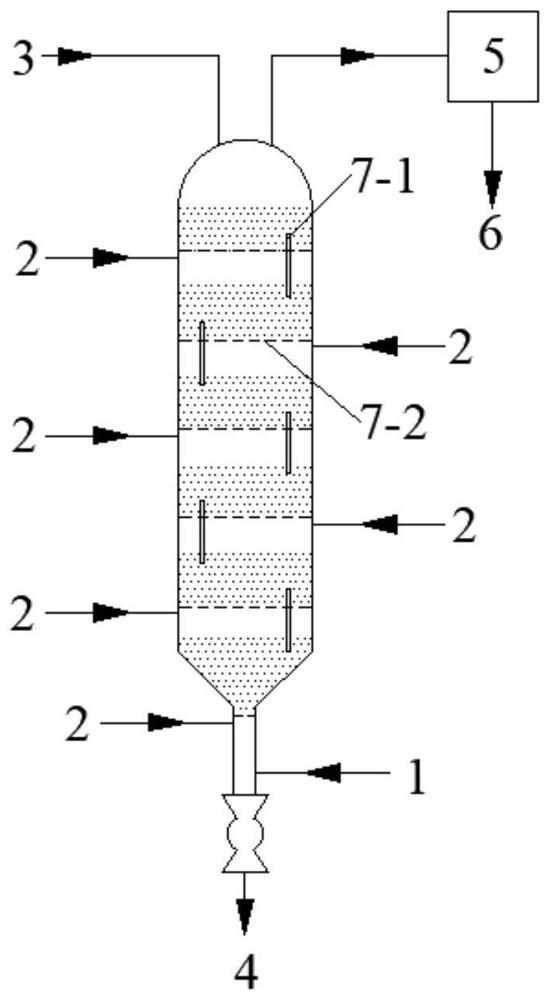

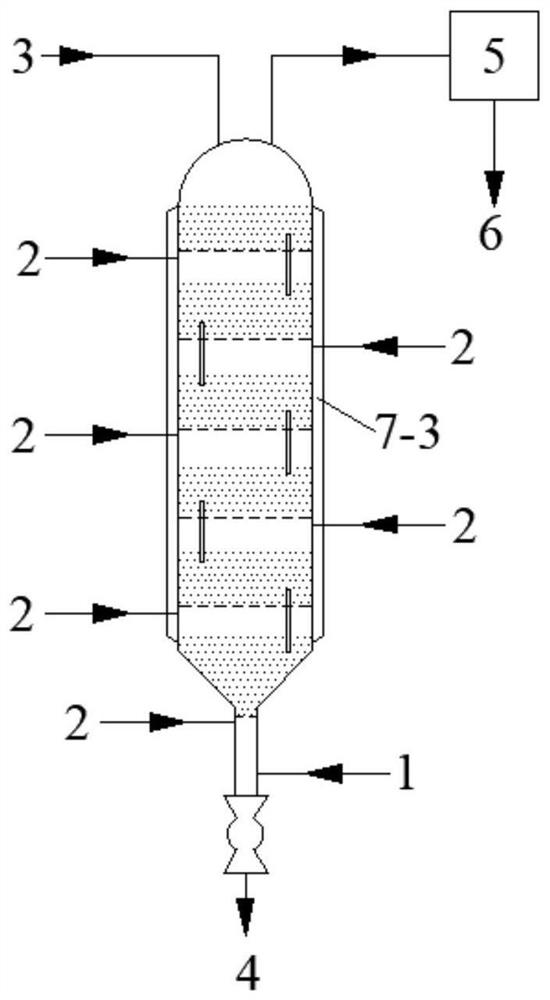

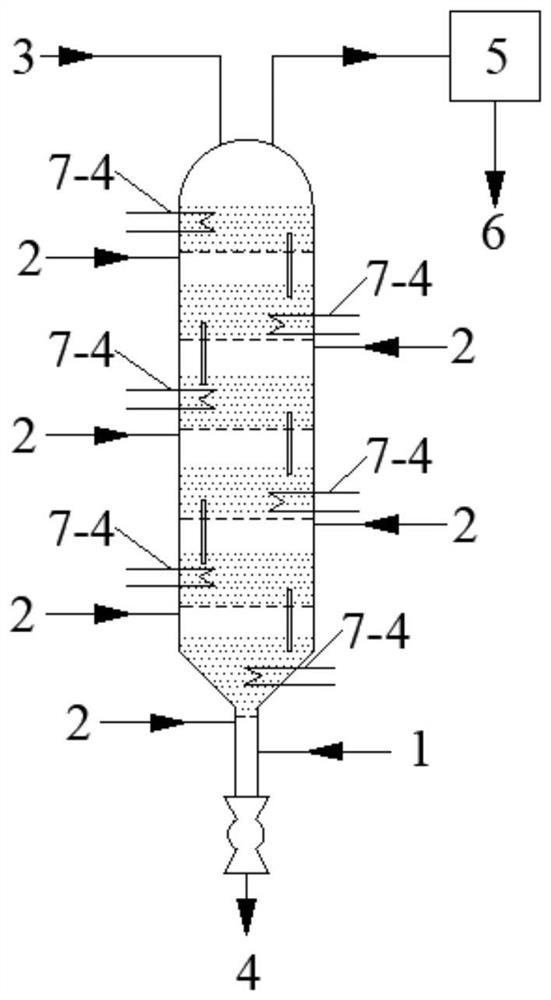

Nitric acid loop oxidation device and selective oxidation of dimethyl nitrobenzene in device

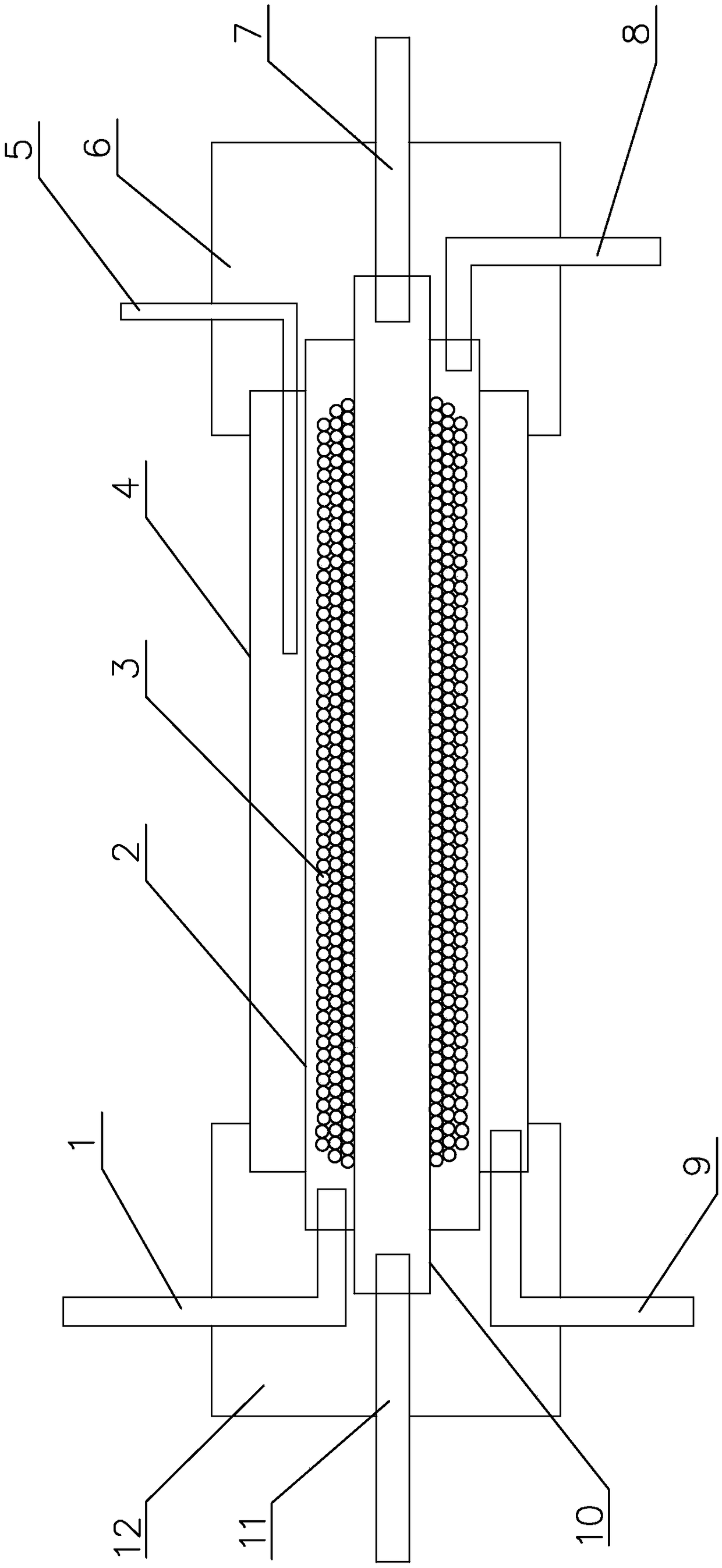

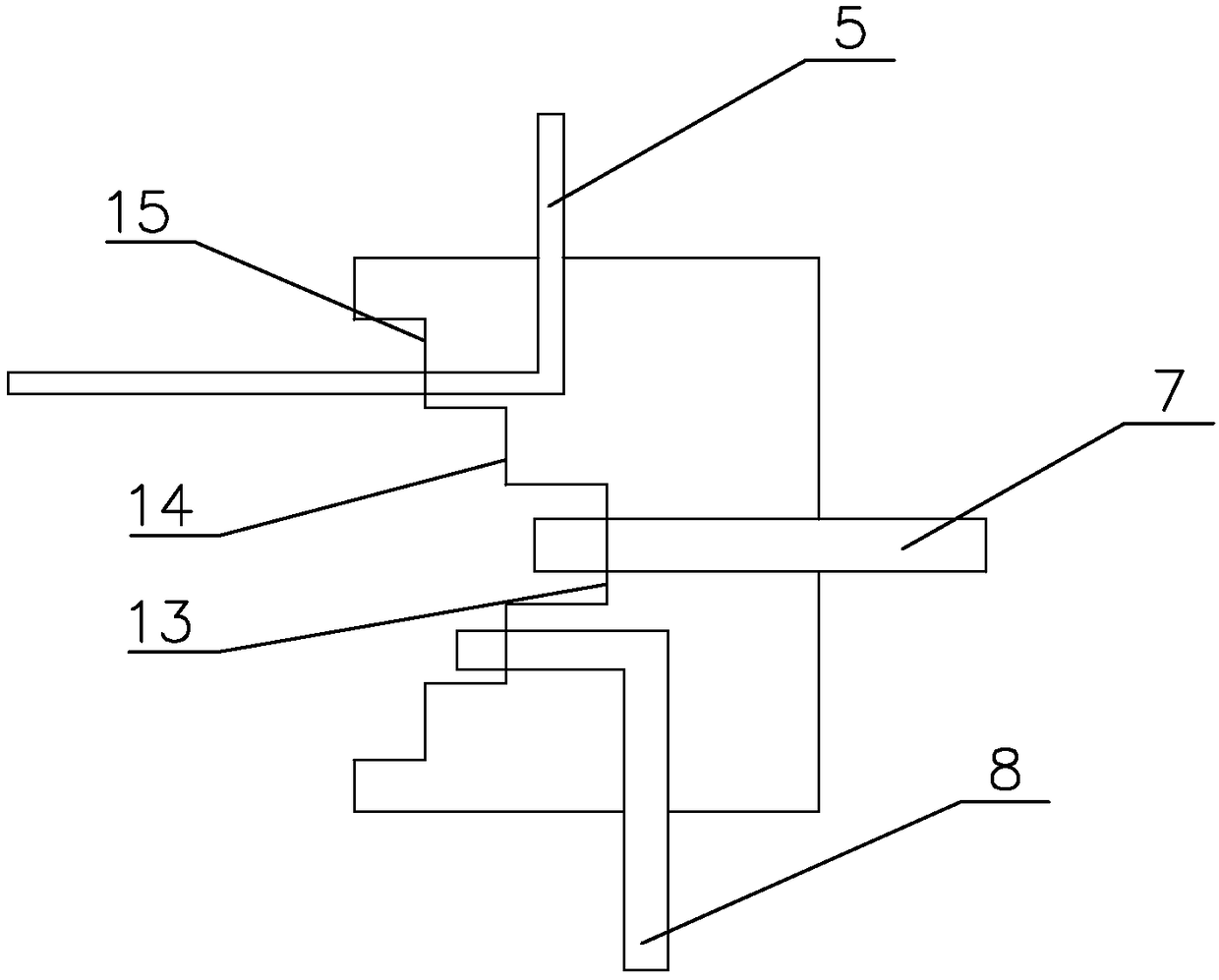

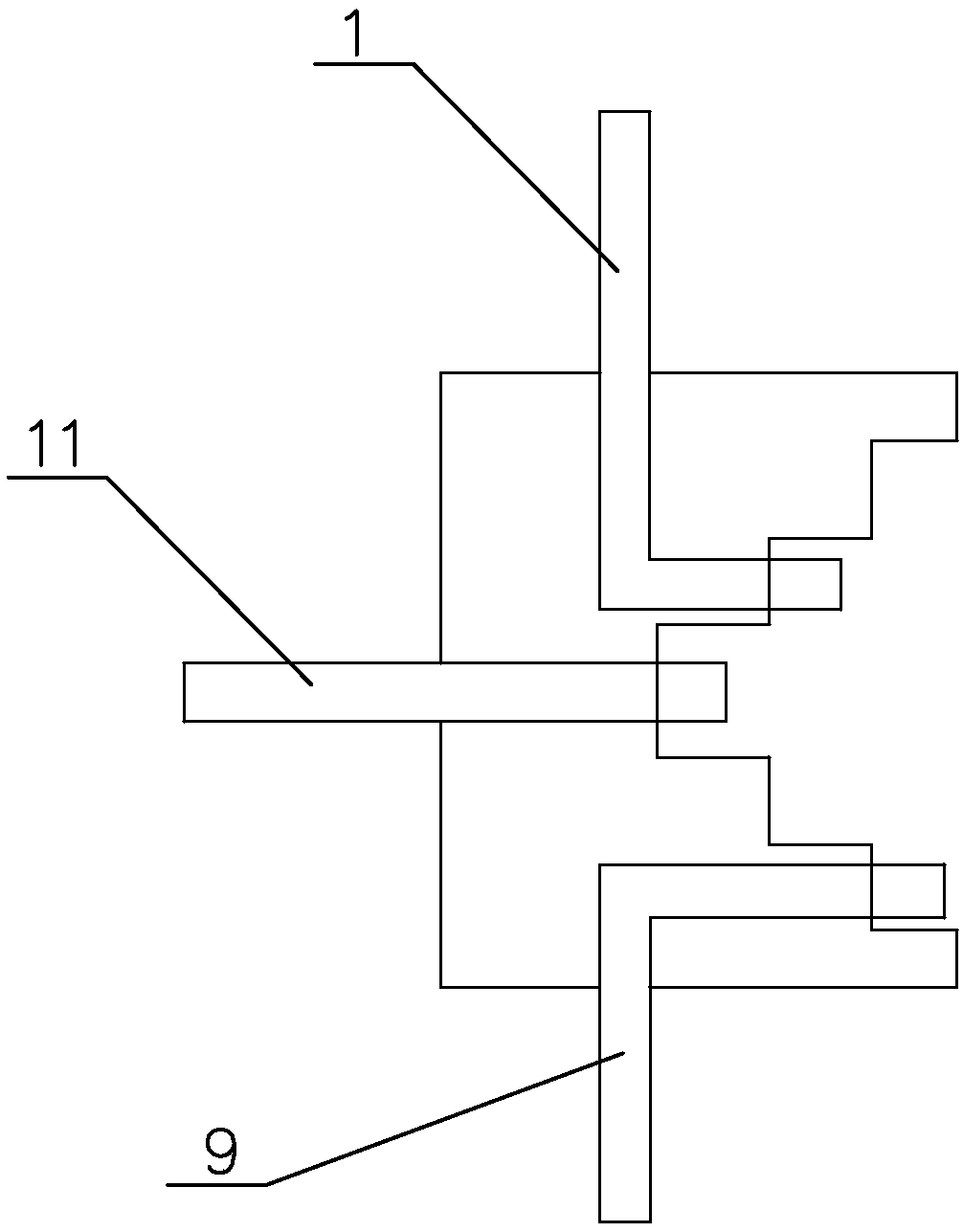

InactiveCN110302731ARelieve pressureEmission reductionOrganic chemistryOrganic compound preparationNitrobenzeneChemistry

The invention discloses a nitric acid loop oxidation device and selective oxidation of dimethyl nitrobenzene in the device. The device is characterized in that the device (as shown in the attached drawings of the specification) consists of 1, a reaction kettle 2, a condenser 3, a pressure relief valve 4, a circulation pipeline 5, an air or oxygen steel cylinder or storage tank 6, a circulation pump 7, a filter pressing tank 8, a spray head 9, a valve III 10, a controller 11, a valve I 12, a valve II 13 and a pressure reducing valve. The selective oxidation of dimethylnitrobenzene is carried out in the device, and the result shows that the device can selectively oxidize the nitromonomethylbenzoic acid generated by dimethylnitrobenzene with high yield and high selectivity. At the same time,nitric acid is recycled by using the principle that oxygen reacts with nitrogen oxides and water to generate nitric acid, the emission of nitrogen oxides is greatly reduced, the total pressure of thereaction system is reduced, and the safety is improved.

Owner:上海泰初化工技术有限公司

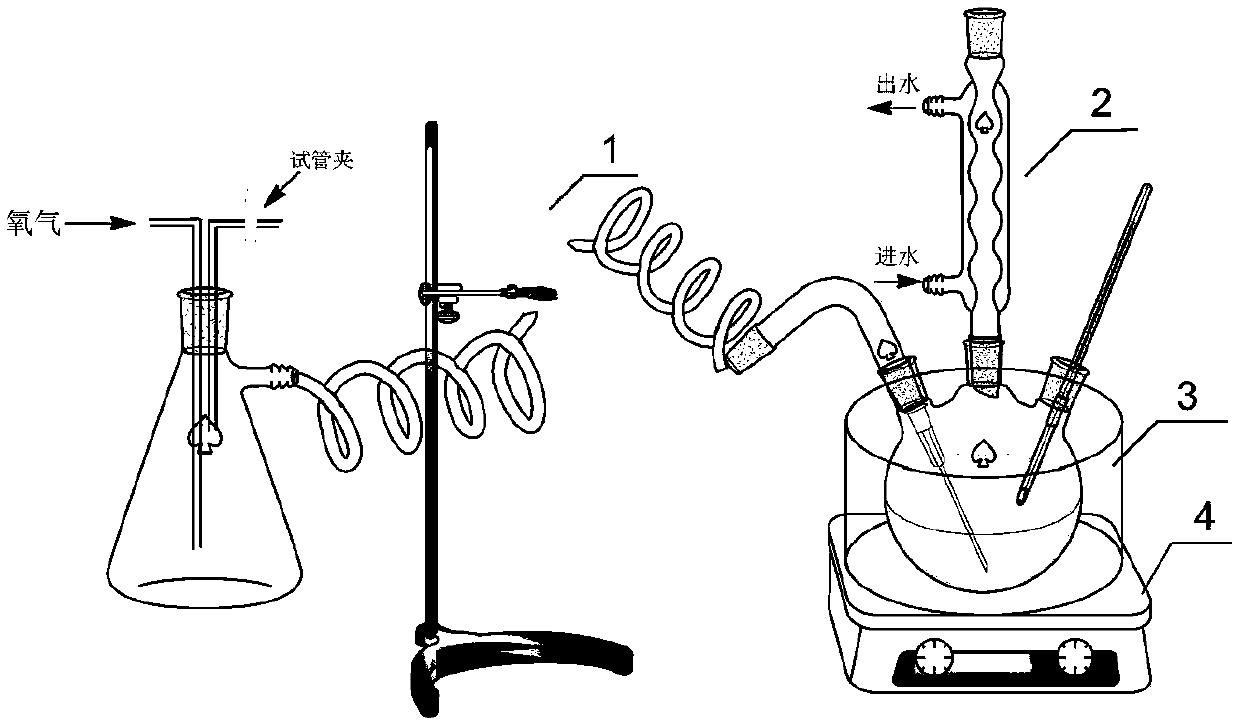

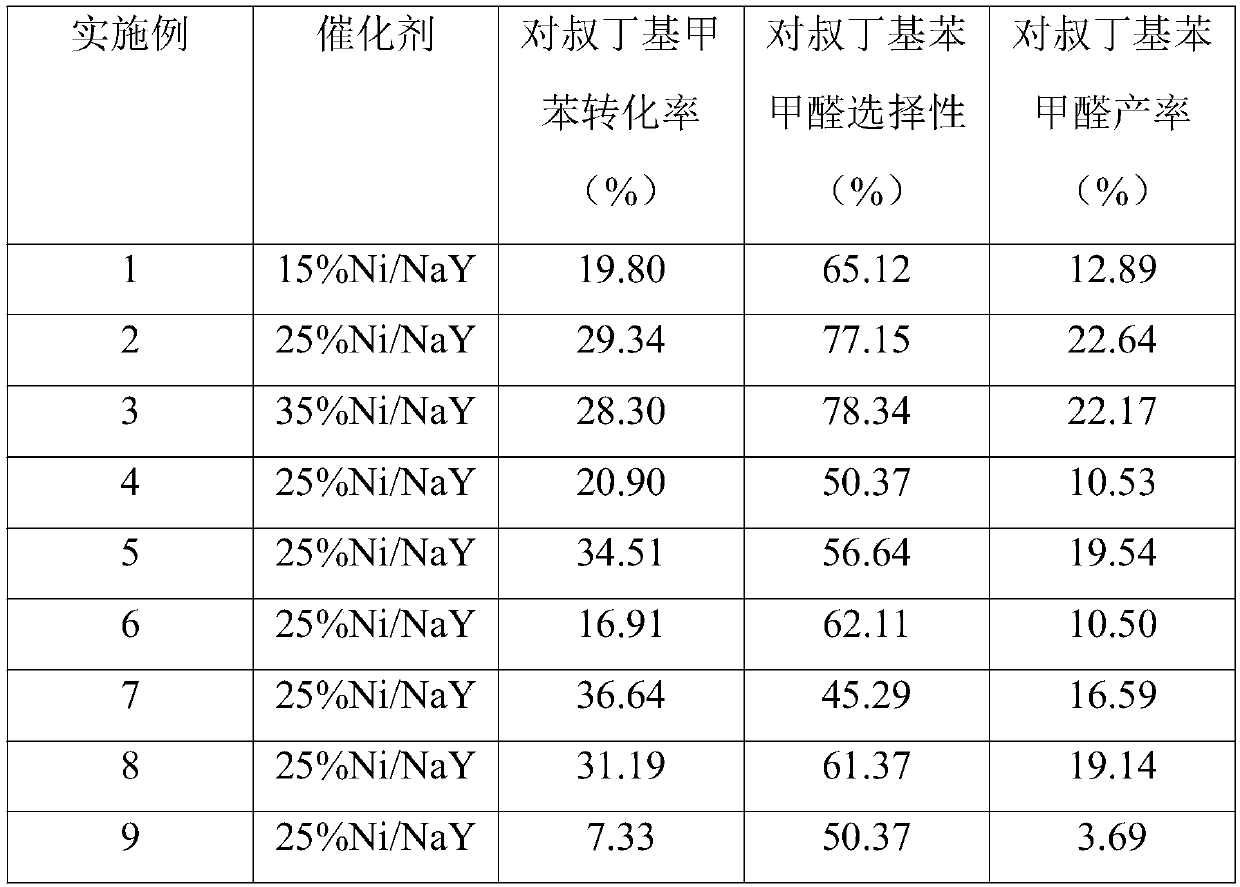

Synthetic method of p-tert-butylbenzaldehyde

InactiveCN109608315AEasy to separateMany cyclesMolecular sieve catalystsOrganic compound preparationNickel saltSolvent

The invention provides a synthetic method of p-tert-butylbenzaldehyde. A liquid-phase oxidation method is used, p-tert-butyltoluene as a raw material, oxygen as an oxidizing agent, N-hydroxyl phthalimide as an initiator and acetonitrile as a solvent are used under the action of a catalyst for reacting for 7 hours at the temperature of 70 DEG c under the magnetic stirring rotating speed of 200r / minso as to obtain the p-tert-butylbenzaldehyde. The selected catalyst is a Ni-loaded microporous molecular sieve, and preparation raw materials comprise a nickel salt, a molecular sieve and deionized water; the microporous molecular sieve is used as a carrier for loading of an active component by an impregnation method to prepare the catalyst containing the active component nickel, the catalyst hasrelatively high selectivity and activity, the conversion rate of the raw material in the reaction for preparing the p-tert-butylbenzaldehyde by the liquid-phase oxidation reaches 30.6%, the selectivity of the target product reaches 77.2%. Compared with other catalysts in the prior art, the catalyst has the advantages that the selectivity is obviously improved.

Owner:CHANGZHOU UNIV

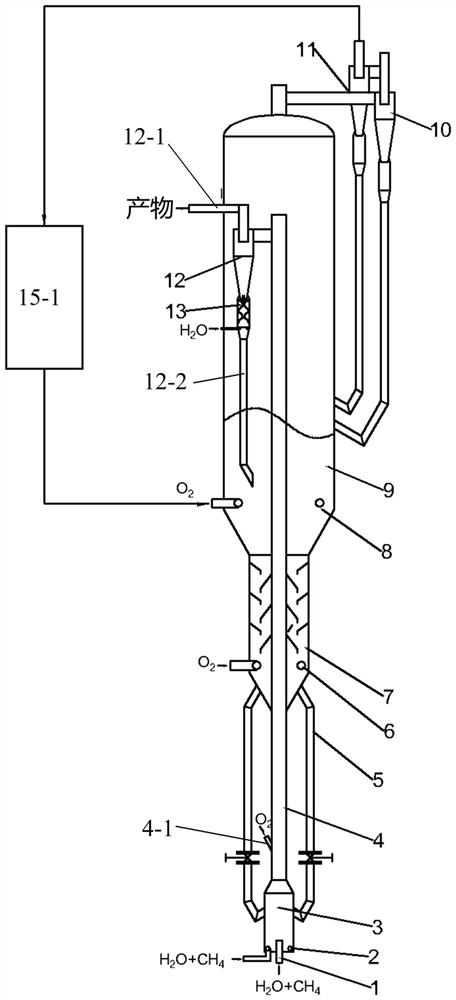

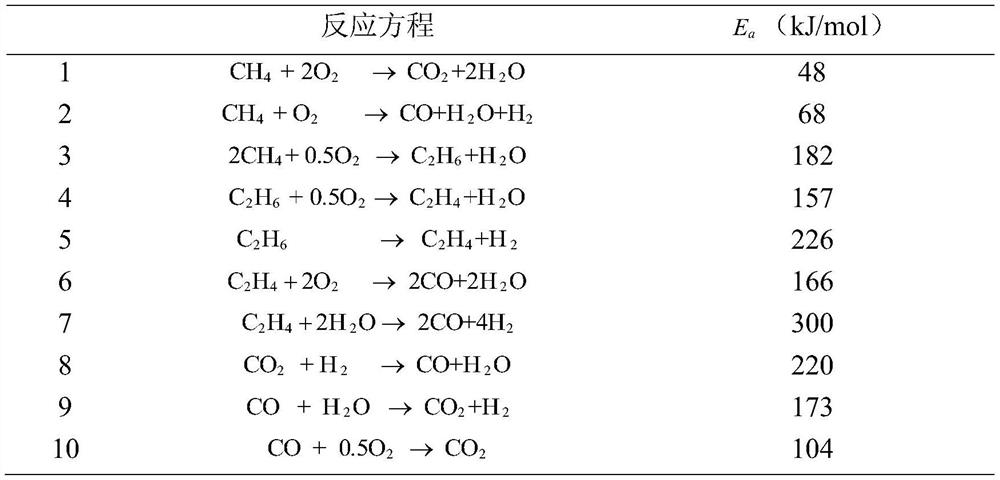

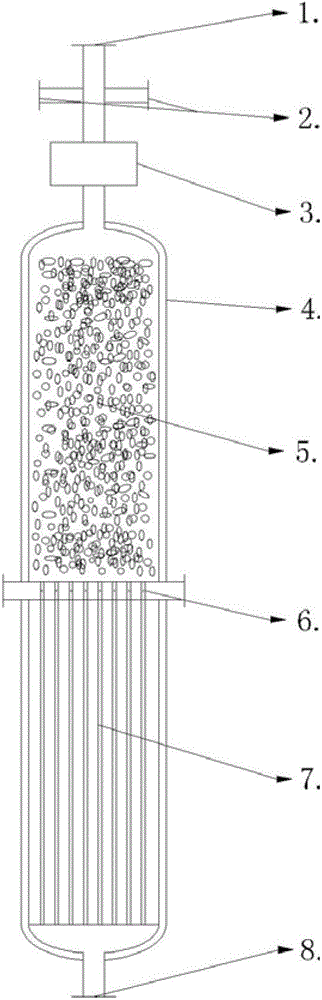

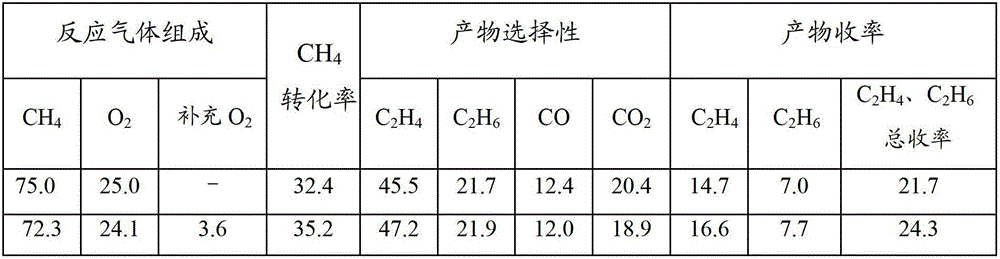

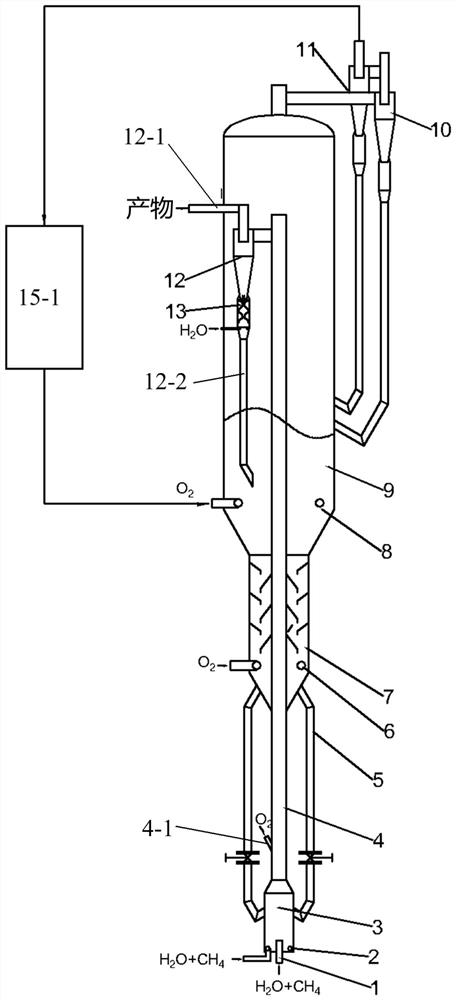

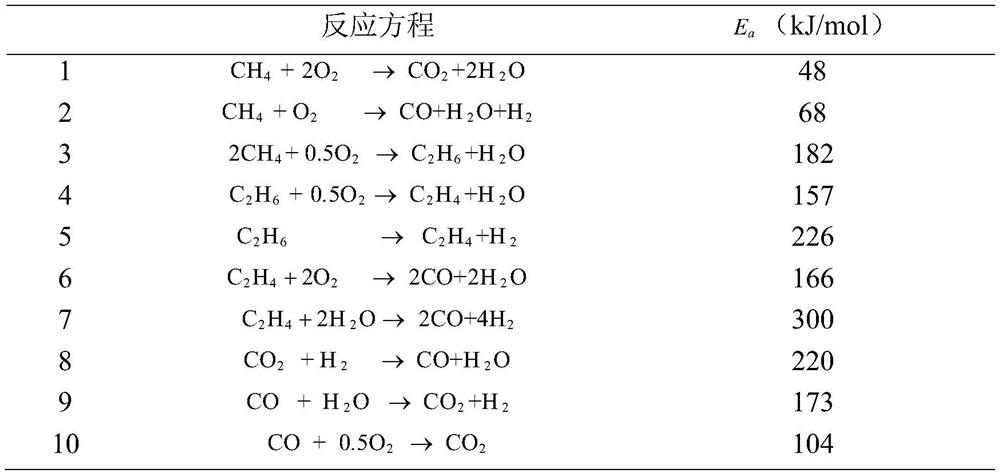

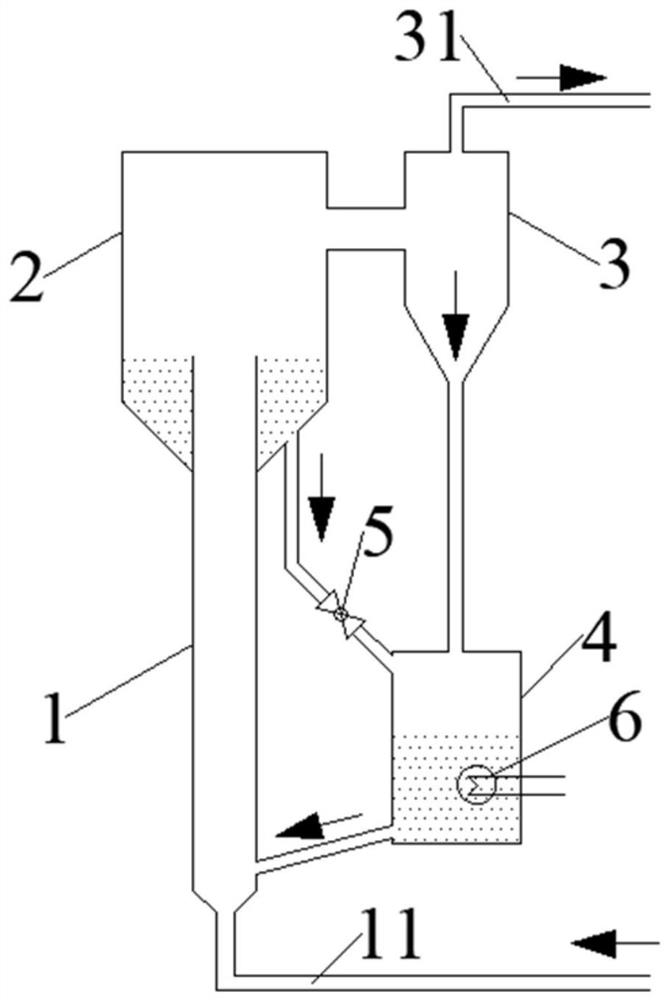

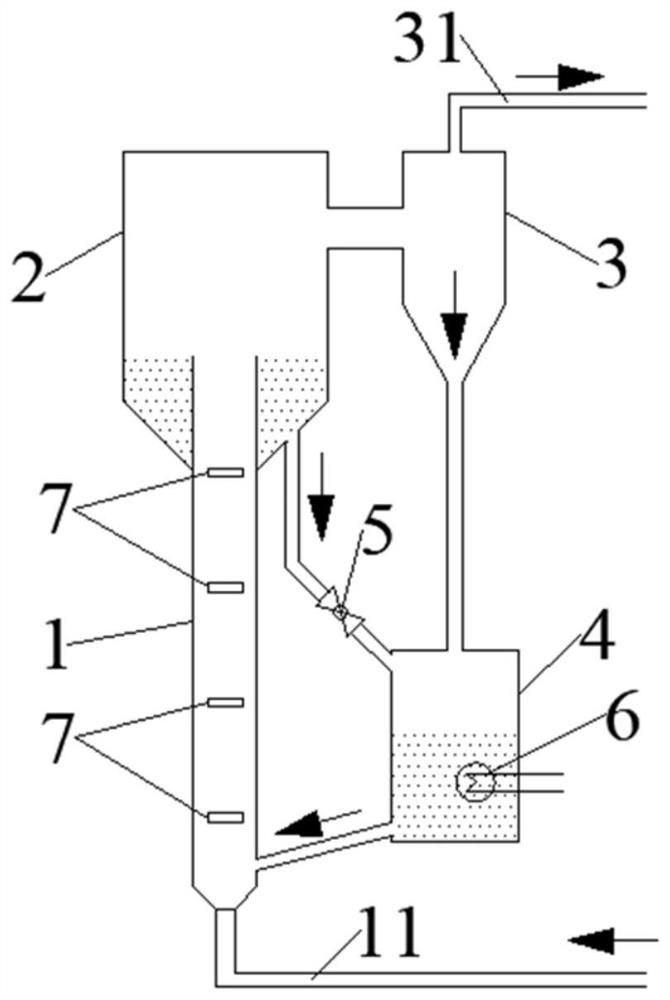

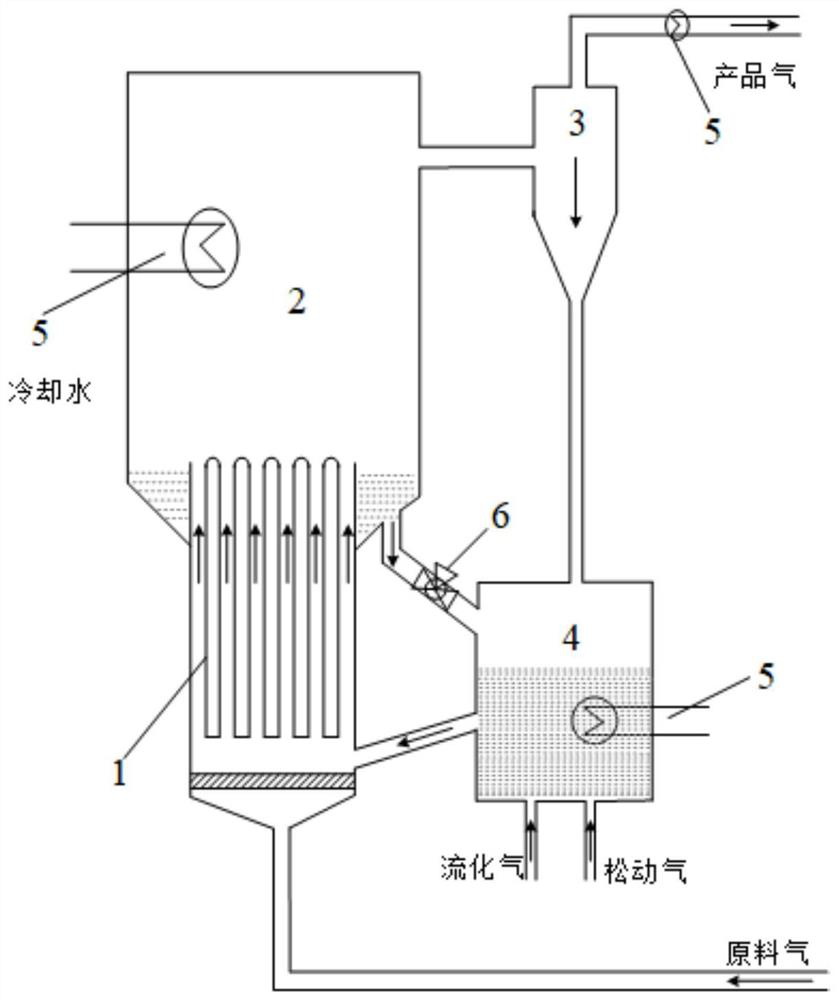

Reaction device and method for preparing ethylene through oxidative coupling of methane

ActiveCN113477191AAvoid deep oxidationHigh selectivityHydrocarbon by hydrocarbon condensationChemical/physical processesPhysical chemistryEngineering

The invention discloses a reaction device and method for preparing ethylene through oxidative coupling of methane. The reaction device comprises a lifting pipe, an oxidizer, a gas stripper, a pre-stripper, a pre-lifting section, a cyclone separator and the like. According to the reaction device, methane and oxygen are separately fed, a multi-mode operation mode is adopted, oxygen supply is flexibly controlled, and flexible control between two reaction mechanisms is realized. Oxygen is not in contact with methane during feeding; and after the reaction, products such as ethylene are directly led out from the reactor and are not mixed with oxygen. The reactor and the oxidizer are coaxially arranged, the reactor is arranged at the lower part, the oxidizer is arranged at the upper part, and the lifting pipe is used as the reactor for reaction. According to the invention, complete separated feeding of oxygen and methane in a methane oxidative coupling reaction process is realized, contact between a product and oxygen is avoided, deep oxidation of the product is avoided, generation of non-selective products is reduced, and the ethylene selectivity and yield are effectively improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

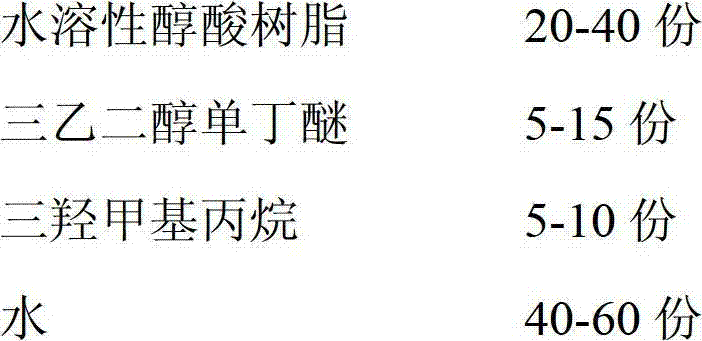

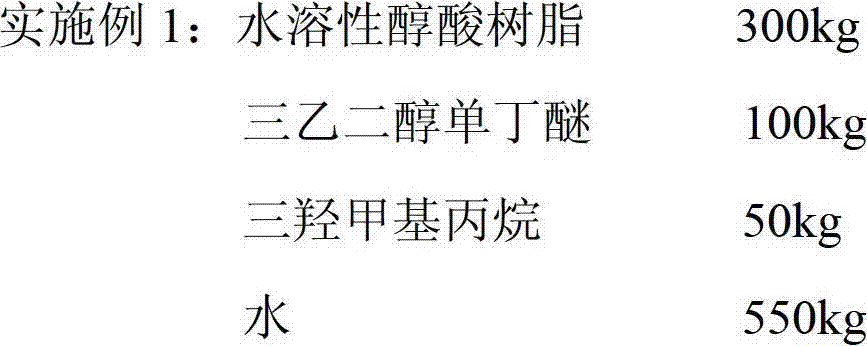

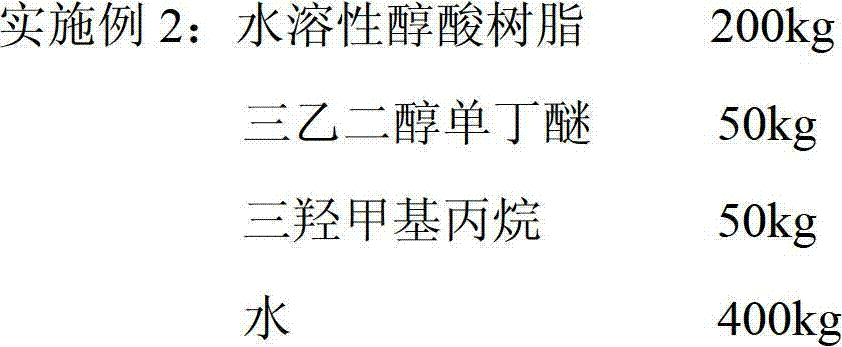

Anti-oxidation dust suppressant and preparation method thereof

The invention provides an anti-oxidation dust suppressant and a preparation method thereof. The anti-oxidation dust suppressant comprises components according to the following parts by weight: 20-40 parts of alkyd resin, 5-15 parts of triethylene glycol momobutyl ether, 5-10 parts of trimethylolpropane and 40-60 parts of water. The preparation method of the anti-oxidation dust suppressant comprises the following steps: according to the parts by weight, taking the water soluble alkyd resin, sequentially adding water, triethylene glycol momobutyl ether and trimethylolpropane, and uniformly stirring to obtain the anti-oxidation dust suppressant. The anti-oxidation dust suppressant has the beneficial effects that the defects of short maintaining time, poor effect, great loss of fuel value, blocking of a conveying system and the like in dust removal by purely watering are overcome, quick surface drying can be realized one hour after spraying, curing and crusting can be realized in a short time so as not to delay the operating time, and the anti-oxidation dust suppressant is long in dust suppression lasting time and good in effect. Meanwhile, the anti-oxidation dust suppressant also has the advantages of quick drying property, high water resistance, wind resistance, oxygen barrier property, acid and alkali resistance and the like.

Owner:天津市瑞德赛恩新材料开发有限公司

CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

ActiveCN102240543BImprove anti-sulfur poisoning performanceSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfurWorking temperature

The invention discloses a CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and a preparation thereof and belongs to the field of nitric oxide post-processing purification. The catalyst has a three-layer structure, wherein cordierite honeycomb ceramic is used as a carrier; an active coating is loaded on the carrier; a modifying coating is loaded on the active coating; the cordierite carrier has a skeleton carrying function; the active coating of the catalyst mainly has a function of activating NOx and NH3; and the modifying coating mainly has functions of storing NH3, avoiding deep oxidation of NH3 on the surface of the catalyst when the catalyst is used at a high temperature and increasing the sulfur poisoning resistance of the catalyst. The preparation process of the catalyst is simple and can be easily industrialized. A working temperature window of the optimized catalyst can reach 250-450 DEG C, and denitration efficiency is above 80%. The catalyst has the significant advantage of being nontoxic and has excellent heat stability and excellent SO2 poisoning resisting property.

Owner:TSINGHUA UNIV +1

Organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and preparation method and application thereof

ActiveCN113731409AImprove catalytic performanceImprove the ability to resist chlorine poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystCatalytic oxidation

The invention relates to the technical field of catalysts, and provides an organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and a preparation method and application thereof. The catalyst provided by the invention comprises a matrix, a carrier and active components, the matrix is honeycomb cordierite, the carrier is a CeO2-ZrO2 compound or a CeO2-ZrO2-R compound (R is one or more of La2O3, Co3O4, Y2O3 and SiO2), the active components are MnO2 and RuO2, and an auxiliary agent WO3-TiO2 is further loaded on the matrix. The catalyst provided by the invention has high catalytic efficiency in a temperature range of 450-650 DEG C, can completely convert organic contaminated soil thermal desorption waste gas, has good high-temperature stability, strong sintering resistance and carbon deposition resistance, and also has good alkali, alkaline earth and heavy metal resistance, chlorine resistance and sulfur poisoning resistance.

Owner:KUNMING UNIV OF SCI & TECH

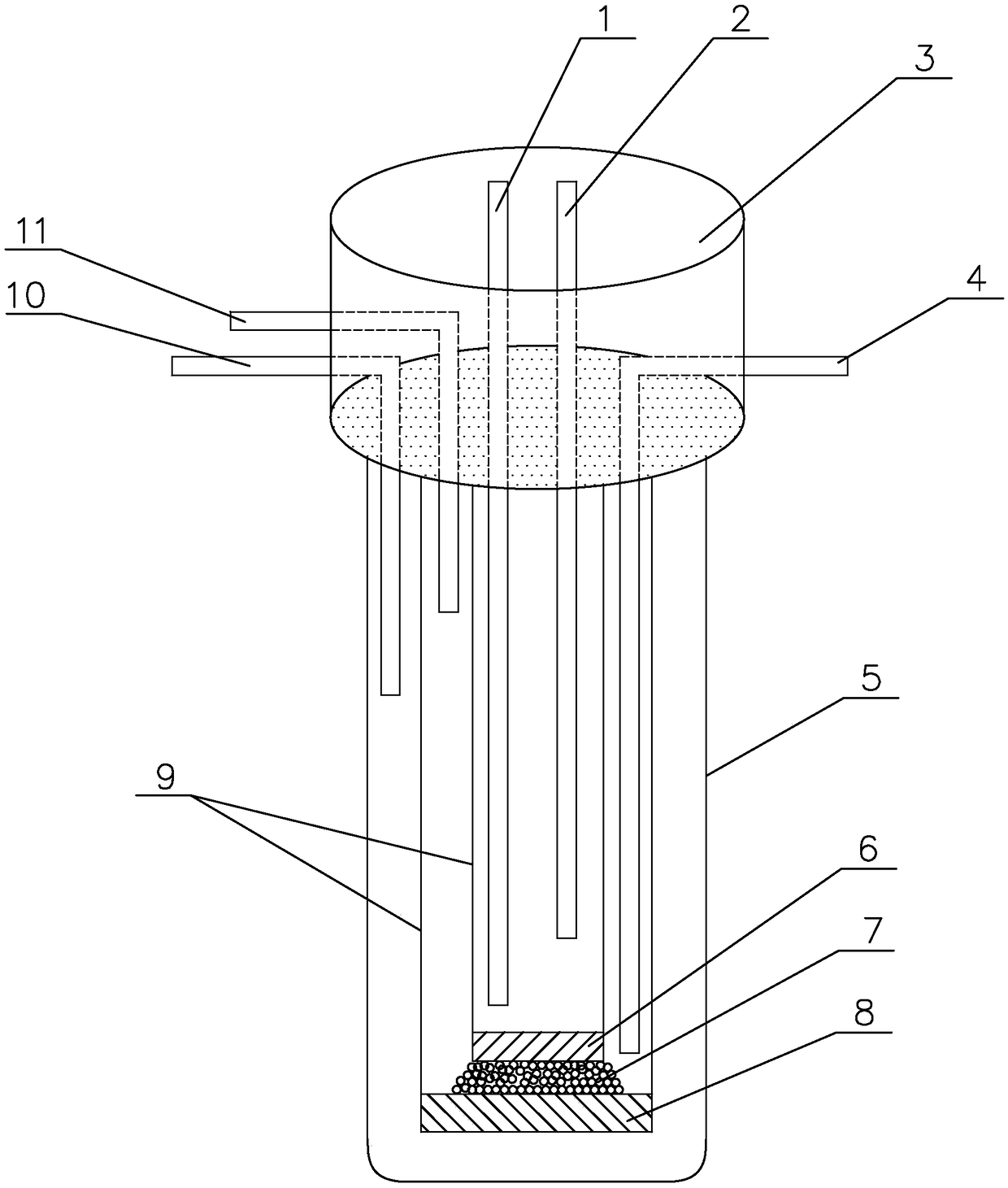

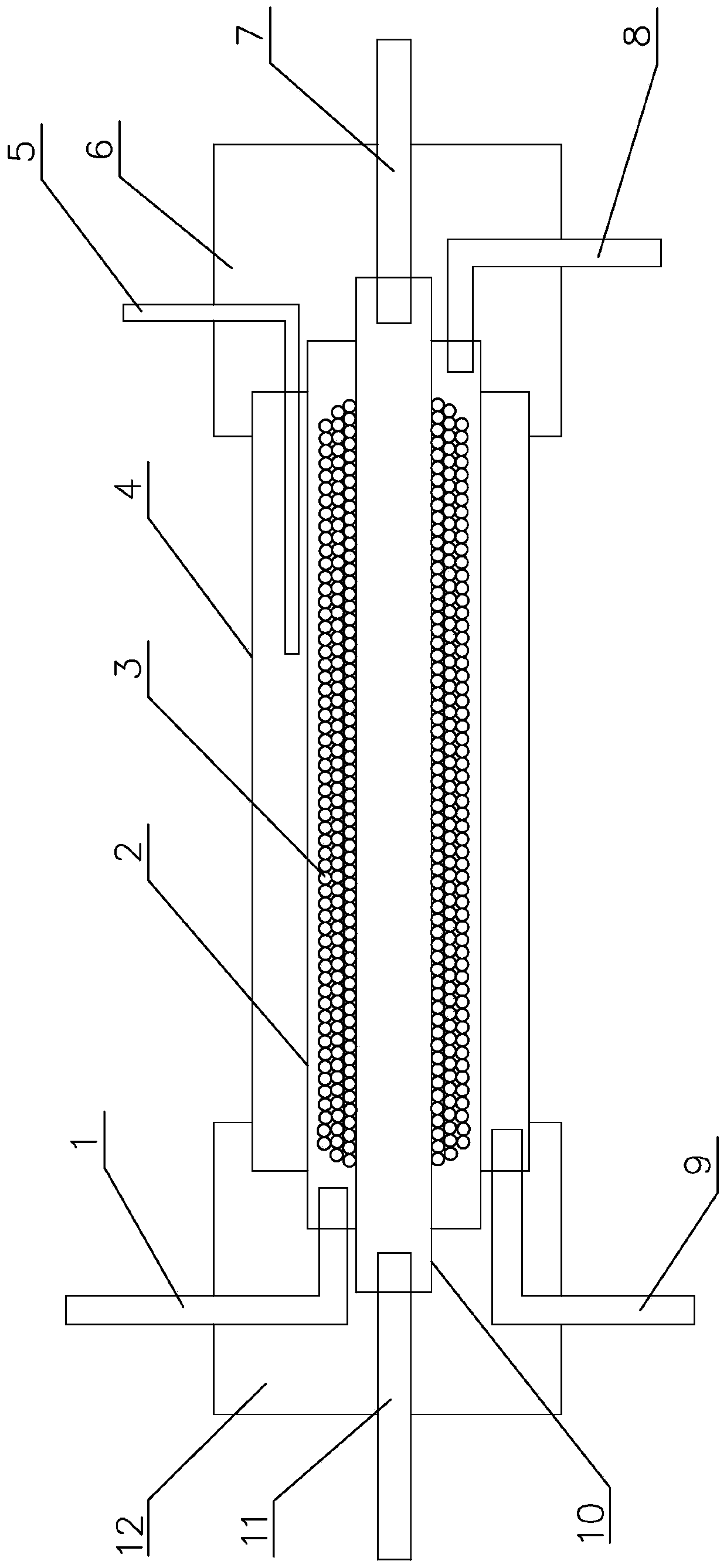

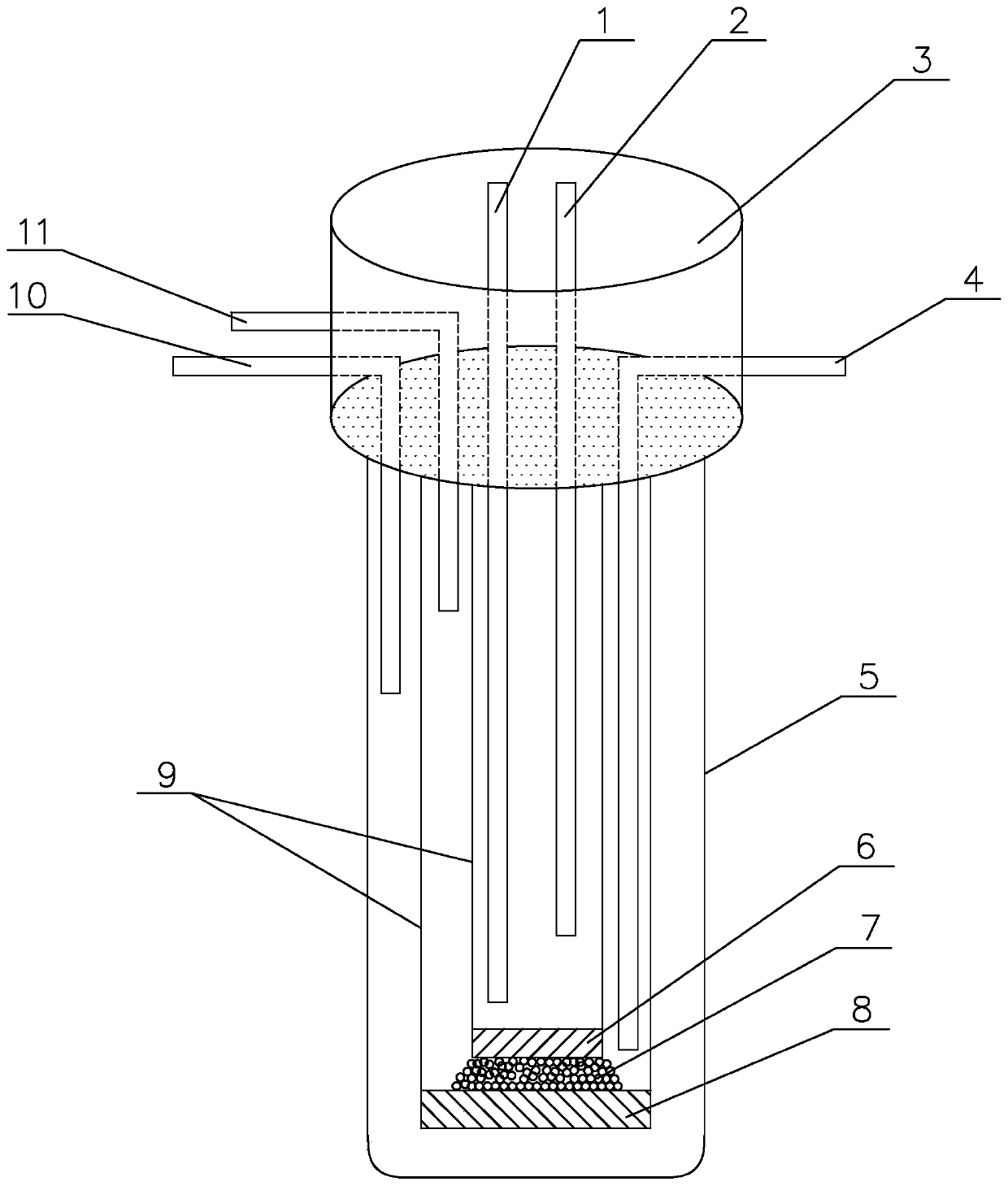

Preparation method for oxygen permeation-hydrogen permeation-reaction three-effect tubular membrane reactor for partial methane oxidation hydrogen production

ActiveCN108745263AAvoid deep oxidationMove quicklyChemical/physical/physico-chemical stationary reactorsNickel catalystOxygen

The invention belongs to the technical field of inorganic membrane reactors and in particular relates to a preparation method for an oxygen permeation-hydrogen permeation-reaction three-effect tubularmembrane reactor for partial methane oxidation hydrogen production. The preparation method comprises the following steps: firstly, preparing a tubular dense ceramic oxygen permeation membrane, a tubular dense ceramic hydrogen permeation membrane and a nickel catalyst; sleeving the tubular dense ceramic oxygen permeation membrane by the tubular dense ceramic hydrogen permeation membrane, mountingone end of the tubular dense ceramic hydrogen permeation membrane on a first sealing head, and filling interlayers of the two tubular membranes with the nickel catalyst; sleeving the hydrogen permeation membrane by a quartz tube, and mounting one end of the quartz tube on the first sealing head; further sealing the quartz tube and the other ends of the two tubular membranes by using second sealingheads, thereby forming a reactor. By adopting the preparation method, deep oxidation of methane can be prevented, real-time separation of hydrogen from carbon monoxide can be achieved, and reaction balance can also be promoted towards a product direction. By adopting the preparation method, the problem that raw material separation, methane reactions and product separation, of a partial methane oxidation reaction, cannot be carried out in a same reactor simultaneously can be solved.

Owner:SHANDONG UNIV OF TECH

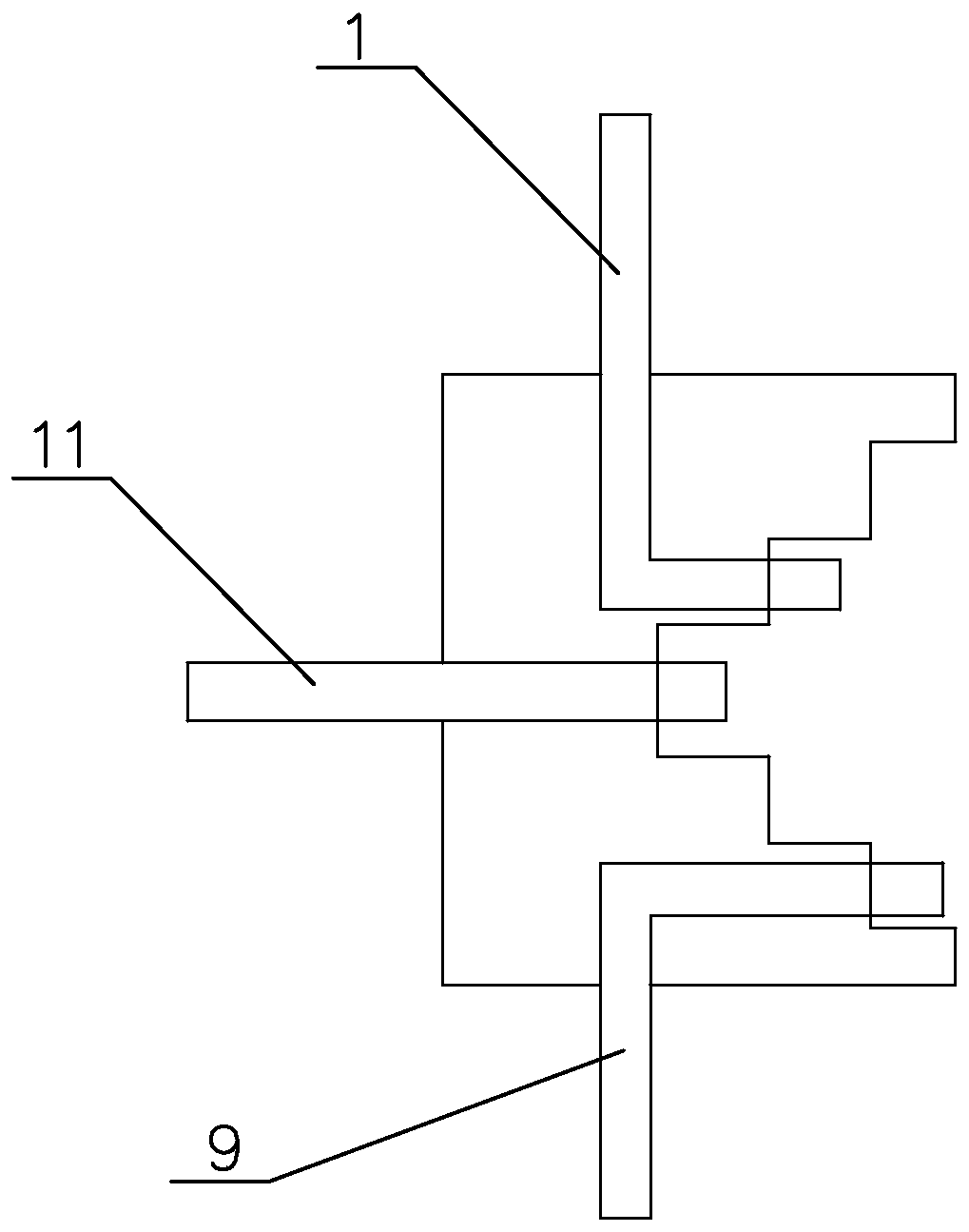

Preparation method of oxygen-permeation-hydrogen permeation-methane partial oxidative dehydrogenation three-effect flat plate type membrane reactor and testing system thereof

ActiveCN108745262AAvoid deep oxidationReduce oxygen contentChemical/physical/physico-chemical stationary reactorsPtru catalystDehydrogenation

The invention belongs to the technical field of inorganic membrane reactors and in particular relates to a preparation method of an oxygen-permeation-hydrogen permeation-methane partial oxidative dehydrogenation three-effect flat plate type membrane reactor and a testing system thereof. The preparation method comprises the following steps: preparing a dense ceramic oxygen-permeation membrane, a dense ceramic hydrogen-permeation membrane and a nickel catalyst, and laying the nickel catalyst on the surface of the hydrogen-permeation membrane; putting an alundum tube for sealing the oxygen-permeation membrane into an alundum tube for sealing the hydrogen-permeation membrane to form a core component, further putting the core component into a quartz tube, and finally connecting a sealing cap with a gas channel with the quartz tube, thereby obtaining the reactor. By adopting the reactor, continuous controllable oxygen supply can be achieved, and deep oxidation of methane can be prevented; in-time separation of hydrogen from carbon monoxide can also be achieved, and reaction balance can be promoted to move towards a product direction. By adopting the preparation method, problems that rawmaterials of partial methanol oxidation reactions are separated and methane reactions and product separation cannot be carried out in a same reactor simultaneously can be solved.

Owner:SHANDONG UNIV OF TECH

Method for producing ethylene and ethane and catalytic reactor

InactiveCN102659500BImprove conversion rateAvoid deep oxidationHydrocarbon by hydrocarbon condensationChemical/physical processesSingle passEthylene

Owner:BEIJING UNIV OF CHEM TECH

A reaction device and method for producing ethylene by oxidative coupling of methane

ActiveCN113477191BAvoid deep oxidationHigh selectivityHydrocarbon by hydrocarbon condensationChemical/physical processesPhysical chemistryOxidative coupling of methane

The invention discloses a reaction device and method for preparing ethylene by oxidative coupling of methane. The reaction device includes a riser, an oxidizer, a stripper, a pre-stripper, a pre-lift section, and a cyclone separator; the reaction device adopts the method of separate feeding of methane and oxygen, multi-mode operation, and flexibly controls the flow rate of oxygen. supply, realizing the flexible control between the two reaction mechanisms. There is no contact between oxygen and methane in the feed; after the reaction, products such as ethylene are directly drawn from the reactor without mixing with oxygen. The reactor and the oxidizer are coaxially arranged, wherein the reactor is at the lower part, the oxidizer is at the upper part, and the riser is used as the reactor for the reaction. The invention realizes the complete separate feeding of oxygen and methane in the process of methane oxidative coupling reaction, eliminates the contact between the product and oxygen, avoids the deep oxidation of the product, reduces the generation of non-selective products, and effectively improves the selectivity of ethylene and yield.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

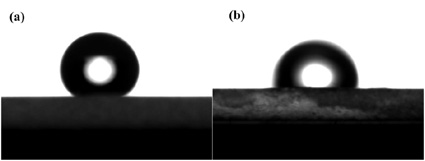

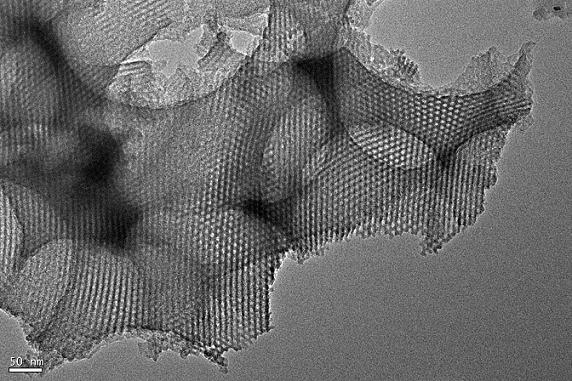

A hydrophobic modified core-shell catalyst zif-67@sio 2 Method for preparing ka oil by catalytic cyclohexane oxidation

ActiveCN109675633BImprove hydrophobicityImprove conversion ratePreparation by oxidation reactionsOrganic compound preparationCyclohexanonePtru catalyst

Hydrophobic modified core-shell catalyst ZIF‑67@SiO of the present invention 2 A method for preparing KA oil by catalytic cyclohexane oxidation. The present invention adopts the method of dehydration condensation to coat a layer of SiO on the surface of ZIF-67 material. 2 shell, to obtain a hydrophobically modified core-shell catalyst ZIF‑67@SiO 2 , by grafting hydrophobic groups on the surface to control the hydrophilic-hydrophobic properties of the catalyst surface, thereby regulating the adsorption and desorption behavior of cyclohexane, cyclohexanol and cyclohexanone, and avoiding the deep oxidation of alcohols and ketones. The modified catalyst surface has Good hydrophobic effect, the catalytic reaction shows that the conversion rate of cyclohexane and the selectivity of the target product are simultaneously improved, and the stability of the catalyst is also significantly improved.

Owner:XIANGTAN UNIV

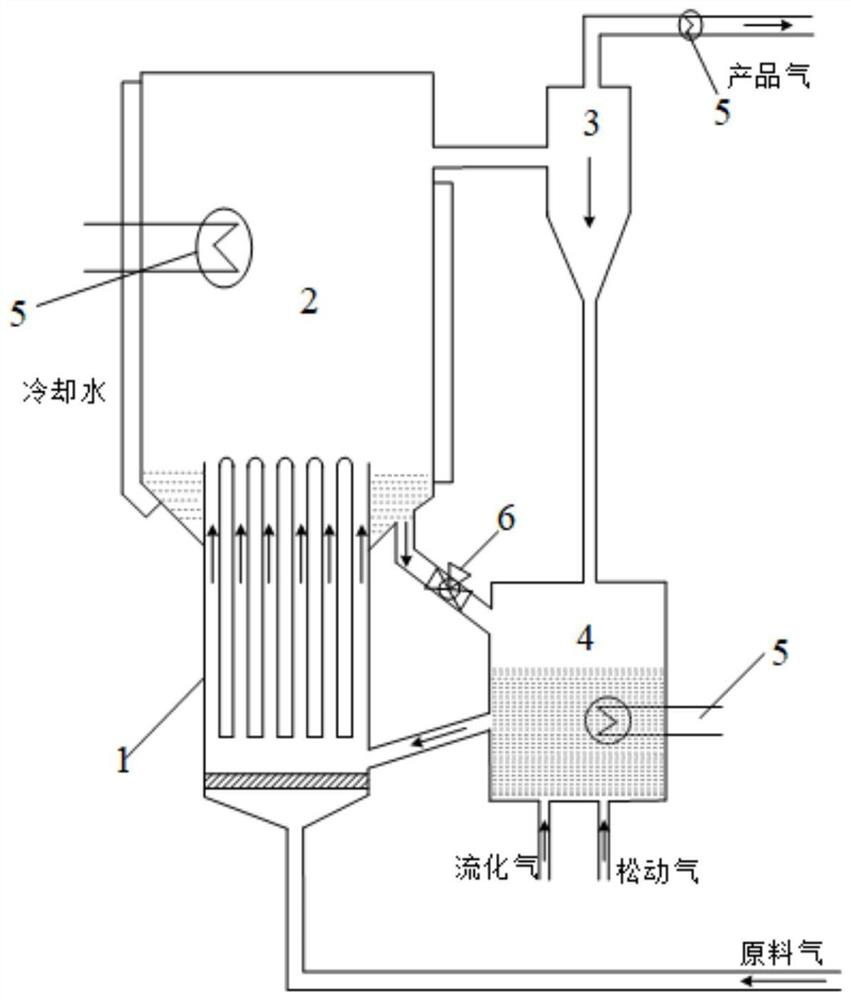

A gas-solid short contact time reaction device and its application

ActiveCN112973579BAvoid deep oxidationReduce wearHydrocarbon by hydrocarbon condensationChemical recyclingThermodynamicsPtru catalyst

The invention belongs to a reaction device with short gas-solid contact time and its application. The reaction device includes a riser reactor, a settling reactor, a gas-solid separator and a feeding device; the riser reactor is installed in the settling At the bottom of the reactor, the discharge port of the riser reactor is higher than the bottom discharge port of the settling reactor; the gas-solid separator is used for the separation of product gas and catalyst particles; the return device collects the bottom discharge port of the settling reactor The transported catalyst particles and the catalyst particles obtained by the gas-solid separator are returned to the bottom of the riser; the bottom of the riser is provided with a feed gas inlet pipe. The present invention realizes short-term contact between the catalyst particles and the gas through the riser reactor, avoiding the deep oxidation of target products such as ethylene, and at the same time, the catalyst particles carry the reaction heat and perform heat exchange outside the reactor, so that the temperature of the hot spot in the reactor is reduced , which is conducive to improving the selectivity of the target product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of oxygen permeation-hydrogen permeation-reaction three-effect tubular membrane reactor for partial oxidation of methane to hydrogen

ActiveCN108745263BAvoid deep oxidationMove quicklyChemical/physical/physico-chemical stationary reactorsNickel catalystPartial oxidation

The invention belongs to the technical field of inorganic membrane reactors, and in particular relates to a preparation method of an oxygen-permeable-hydrogen-permeable-reaction three-effect tubular membrane reactor for hydrogen production by partial oxidation of methane: first prepare a tubular dense ceramic oxygen permeable membrane, a tubular dense ceramic permeable membrane Hydrogen membrane, nickel catalyst; set the tubular dense ceramic hydrogen permeable membrane on the outside of the tubular dense ceramic oxygen permeable membrane, install one end on the first sealing head, and then fill the nickel catalyst in the interlayer of the two tubular membranes; set the quartz tube On the outside of the hydrogen permeable membrane, one end of the quartz tube is installed on the first sealing head; then the quartz tube and the other ends of the two tubular membranes are sealed to the second sealing head to form a reactor. The invention can prevent the deep oxidation of methane; can also realize the instant separation of hydrogen and carbon monoxide, and can promote the movement of the reaction balance to the product direction. The invention solves the problem that the raw material separation of methane partial oxidation reaction, methane reaction and product separation cannot be carried out simultaneously in the same reactor.

Owner:SHANDONG UNIV OF TECH

A kind of hierarchical porous catalyst and its preparation method and application

ActiveCN111939952BReduce spawn rateQuick breakOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystPorous catalyst

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Catalyst for preparing phenol by hydroxylation of benzene and preparation method

InactiveCN102294272BImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationBenzeneSolvent

The invention relates to a catalyst for preparing phenol by hydroxylation of benzene and a preparation method thereof. The component expression of the catalyst provided by the invention is Cs2.5(MIMPS)nH1.5-nPMo11VO40, wherein MIMPS indicates [N-(3-sulfonic)propyl-imidazolium] and n equals to 0.5-1.5. The preparation method provided by the invention comprises the following steps of: (1) preparingpure vanadium substituted heteropolymolybdates; (2) mixing the pure vanadium substituted heteropolymolybdates obtained from the step (1) with deionized water, adding dropwisely an inorganic cesium salt solution into the above solution with stirring, followed by a reaction, removing water from a suspending liquid obtained after the reaction so as to obtain a solid, drying to obtain a heteropolyacid inorganic cesium salt; (3) mixing the heteropolyacid inorganic cesium salt obtained from the step (2) with deionized water, adding dropwisely an MIMPS aqueous solution with stirring, followed by a reaction, removing the solvent from a suspending liquid obtained after the reaction so as to obtain a solid, and drying to obtain the catalyst for preparing phenol by hydroxylation of benzene. By the adoption of the catalyst provided by the invention, the yield of phenol can be obviously raised; in addition, the catalyst is easy to recover and convenient to repeatedly use.

Owner:ZHEJIANG NORMAL UNIVERSITY

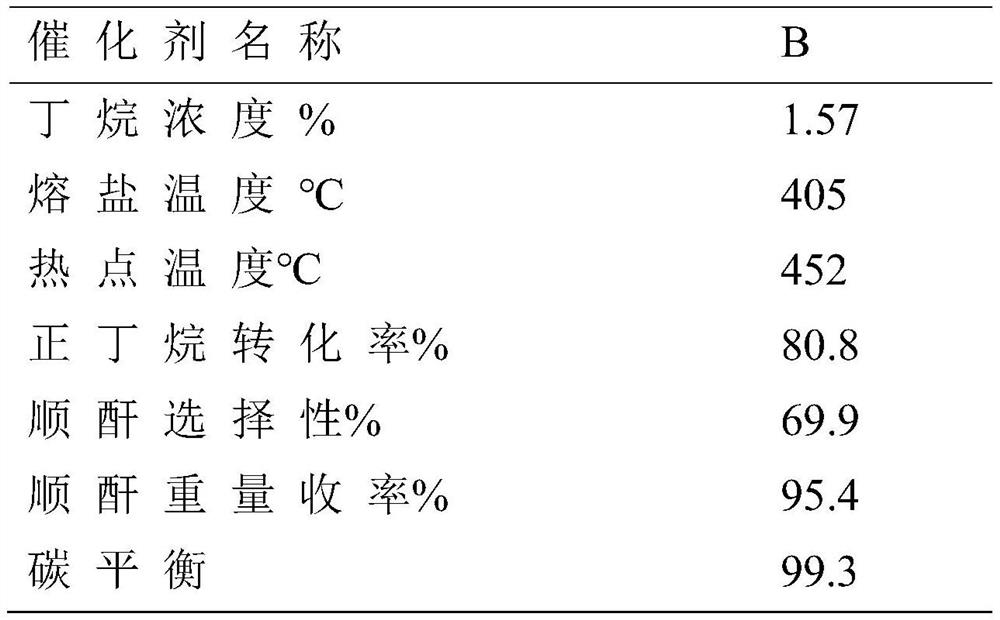

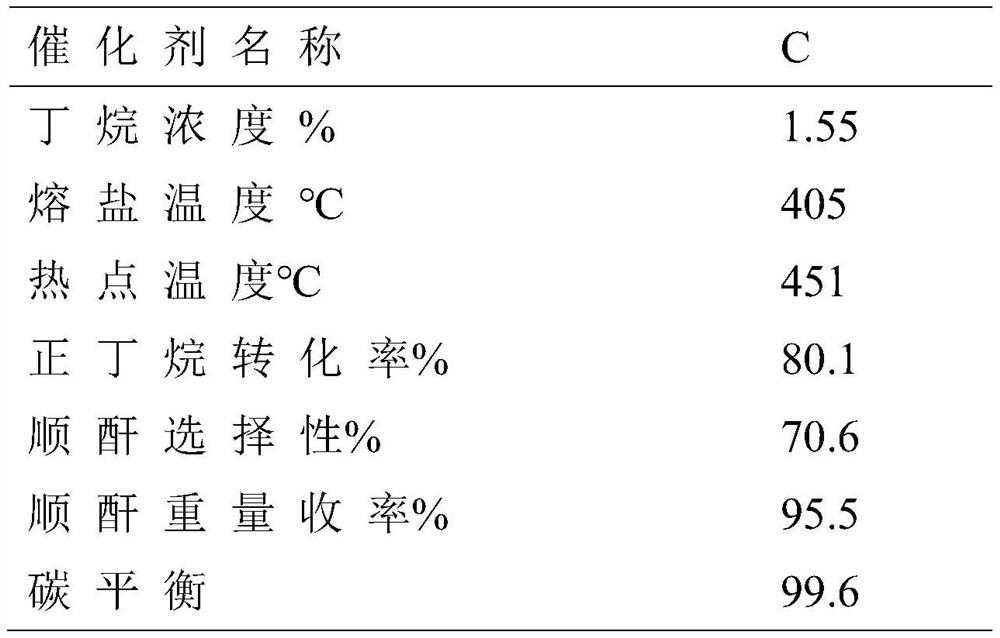

Catalyst for preparing maleic anhydride by oxidizing n-butane as well as preparation method and application of catalyst

PendingCN113522329AAvoid deep oxidationHigh selectivityOrganic chemistryCatalyst activation/preparationMaleic anhydrideChemistry

The invention discloses a catalyst for preparing maleic anhydride by oxidizing n-butane as well as a preparation method and application of the catalyst. The catalyst comprises a catalyst substrate and an inert carrier, the catalyst substrate comprises vanadium phosphorus oxide, and the inert carrier is an inert heat conduction material. The inert carrier is selected from at least one of silicon nitride, aluminum nitride and boron nitride. The preparation method comprises the following steps: uniformly mixing the inert carrier and the catalyst matrix powder, carrying out compression molding, crushing, adding the pore-forming agent, repeating the molding and crushing processes for 2-10 times, molding, and carrying out heat treatment to obtain the catalyst. By adopting the inert carrier, hot spots of the reaction can be diluted, a local specific inert region can be formed, heat in the oxidation reaction process can be transferred, deep oxidation of maleic anhydride is avoided, and the selectivity of the catalyst is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

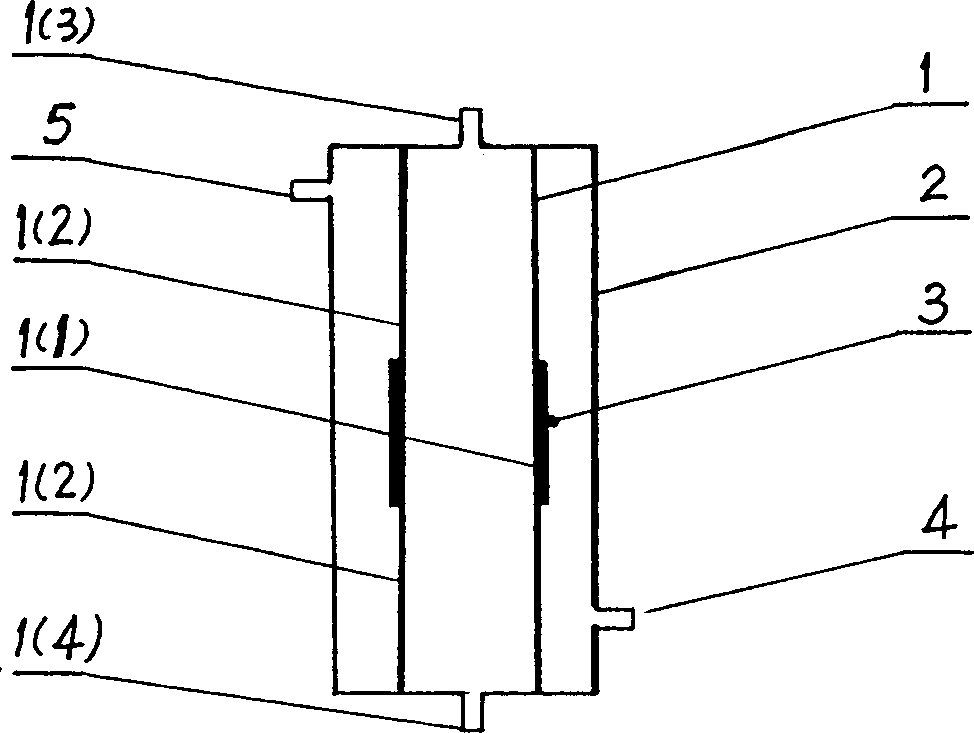

Tubular catalytic membrane reactor for selective oxygenation of hydrocarbons

InactiveCN1117612CTake advantage ofHigh catalytic activityCatalyst carriersGas-gas reaction processesMicrometerPhysical chemistry

The tubular catalytic membrane reactor comprises external tube and internal tube, between external tube and internal tube there is a gap through which air stream can be easily passed. The internal tube s made up by welding imporous metal tube onto both ends of microporous metal tube respectively, and the micropore size of the microporous metal tube is micrometer level, and the external urface of microporous metal tube is coated with catalytic membrane layer. Said invention adopts metal tube as support body, and adopts membrane type catalyst, so that it improves heat-transferring condition, and is favourable for accelerating reaction speed and raising yield of product.

Owner:JINAN UNIVERSITY

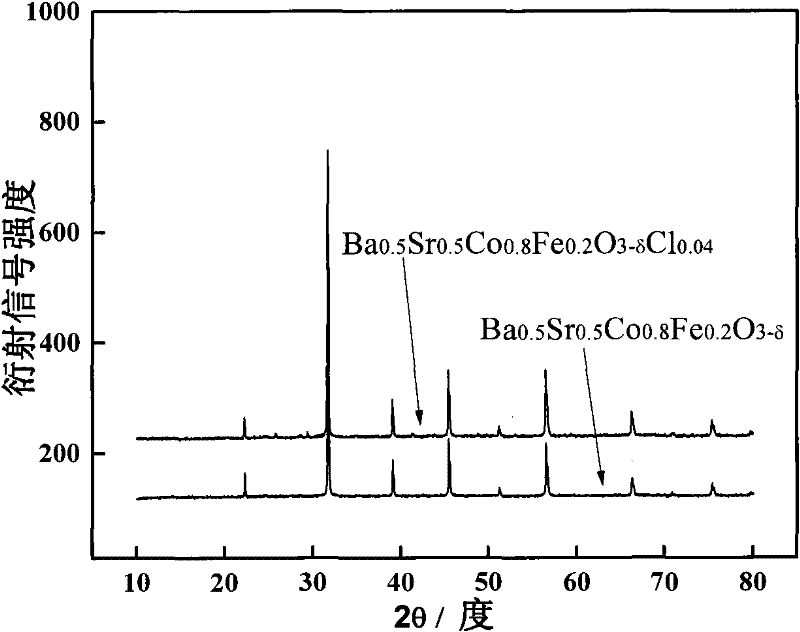

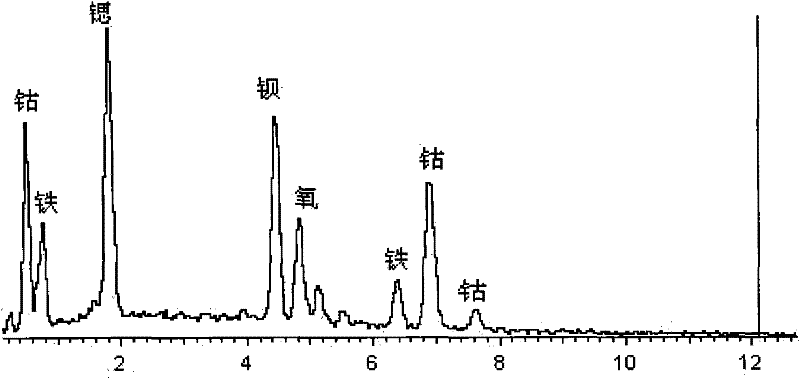

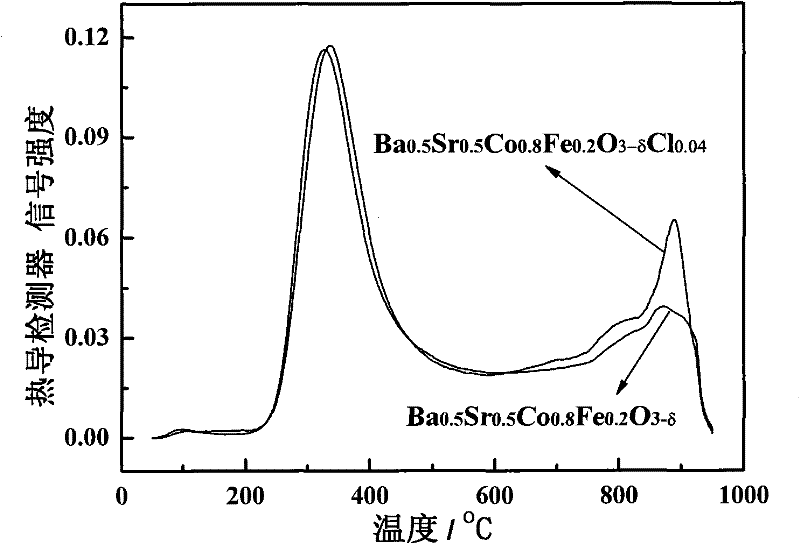

Halogen doped perovskite composite oxide catalyst as well as preparation method and application thereof

ActiveCN101954289BEasy to moveHigh activityPhysical/chemical process catalystsHydrocarbon by hydrocarbon condensationHalogenCoupling reaction

The invention relates to a preparation method of a halogen doped perovskite composite oxide catalyst and an application thereof in the aspect of catalyzing methane oxidative coupling, belonging to the field of nonhomogeneous catalysis. The halogen element doped composite oxide catalyst with a pure phase perovskite structure is prepared by using the EDTA-citric acid method, and the composite oxidecatalyst is applied to methane oxidative coupling reaction. Results show that the catalytic performance of the halogen element doped material in methane oxidative coupling is greatly improved, and the catalyst shows good catalytic activity stability. Thus, the catalyst is an excellent catalyst for the methane coupling reaction to prepare ethane and ethylene.

Owner:SOUTH CHINA UNIV OF TECH

Oxygen permeation-hydrogen permeation-methane partial oxidation dehydrogenation three-effect flat-plate membrane reactor preparation method and test system

ActiveCN108745262BAvoid deep oxidationReduce oxygen contentChemical/physical/physico-chemical stationary reactorsNickel catalystPartial oxidation

The invention belongs to the technical field of inorganic membrane reactors, and in particular relates to a preparation method of an oxygen-permeable-hydrogen-permeable-methane partial oxidation dehydrogenation three-effect flat-plate membrane reactor and a test system thereof. The preparation method includes first preparing a dense ceramic oxygen permeable membrane, a dense ceramic hydrogen permeable membrane, and a nickel catalyst, and then spreading the nickel catalyst on the surface of the hydrogen permeable membrane; placing the corundum tube encapsulating the oxygen permeable membrane on the corundum tube encapsulating the hydrogen permeable membrane Inside, the core component is formed, and then the core component is placed in the quartz tube, and finally the sealing cap equipped with the gas channel is connected with the quartz tube to form the reactor. It can realize the continuous and controllable supply of oxygen to prevent the deep oxidation of methane; it can also realize the instant separation of hydrogen and carbon monoxide, and can promote the shift of the reaction balance to the product direction. The invention solves the problem that the raw material separation of methane partial oxidation reaction, methane reaction and product separation cannot be carried out simultaneously in the same reactor.

Owner:SHANDONG UNIV OF TECH

Catalyst with isolated dehydrogenation and oxidation double active sites and preparation and application thereof

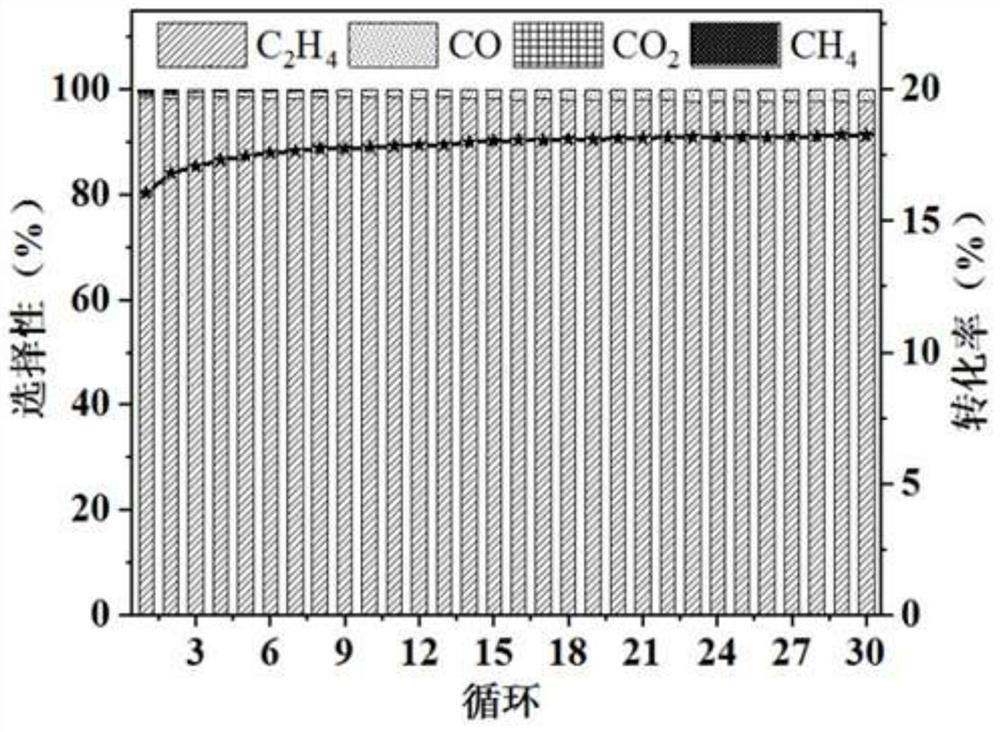

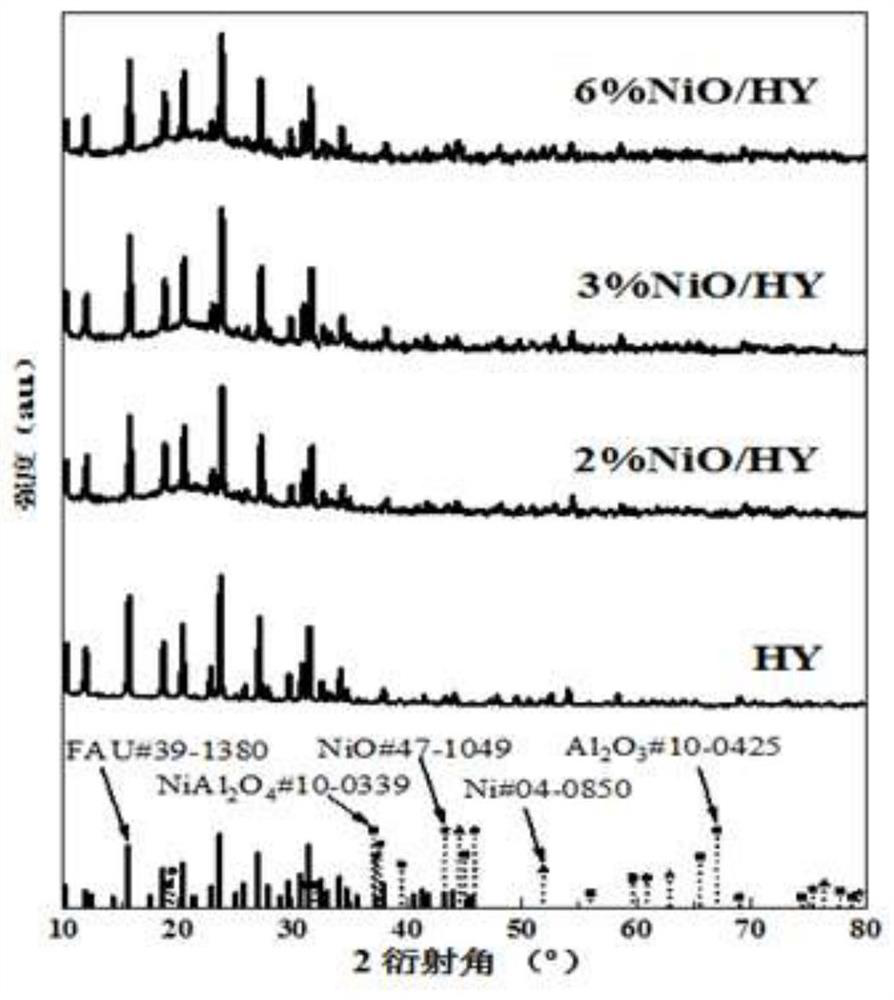

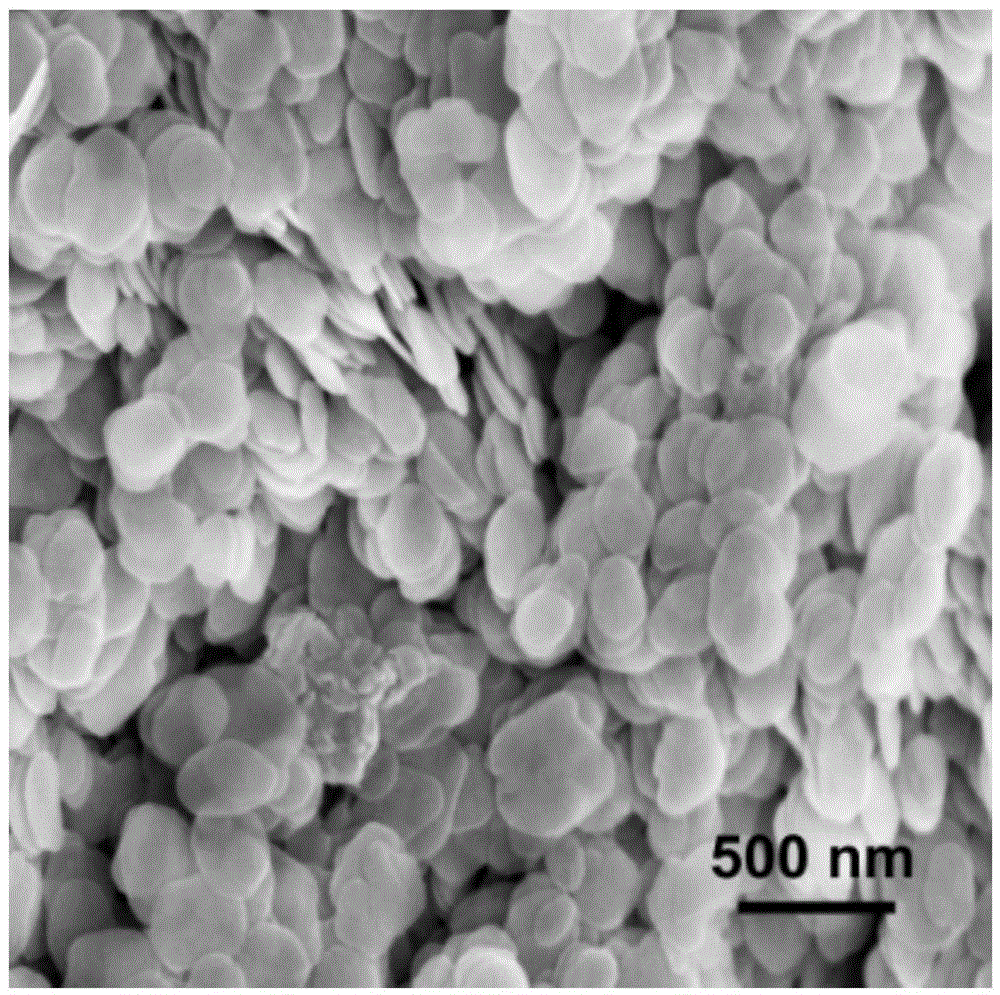

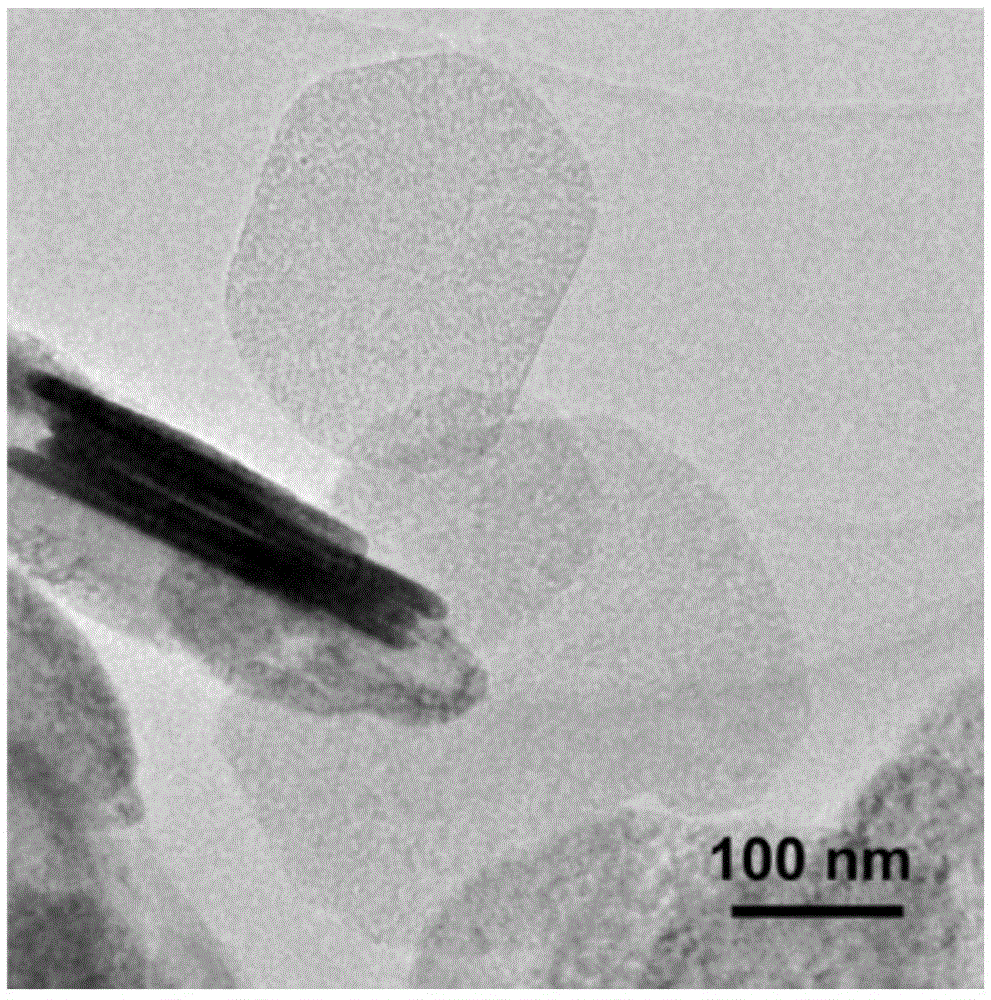

PendingCN114797952AEnhanced adsorption and activationGenerate efficientlyMolecular sieve catalystsHydrocarbonsMolecular sievePtru catalyst

The invention relates to a catalyst with isolated dehydrogenation and oxidation double active sites as well as preparation and application of the catalyst. Double active sites of the catalyst are an active metal Lewis acid site loaded on the surface of an HY molecular sieve and a metal oxide nanocluster active site limited in a molecular sieve pore channel, the metal oxide loading amount is 1%-5% of the mass of the catalyst, and the mass ratio of the active metal Lewis acid to the metal oxide limited in the molecular sieve pore channel is 0.8-9.0. The HY molecular sieve carrier is H-type, and the SiO2 / Al2O3 ratio is 2-10. Under the reaction temperature of 500-700 DEG C, H2 generated by ethane dehydrogenation and limited range NiO selective oxidation is activated through Ni Lewis acid, ethane is converted into ethylene with high selectivity, and deep oxidation of ethane is effectively avoided. Compared with the prior art, the catalyst disclosed by the invention can be used for isolated dehydrogenation and oxidation, so that the ethylene selectivity is close to 100%, and particularly, the catalyst disclosed by the invention can also be used for catalytic decomposition of ADN-based and HAN-based single-component propellants.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

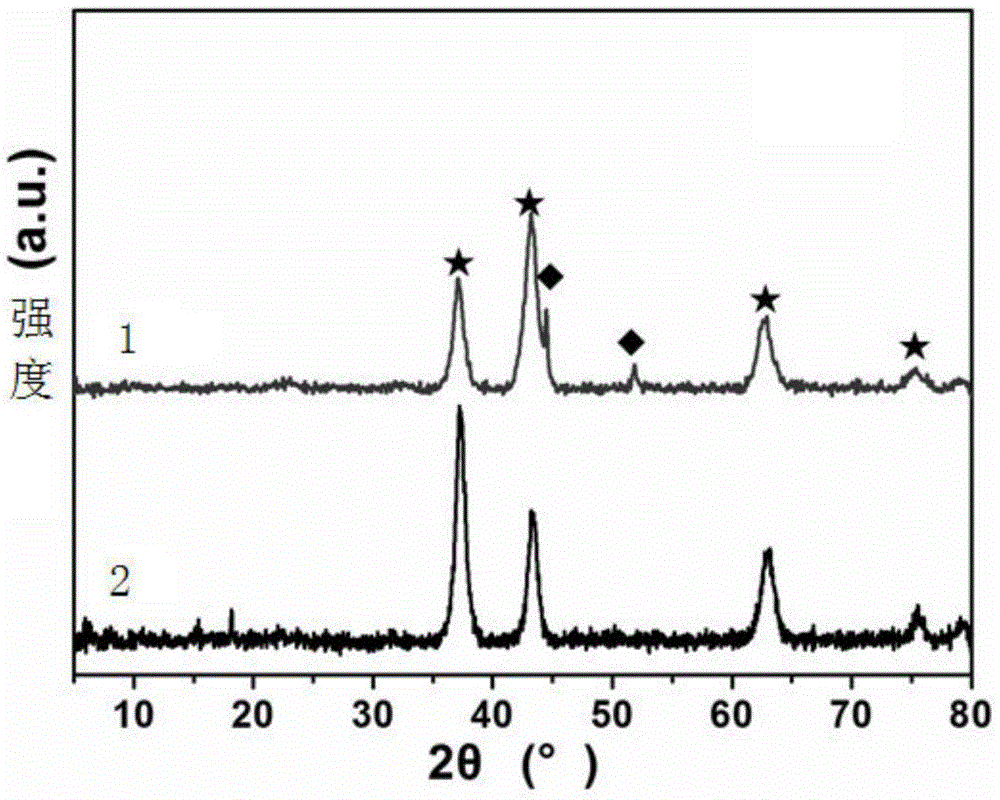

A preparation method of self-supporting two-dimensional transition metal/metal oxide mixed-phase nanosheets

A preparation method of a self-supporting two-dimensional transition metal / metal oxide mixed-phase nanosheet relates to a preparation method of a two-dimensional nano material and solves the problems of complex technology, harsh reaction condition and poor electric conductibility of transition metal oxide in the conventional method for preparing the self-supporting two-dimensional transition metal / metal oxide mixed-phase nanosheet. The preparation method of the mixed-phase nanosheet comprises the following steps: firstly, inorganic transition metal salt, organic amine, alcohol and water are mixed to form a turbid liquid of an organic amine complex containing metal ions; secondly, the turbid liquid reacts under a high-temperature solvent thermal condition to generate a precursor of the metal / metal oxide mixed-phase nanosheet; finally, high-heat treatment is conducted under the protection of inert gas to control the crystallinity of the two-dimensional metal / metal oxide mixed-phase nanosheet. The preparation method provided by the invention has the advantages of simple technology and lower equipment requirement; the mixed-phase nanosheet prepared by the method has excellent electric conductibility.

Owner:HEILONGJIANG UNIV

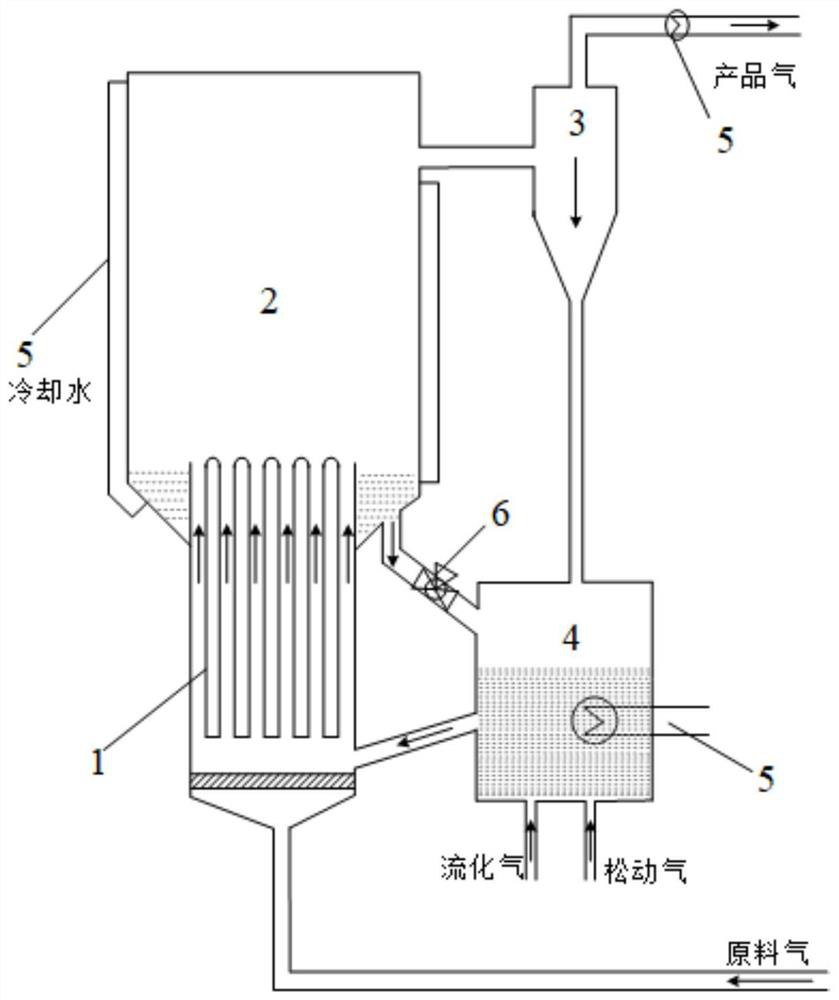

Multi-channel riser reaction device and application thereof

ActiveCN113750911AUniform temperatureHigh selectivityChemical/physical processesReaction zoneMechanical engineering

The invention provides a multi-channel riser reaction device and application thereof. The reaction device comprises at least three riser reactors, a sedimentation device, a gas-solid separation device and a material returning device, wherein the riser reactors are arranged in parallel, and heat transfer is performed between the adjacent riser reactors; the upper part of the riser reactor is connected with the bottom of the sedimentation device, and a discharge hole of the riser reactor is higher than a discharge hole in the bottom of the sedimentation device; the bottom of the riser reactor is connected with a discharge hole of the material returning device; and a feed gas inlet pipeline is arranged at the bottom of the riser reactor. The at least three riser reactors are connected in parallel so as to be suitable for the cascade reaction with strong heat absorption / heat release characteristics, and through the gap heat transfer of each riser reactor, the bed temperature of the riser reaction zone is uniform, such that the isothermal reaction process is easily achieved, and the selectivity of the target product is further improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

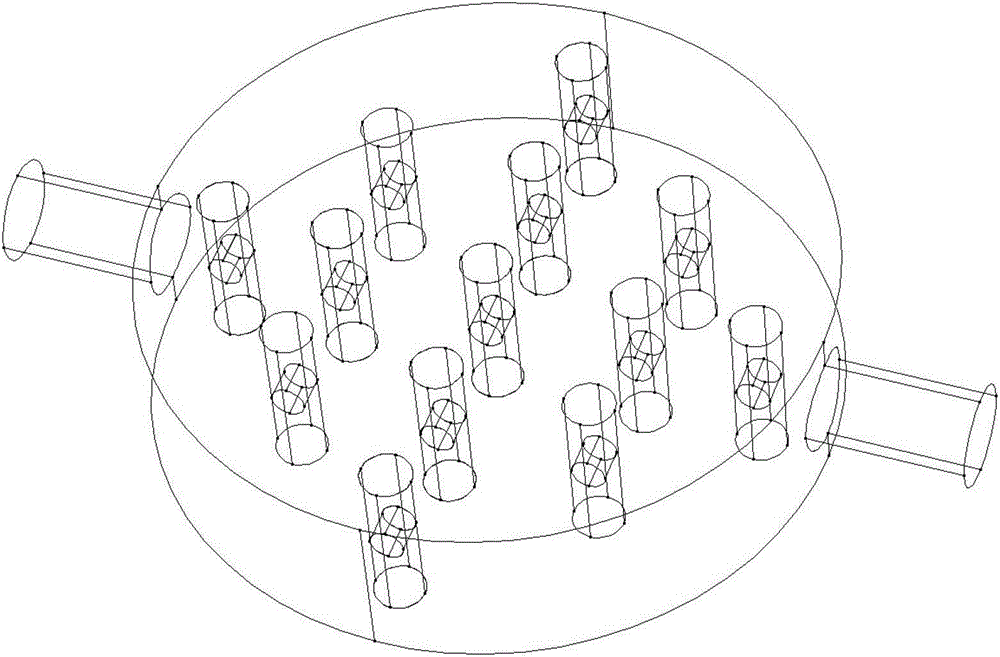

Fluidized bed reaction device and application thereof

ActiveCN112973584AUniform temperature distributionGood gas-solid contact effectHydrocarbon by hydrocarbon condensationChemical/physical processesPtru catalystFluidized bed

The invention provides a fluidized bed reaction device and application thereof. The fluidized bed reaction device comprises a fluidized bed reactor, the top of the fluidized bed reactor is provided with a catalyst inlet and a product gas outlet, and the bottom of the fluidized bed reactor is provided with a catalyst outlet and a feed gas inlet. In the axial direction, at least two layers of fluidized beds are arranged in the fluidized bed reactor. A pore plate is arranged at the bottom of each layer of fluidized bed. An overflow pipe is arranged between every two adjacent layers of fluidized beds. The structure of the fluidized bed reaction device is improved, so that gas back-mixing is reduced, the fluidized state is effectively stabilized, and unstable product composition caused by an unstable fluidized bed state is avoided. The fluidized bed reaction device is applied to a methane oxidative coupling reaction, oxygen enters the fluidized bed reactor in a graded mode, deep oxidation of methane is avoided, and C2 + selectivity is improved on the premise that the methane conversion rate is guaranteed. The fluidized bed reactor can adjust the dosage of a catalyst and the flow velocity of a heat exchange medium according to the gas treatment amount, and the load change resistance is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com