Method for producing ethylene and ethane and catalytic reactor

A catalytic reactor and reactor technology, applied in chemical instruments and methods, organic chemistry, bulk chemical production, etc., can solve the problems of low production efficiency, high energy consumption, long process flow, etc., and achieve simple structure and equipment investment. The effect of less and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a detailed description of the present invention, which does not constitute any limitation to the present invention. The known technical parts involved in the present invention are not described in detail, nor are they marked in the accompanying drawings. In addition, the feed gas of the present invention may be one or more of methane-rich coalbed methane, natural gas, and biogas. For the convenience of describing the present invention, coalbed methane is used as the feedstock gas for illustration. According to the description of this embodiment, those skilled in the art can understand that the present invention can also be accomplished by using other raw material gases.

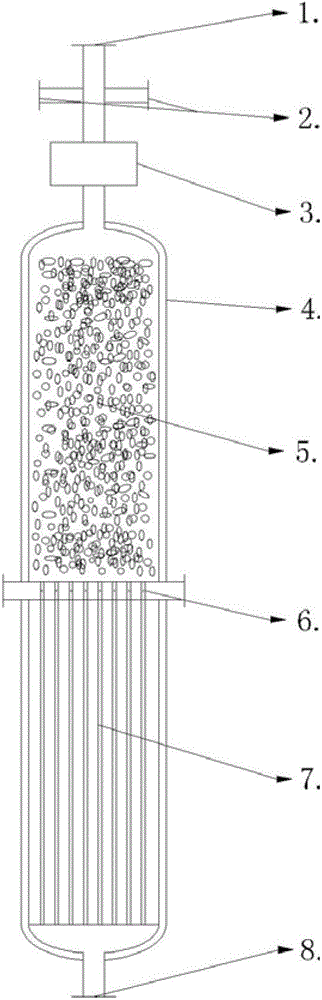

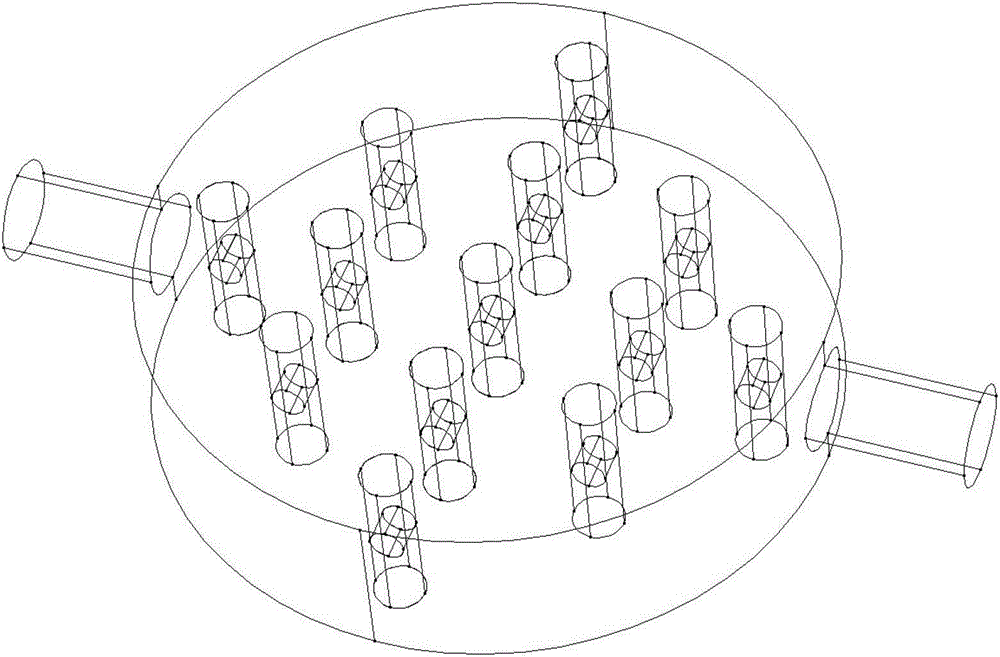

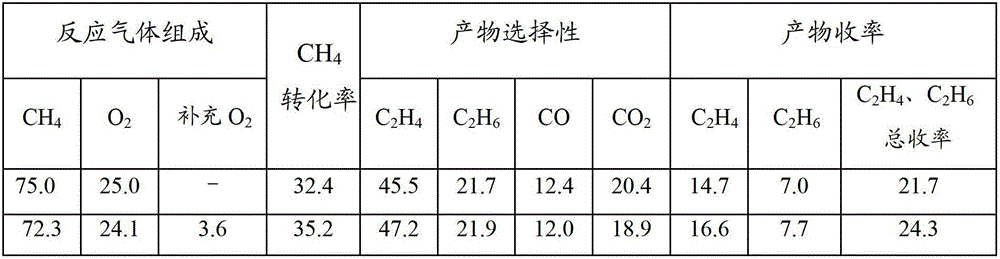

[0024] The catalytic reaction of the present invention is carried out under the pressure condition of 0.1~1.5MPa, raw material gas and oxidizing gas are mixed with 1.0×10 2 ~5.0 x 10 6 h -1 The gas space velocity of the gas enters the gas premixing chamber at the top of the catalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com