Reaction device and method for preparing ethylene through oxidative coupling of methane

A reaction device, oxidative coupling technology, applied in chemical instruments and methods, organic chemistry, bulk chemical production, etc., can solve the problems of deep oxidation of ethylene, low selectivity, low ethylene yield, etc., to reduce CO and CO2 , improve selectivity and yield, improve the effect of methane conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This example aims at the mechanism of activation of methane in the oxidative coupling reaction of methane with lattice oxygen on the surface of the catalyst as the oxidant.

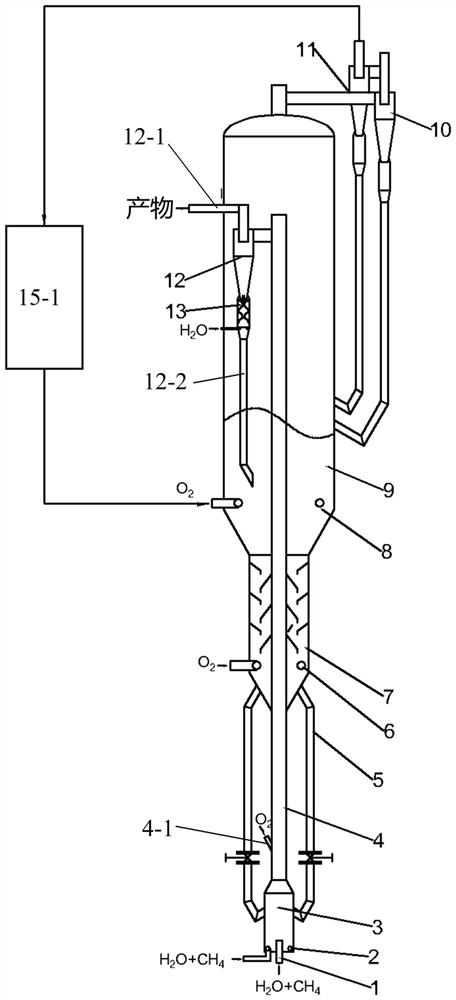

[0074] Such as figure 1 As shown, the reaction device for oxidative coupling of methane to ethylene includes a pre-lift section 3 , a riser 4 , a catalyst circulation pipe 5 , a stripper 7 , an oxidizer 9 and a first cyclone separator 12 .

[0075] The upper section of the riser 4 extends coaxially into its inner cavity from the bottom of the oxidizer 9; the top of the riser 4 is connected with a first cyclone separator 12, and the gas riser of the first cyclone separator 12 The outlet of 12-1 communicates with the outside of the oxidizer 9, and the outlet of the cyclone material leg 12-2 of the first cyclone separator 12 communicates with the inner cavity of the oxidizer 9; the first cyclone separator A pre-stripping device 13 is arranged on the cyclone material leg of 12.

[0076] An oxygen dis...

Embodiment 2

[0083] This example aims at the mechanism of methane activation using oxygen as an oxidant in the oxidative coupling reaction of methane.

[0084] Such as figure 2 As shown, the reaction device for oxidative coupling of methane to ethylene includes a pre-lift section 3 , a riser 4 , a catalyst circulation pipe 5 , a stripper 7 , an oxidizer 9 and a first cyclone separator 12 .

[0085] The upper section of the riser 4 extends coaxially into its inner cavity from the bottom of the oxidizer 9; the top of the riser 4 is connected with a first cyclone separator 12, and the gas riser of the first cyclone separator 12 The outlet of 12-1 communicates with the outside of the oxidizer 9, and the outlet of the cyclone material leg 12-2 of the first cyclone separator 12 communicates with the inner cavity of the oxidizer 9; the first cyclone separator A pre-stripping device 13 is arranged on the cyclone material leg of 12.

[0086] An oxygen distributor 8 is provided at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com