Anti-oxidation dust suppressant and preparation method thereof

A technology of dust suppressant and alkyd resin, which is applied in the field of environmental protection and governance, can solve problems such as scattered lumps, potential safety hazards of passing vehicles, waste of materials, etc., and achieve saving of coal and iron ore resources, long duration of dust suppression, The effect of expanding the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

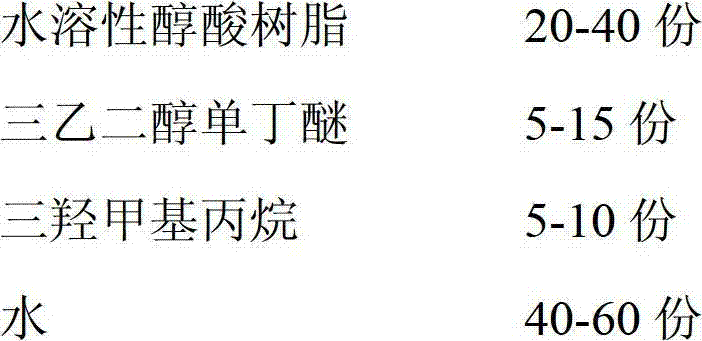

[0021] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0022]

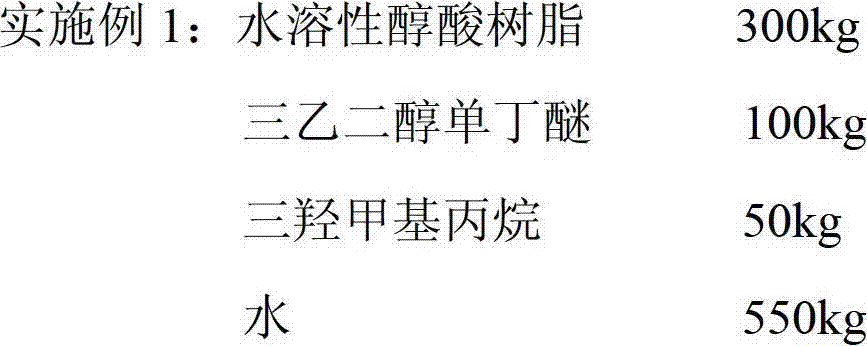

[0023] Preparation method: Add 300Kg of water-soluble alkyd resin into the reaction kettle, add 550Kg of water, stir evenly, then add 100Kg of triethylene glycol monobutyl ether and 50Kg of trimethylolpropane, stir evenly, and discharge.

[0024] The specific application effect is as follows: when in use, the directly obtained product can be sprayed. It can also be diluted with water according to the actual situation. The anti-oxidant dust suppressant will dry quickly 30 minutes after spraying, but it will not crust. There will still be no dust in the wind of level 7 in the experimental site.

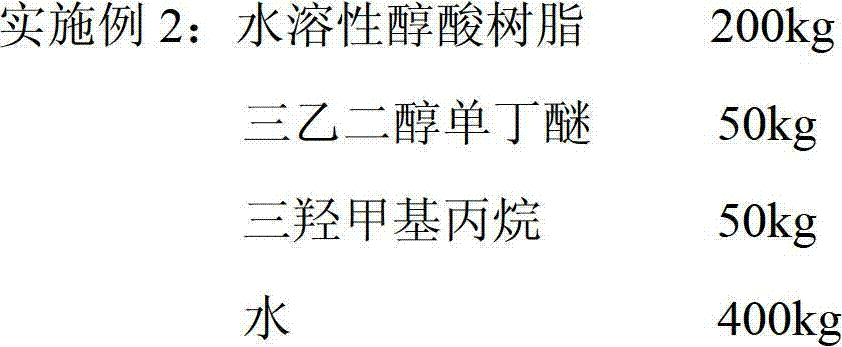

[0025]

[0026] Preparation method: Add 200Kg of water-soluble alkyd resin into the reaction kettle, add 400Kg of water, stir evenly, then add 50Kg of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com