CeO2-ZrO2 based SCR (selective catalytic reduction) catalyst used for denitration and preparation thereof

An SCR catalyst and catalyst technology, applied in the field of nitrogen oxides (NOx) post-treatment purification, can solve the problems of poor high temperature resistance of catalysts, environmental and human hazards, restrictions, etc., and achieve low production cost, easy industrialization, and working temperature window. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

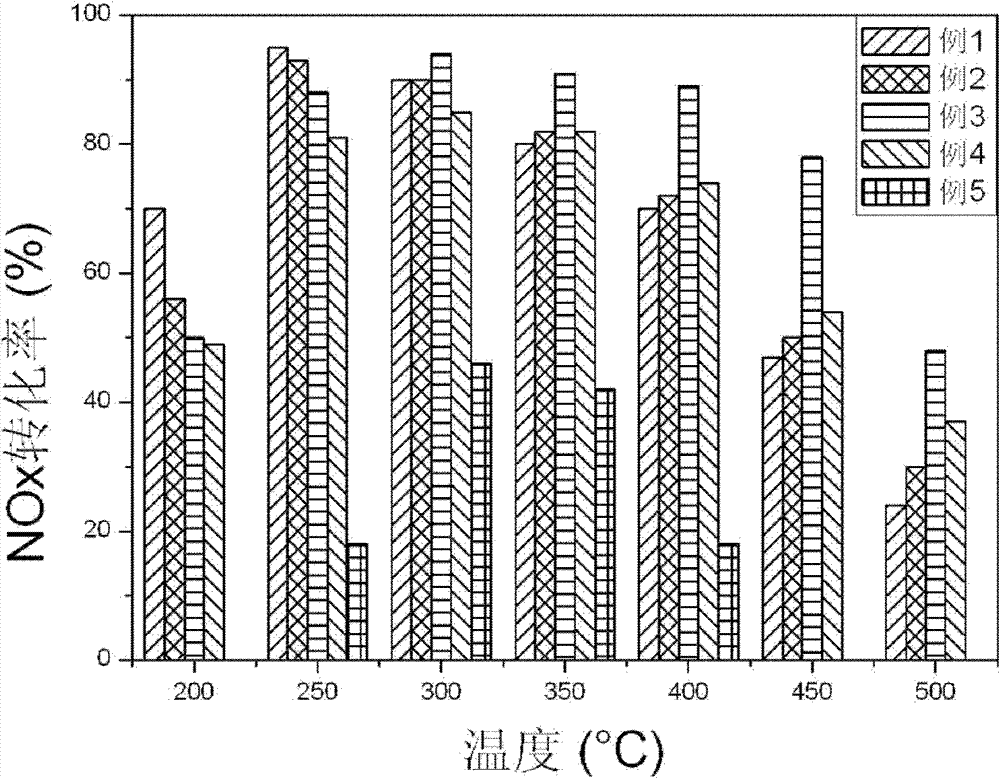

Embodiment 1

[0033] Take a certain amount of cerium-zirconium solid solution powder (the molar ratio of Ce to Zr is 3:1), zirconium acetate and water are mixed at a mass ratio of 40:10:50 at a stirring speed of 500 rpm to prepare slurry A. Soak the 200-mesh cordierite honeycomb ceramic carrier in the solution for 10 seconds, blow out the excess solution in the channels with high-pressure gas to ensure the penetration of the honeycomb channels, and then dry the carrier at 150°C for 1 hour; repeat the above steps 3 times to obtain the loaded active component Carrier B is a cerium-zirconium solid solution, and the carrier B is calcined at 500 ° C for 1 hour to obtain a carrier C whose active component is a cerium-zirconium solid solution active coating. The water absorption rate is 25wt%. Configure the required niobium oxalate (C 12 h 7 NbO 24 ) salt solution, and use this solution to load Nb on the surface of carrier C by equal volume impregnation method 2 o 5 The carrier of the modifie...

Embodiment 2

[0037] Preparation conditions and preparation procedures are the same as Example 1, adjust Nb 2 o 5 The catalyst is prepared as 10% of the total mass of active coating + modified coating, and this SCR catalyst is marked as Nb10ZrCZ-f.

[0038] The obtained catalyst has a three-layer structure, with cordierite honeycomb ceramics as a carrier, an active coating is loaded on the carrier, a modified coating is loaded on the active coating, and the active coating uses cerium-zirconium solid solution as the active group points, the modified coating is Nb 2 o 5 oxide layer.

[0039] The catalyst can be represented by the following formula, Nb 2 o 5 -ZrO 2 -Ce 0.75 Zr 0.25 o 2 , where ZrO 2 Indicates the binder used in the active coating. In the catalyst, the mass of cerium-zirconium solid solution accounts for 82.3% of the total mass of the active coating and the modified coating. ZrO 2 The mass accounts for 7.7% of the total mass of active coating and modified coating, Nb...

Embodiment 3

[0041] Preparation conditions and preparation procedures are the same as Example 1, adjust Nb 2 o 5 A catalyst was prepared for 5% of the total mass of active coating + modified coating, and this SCR catalyst was labeled as Nb5ZrCZ-f.

[0042] The obtained catalyst has a three-layer structure, with cordierite honeycomb ceramics as a carrier, an active coating is loaded on the carrier, a modified coating is loaded on the active coating, and the active coating uses cerium-zirconium solid solution as the active group points, the modified coating is Nb 2 o 5 oxide layer.

[0043] The catalyst can be represented by the following formula, Nb 2 o 5 -ZrO 2 -Ce 0.75 Zr 0.25 o 2 , where ZrO 2 Indicates the binder used in the active coating. In the catalyst, the mass of cerium-zirconium solid solution accounts for 86.8% of the total mass of the active coating and the modified coating. ZrO 2 The mass accounts for 8.2% of the total mass of active coating and modified coating, Nb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com