Rare earth doped ZIF-8 nanoporous carbon catalyst, and preparation method and application thereof

A technology of ZIF-8 and nanoporous carbon, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of poor oxidation resistance and desulfurization efficiency, and achieve high low-temperature activity , good selectivity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method based on rare earth doped ZIF-8 nanoporous carbon catalyst, comprising the following steps:

[0037] (1) 11.5g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 800mL of anhydrous methanol, and 25.4g of 2-methylimidazole was added under stirring, then 37.5mL of 15%wt% ammonia water was added, and the reaction was stirred at room temperature, and the mixed solution obtained by the reaction was washed 3 times with methanol, Vacuum drying at 60°C for 12 hours to obtain powder ZIF-8;

[0038] (2) Take 15g ZIF-8 powder and disperse it in 600mL absolute ethanol, then add 4.34g Ce(NO 3 ) 3 ·6H 2 O and 4.33g La(NO 3 ) 3 ·6H 2 O, after 20KHz ultrasonic dissolution for 0.5h, let it stand at room temperature for 8h, and rotate to dryness at 60°C to obtain La-Ce / ZIF-8-1;

[0039] (3) Take 12g La-Ce / ZIF-8 powder sample and place it in a tube furnace, calcinate it at 800°C for 1h in an argon atmosphere, with a heating rate of 5°C / min, and cool naturally to obtain LaC...

Embodiment 2

[0043] A preparation method based on rare earth doped ZIF-8 nanoporous carbon catalyst, comprising the following steps:

[0044] (1) 10.6g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 800mL of anhydrous methanol, 28.9g of 2-methylimidazole was added under stirring conditions, and then 37.5mL of 15%wt% ammonia water was added, and the reaction was stirred at room temperature, and the mixed solution obtained by the reaction was washed 5 times with methanol , vacuum-dried at 60°C for 12 hours to obtain powder ZIF-8;

[0045] (2) Take 15g ZIF-8 powder and disperse it in 600mL absolute ethanol, then add 4.34g Ce(NO 3 ) 3 ·6H 2 O and 24.53 g LaCl 3 , after 20KH sonication for 1h, let it stand at room temperature for 12h, and spin dry at 60°C to get La-Ce / ZIF-8-2;

[0046] (3) Take 12g of La-Ce / ZIF-8 powder sample and place it in a tube furnace, calcinate at 800°C for 1h under argon atmosphere, with a heating rate of 5°C / min, and cool naturally to obtain LaCeO x / NPC-2;

[0047] (4)...

Embodiment 3

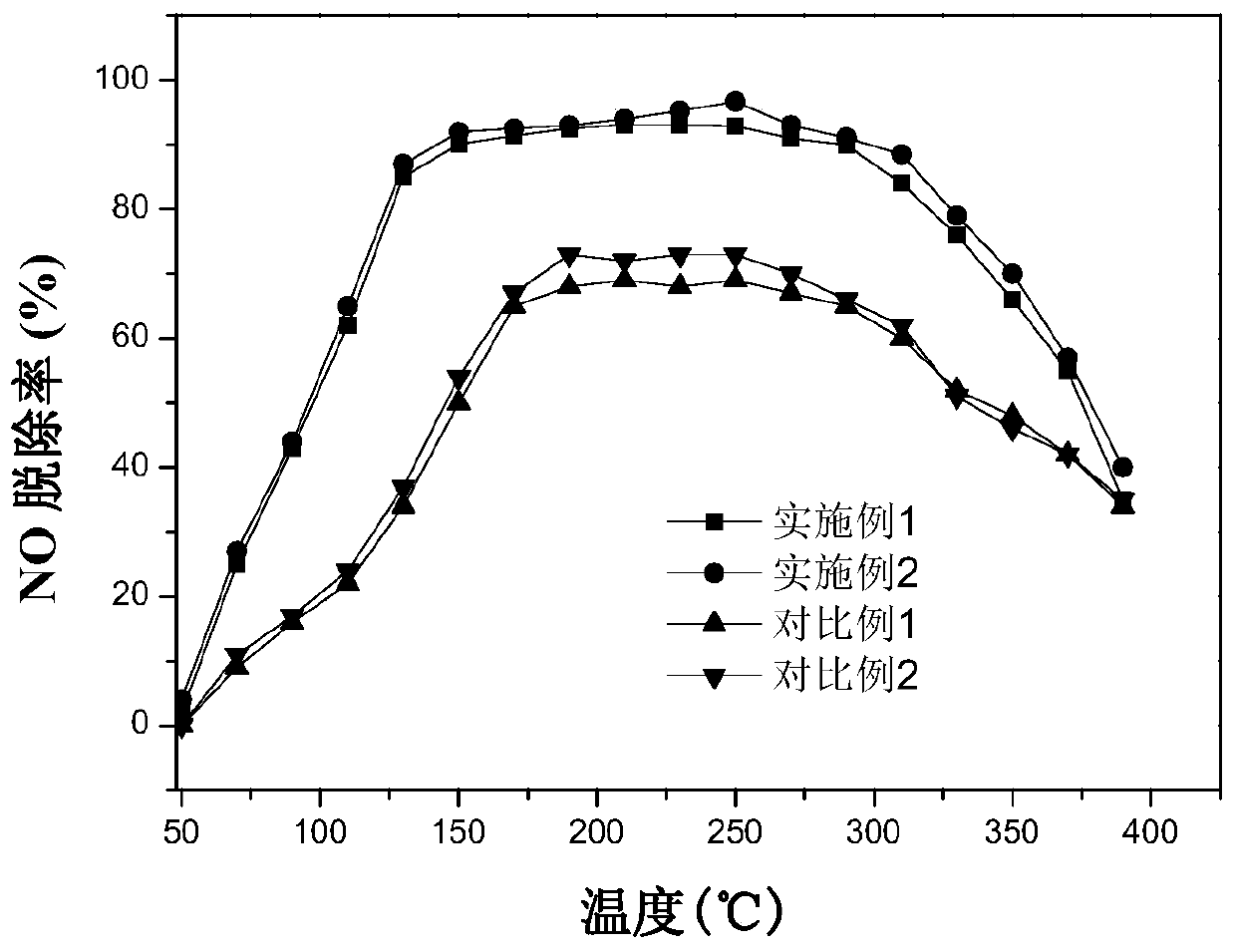

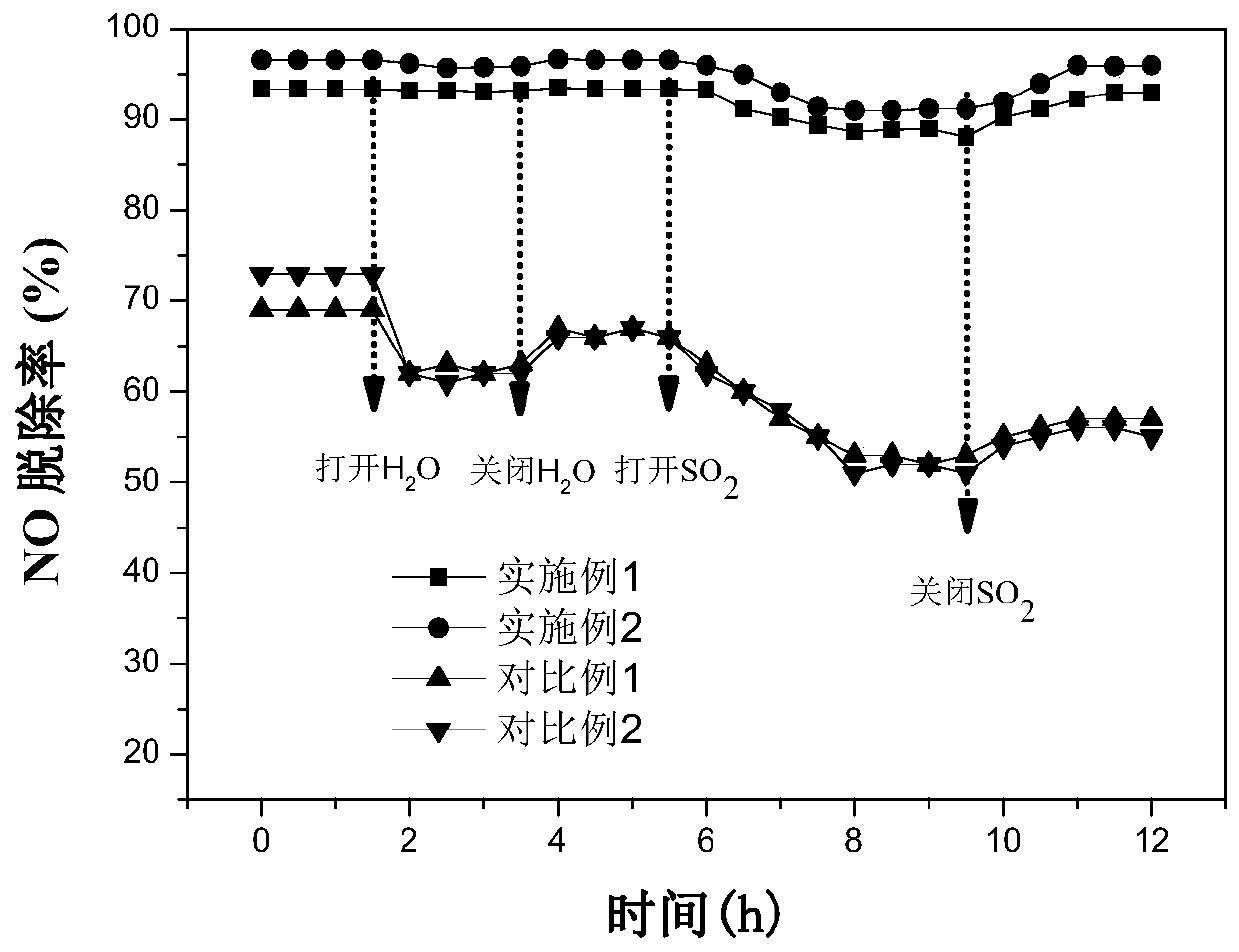

[0050] The denitration catalytic activity of the rare earth-doped ZIF-8 nanoporous carbon catalyst prepared in Example 1-2 was determined.

[0051] Using SCR catalytic reaction system to evaluate the MnO prepared in this example x -LaCeO x / NPC-Al 2 o 3 -1 The denitrification catalytic activity of the catalyst; the SCR catalytic reaction system consists of a fixed bed reaction device and a tubular resistance furnace, wherein the fixed bed is a quartz tube with an inner diameter of 0.8cm and a length of 40cm to heat the fixed bed reaction device through the tubular resistance furnace , the temperature of the fixed-bed reaction device is controlled by a program temperature controller, and the SCR catalytic reaction temperature range is 50-390°C.

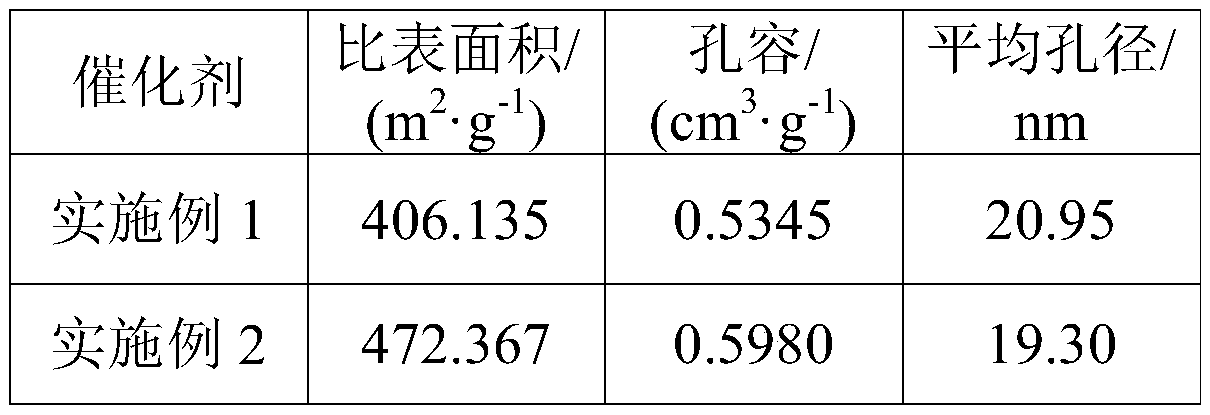

[0052] Adopt standard GB / T7702.20-2008 coal-based granular activated carbon test method to the specific surface area (m 2 g -1 ), pore volume (cm 3 g -1 ) and average pore diameter (nm) were measured.

[0053] Table 1 is the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com