Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve low temperature denitrification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature sulfur-resistant denitration catalyst and preparing method thereof

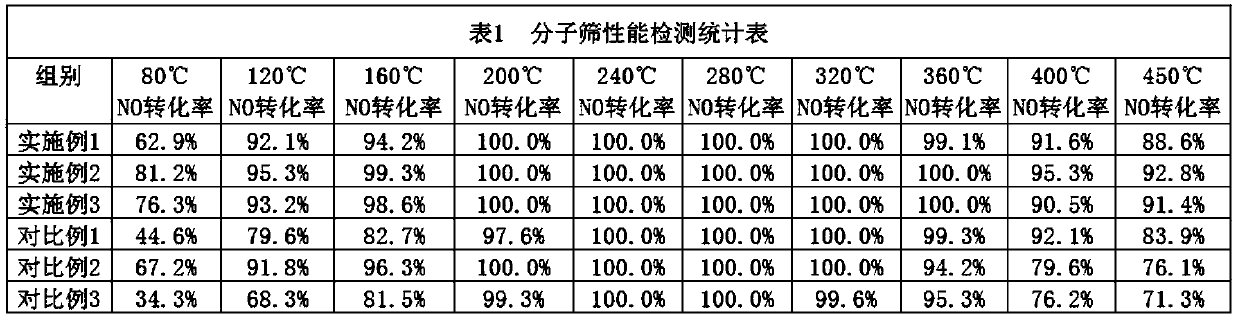

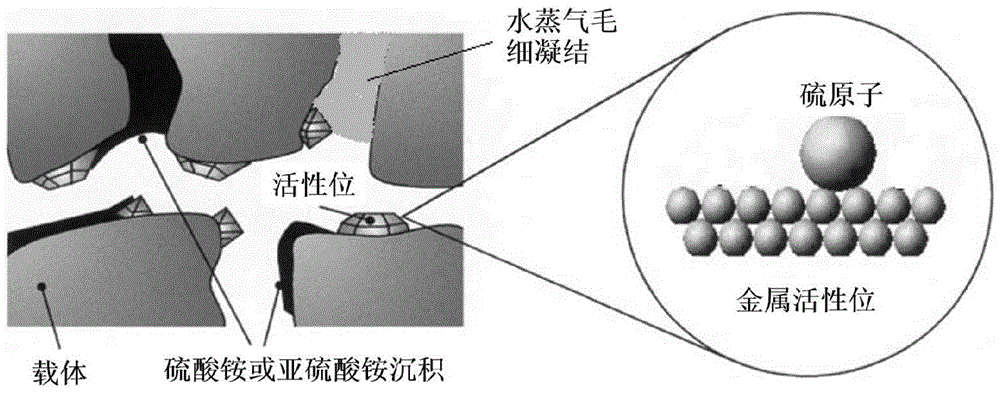

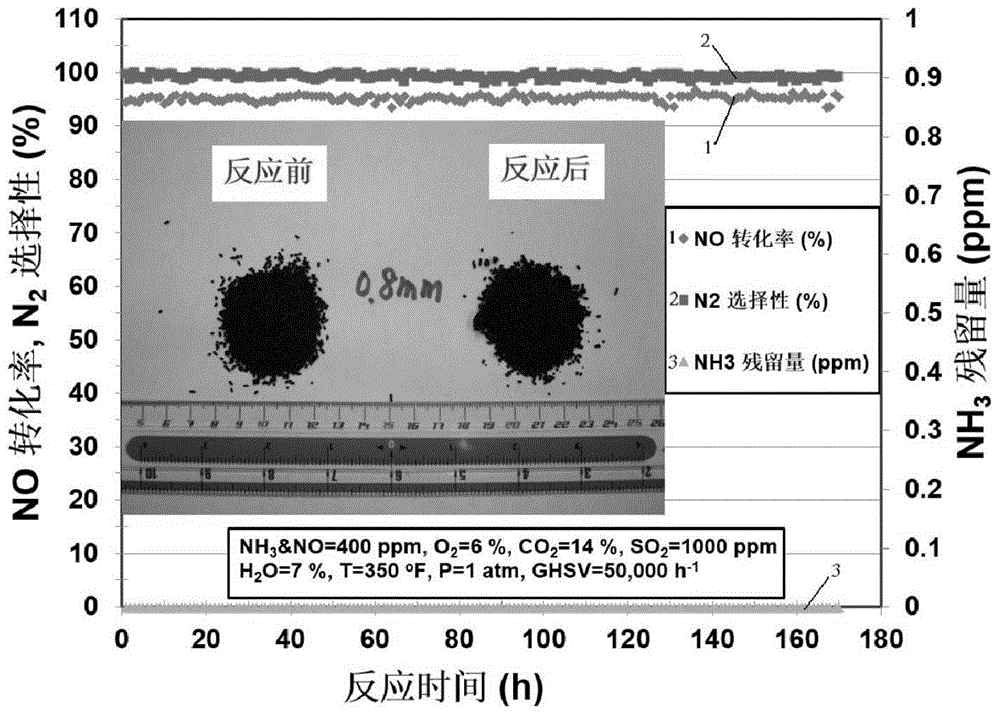

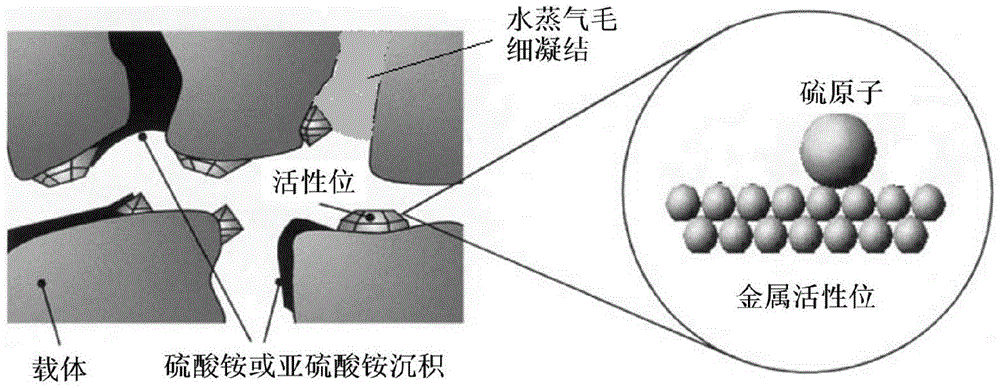

ActiveCN104056658AStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationCapillary condensationMolecular sieve

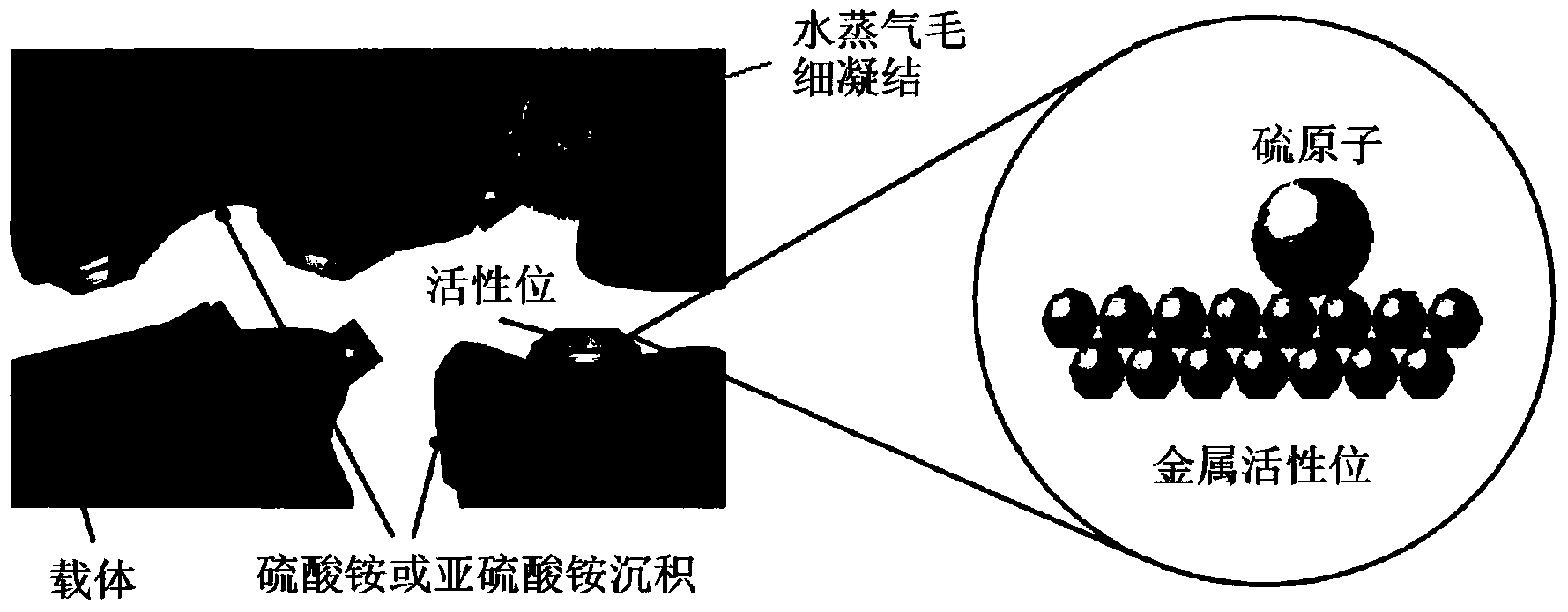

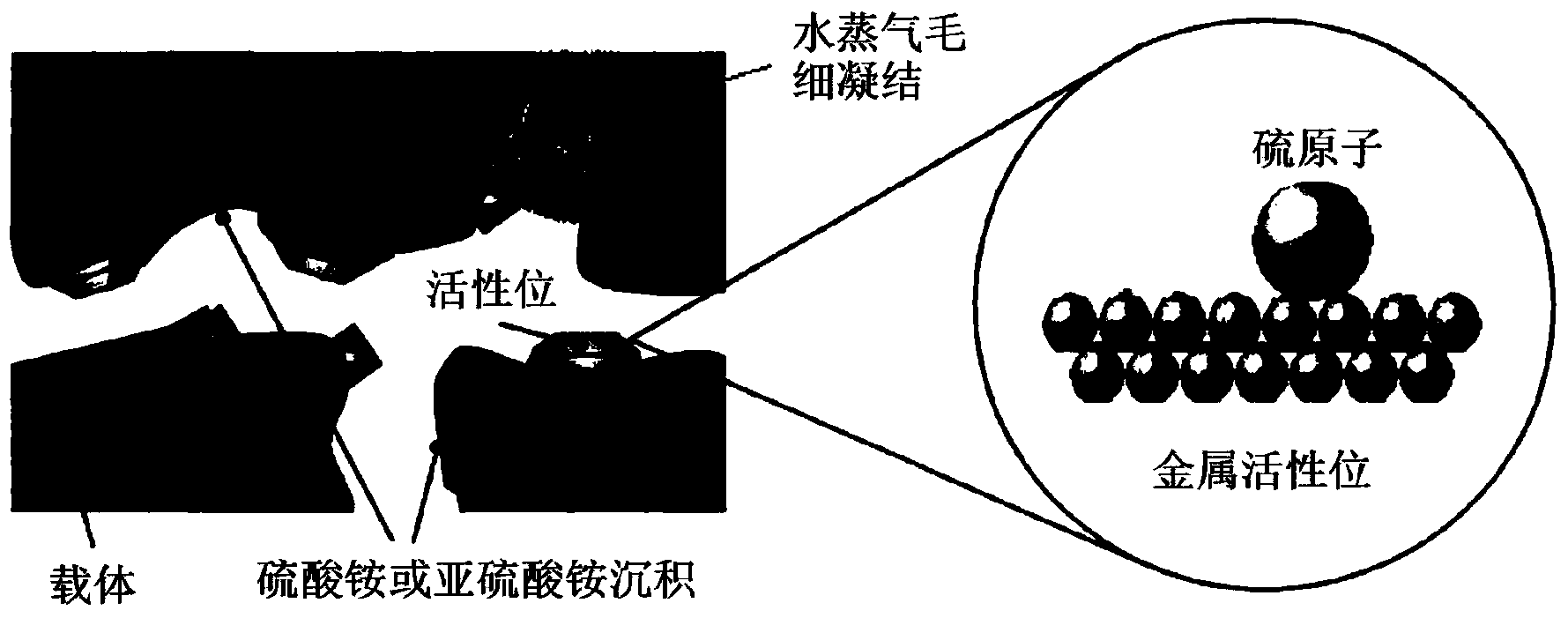

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

Low-temperature sulphur-resisting denitration catalyst and preparation method thereof

ActiveCN104069852AStrong water resistanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCapillary condensationOpen framework

The invention discloses a low-temperature sulphur-resisting denitration catalyst and preparation method thereof. The catalyst is formed by mixing the following components in weight percent: 1-15% of active site and 85-99% of a carbon-base carrier, wherein the active site is formed by mixing one or several of Ag2O, K2O, BaO, SnO2, Bi2O3 or PbO improved vanadium-base alloy oxides. The preparation method comprises the steps of mixing the active site and the carbon-base carrier to prepare the low-temperature sulphur-resisting denitration catalyst. Since the surface hydrophobic treatment is performed on the catalyst prepared by the invention, the situation that water molecules in the flue gas adhere to an open-framework structure of the catalyst to form capillary condensation or form sulfuric acid or ammonium sulfite with adsorbed NH3 and SO2 or SO3 to inactivate the catalyst is avoided.

Owner:XIAN SINO GREEN HI TECH CO LTD

Medium/low temperature SCR (Selective Catalytic Reduction) denitration catalyst with gamma-Al2O3 as carrier and preparation method thereof

InactiveCN102527404AReduce dosageIncrease profitDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsLanthanum nitrateOxide

The invention belongs to the technical field of NOx control in environmental protection and relates to a medium / low temperature SCR (Selective Catalytic Reduction) denitration catalyst taking gamma-Al2O3 as a carrier and a preparation method thereof. The catalyst consists of the following ingredients according to the mass percentage content: 2-16% of MnO, 1-10% of La2O, 1-10% of FeO and the allowance of the carrier gamma-Al2O3; and the preparation method comprises the following steps: gamma-Al2O3 is soaked into composite soaking liquid with 5-25% of manganese acetate, 1-10% of lanthanum nitrate and 5-25% of ferric nitrate respectively, then is dried and is calcined at 350-600 DEG C for 1-6 hours, therefore, the catalyst is obtained. The medium / low temperature denitration catalyst is prepared by loading various metallic oxides to realize the dispersion optimization of active ingredients and the catalysis cooperation among the ingredients; at 200 DEG C, the conversion rate of NO is morethan 85%, and the water and sulfur resistance is better. The preparation method is simple and is easy in operation, and the catalyst is steady in activity and long in service life.

Owner:HUNAN UNIV

Compounded denitration catalyst, as well as preparation method and application thereof

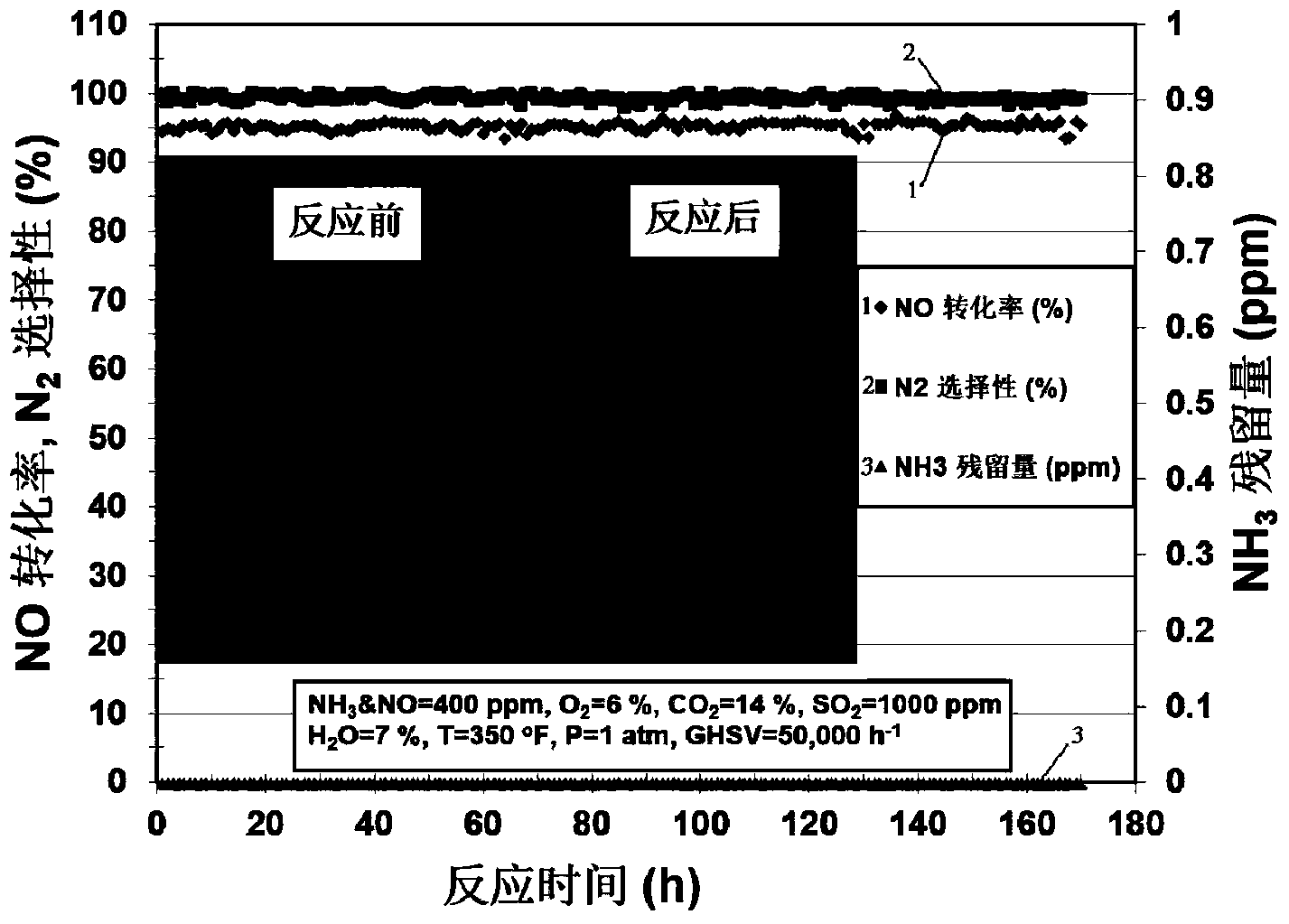

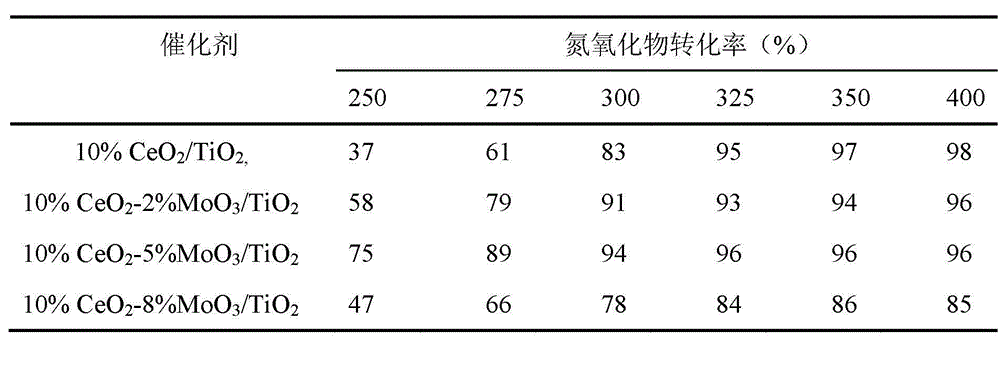

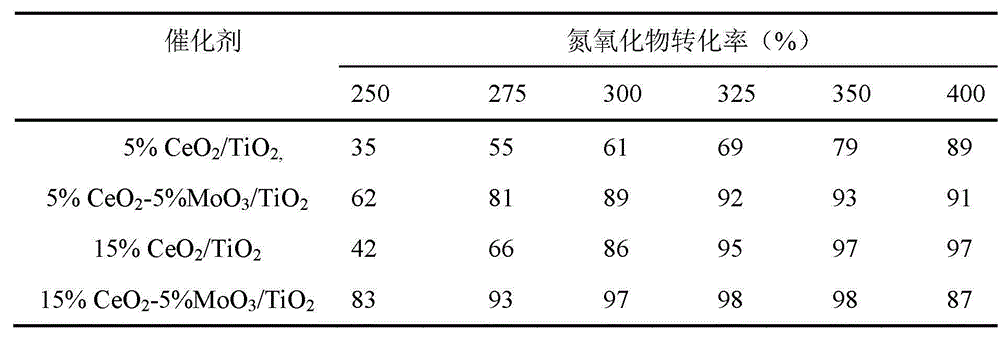

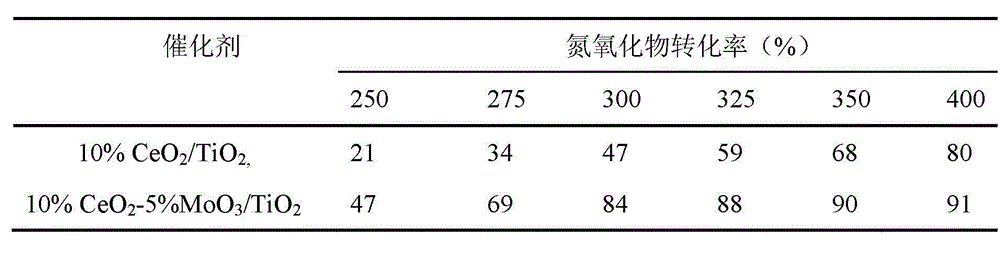

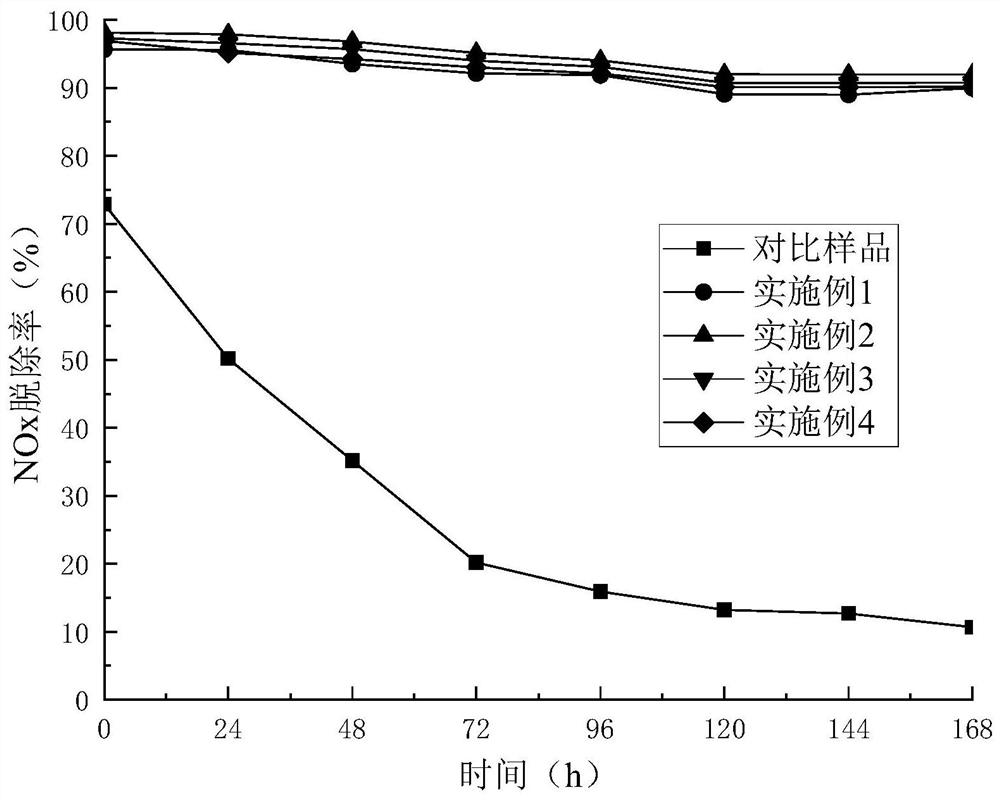

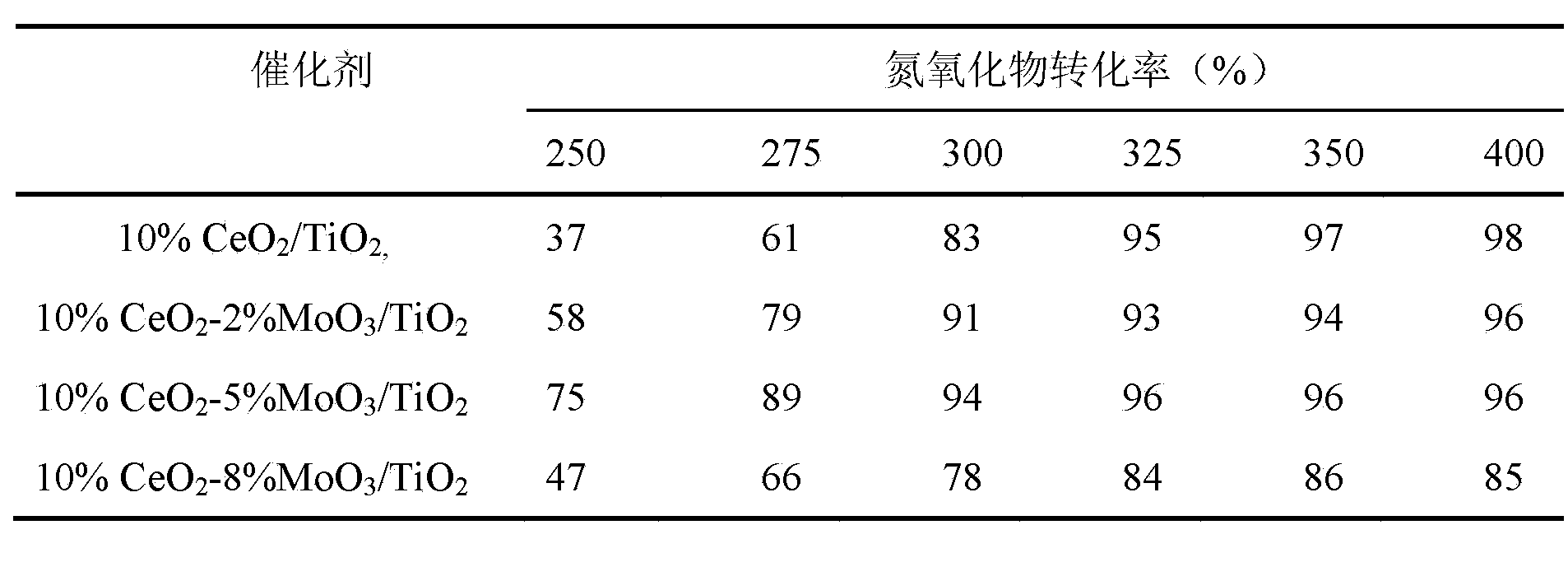

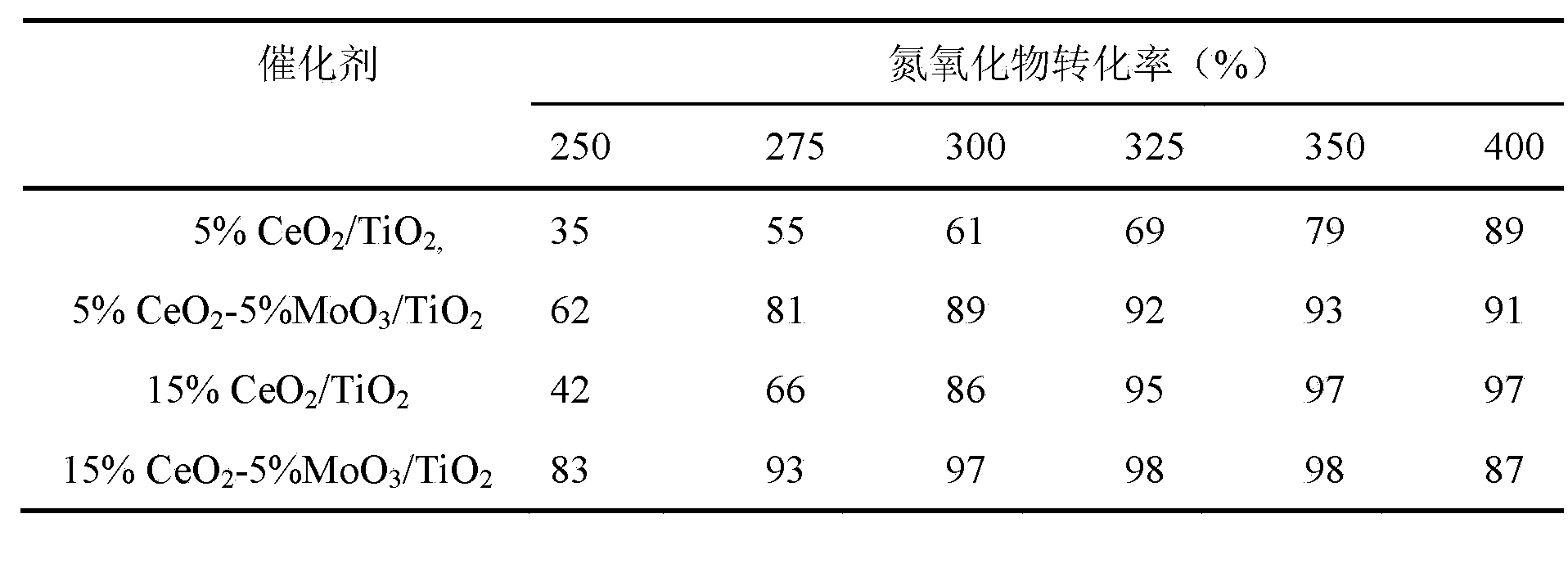

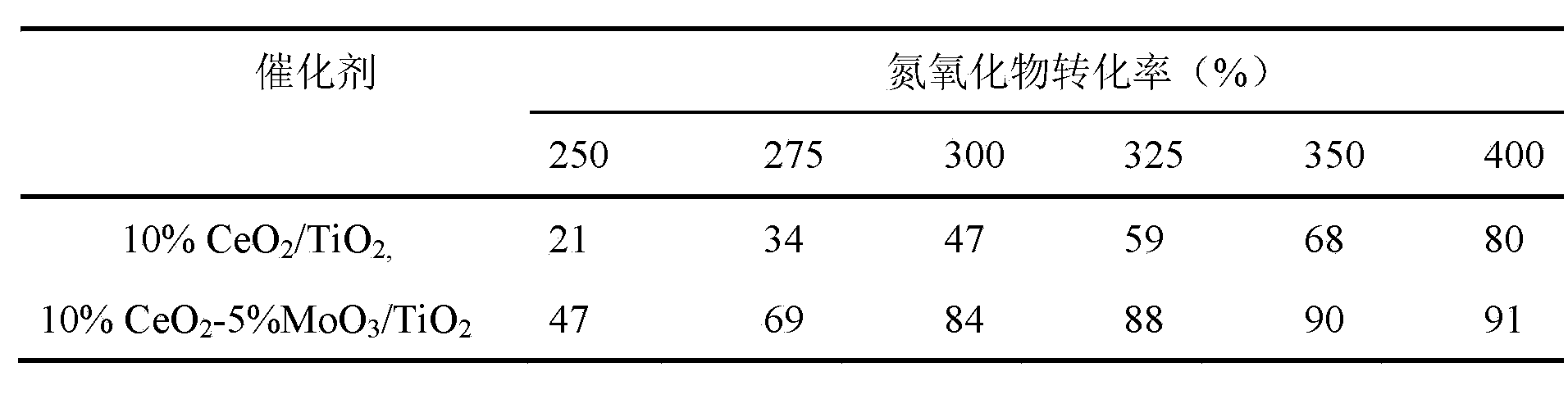

ActiveCN102909004AImprove low temperature denitrification performanceWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureFixed bed

The invention provides a compounded denitration catalyst and a preparation method thereof, and belongs to the technical field of environment catalysis and atmospheric pollution controlling. The catalyst adopts titanium dioxide as a carrier, cerium dioxide as a main active component, and molybdenum trioxide as secondary active component performing a synergistic effect, and is prepared according to a stepped impregnation method. The compounded denitration catalyst is characterized in that due to the adding of molybdenum trioxide, the denitration performance of cerium-titanium catalyst is improved obviously, the active temperature window is widened, and the water resistance of the catalyst is also improved obviously. The method for reducing nitrogen oxides comprises the following steps: filling the catalyst into a fixed bed reactor; controlling the reaction temperature range to be 250 to 400 DEG C; and taking ammonia as a reducing agent. The cerium-molybdenum-titanium compounded catalyst prepared according to the invention is 12,8000 per hour in space velocity, and can purify nitrogen oxides with the efficiency ranging from 83 to 98 percent at the temperature ranging from 250 to 400 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

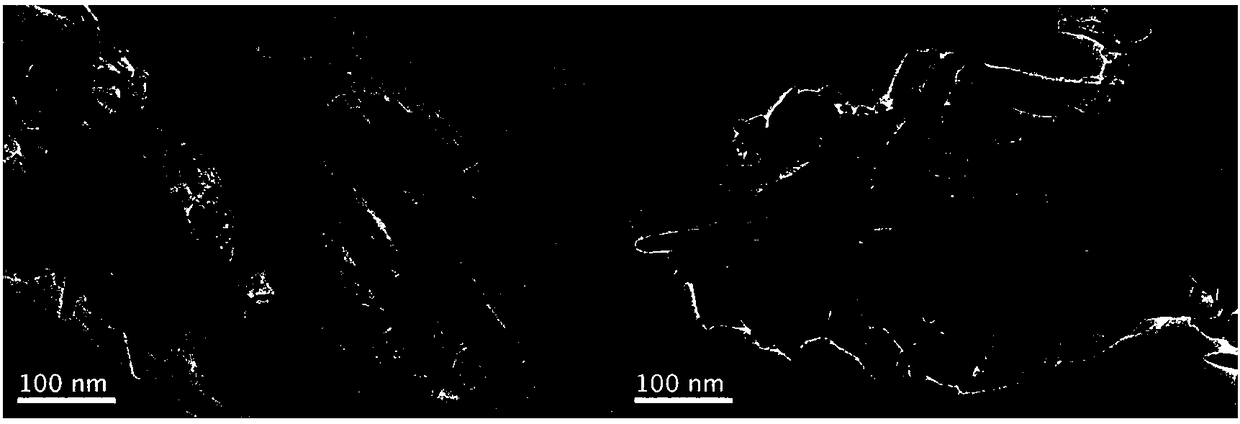

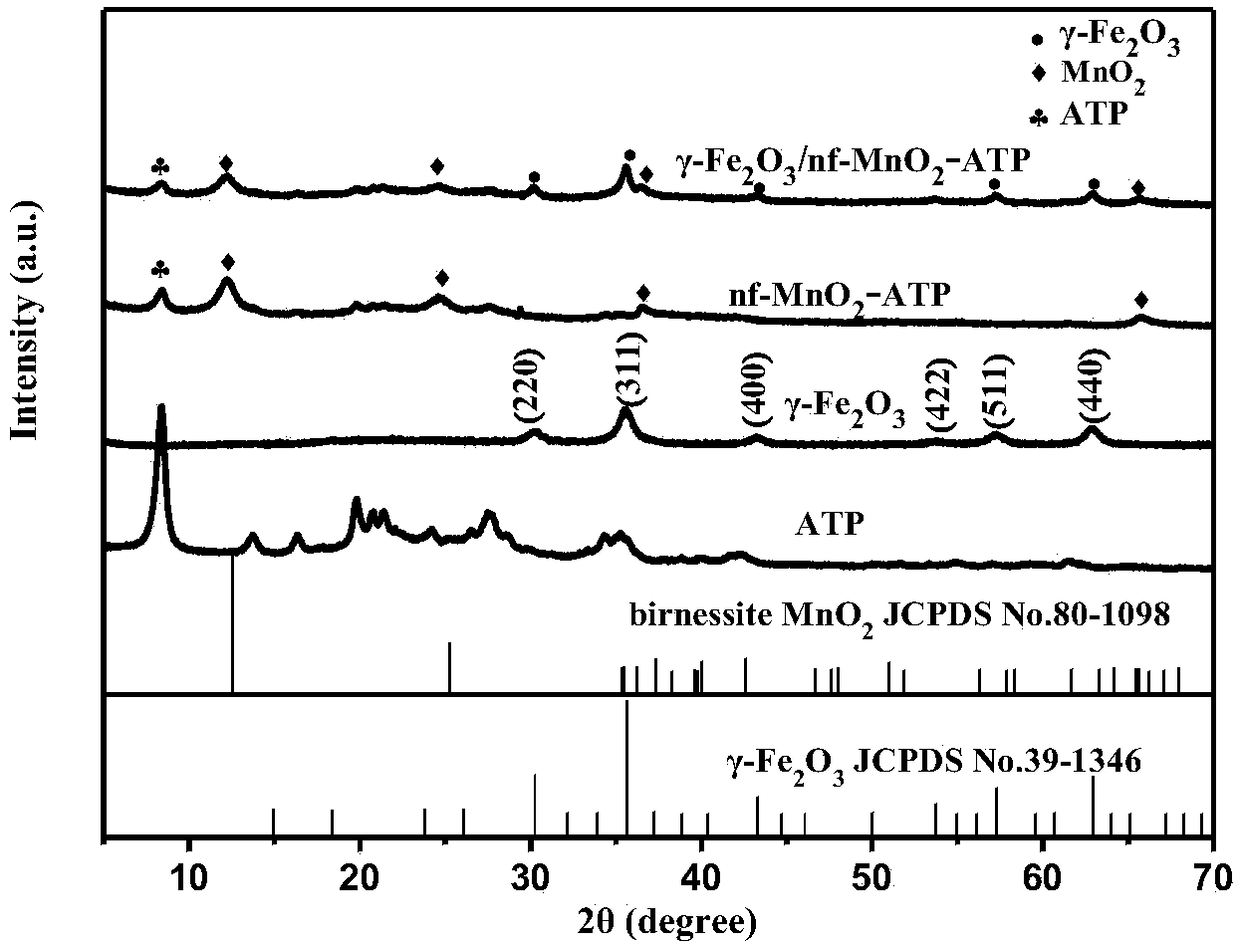

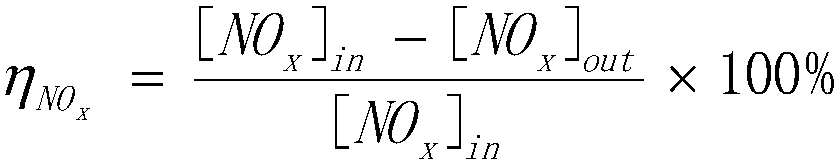

Gamma-Fe2O3 nanoparticle modified nf-MnO2/ATP low-temperature denitration catalyst

ActiveCN108465470AWide active temperatureImprove performanceGas treatmentDispersed particle separationFlue gasCatalyst support

The invention belongs to the field of flue gas denitration, and specifically provides a gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst. Directed at the disadvantages of low carrier strength, poor SO2 resistance and complicated preparation method for a conventional flue gas denitration catalyst, the invention provides the gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: with attapulgite clay with large specific surface area and high adsorption performance as a carrier and a reducing agent, allowing the attapulgite clay to react with KMnO4 under a hydrothermal condition so as to prepare a nanoflower-like MnO2-coated attapulgite clay (nf-MnO2-ATP) catalyst, preparing high-performance gamma-Fe2O3 nanoparticles under a low-temperature hydrothermal condition at the same time, and subjecting nf-MnO2 / ATP to surface modification with the high-performance gamma-Fe2O3 nanoparticles so as to prepare the gamma-Fe2O3 / nf-MnO2-ATP denitration catalyst. Thus, N2 selectivity and SO2 resistance of nf-MnO2-ATP are improved. Meanwhile, the preparation method provided by the invention has mild preparation conditions and simple preparation process, and is a safe and highly-efficient preparation method for a low-temperature denitration catalyst.

Owner:CHANGZHOU UNIV

Manganese-iron-cobalt monolithic SCR low-temperature catalyst preparation method, product and application thereof

InactiveCN107537514AImprove low temperature denitrification performanceUniform coatingDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAdhesive

The invention relates to a manganese-iron-cobalt monolithic SCR low-temperature catalyst and a preparation method and application thereof. Active components are manganese oxide, iron oxide, cobalt oxide or two or three composite oxides thereof; and a carrier is a cordierite carrier. The preparation method comprises the following steps: dissolving manganous nitrate, ferric nitrate and cobalt nitrate in water, putting cordierite honeycomb ceramics into the nitrate aqueous solution, putting the carrier into a concentrated ammonia solution, and drying and roasting to prepare the manganese-iron-cobalt monolithic SCR low-temperature catalyst. The preparation method is economical and environment-friendly. Raw materials are fully utilized in the preparation process, there is no need to introduce an adhesive, and no waste liquid or refuse is generated. The preparation technology is simple and is convenient to use for large-scale industrialization. The catalyst film is uniform and is not easy tofall off from cordierite. Under the synergistic effect of the three oxides including manganese oxide, iron oxide and cobalt oxide, low temperature denitration performance of the catalyst is excellent, denitration rate within 125-200 DEG C can reach 80% and above, and the highest denitration performance reaches 95%.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

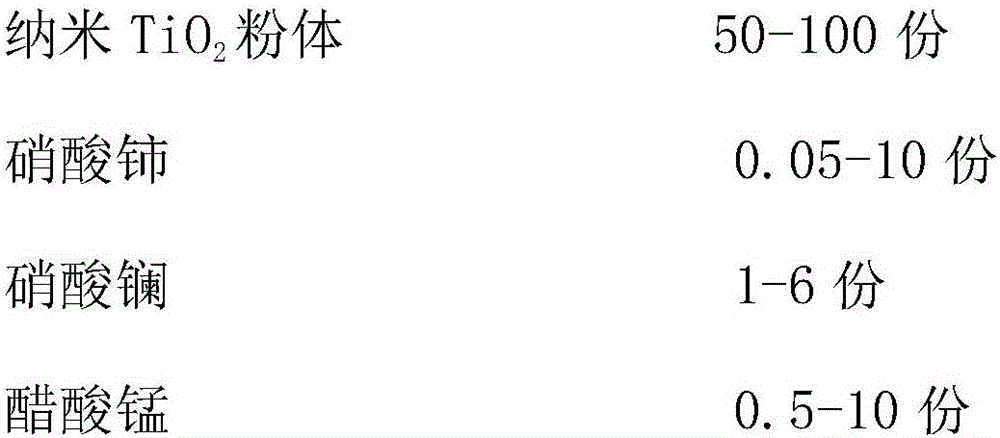

Low-temperature denitration catalyst and preparation method thereof

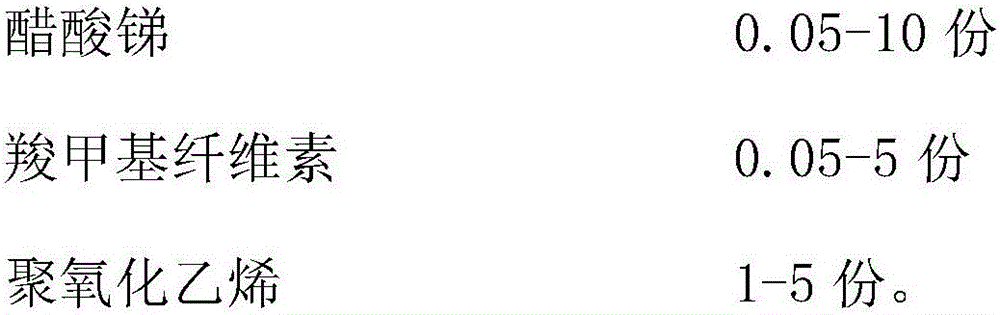

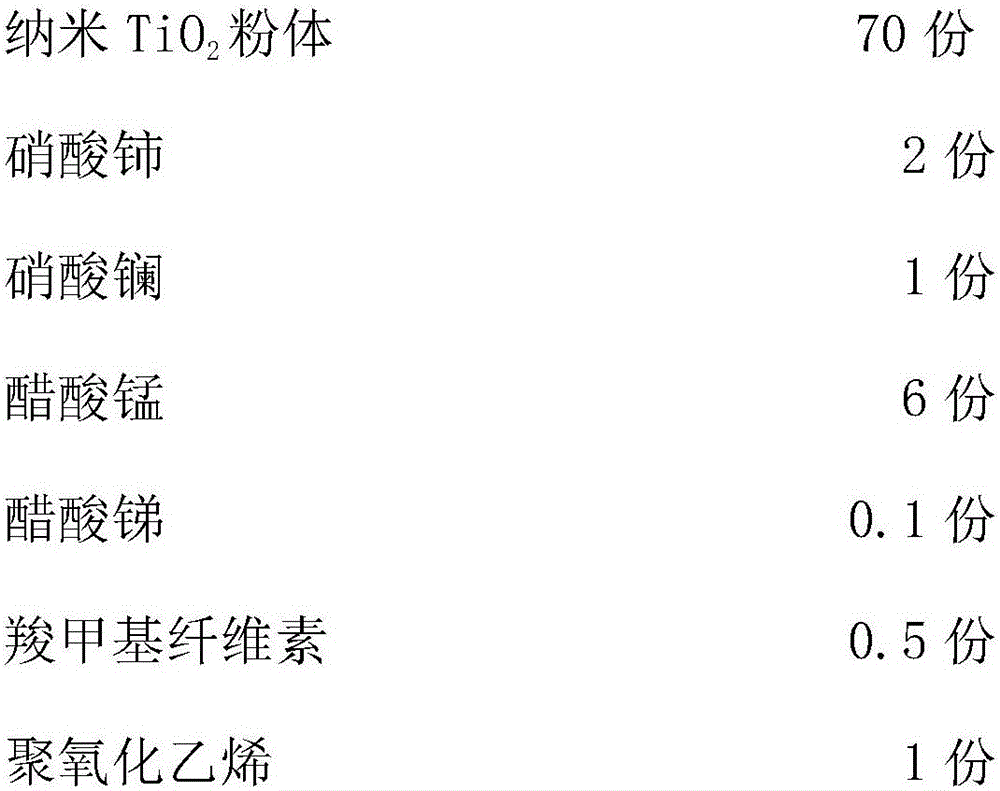

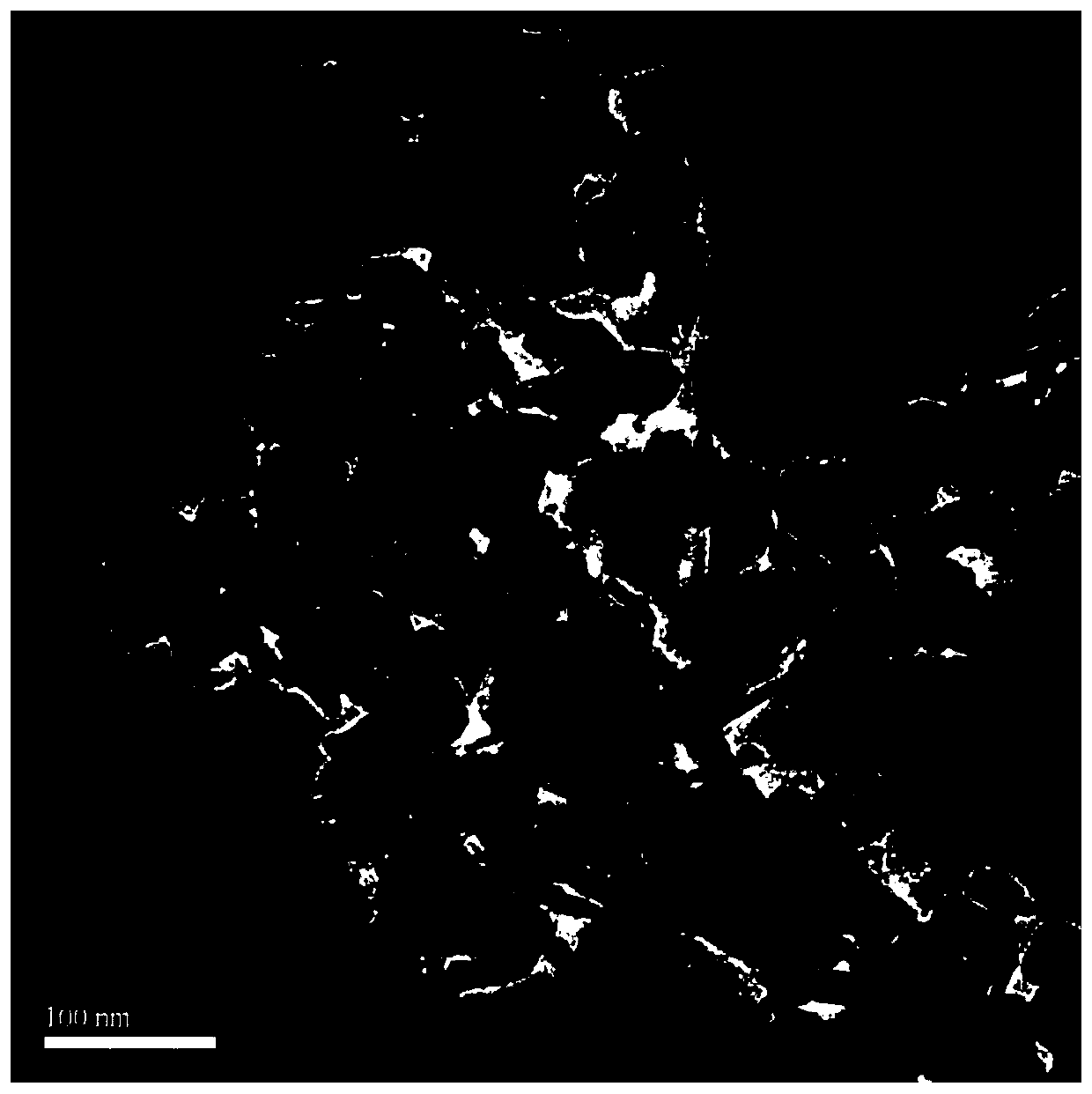

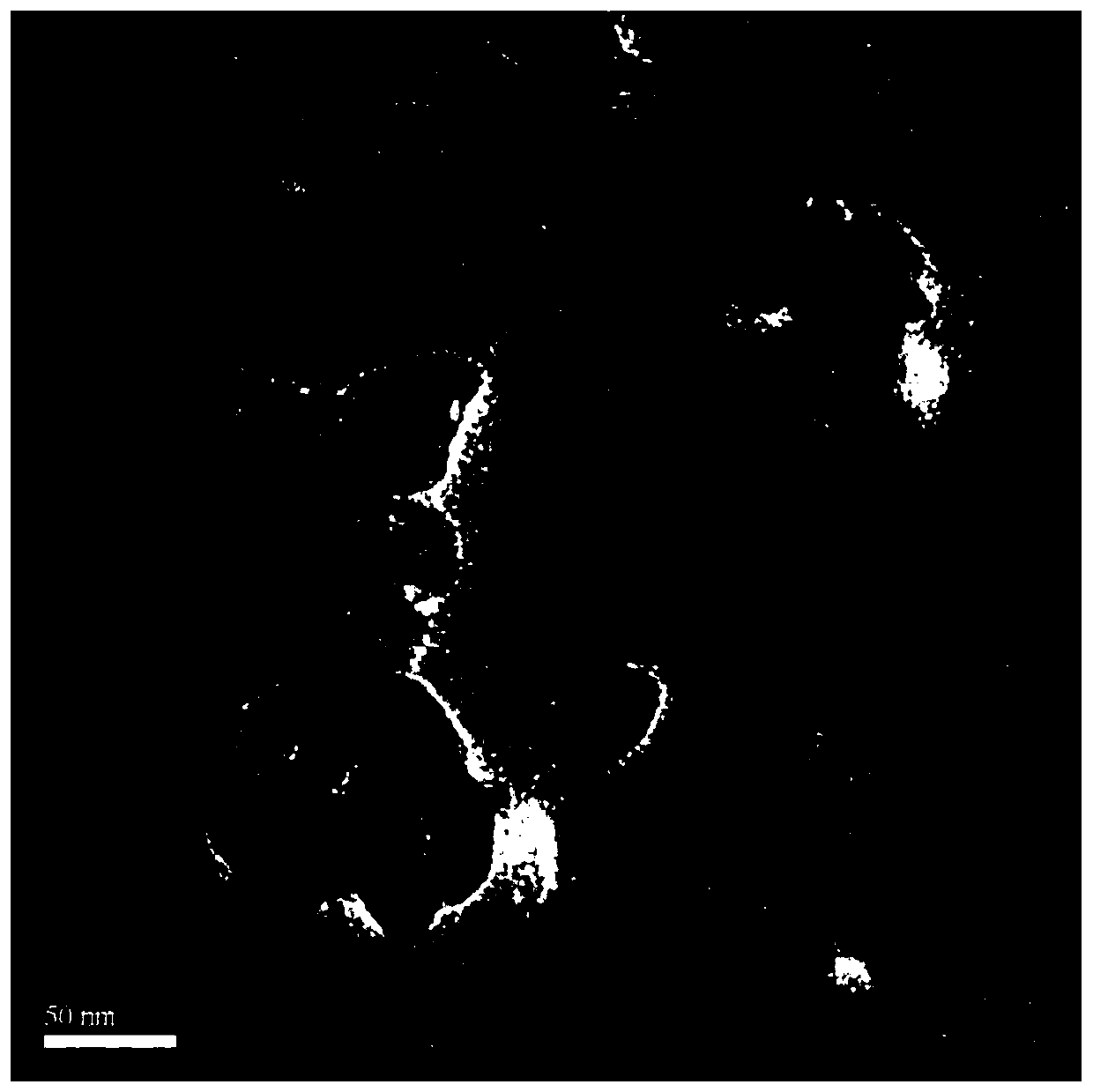

InactiveCN106268786ALarge specific surface areaHigh activityHeterogenous catalyst chemical elementsDispersed particle separationCarboxymethyl celluloseMANGANESE ACETATE

The invention discloses a low-temperature denitration catalyst and a preparation method thereof. The low-temperature denitration catalyst mainly comprises 50-100 parts of nanometer TiO2 powder, 0.05-10 parts of cerous nitrate, 1-6 parts of lanthanum nitrate, 0.5-10 parts of manganese acetate, 0.05-10 parts of antimony acetate, 1-5 parts of carboxymethyl cellulose and 1-5 parts of polyoxyethylene. The method for preparing the low-temperature denitration catalyst comprises the steps of first evenly mixing and calcining cerous nitrate, lanthanum nitrate, manganese acetate and antimony acetate, adding nanometer TiO2 powder, carboxymethyl cellulose and polyoxyethylene, performing uniform mixing, and performing drying and calcination to obtain the finished product. The low-temperature denitration catalyst is low in cost, high in specific area, wide in working temperature and good in low-temperature denitration performance.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

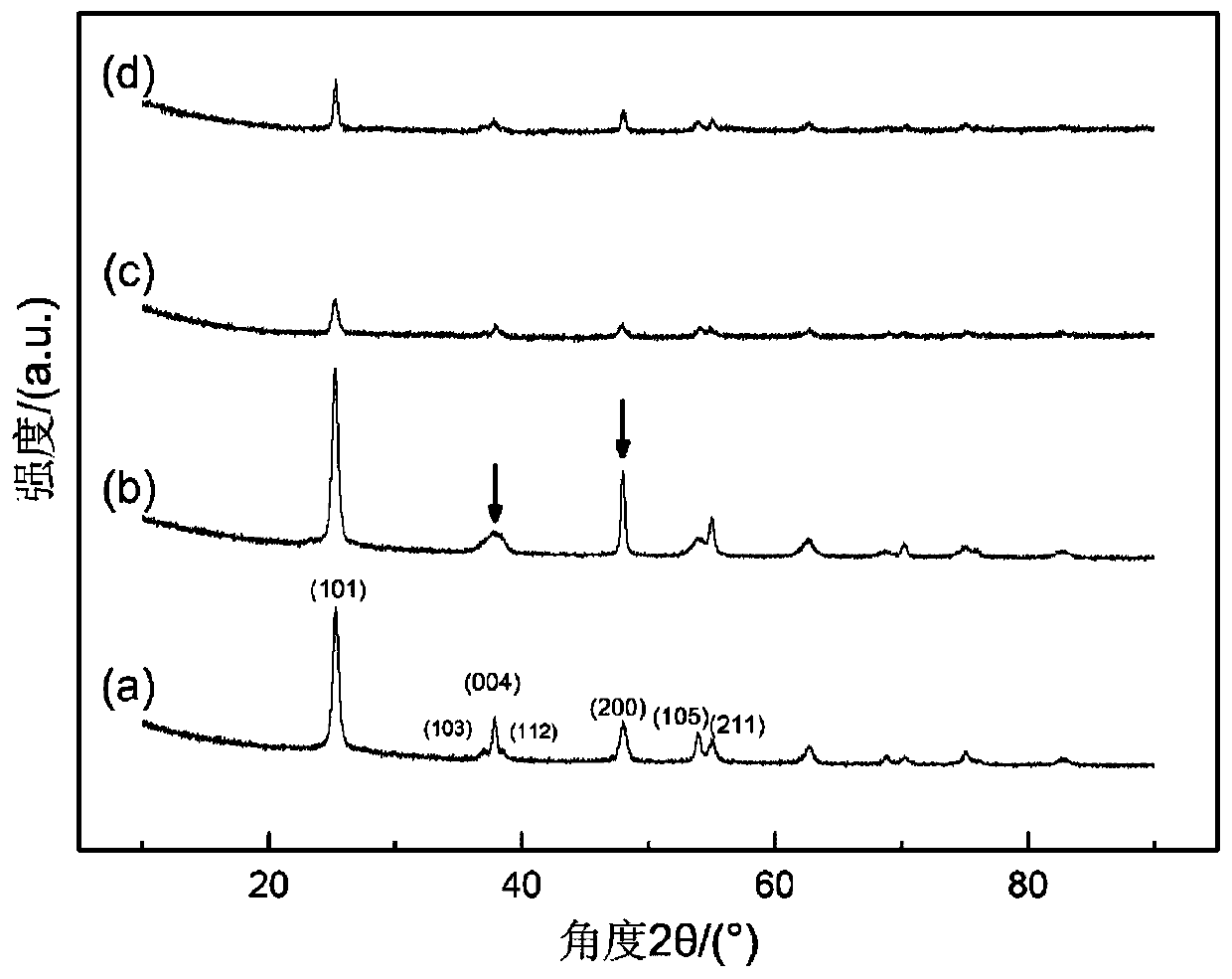

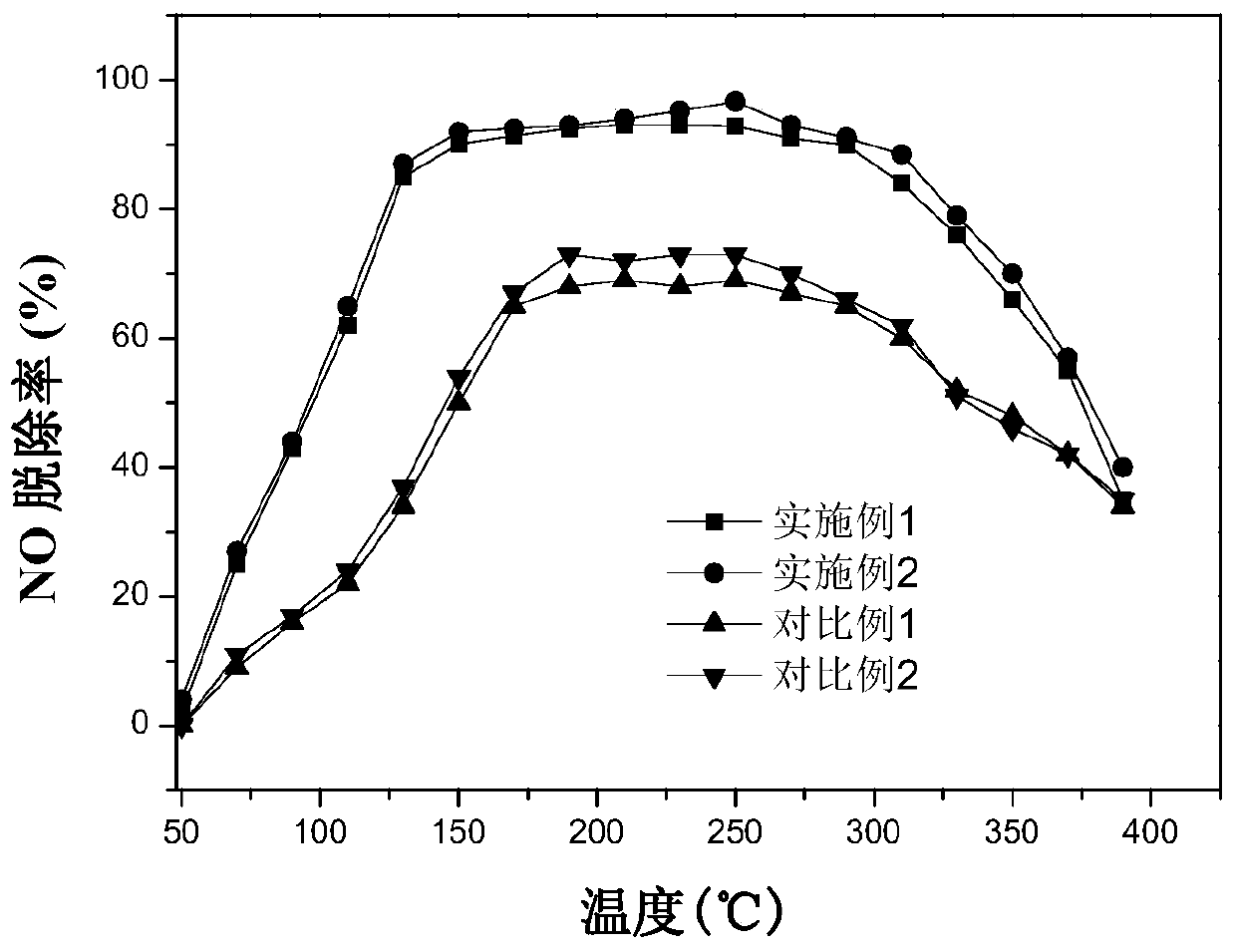

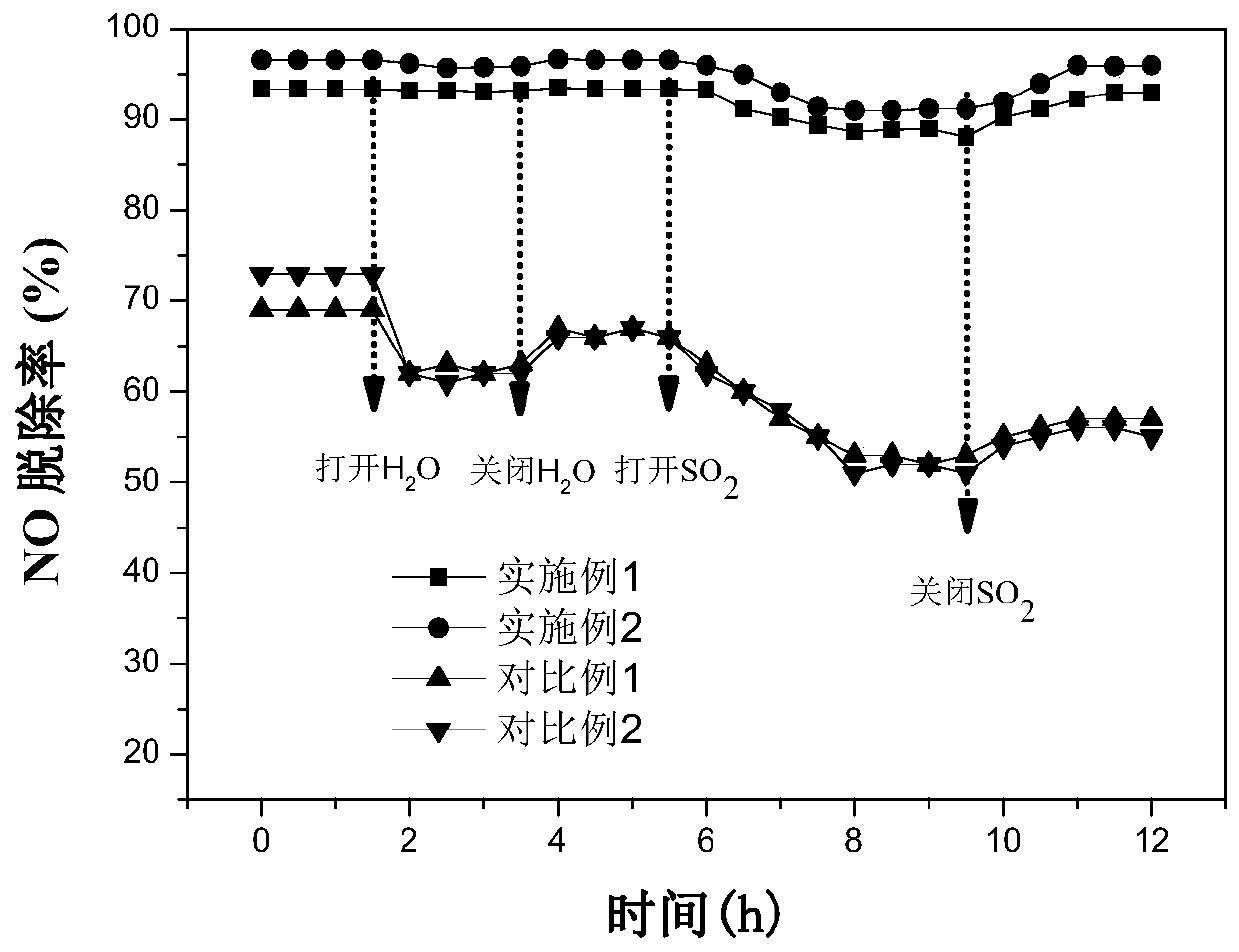

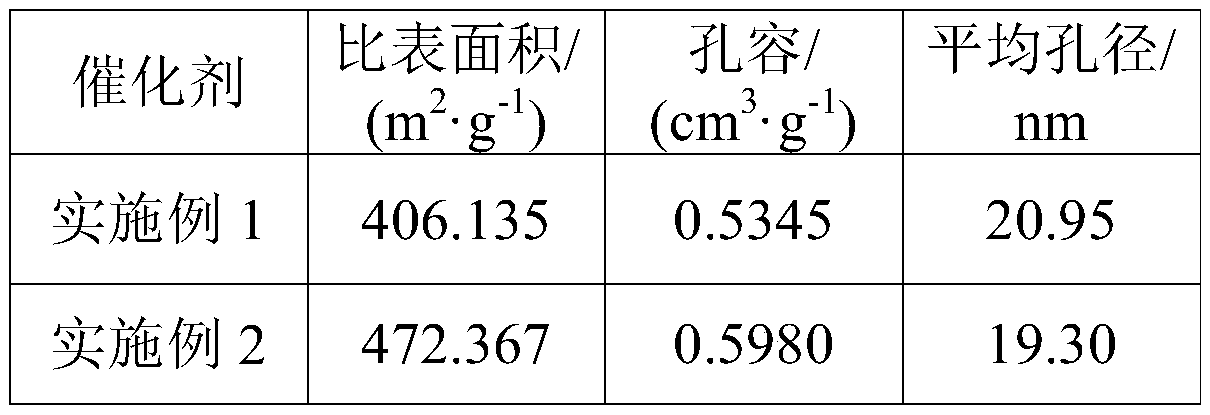

Manganese-cerium composition with flaky anatase type TiO2 as carrier and preparation and application

InactiveCN110339832ASolve the technical problem of low catalytic efficiencyHigh catalytic activityGas treatmentHeterogenous catalyst chemical elementsCeriumManganese oxide

The invention discloses a manganese-cerium composition with flaky anatase type TiO2 as a carrier and preparation and application and relates to the field of denitration catalyst. The composition is carried on the surface of anatase type TiO2; the anatase type TiO2 has a flaky morphology; and the composition is a composition of manganese oxide and cerium oxide. The preparation comprises the following steps: firstly, preparing the flaky anatase type TiO2 of which a crystal surface is firstly exposed {001} by using a hydrothermal method, and further preparing the composition that the manganese oxide and the cerium oxide are supported on the surface by using a dipping method. The manganese-cerium catalyst with the flaky morphology, which is disclosed by the invention, has high denitration activity at 80-240 DEG C when being compared with a manganese-cerium catalyst of which the crystal surface is firstly exposed {101} with a carrier of a cambiform morphology. The manganese-cerium composition crystal surface catalyst with the flaky anatase type TiO2 as the carrier, which is disclosed by the invention, is high in efficiency, low in cost and simple and easy in preparation method operation, and has instructive functions on research on low-temperature denitration catalysts.

Owner:HUAZHONG UNIV OF SCI & TECH

Rare earth doped ZIF-8 nanoporous carbon catalyst, and preparation method and application thereof

PendingCN111203205ALarge specific surface areaGood choiceGas treatmentHeterogenous catalyst chemical elementsOxideNanoporous carbon

The invention discloses a preparation method of a rare earth doped ZIF-8 nanoporous carbon catalyst, and relates to the field of environment-friendly catalytic materials. The method is provided against the problems of poor sulfur resistance and low-temperature catalytic performance of an existing denitration catalyst. The preparation method comprises the following steps: taking ZIF-8 as a precursor, impregnating a rare earth metal salt in the pore channels of the precursor, carrying out heat treatment in the presence of an inert gas to make the ZIF-8 form nanoporous carbon and make rare earthsalt converted into an oxide attached to the interior of the porous carbon in order to obtain the rare earth oxide modified nanoporous carbon (NPC), grinding and fully mixing the rare earth oxide modified nanoporous carbon (NPC) and nanoscale gamma-Al2O3 to obtain a composite carrier, and finally impregnating and loading a MnOx active component to obtain the target catalyst. The invention also discloses an application of the rare earth doped ZIF-8 nanoporous carbon catalyst. The catalyst has the advantages of excellent NOx removal efficiency under the low-temperature condition, the denitrationefficiency at 150 DEG C reaches 95%, and the overall specific surface area and SO2 poisoning resistance of the catalyst are improved through a special composite structure.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH +1

Spherical denitration catalyst and preparation method thereof

ActiveCN107970918AShort manufacturing timeRetain spherical structureGas treatmentHeterogenous catalyst chemical elementsSalt solutionLoad capacity

The invention discloses a spherical denitration catalyst and a preparation method thereof, and belongs to the field of catalysts. The preparation method of the spherical denitration catalyst comprisesthe following steps: (1) preparing a precursor salt solution; (2) preparing a precursor; and (3) drying the precursor, and then calcining the dried precursor to obtain a spherical denitration catalyst powder. The invention also discloses the spherical denitration catalyst. According to the spherical denitration catalyst and the preparation method thereof, the preparation cycle is short, and the operation is simple, thus the preparation method can be used for large-batch continuous production; and the prepared spherical denitration catalyst powder has a high low-temperature activity, and has excellent fluidity and dispersibility, so that in overall catalyst coating, increase of coating thickness and load capacity is facilitated.

Owner:浙江天麟环境工程有限公司

Thin-wall flat plate type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

ActiveCN111715230APromote decompositionImprove denitrification activityHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The embodiment of the invention provides a thin-wall flat plate type low-temperature sulfur-resistant SCR denitration catalyst and a preparation method thereof. The catalyst is prepared by taking TiO2-Nb2O5-Fe2O3 composite nano oxide as a carrier, V2O5 as an active component and MoO3 and MnSO4 as active aids, adding organic and inorganic structural aids, and performing multi-stage rolling, dryingand the like. According to the catalyst disclosed by the invention, the low-temperature denitration performance and sulfur poisoning resistance are improved by developing a carrier for accelerating denitration reaction, promoting decomposition of ammonium sulfate salt, optimizing active ingredients and active aids, optimizing forming aids, a preparation process and the like so that the catalyst has excellent denitration activity and stability within a temperature range of 150-250 DEG C. Due to the plate thickness of 0.35-0.40 mm, the catalyst has relatively low sulfur dioxide oxidation rate and relatively strong sulfur poisoning resistance, the raw material cost required by production is greatly reduced, and the operation cost of an SCR denitration system is saved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Supported manganese-based medium-and-low-temperature denitration catalyst and preparation method and application thereof

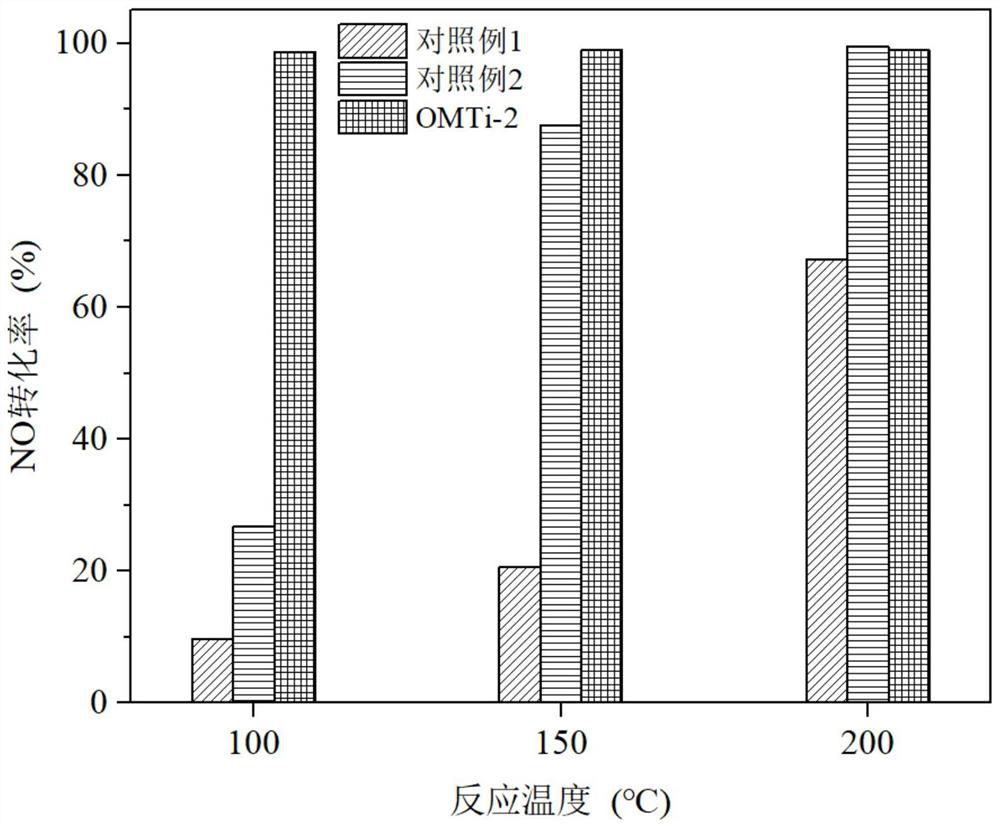

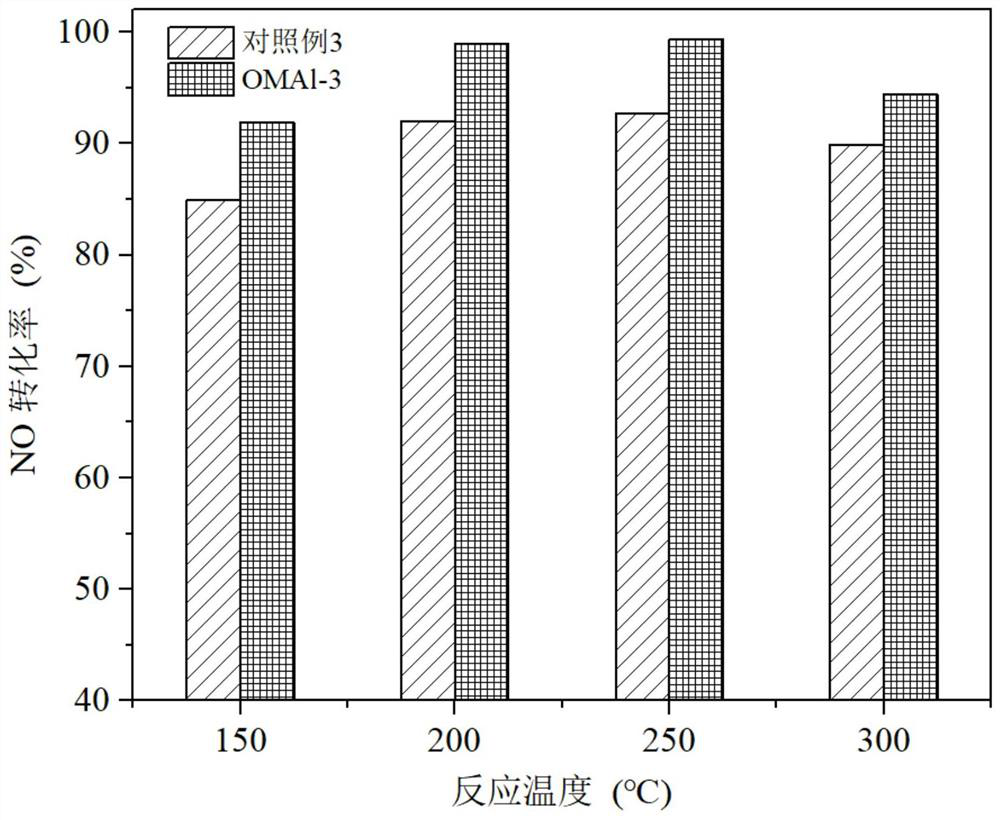

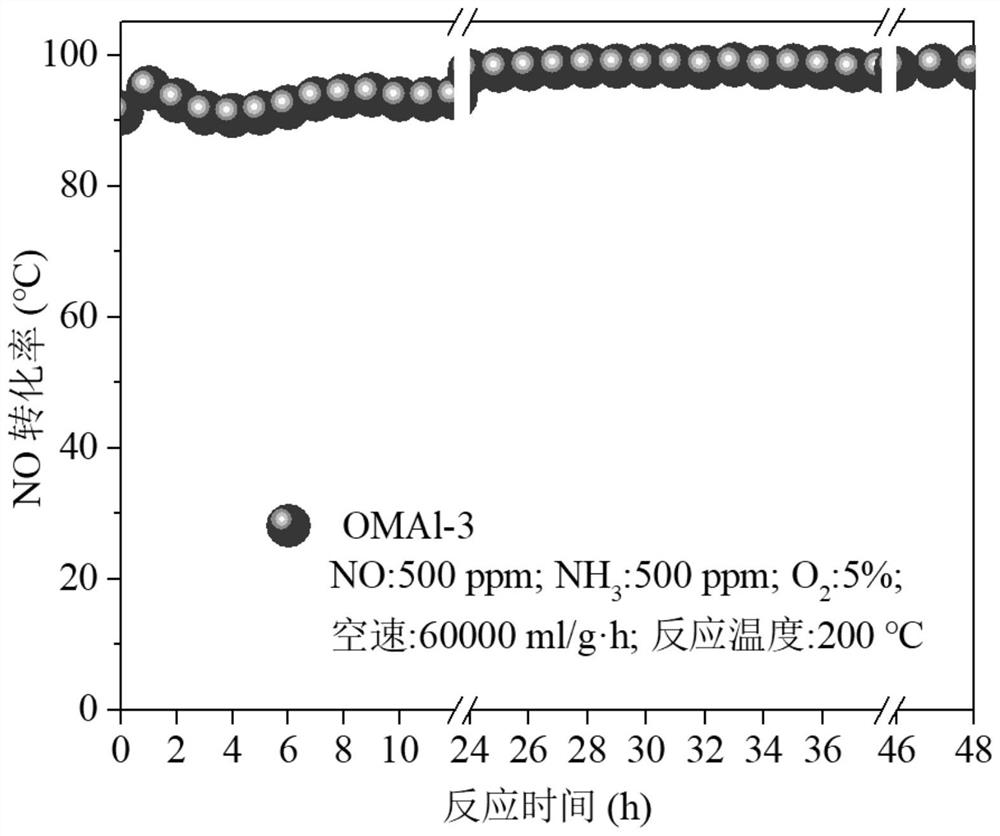

ActiveCN110773153ASmall grainFully contactedGas treatmentDispersed particle separationPtru catalystPotassium manganate

The invention discloses a supported manganese-based medium-and-low-temperature denitration catalyst, and preparation and application thereof, belonging to the technical field of environment-friendly catalytic materials. The catalyst is prepared by adding a carrier titanium dioxide or aluminum oxide into a divalent manganese salt solution, then carrying out stirring, mixing and drying, adding potassium permanganate, and carrying out a solid-phase interface reaction. The denitration catalyst provided by the invention is used for a selective catalytic reduction denitration reaction; the catalysthas obviously-enhanced low-temperature (100-200 DEG C) or medium-and-low-temperature (200-300 DEG C) catalytic activity; the catalyst has excellent low-temperature denitration performance in the caseof a high loading amount, and a typical sample allows the conversion rate of NO in mixed gas to reach 98.7% at 100 DEG C and to reach 98.9% at 200 DEG C under the condition of an air speed of 30,000 ml / g.h; and the catalyst has excellent medium-temperature denitration performance in the case of a low loading amount, and a typical sample allows the conversion rate of NO in mixed gas to reach 99.0%at 200 DEG C and to reach 99.6% at 300 DEG C under the condition of an air speed of 60,000 ml / g.h. The denitration catalyst provided by the invention has a potential application value.

Owner:SICHUAN UNIV +1

Method for preparing diesel vehicle exhaust gas purification molecular sieve

InactiveCN110694670AImprove low temperature denitrification performanceImprove high temperature activityGas treatmentMolecular sieve catalystsIon exchangeMolecular sieve

The invention relates to a method for preparing a diesel vehicle exhaust gas purification molecular sieve. The method comprises the following steps: (1) dissolving aluminum sulfate and manganese nitrate into deionized water, adding a template agent to the solution, further adding sodium hydroxide, performing stirring, adding silicon sol, and stirring the mixed gel so as to obtain a precursor solution; (2) crystallizing the precursor solution, filtering and washing the obtained solution, and performing drying and roasting so as to obtain an untreated molecular sieve; (3) sequentially adding ammonium nitrate, copper nitrate, chromium nitrate and cerium nitrate to the molecular sieve, performing ion exchange, and performing filtering, washing and drying so as to obtain an activated molecularsieve; and (4) adding samarium nitrate to the activated molecular sieve, performing ion exchange, and performing filtering, washing, drying and roasting, so as to obtain the diesel vehicle exhaust gaspurification molecular sieve. Defects of the prior art are overcome, a diesel vehicle exhaust gas is purified by using the molecular sieve, the hydrothermal stability and the low temperature activityof the molecular sieve can be improved, the toxicity of the molecular sieve can be degraded, thus being safe and environment-friendly.

Owner:天长市润源催化剂有限公司

Non-metal doped metal oxide denitration catalyst with high toxicity resistance, and preparation method and application thereof

PendingCN112844365AImprove low temperature denitrification performanceEasy to prepareDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

The invention discloses a non-metal doped metal oxide denitration catalyst with high poisoning resistance as well as a preparation method and application thereof. The catalyst is a metal oxide denitration catalyst with high resistance to poisoning of one or more poisons of alkali / alkaline earth metal and heavy metal. According to the catalyst, an oxide precursor is obtained on an oxide carrier mainly by dipping nonmetal precursor salt and metal precursor salt in different proportions, and the nonmetal precursor salt is doped into active component lattices, so that the dispersity of the active components is improved, the interaction between the active components and the carrier is enhanced, and the catalytic activity of the catalyst is improved; and finally calcination is carried out to form the metal oxide catalyst. The catalyst is excellent in medium and low temperature denitration performance, simple in preparation method and low in industrial cost, has extremely strong alkali / alkaline earth metal poisoning resistance and heavy metal poisoning resistance, and is suitable for denitration of fixed source flue gas containing alkali / alkaline earth metal fly ash and heavy metals, such as garbage incinerators, cement furnaces, biomass fuel boilers and glass furnaces.

Owner:SHANGHAI UNIV

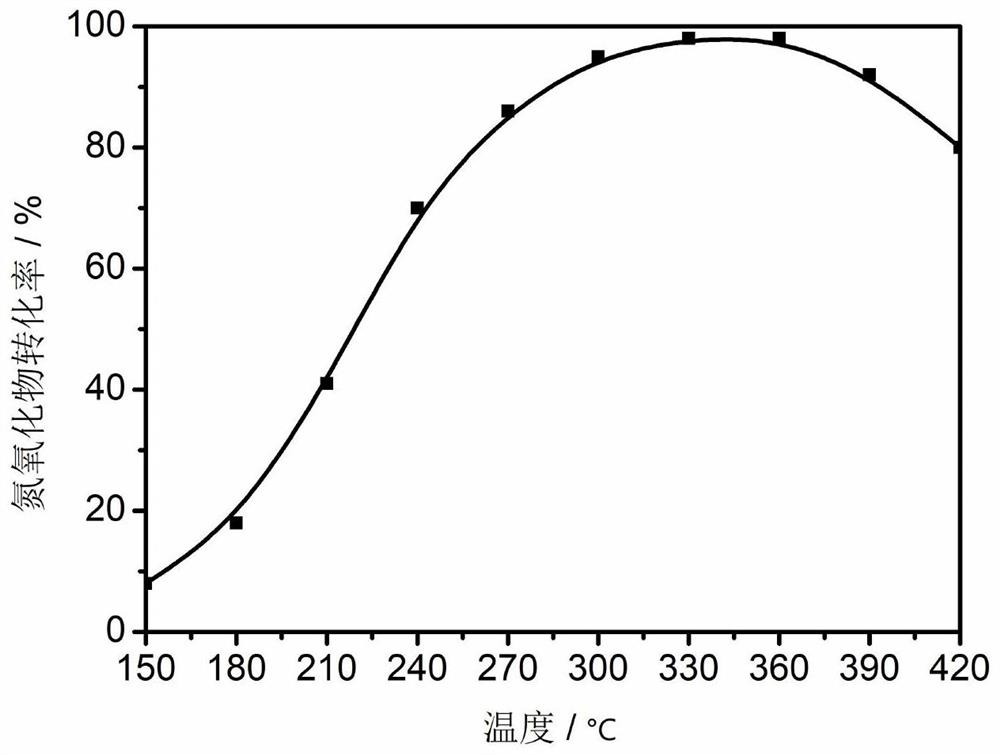

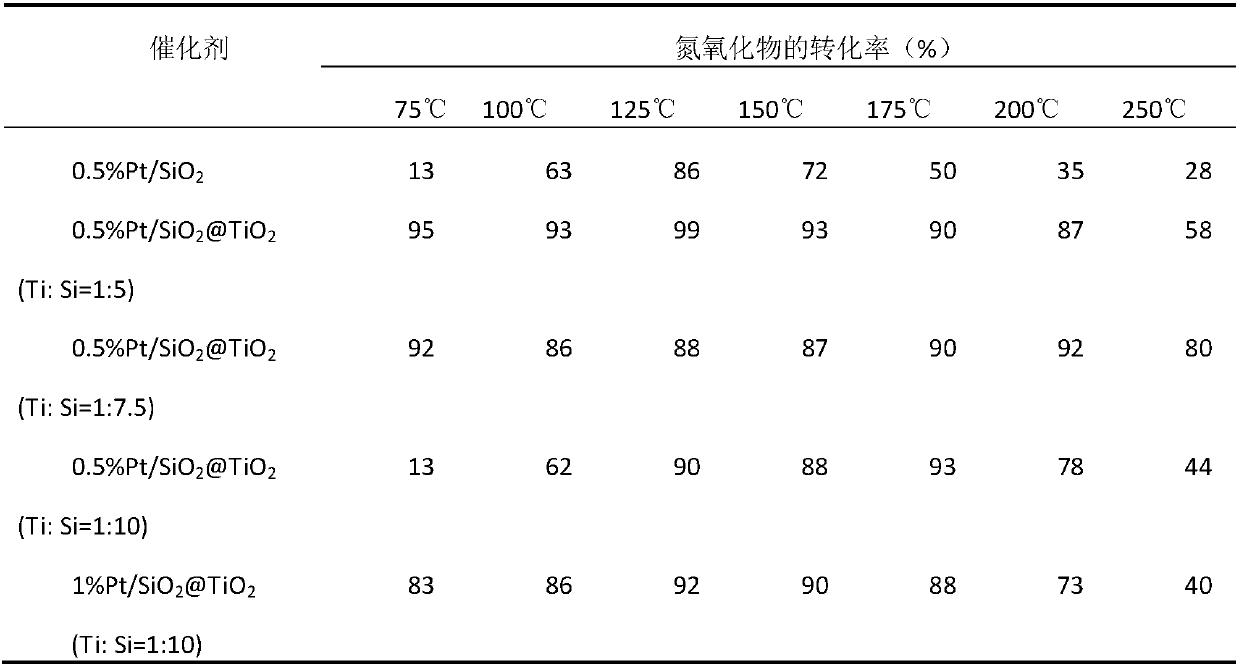

Core-shell-structured oxide supported Pt catalyst as well as preparation method and application of Pt catalyst

ActiveCN107597104AImprove low temperature denitrification performanceReduce loadDispersed particle separationCatalyst activation/preparationHydrogenActive component

The invention provides a core-shell-structured oxide supported Pt catalyst as well as a preparation method and an application of the Pt catalyst, and belongs to the technical field of environmental catalysis and air pollution control. The catalyst takes SiO2@TiO2 with a core-shell structure as a supporter and Pt as an active component and is characterized in that spherical SiO2 is taken as the inner core, and the surface of SiO2 as the inner core is coated with TiO2. By means of generation of the core-shell structure of SiO2@TiO2, performance of selective reduction of NOx by hydrogen on the Ptcatalyst is remarkably improved, so that the catalyst has good low-temperature denitration performance. The Pt catalyst adopts a simple preparation process, can realize efficient removal of NOx at low temperature, and has wide application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Medium/low temperature SCR (Selective Catalytic Reduction) denitration catalyst with gamma-Al2O3 as carrier and preparation method thereof

InactiveCN102527404BReduce loadLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATENitrate

The invention belongs to the technical field of NOx control in environmental protection and relates to a medium / low temperature SCR (Selective Catalytic Reduction) denitration catalyst taking gamma-Al2O3 as a carrier and a preparation method thereof. The catalyst consists of the following ingredients according to the mass percentage content: 2-16% of MnO, 1-10% of La2O, 1-10% of FeO and the allowance of the carrier gamma-Al2O3; and the preparation method comprises the following steps: gamma-Al2O3 is soaked into composite soaking liquid with 5-25% of manganese acetate, 1-10% of lanthanum nitrate and 5-25% of ferric nitrate respectively, then is dried and is calcined at 350-600 DEG C for 1-6 hours, therefore, the catalyst is obtained. The medium / low temperature denitration catalyst is prepared by loading various metallic oxides to realize the dispersion optimization of active ingredients and the catalysis cooperation among the ingredients; at 200 DEG C, the conversion rate of NO is morethan 85%, and the water and sulfur resistance is better. The preparation method is simple and is easy in operation, and the catalyst is steady in activity and long in service life.

Owner:HUNAN UNIV

Method of selectively recovering yttrium from CRT fluorescent powder for doping preparation of ternary composite oxide catalyst

ActiveCN108686668AImprove low temperature denitrification performanceTake advantage ofHeterogenous catalyst chemical elementsDispersed particle separationRare-earth elementYttrium

The invention belongs to the technical field of environmental catalysis, and especially relates to a method of selectively recovering yttrium from CRT fluorescent powder for doping preparation of ternary composite oxide catalyst, which includes the steps of: 1) performing initial treatment to the waste CRT fluorescent powder and performing high temperature alkali melting to prepare an alkali molten product; 2) leaching the alkali molten product with ammonia water and performing solid liquid separation to removal a major impurity, zinc; 3) performing extraction with diluted hydrochloric acid and enriching and recovering rare earths through a two-step precipitation method, and performing secondary extraction with diluted hydrochloric acid to obtain a rare earth extract liquid; 4) preparing yttrium oxalate by combining photochemical method and chemical precipitation method; 5) performing coprecipitation to obtain the ternary composite oxide catalyst. The method can high-effectively separate and extract and fully utilize the rare earths in the waste CRT fluorescent powder. By doping the yttrium, low temperature denitration performance of the catalyst is significantly improved. The method reduces production cost of the catalyst and actually achieves treating waste by waste.

Owner:BEIJING UNIV OF TECH

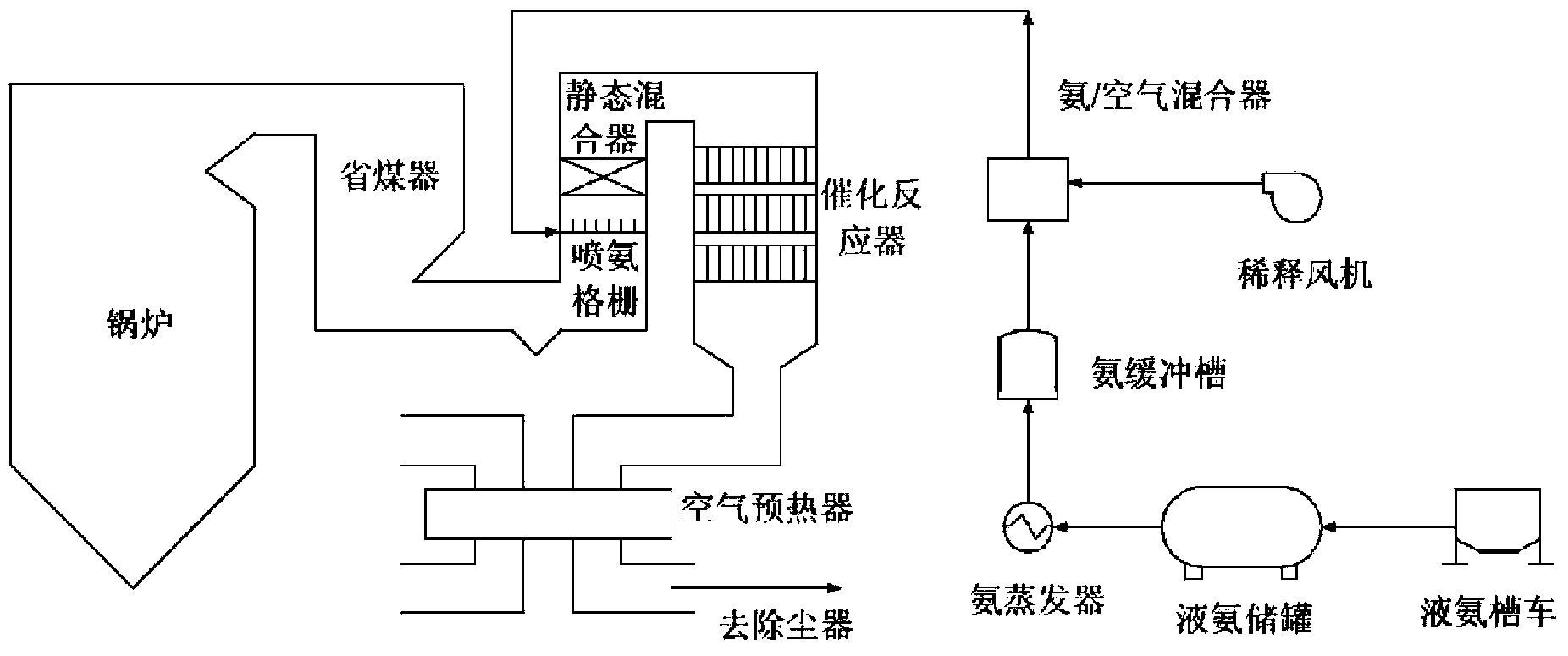

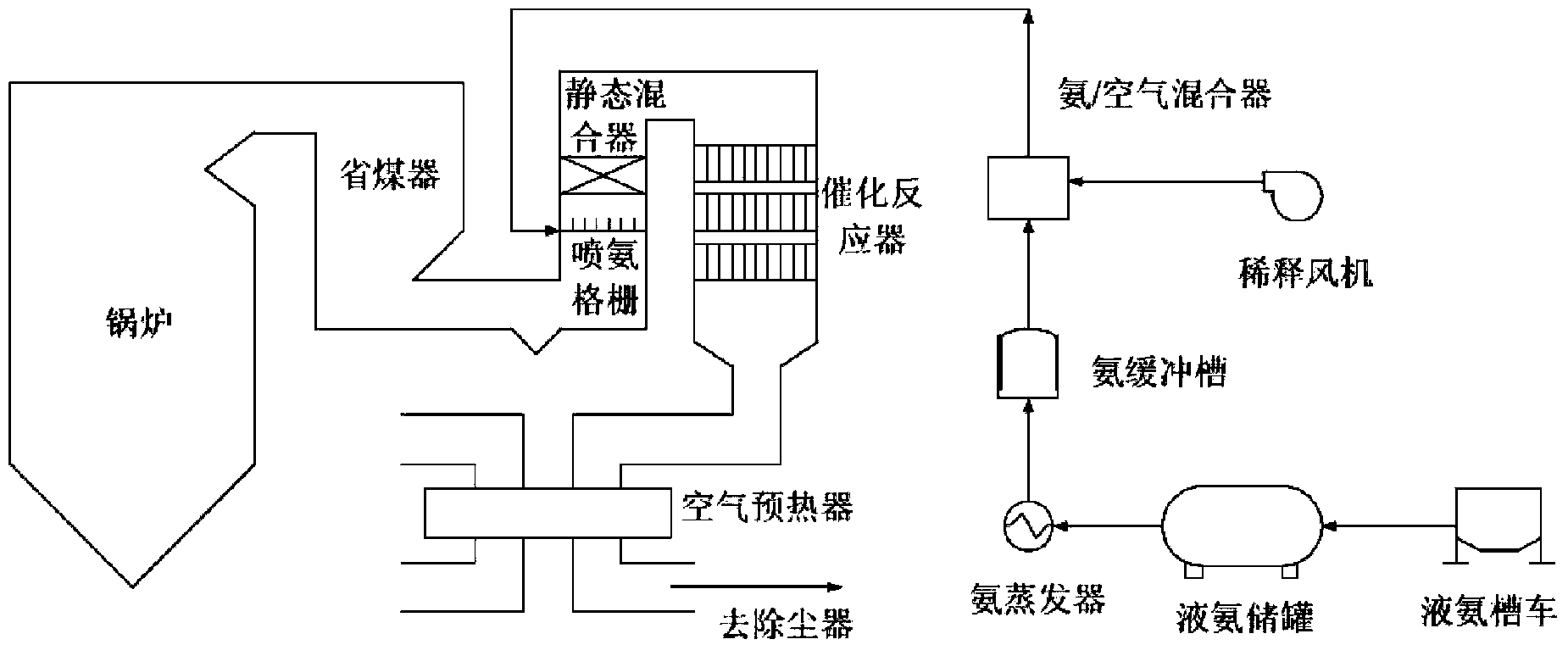

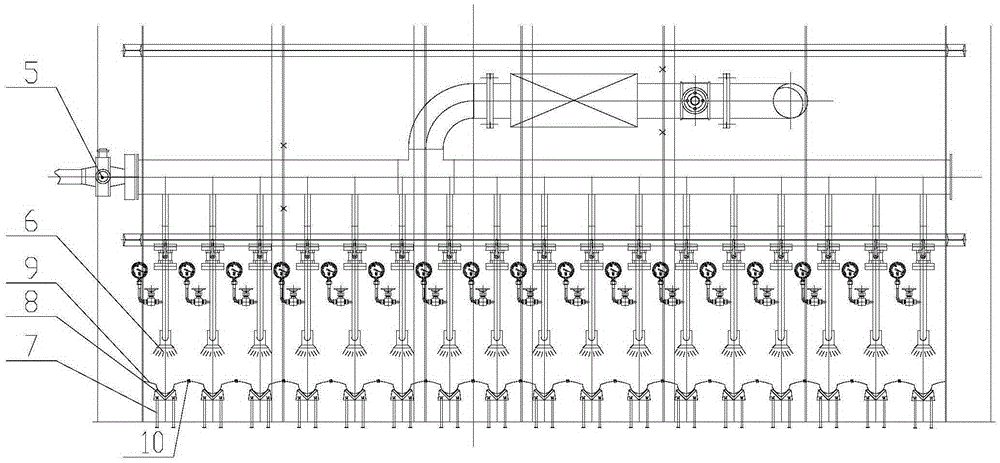

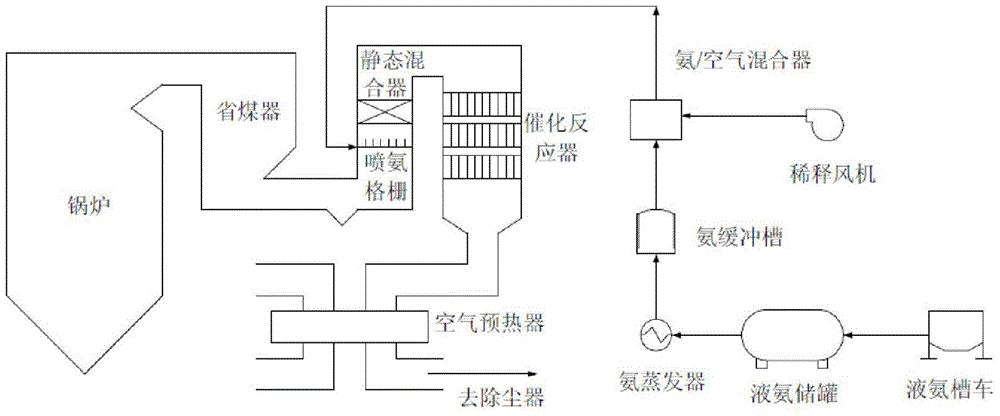

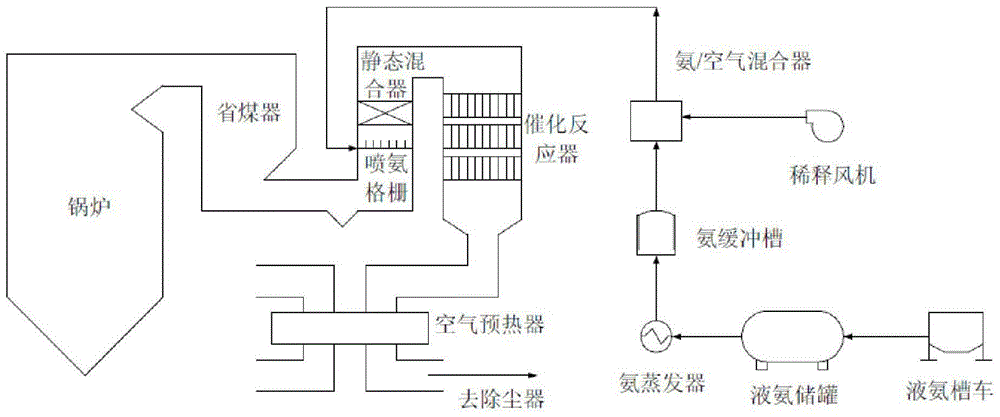

Low-temperature denitration device and method for denitration through low-temperature denitration device

ActiveCN105289272AImprove low temperature denitrification performanceAvoid blockingDispersed particle separationAtmospheric airSpray nozzle

The invention relates to a low-temperature denitration device and a method for denitration through the low-temperature denitration device and belongs to the technical field of atmospheric environment protection. The device comprises a powder adding device, an ammonia adding device, a mixing device and a reaction device. The powder adding device comprises a digester and a warehousing device. An outlet of the digester is connected with an inlet of the warehousing device, an outlet of the warehousing device is connected with a spreading device through a regulating valve, the spreading device comprises at least one vaporific spray gun, an impact spray gun with an upward spray nozzle is correspondingly arranged under each vaporific spray gun, V-shaped supports are arranged between the vaporific spray guns and the impact spray guns, circular groove uniform distribution plates are arranged on the V-shaped supports, and the uniform distribution plates are connected through springs. Compared with the prior art, according to the method for denitration through the low-temperature denitration device, severe harmful interference generated in the operating process of a catalyst is eliminated, normal operation of the catalyst is achieved, the low-temperature denitration capacity of the denitration device is improved accordingly, and worries of relevant emission enterprises are truly avoided.

Owner:江苏海澜正和环境科技有限公司

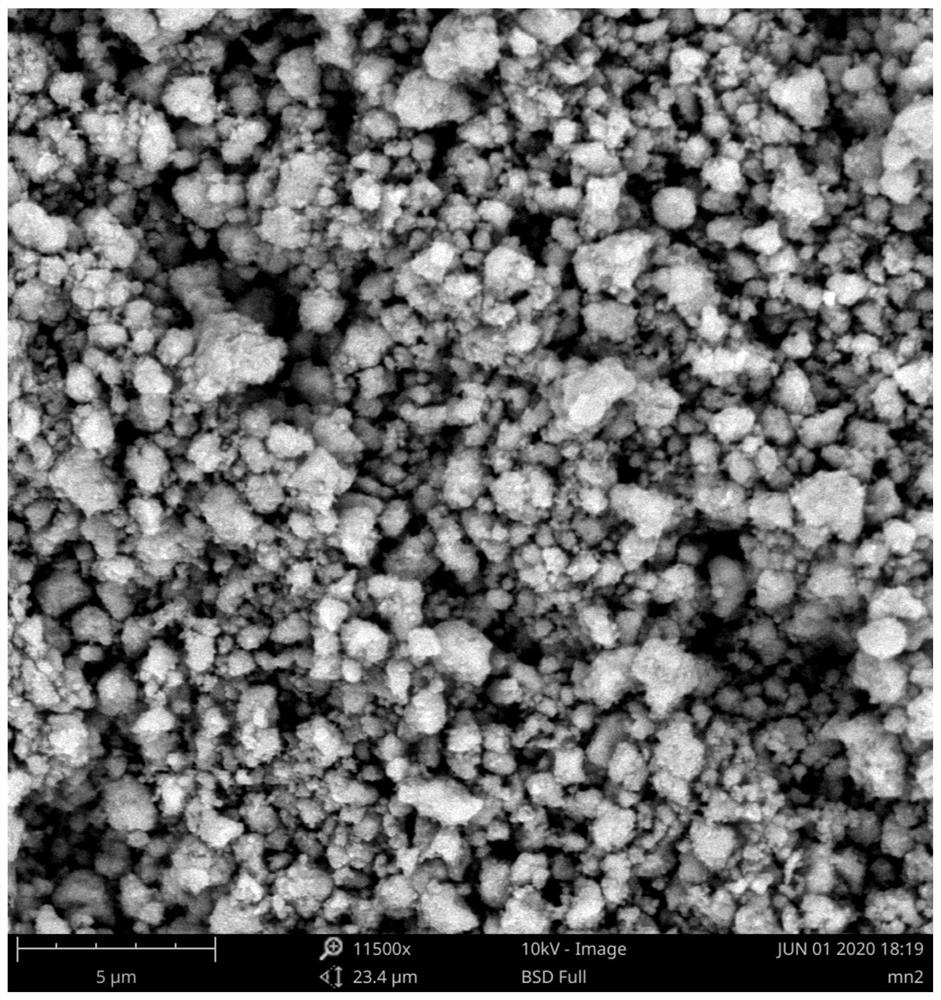

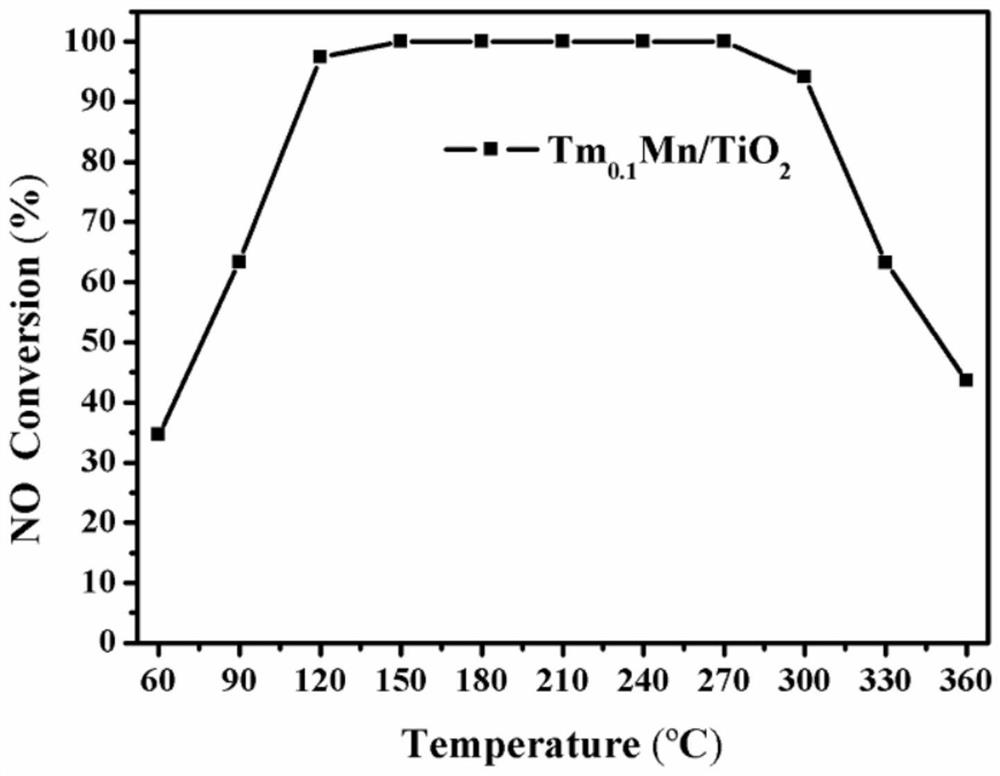

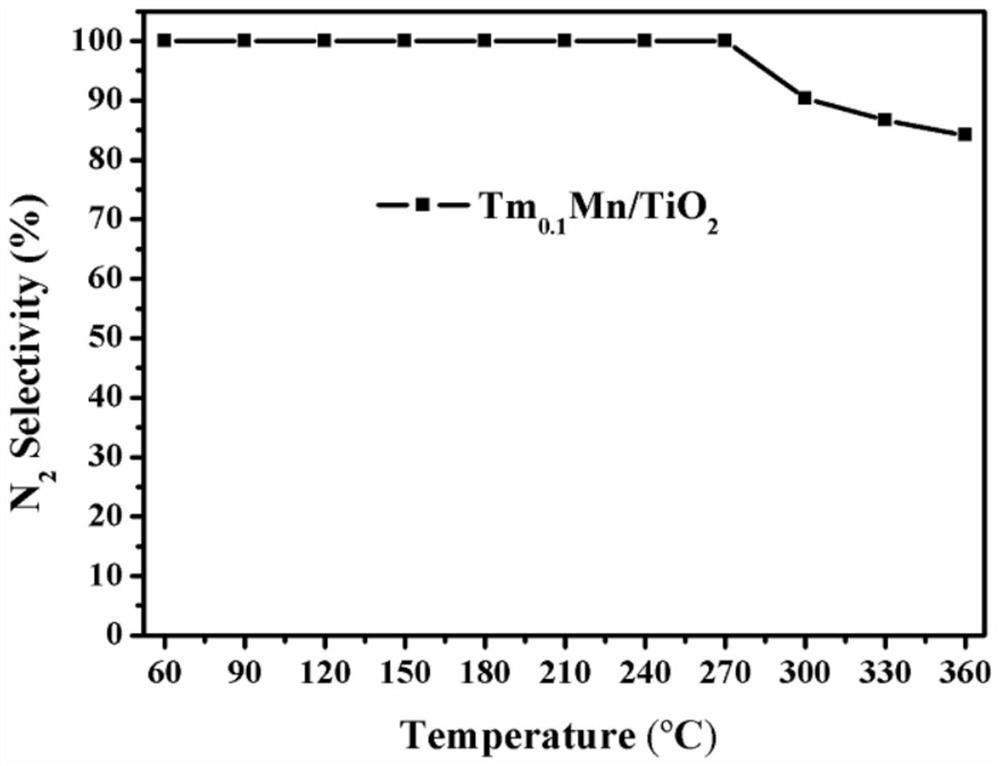

Titanium-oxide-loaded thulium-modified manganese oxide low-temperature denitration catalyst with high specific surface area as well as preparation method and application thereof

InactiveCN112076743ALarge specific surface areaFacilitates fully dispersed exposureGas treatmentDispersed particle separationMANGANESE ACETATEPtru catalyst

The invention discloses a titanium-oxide-loaded thulium-modified manganese oxide low-temperature denitration catalyst with high specific surface area as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving manganese acetate and thulium nitrate in deionized water at a room temperature, and performing stirring to obtain a mixed solution; (2)putting titanium dioxide powder into the mixed solution obtained in the step (1) at a room temperature, and performing stirring to obtain a mixed solution; (3) stirring the mixed solution obtained inthe step (2) at 60-90 DEG C until all water is evaporated to dryness to obtain a solid powder, and performing drying to obtain a dried product; and (4) calcining the dried product obtained in the step(3) at a temperature of 360-400 DEG C for 3-8 hours to obtain the titanium-oxide-loaded thulium-modified manganese oxide low-temperature denitration catalyst with high specific surface area. Thuliumoxide and manganese oxide are impregnated on a TiO2 carrier with a high specific surface area, so that the prepared catalyst has a large specific surface area, and complete dispersion and exposure ofactive components are facilitated.

Owner:XI AN JIAOTONG UNIV +1

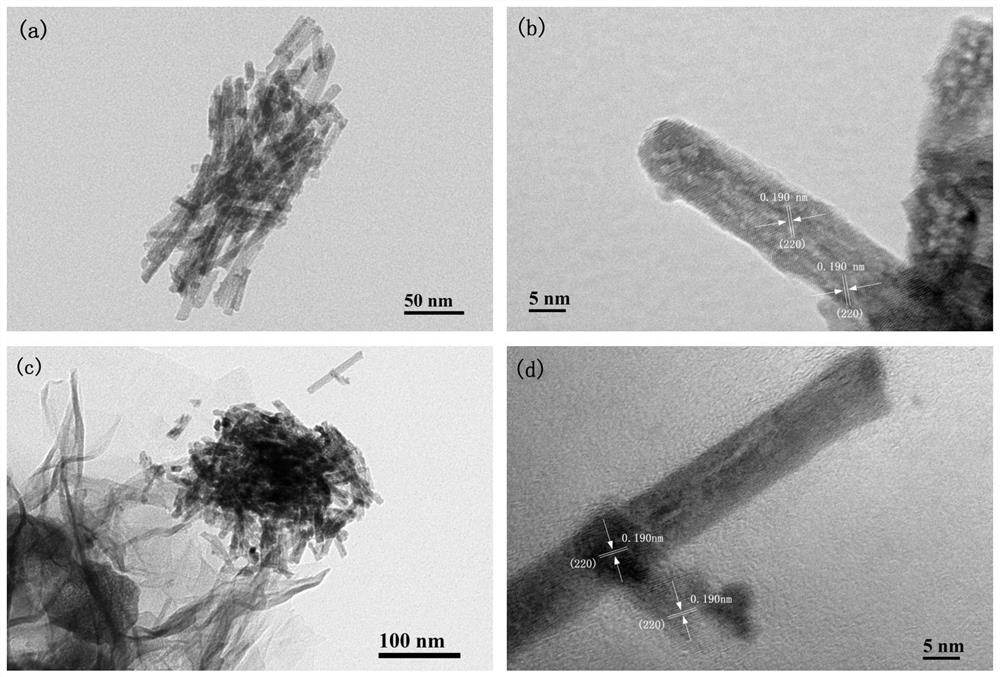

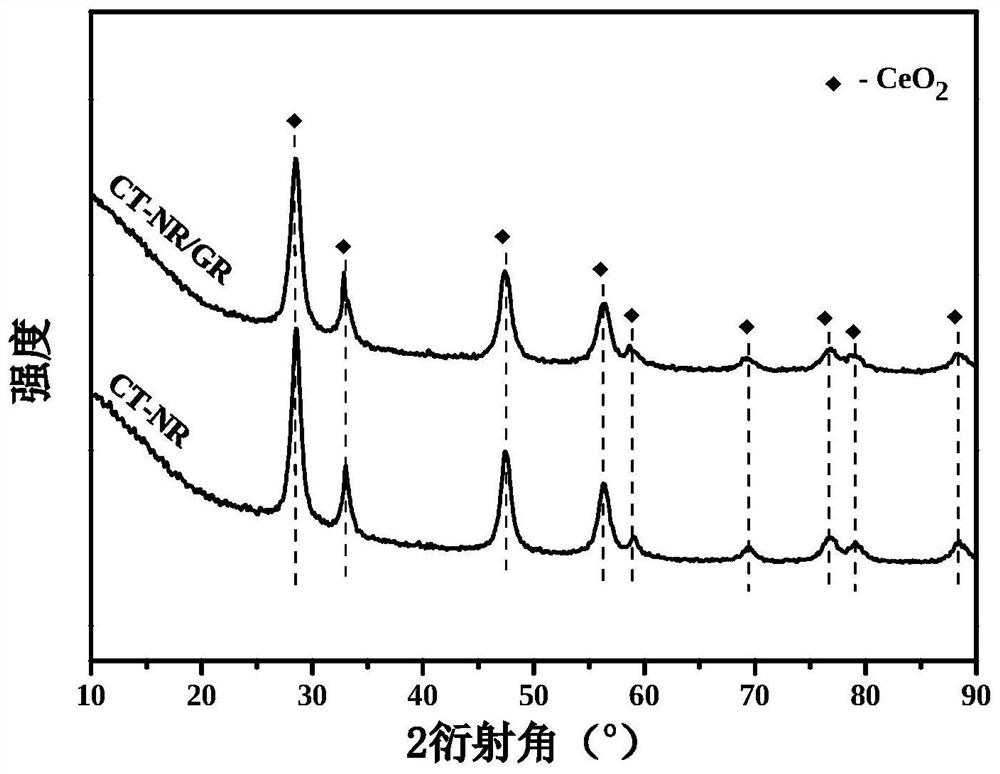

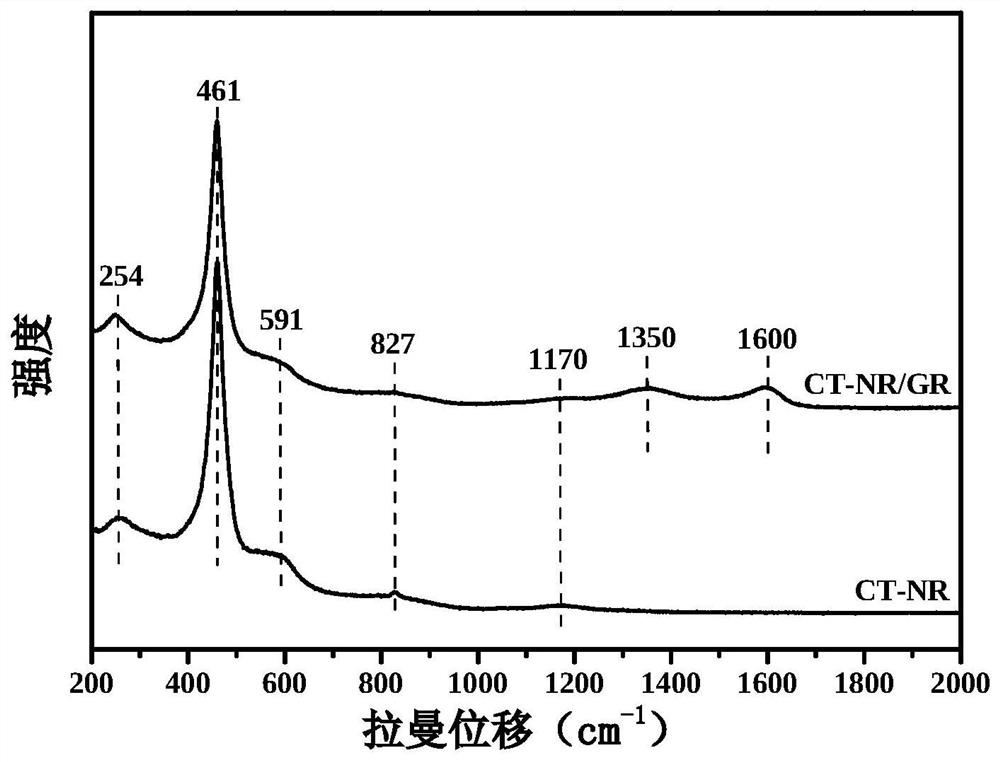

CeO2-TiO2 nanorod/graphene denitration catalyst as well as preparation and application thereof

PendingCN113262774AEasy to operateAbundant resourcesGas treatmentDispersed particle separationPtru catalystPhysical chemistry

The invention provides a CeO2-TiO2 nanorod / graphene denitration catalyst as well as preparation and application thereof. A preparation method comprises the following steps: 1) dissolving precursor salt containing Ce element and precursor salt containing Ti in water to prepare a mixed solution; (2) adding graphene into the mixed solution, and uniformly stirring to obtain a turbid liquid; (3) adding excessive NaOH solution into the turbid liquid, and stirring and mixing to obtain a slurry; 4) transferring the slurry into a hydrothermal reaction kettle for high-temperature hydrothermal reaction; and 5) centrifuging, washing, drying and roasting the product of the hydrothermal reaction to obtain the catalyst. The prepared catalyst is excellent in low-temperature denitration performance, the needed raw materials are rich in resource, low in price and easy to obtain, the preparation technology is simple, operability is high, the process is safe, large-scale production can be achieved, and wide application prospects are achieved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

A low-temperature anti-sulfur denitrification catalyst and preparation method thereof

ActiveCN104069852BStrong water resistanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCapillary condensationMixed oxide

The invention discloses a low-temperature anti-sulfur denitrification catalyst and a preparation method thereof. The catalyst is formed by mixing components containing the following weight percentages: active site 1-15%; carbon-based carrier 85-99%; wherein, active site by Ag 2 O, K 2 O, BaO, SnO 2 、 Bi 2 o 3 Or one or more mixed compositions of vanadium-based alloy oxides improved by PbO. The preparation method is to prepare a low-temperature anti-sulfur denitrification catalyst by mixing active sites and carbon-based supports. Due to the surface hydrophobic treatment of the catalyst prepared by the present invention, the water molecules contained in the flue gas are difficult to attach to the pore structure of the catalyst to form capillary condensation or with the adsorbed NH 3 and SO 2 or SO 3 Formation of sulfuric acid or ammonium sulfite leads to catalyst deactivation.

Owner:XIAN SINO GREEN HI TECH CO LTD

Preparation method of wide-temperature-range honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst

PendingCN114433056AHigh strengthImprove impact resistanceHeterogenous catalyst chemical elementsDispersed particle separationChemistryHoneycomb

The invention provides a preparation method of a wide-temperature-range honeycomb type SCR (Selective Catalytic Reduction) denitration catalyst, a pretreated Fe-Cr-C material metal honeycomb is arranged in the honeycomb type catalyst, a nano TiO2-Al2O3 carrier layer is firstly coated on the metal honeycomb, then an active layer with V2O5 as an active component and MoO3 and Nb2O5 as active auxiliaries is coated on the carrier layer, and the active layer is coated on the carrier layer. And finally, roasting to obtain the honeycomb catalyst. The prepared catalyst can be suitable for various severe flue gas working conditions, the internal metal honeycomb matrix can be recycled, the denitration efficiency of the catalyst is high, and the catalyst has excellent denitration performance within the range of 200-450 DEG C.

Owner:浙江科卓环保科技有限公司

A low-temperature anti-sulfur denitrification catalyst and preparation method thereof

ActiveCN104056658BStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationChemical formulaMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

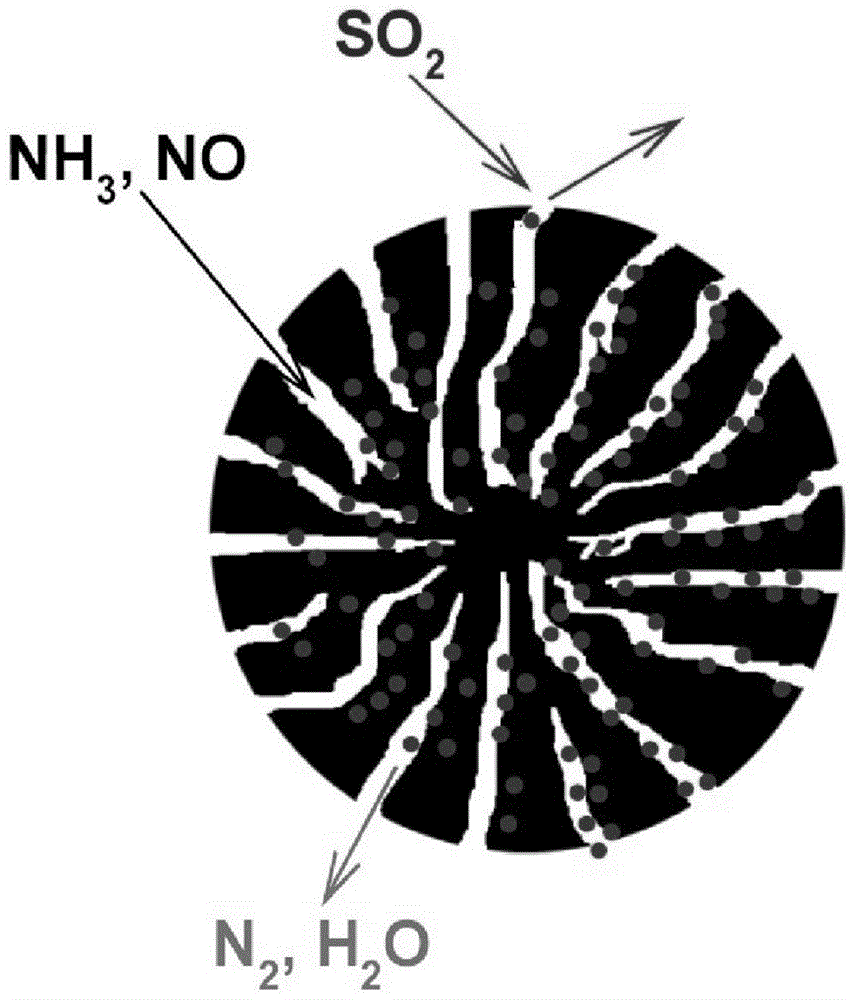

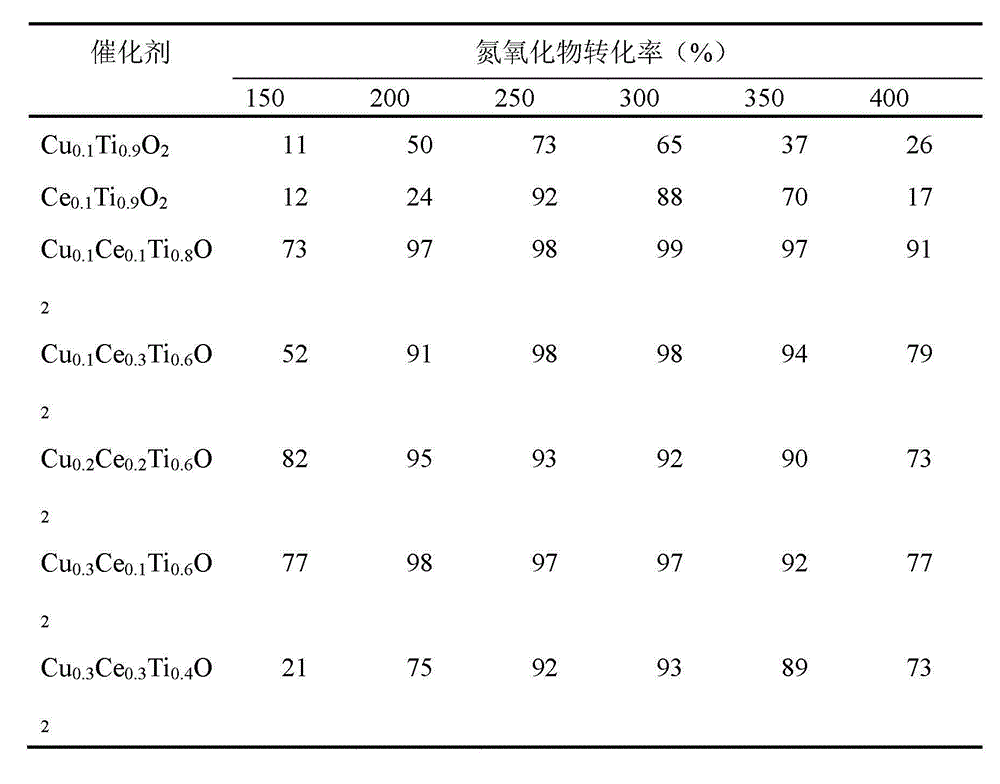

Denitration catalyst of wide activity temperature window as well as preparation method and application thereof

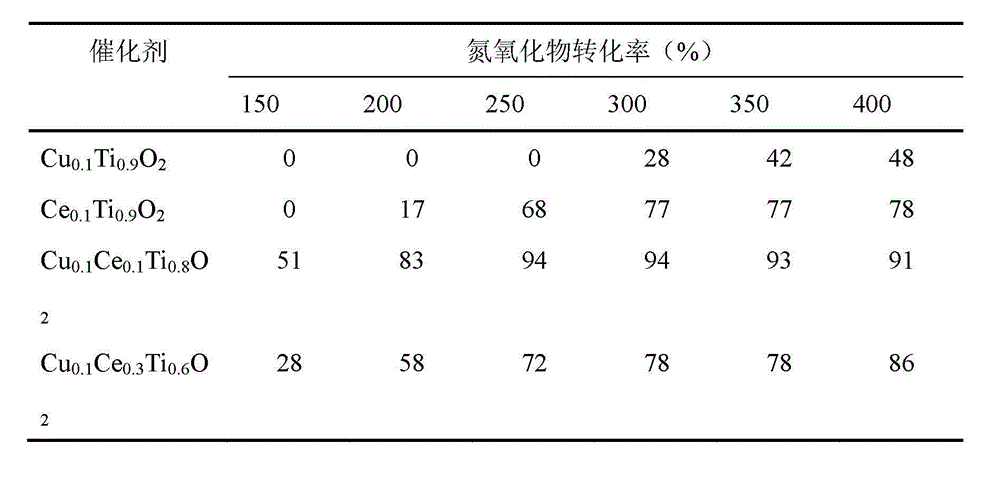

ActiveCN102962074BImprove low temperature denitrification performanceWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumReaction temperature

The invention provides a denitration catalyst of a wide activity temperature window as well as a preparation method and application of the denitration catalyst, and belongs to the technical fields of environment catalysis and atmosphere pollution control. The composite oxide catalyst is prepared by a hydrothermal method. The denitration catalyst is characterized in that the activity temperature window is wide and has good waterproof property and good sulfur tolerance. The provided method for reducing nitric oxide comprises the following steps of: loading the catalyst in a reactor of a stationary bed; controlling the reaction temperature within the range of 150-400 DEG C; and using ammonia as a reducing agent. According to the copper-cerium-titanium composite oxide prepared by the invention, the air speed is 64000 / h; and the purification efficiency of the nitric oxide is 91-99% within the range of 200-400 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of manganese dioxide nanosheet/carbon nanotube core-shell structure denitration catalyst

ActiveCN103071484BImprove low temperature denitrification performanceEasy to makeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystNitrogen oxides

Owner:SHANGHAI UNIV

A supported manganese-based medium and low temperature denitrification catalyst, its preparation method and its application

ActiveCN110773153BEnhancing catalytic activity at medium and low temperaturesImprove low temperature denitrification performanceGas treatmentDispersed particle separationPtru catalystPotassium manganate

The invention discloses a supported manganese-based medium-low temperature denitrification catalyst, its preparation and application, and belongs to the technical field of environment-friendly catalytic materials. The catalyst is prepared by adding carrier titania or aluminum oxide to divalent manganese salt solution, stirring and mixing, drying, and then adding potassium permanganate through solid phase interface reaction. The denitration catalyst provided by the present invention is used for selective catalytic reduction denitration reaction, has significantly enhanced low-temperature (100-200°C) or medium-low temperature (200-300°C) catalytic activity, and has excellent low-temperature denitrification performance at high loading capacity , a typical sample at a space velocity of 30000ml / g h, the NO conversion rate in the mixed gas reaches 98.7% at 100 °C, and the NO conversion rate at 200 °C is 98.9%; it has excellent medium temperature denitrification performance at low loading capacity, typical sample At a space velocity of 60000ml / g·h and 200°C, the conversion rate of NO in the mixed gas reaches 99.0%, and the conversion rate of NO is still 99.6% when the temperature rises to 300°C. The denitration catalyst provided by the invention has potential application value.

Owner:SICHUAN UNIV +1

A method for selectively reclaiming yttrium in crt fluorescent powder for doping to prepare ternary composite oxide catalyst

ActiveCN108686668BImprove low temperature denitrification performanceTake advantage ofHeterogenous catalyst chemical elementsDispersed particle separationRare-earth elementPtru catalyst

The invention belongs to the technical field of environmental catalysis, and particularly relates to a method for selectively recovering yttrium in CRT fluorescent powder for doping to prepare a ternary composite oxide catalyst. Alkali fusion products are obtained; ammonia water is used to leach alkali fusion products, and the main impurity zinc is removed by solid-liquid separation; after leaching with dilute hydrochloric acid, two-step precipitation is used to enrich and recover rare earths, and dilute hydrochloric acid is used for secondary leaching to obtain rare earth leachate ; Obtain yttrium oxalate by photochemical method combined with chemical precipitation method; finally prepare ternary composite oxide catalyst by co-precipitation method. The invention is a method for selectively recovering yttrium in CRT fluorescent powder for doping to prepare a ternary composite oxide catalyst, which can efficiently separate, extract and fully utilize the rare earth elements in waste CRT fluorescent powder, and the doping of yttrium can obviously improve the efficiency of the catalyst. Low-temperature denitrification performance, lower catalyst production costs, and truly realize waste treatment with waste.

Owner:BEIJING UNIV OF TECH

A kind of thin-wall flat type low-temperature anti-sulfur SCR denitrification catalyst and preparation method thereof

ActiveCN111715230BPromote decompositionImprove denitrification activityHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

Embodiments of the present invention provide a thin-walled flat plate type low-temperature sulfur-resistant SCR denitration catalyst and a preparation method thereof. The catalyst is TiO 2 ‑Nb 2 O 5 ‑Fe 2 O 3 Composite nanooxide as carrier, V 2 O 5 is the active ingredient, MoO 3 and MnSO 4 It is an active additive, adding organic and inorganic structural additives, and is made through multi-stage rolling, drying and other steps. The catalyst of the present invention improves the low-temperature denitrification performance and resistance to sulfur poisoning by developing a carrier that accelerates the denitrification reaction and promotes the decomposition of ammonium sulfate salt, optimizing active ingredients and active additives, optimizing molding additives and preparation processes, and enables the catalyst to It has excellent denitrification activity and stability in the temperature range of 150-250℃. The plate thickness of 0.35-0.40mm enables the catalyst to have a low sulfur dioxide oxidation rate and strong resistance to sulfur poisoning, greatly reducing the cost of raw materials required for production and saving the operating cost of the SCR denitration system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Compounded denitration catalyst, as well as preparation method and application thereof

ActiveCN102909004BImprove low temperature denitrification performanceWide active temperature windowDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium(IV) oxideReaction temperature

The invention provides a compounded denitration catalyst and a preparation method thereof, and belongs to the technical field of environment catalysis and atmospheric pollution controlling. The catalyst adopts titanium dioxide as a carrier, cerium dioxide as a main active component, and molybdenum trioxide as secondary active component performing a synergistic effect, and is prepared according to a stepped impregnation method. The compounded denitration catalyst is characterized in that due to the adding of molybdenum trioxide, the denitration performance of cerium-titanium catalyst is improved obviously, the active temperature window is widened, and the water resistance of the catalyst is also improved obviously. The method for reducing nitrogen oxides comprises the following steps: filling the catalyst into a fixed bed reactor; controlling the reaction temperature range to be 250 to 400 DEG C; and taking ammonia as a reducing agent. The cerium-molybdenum-titanium compounded catalyst prepared according to the invention is 12,8000 per hour in space velocity, and can purify nitrogen oxides with the efficiency ranging from 83 to 98 percent at the temperature ranging from 250 to 400 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

Efficient response optical coupling denitration catalyst and preparation method thereof

PendingCN112675868ARealize high value-added applicationsFacilitating Light-Coupled Low-Temperature Denitrification PerformanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementIndustrial waste

The invention discloses an efficient response optical coupling denitration catalyst and a preparation method thereof, and belongs to the technical field of blast furnace slag application. The preparation method of the product comprises the following steps: uniformly mixing the titanium-containing blast furnace slag with the rare earth element oxide, the transition metal oxide and a certain amount of sodium hydroxide, heating to melt, reconfiguring a silicate phase while solid-dissolving transition group elements into a perovskite phase, and stripping the silicate phase through acid leaching treatment, thereby finally obtaining the perovskite-based functional material. The obtained product is the optical coupling low-temperature denitration catalyst with efficient response activity. According to the catalyst prepared by the method disclosed by the invention, the removal rate of NOx can reach 100% and the N2 selectivity can reach 92% under a low-temperature condition (140 DEG C) in a manner of adding a light source, so that the denitration catalyst capable of efficiently responding under the low-temperature condition is prepared at low cost in a short process; and the method disclosed by the invention has great significance in high-added-value application of the titanium-containing blast furnace slag and continuous and efficient removal of NOx in industrial waste gas.

Owner:安徽工业大学科技园有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com