Low-temperature denitration catalyst and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of limited profit margins, catalyst manufacturing cost constraints, high prices, etc., and achieve low raw material costs , good low temperature denitrification performance, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

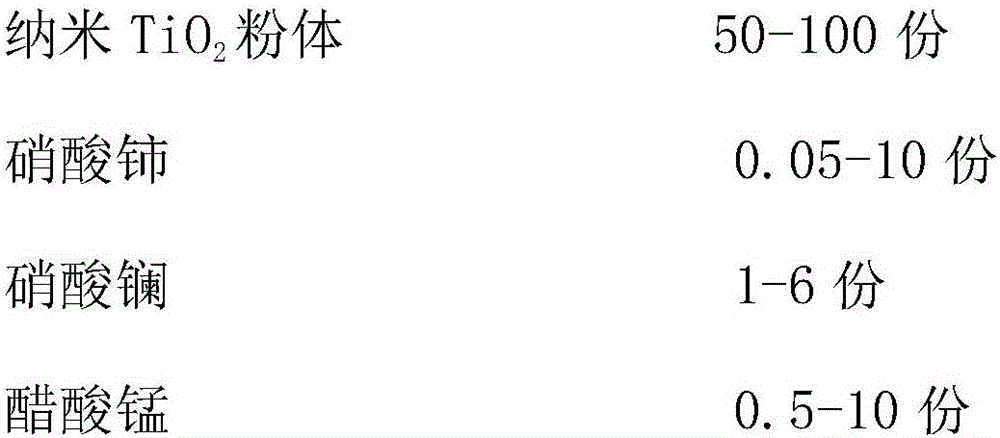

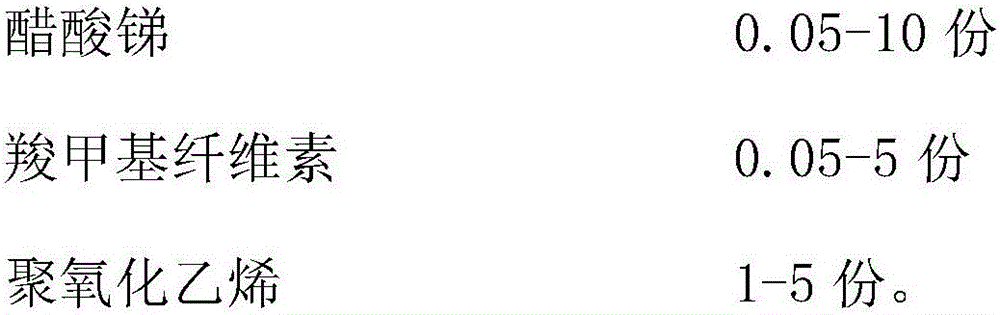

[0024] Take the components according to the following parts by weight:

[0025]

[0026] A low-temperature denitration catalyst and a preparation method thereof, the steps are as follows:

[0027] 1) Mix cerium nitrate, lanthanum nitrate, manganese acetate and antimony acetate evenly, and calcinate at 400°C for 33 hours to obtain sample a;

[0028] 2) Grinding the sample a to a particle size of 0-3 microns to obtain sample b;

[0029] 3) Match sample b with nano-TiO 2 , carboxymethyl cellulose and polyethylene oxide, mixed uniformly, and calcined at 450°C for 30 hours to obtain sample c;

[0030] 4) Grinding sample c to a particle size of 0-3 microns to obtain the product as a low-temperature denitration catalyst.

Embodiment 2

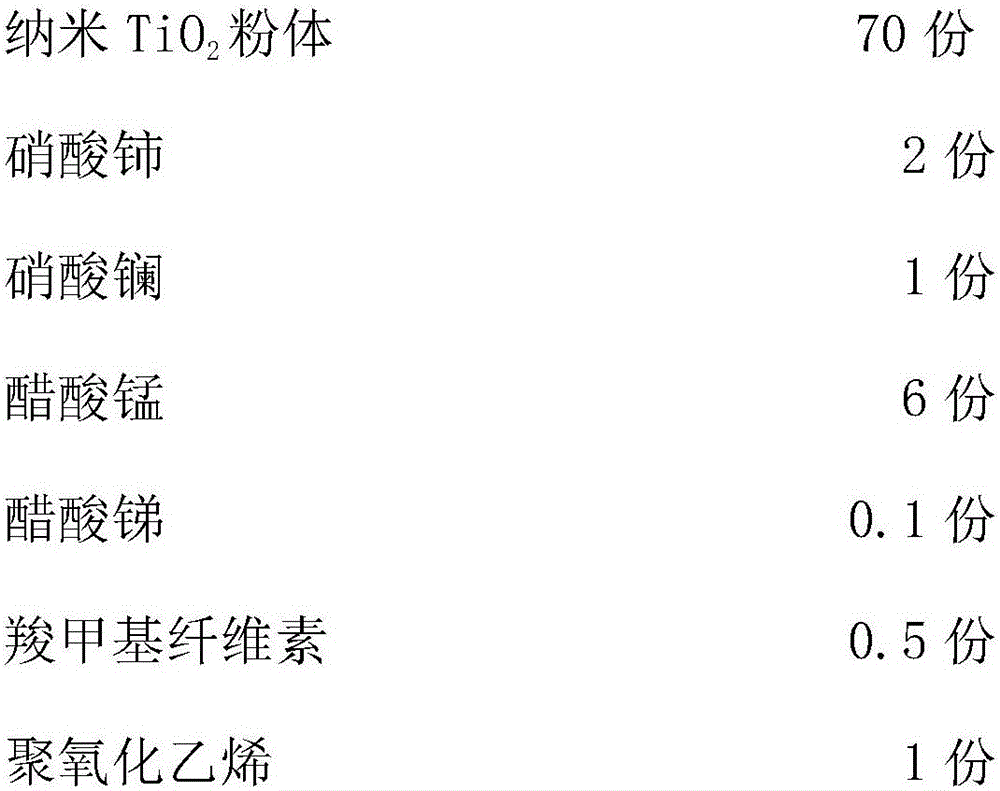

[0032]

[0033] A low-temperature denitration catalyst and a preparation method thereof, the steps are as follows:

[0034] 1) Mix cerium nitrate, lanthanum nitrate, manganese acetate, and antimony acetate evenly, and calcinate at 460°C for 35 hours to obtain sample a;

[0035] 2) Grinding the sample a to a particle size of 0-3 microns to obtain sample b;

[0036] 3) Match sample b with nano-TiO 2 , carboxymethyl cellulose and polyethylene oxide, mixed uniformly, and calcined at 400°C for 33 hours to obtain sample c;

[0037] 4) Grinding sample c to a particle size of 0-3 microns to obtain the product as a low-temperature denitration catalyst.

Embodiment 3

[0039]

[0040]

[0041] A low-temperature denitration catalyst and a preparation method thereof, the steps are as follows:

[0042] 1) Mix cerium nitrate, lanthanum nitrate, manganese acetate and antimony acetate evenly, and calcinate at 500°C for 38 hours to obtain sample a;

[0043] 2) Grinding the sample a to a particle size of 0-3 microns to obtain sample b;

[0044] 3) Match sample b with nano-TiO 2 , carboxymethyl cellulose, and polyethylene oxide, mixed uniformly, and calcined at 480°C for 35 hours to obtain sample c;

[0045] 4) Grinding sample c to a particle size of 0-3 microns to obtain the product as a low-temperature denitration catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com