Titanium-oxide-loaded thulium-modified manganese oxide low-temperature denitration catalyst with high specific surface area as well as preparation method and application thereof

A high specific surface area, low temperature denitrification technology, applied in the field of denitrification treatment, to achieve the effect of complete dispersion and exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Prepare the thulium-modified manganese oxide low-temperature denitrification catalyst supported by titanium oxide with high specific surface area according to the method proposed by the present invention:

[0051] (1) Dissolve 1.0 g of manganese acetate and 0.6 g of thulium nitrate in 20 mL of deionized water at room temperature, and stir for 60 min;

[0052] (2) Place 1.0 g of titanium dioxide powder in the above solution at room temperature, and stir for 60 min;

[0053] (3) Stir the above solution at 80°C for 12h until all water is evaporated; dry the obtained solid powder at 80°C for 12h;

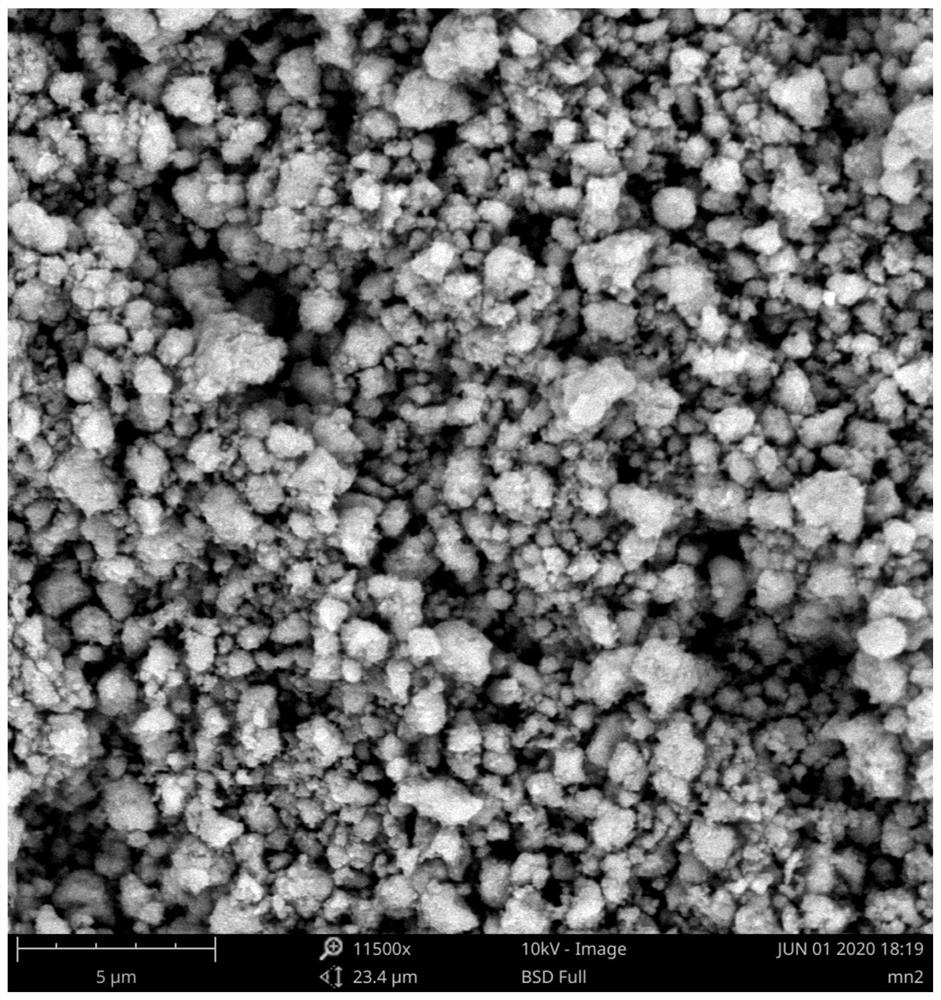

[0054] (4) Calcining the dried product in a muffle furnace, the calcination temperature is 360°C, and the heating rate is 1°C / min. After 4 hours of calcination, a thulium-modified manganese oxide low-temperature denitrification catalyst supported by titanium oxide with a high specific surface area is obtained. The morphology of the obtained catalyst is as follows figure 1 shown...

Embodiment 2

[0059] Prepare the thulium-modified manganese oxide low-temperature denitrification catalyst supported by titanium oxide with high specific surface area according to the method proposed by the present invention:

[0060] (1) Dissolve 0.8 g of manganese acetate and 0.5 g of thulium nitrate in 20 mL of deionized water at room temperature, and stir for 60 min;

[0061] (2) Place 1.0 g of titanium dioxide powder in the above solution at room temperature, and stir for 60 min;

[0062] (3) Stir the above solution at 80°C for 12h until all water is evaporated, and dry the obtained solid powder at 80°C for 12h;

[0063] (4) The dried product was calcined in a muffle furnace at a calcination temperature of 400° C. and a heating rate of 1° C. / min. After 5 hours of calcination, a thulium-modified manganese-titanium oxide catalyst was obtained.

[0064] In this catalyst, rare earth Tm and transition metal Mn oxides are evenly distributed in TiO 2 On the surface of the carrier, their mol...

Embodiment 3

[0067] A thulium-modified manganese oxide low-temperature denitrification catalyst supported by high specific surface area titanium oxide according to the embodiment of the present invention, the oxides of rare earth Tm and Mn are evenly distributed on TiO 2 The surface of the carrier; wherein, in terms of molar ratio, Tm:Mn:Ti=0.07:0.2:1. Tm is positive trivalent. The oxide of Mn is in the amorphous state, and the Mn 2+ , Mn 3+ , Mn 4+ Composed of three valence states. In mole percent, Mn 2 + :Mn 3+ :Mn 4+ =20%:50%:30%. TiO 2The carrier is anatase type, and Ti is positive tetravalent. The specific surface area of the thulium-modified manganese oxide low-temperature denitrification catalyst is 110-190m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com