Thin-wall flat plate type low-temperature sulfur-resistant SCR denitration catalyst and preparation method thereof

A denitrification catalyst, a flat-plate technology, applied in the field of environmental protection technology and denitrification catalysis, can solve the problems of poor low-temperature activity and ammonium sulfate poisoning, and achieve the effects of overcoming poor mechanical properties, saving usage, and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

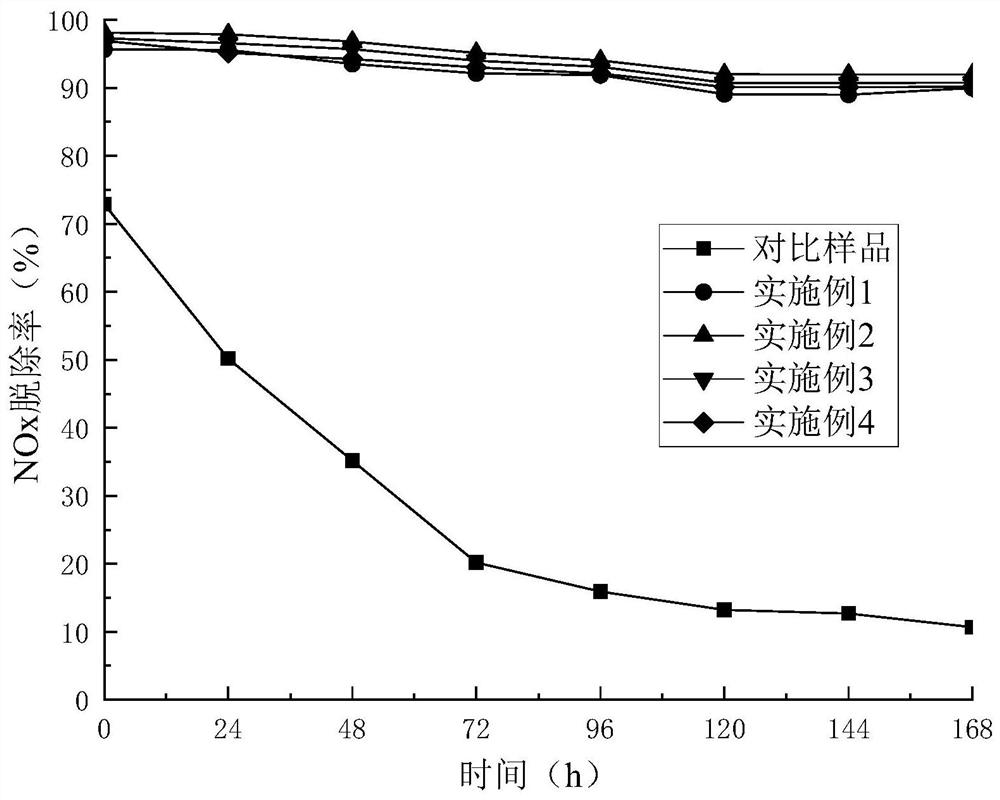

Examples

preparation example Construction

[0041] In order to better realize the above-mentioned technical solution, the present invention also provides a method for preparing a thin-walled plate-type low-temperature sulfur-resistant SCR denitration catalyst, the specific steps including:

[0042] S1. Preparation of TiO 2 -Nb 2 o 5 -Fe 2 o 3 composite nanocarrier

[0043] Prepare titanium tetrachloride solution with cold water, add monoglyceride stearate and stir evenly, adjust the pH value to 6.5-7.5 with ammonia water, then heat the solution to 50°C to obtain a uniform white emulsion; then slowly add five Niobium chloride ethanol solution and ferric chloride solution, adjust the pH value to 8-9 with ammonia solution, heat the solution to 80°C, and keep stirring for 2-4h; wash the hydrolysis precipitate with ethanol and deionized water in turn, and finally roast Get TiO 2 -Nb 2 o 5 -Fe 2 o 3 Composite nanocarriers;

[0044] S2. Preparation of catalyst material

[0045] The prepared ammonium metavanadate, a...

Embodiment 1

[0053] This example provides a thin-walled flat-plate low-temperature sulfur-resistant SCR denitration catalyst and its preparation method. The specific steps include:

[0054] (1) Preparation of TiO 2 -Nb 2 o 5 -Fe 2 o 3 composite nanocarrier

[0055] Dissolve 2015.35g of titanium tetrachloride in 21.25L of water, 101.64g of niobium pentachloride in 276mL of ethanol, and 202.76g of ferric chloride in 417mL of water to obtain titanium solution, niobium solution and iron solution; add 38.1g Stearic acid monoglyceride, use ammonia water to adjust the pH of the solution to 6.5, and then heat the solution to 50°C to hydrolyze the titanium solution to obtain a uniform white emulsion; add niobium solution and iron solution to the emulsion in turn to adjust the pH of the solution to 8 , heated the solution to 80°C and kept stirring for 2h; filtered to obtain the hydrolyzed precipitate, washed with ethanol and deionized water, and roasted at 500°C for 10h to obtain 2 o 5 and 10...

Embodiment 2

[0069] Embodiment 2 also describes a thin-walled flat plate low-temperature anti-sulfur SCR denitration catalyst and its preparation method. The specific steps include:

[0070] (1) Preparation of TiO 2 -Nb 2 o 5 -Fe 2 o 3 composite nanocarrier

[0071] Dissolve 2015.35g of titanium tetrachloride in 7.08L of water, 203.28g of niobium pentachloride in 555mL of ethanol, and 101.38g of ferric chloride in 208mL of water to obtain titanium solution, niobium solution and iron solution; add 114.3g Stearic acid monoglyceride, use ammonia water to adjust the pH of the solution to 7.5, and then heat the solution to 50°C to hydrolyze the titanium solution to obtain a uniform white emulsion; add niobium solution and iron solution to the emulsion in turn to adjust the pH of the solution to 9 , heated the solution to 80°C and kept stirring for 4h; filtered to obtain the hydrolyzed precipitate, washed with ethanol and deionized water, and roasted at 650°C for 3h to obtain 2 o 5 and 5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com