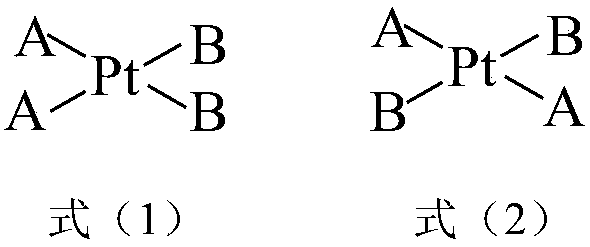

Platinum catalyst resistant to sulfur poisoning and preparation method of platinum catalyst

A platinum catalyst, sulfur poisoning technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. It has the effect of inhibiting sulfur poisoning, stable catalyst activity and long storage period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

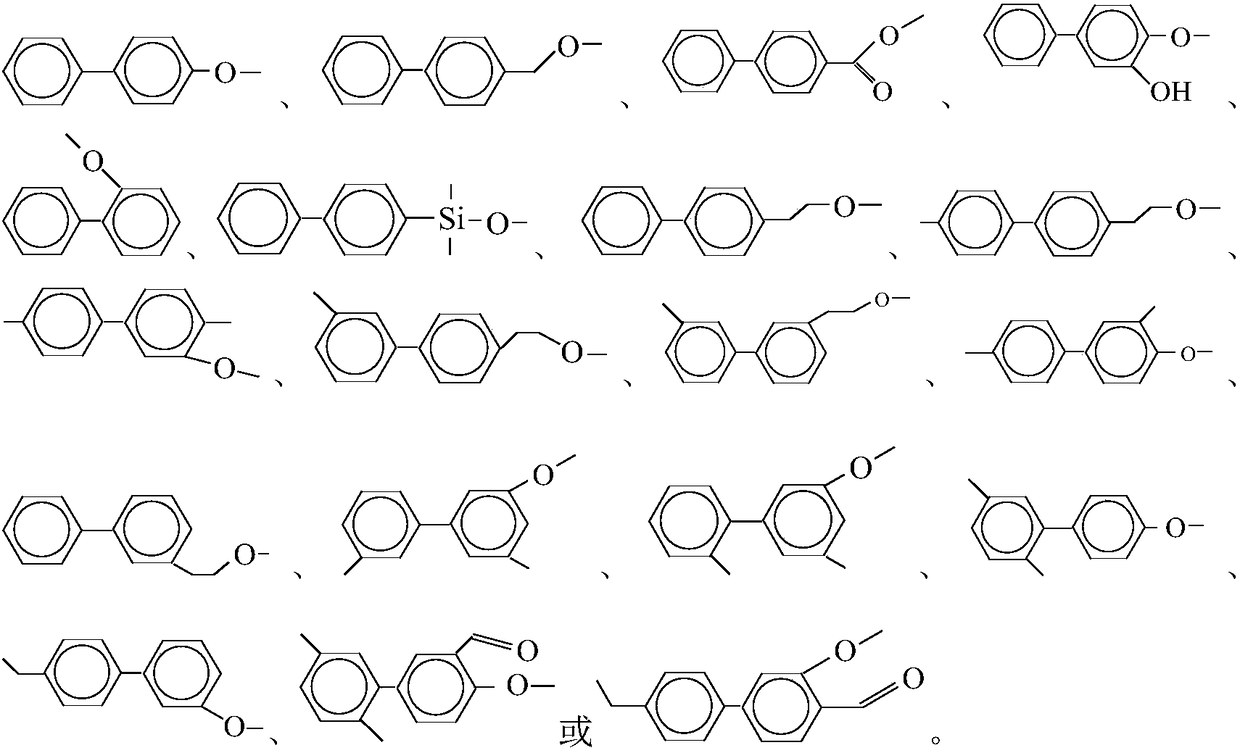

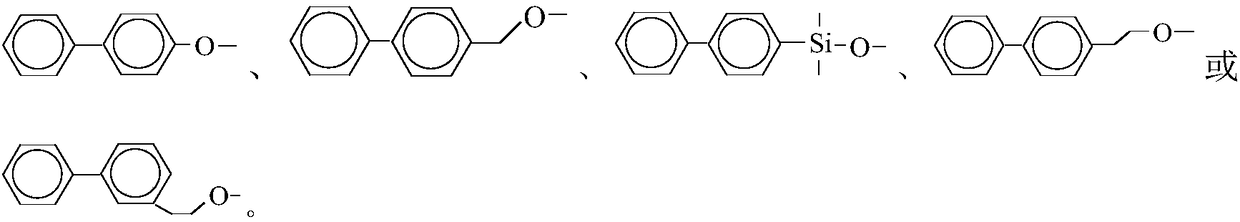

[0045] 1. Pt(bphO) 2 (SEt 2 ) 2 Preparation of intermediates

[0046] In the four-necked flask equipped with a condenser tube and nitrogen inlet, feed nitrogen, add toluene (235.92g), ethanol (78.64g), 4-hydroxybiphenyl (34.00g, 0.2mol) and cis-dichlorobis(di Ethyl sulfide) platinum (II) (44.64g, 0.1mol), after stirring for 20min with a magnet, add dichloroacetic acid (0.71g) and trifluoromethanesulfonic acid (0.63g), stir for 10min, then use a peristaltic pump to control Drop distilled water (1.44g) into the reaction system at a rate of 6 drops / min, react at 80°C for 24h, cool down to room temperature, add ammonium bicarbonate (1.15g, 0.015mol) into the reaction system, and stir for 40min , filtered, and rectified by rotary distillation at 90°C for 80 minutes, weighed ethyl acetate (235.92g), took half of it and put it into the one-necked bottle after rotary steaming, filtered it with electromagnetic shock for 10 minutes, and rinsed the one-necked bottle with the remaining...

Embodiment 2

[0051] 1. Pt(bphO) 2 (SEt 2 ) 2 Preparation of intermediates

[0052] In the four-necked flask equipped with a condenser tube and nitrogen inlet, argon gas was introduced, and chloroform (168.58g), isopropanol (67.43g), 4-hydroxyethylbiphenyl (39.65g, 0.2mol) and cis- Dichlorobis(diethylsulfide)platinum (II) (44.64g, 0.1mol), after stirring for 30min with a magnet, add dichloroacetic acid (0.42g) and trifluoromethanesulfonic acid (0.42g), and stir for 10min , use a peristaltic pump to control the speed of 8 drops / min, and drop distilled water (1.17g) into the reaction system dropwise, react at a temperature of 90°C for 36h, cool to room temperature, add ammonium bicarbonate (0.55g, 0.007mol ) in the reaction system, stirred for 60 minutes, then rotary evaporated at 80°C for 80 minutes, weighed tetrahydrofuran (168.58g), took half of it and put it into the single-necked bottle after rotary steaming, filtered it with electromagnetic shock for 15 minutes, rinsed the single-nec...

Embodiment 3

[0057] 1. Pt(bphO) 2 (SEt 2 ) 2 Preparation of intermediates

[0058] In the four-necked flask that condenser tube and nitrogen inlet and constant pressure funnel are housed, pass into nitrogen, add cyclohexane (81.49g), isobutanol (48.89g), 4-(4-methylphenyl)phenol ( 36.85g, 0.2mol) and trans-dichlorobis(diethylsulfide) platinum (Ⅱ) (44.64g, 0.1mol), after stirring for 40min with a magnet, add 2-propiolic acid (0.24g) and strong acid The cationic resin (0.65g) was stirred for 30min, and distilled water (1.08g) was dripped into the reaction system at a rate of 10 drops / min controlled by a peristaltic pump. After reacting at a temperature of 80°C for 48h, the temperature was lowered to room temperature. , add ammonium bicarbonate (0.21g, 0.003mol) into the reaction system, stir for 40min, then spin evaporate at 90°C for 100min, weigh n-hexane (81.49g), take half of it and add it to the one-necked flask after spin steam, and electromagnetically Suction filtration after shaki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com