Layered manganese oxide with water resistance and sulfur poisoning resistance and preparation method and application thereof

A layered manganese oxide and sulfur poisoning technology, applied in chemical instruments and methods, manganese oxide/hydroxide, combustion methods, etc., can solve problems such as catalyst activity reduction, and achieve low light-off temperature, water resistance and sulfur resistance. Good toxicity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

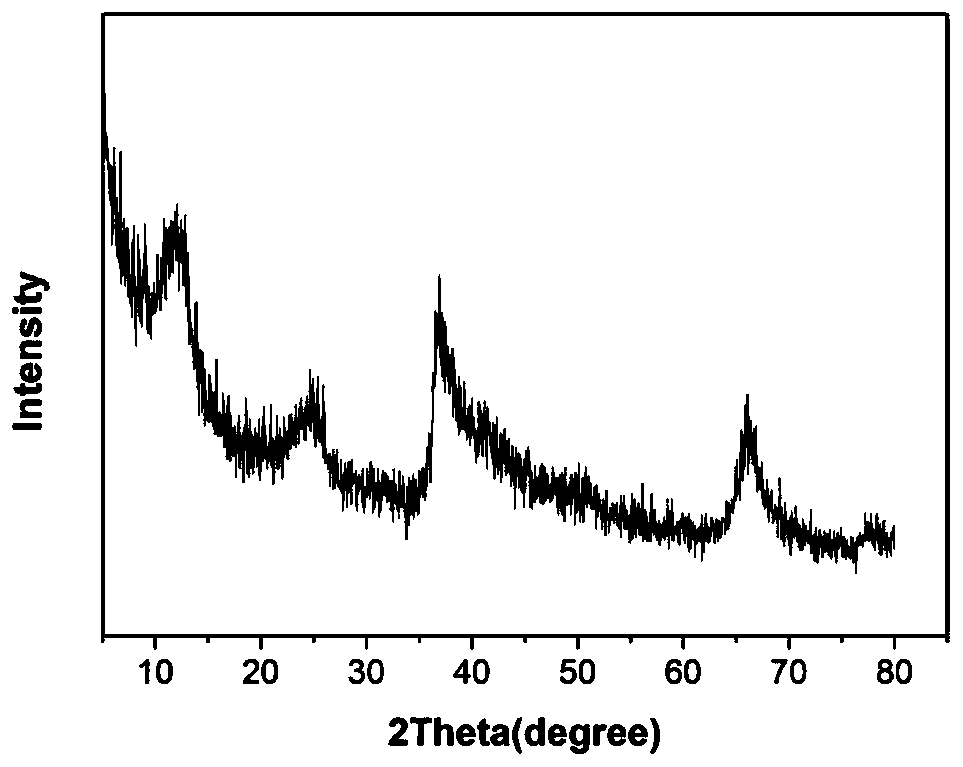

[0029] The molar ratio of potassium permanganate to ethanol is 2:3, KMnO 4 The solution was added into the ethanol solution under constant stirring, and the KMnO 4 KMnO in solution 4 The dropping rate is 1.58mg / s. The above mixed solution was stirred at 10°C for 24h. Then, the generated precipitate was filtered, washed with deionized water, and dried at 80° C. to obtain a layered manganese oxide catalyst. The XRD of the layered manganese oxide catalyst that present embodiment obtains is as follows: figure 1 shown by figure 1 It can be seen that the positions of 12.5°, 25°, 36.5° and 65.5° correspond to δ-MnO 2 Crystal face (001)(002)(-111)(-312) of (JCPDS 80-1098). Among them, the diffraction peaks appearing on the (001) crystal plane indicate that the manganese oxide has a layered structure and belongs to the monoclinic crystal system.

Embodiment 2

[0031] The molar ratio of potassium permanganate to methanol is 1:1, KMnO 4 The solution was added into the ethanol solution under constant stirring, and the KMnO 4 KMnO in solution 4 The dropping rate is 4.74mg / s. The above mixed solution was stirred at 15°C for 48h. Then, the generated precipitate was filtered, washed with deionized water, and dried at 80° C. to obtain a layered manganese oxide catalyst.

Embodiment 3

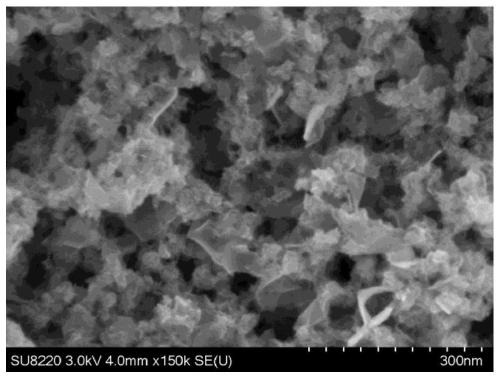

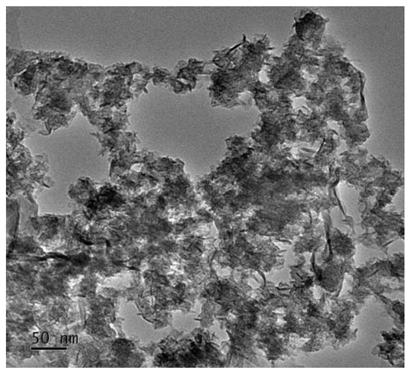

[0033]The molar ratio of potassium permanganate to ethanol is 2:3, and the ethanol solution is quickly poured into the potassium permanganate solution under constant stirring. The above mixed solution was stirred at 10°C for 24h. Then the generated precipitate was filtered, washed with deionized water, and dried at 60° C. by blowing air to obtain a layered manganese oxide catalyst. The SEM and TEM images of the layered manganese oxide catalyst obtained in this example are shown in Figure 2(a) and Figure 2(b), respectively. It can be seen from Figure 2(a) that the layered oxide is randomly assembled from fine nanosheets into more agglomerates with a lamellar structure. It can be seen from Figure 2(b) that the surface of the nanosheets is rough and irregular, indicating that there are a large number of surface defects and oxygen vacancies on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com