Low-temperature plasma non-hot point fire steadying flame device

A low-temperature plasma and flame-stabilizing device technology, which is applied in the field of aerospace power propulsion systems, can solve the problems of low flow rate of combustible mixed gas ignition gas, easy breakdown of ceramics, and limited application, so as to expand the range of working parameters and prolong life , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

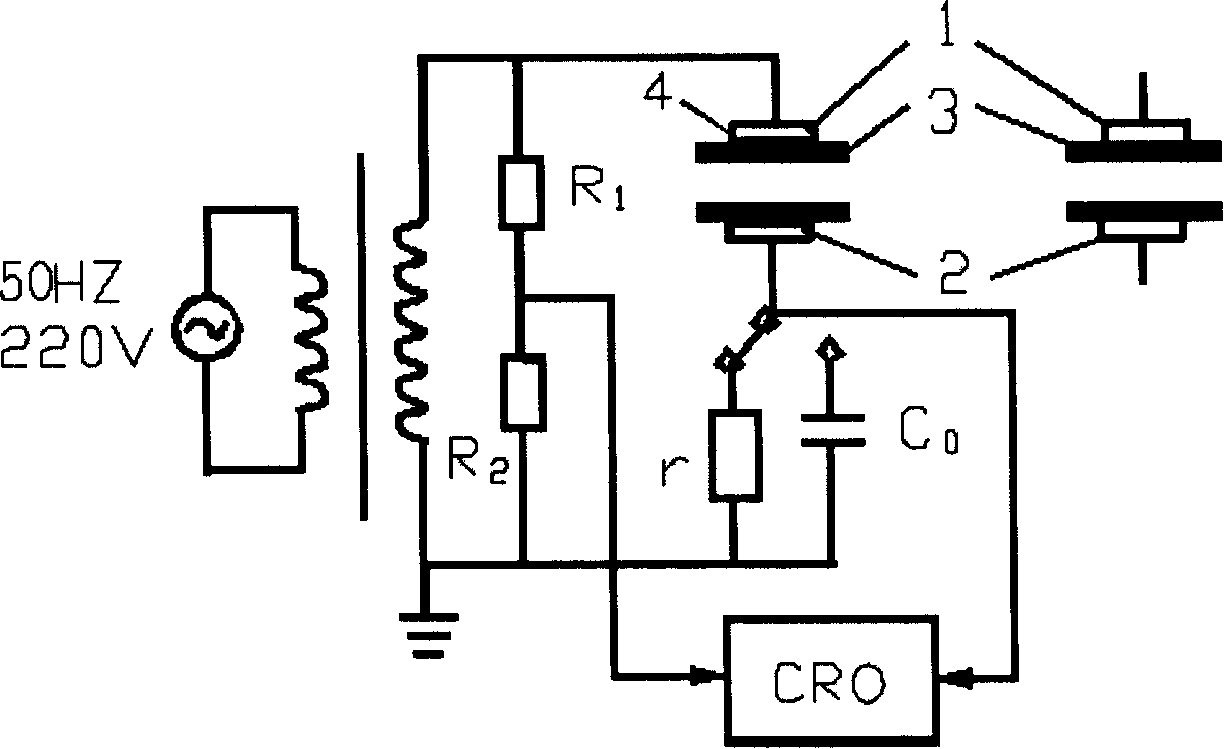

[0029] Figure 5 It is a schematic diagram of a low-temperature plasma non-thermal ignition flame stabilization device, which consists of a high-voltage power supply 1, a high-voltage electrode 2, an air inlet 3, an air inlet seat 4, a barrier medium 5, a low-voltage electrode 6, a rectifier 7, and a combustion chamber 8 .

[0030] The high-voltage electrode 2 is sealed and connected with the air intake seat 4, and is connected with the high-voltage electrode 1; the air intake hole 3 is opened on the air intake seat 4 or adopts other air intake types; the air intake seat 4 is sealed and connected with the high-voltage electrode 2, and the inner side is connected with the The barrier medium 5 is sealed and connected; the inside of the barrier medium 5 is the high-voltage electrode 2, and the upstream is sealed and connected with the air intake seat 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com