Nitric acid loop oxidation device and selective oxidation of dimethyl nitrobenzene in device

A technology of dimethylnitrobenzene and oxidation device, which is applied in the field of environmental protection and safety production, and can solve problems such as COD increase, production safety cannot be guaranteed, and product yield reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

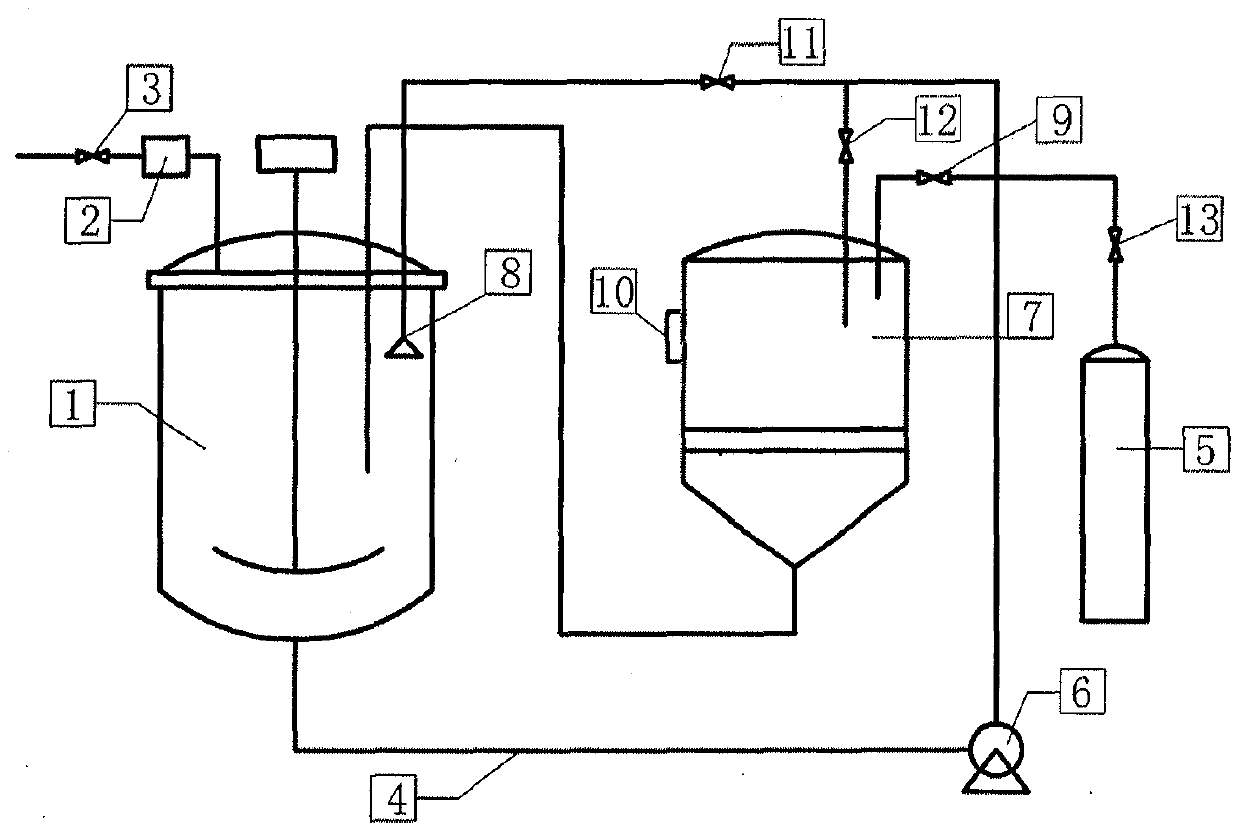

Method used

Image

Examples

Embodiment 1

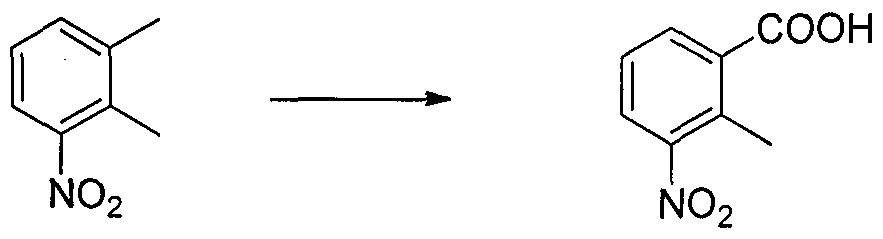

[0022] Embodiment 1, 3-nitro o-xylene oxidation preparation 3-nitro-2-methylbenzoic acid

[0023]

[0024] Put 400 kilograms of 30% nitric acid, 25 grams of catalyst and 100 kilograms of 3-nitroxylene raw materials into a 1000L reactor, heat up to 110°C-120°C, wait until the pressure of the reactor rises to 0.3MPA, turn on the circulation pump, and the mixture Pour into a 200-liter separation tank. When the liquid level in the separation tank reaches a certain height, the controller closes valve 2 and opens valve-1, so that the liquid directly flows back to the reactor, and the system forms an internal cycle. Open the gas valve -3, adjust the pressure of air or oxygen at 0.4MPA, the liquid in the separation tank and air or oxygen are pressed into the reaction kettle, the excess gas is released from the pressure relief valve, and the liquid in the separation tank is emptied Finally, the controller automatically opens valve-2, closes valve-1, and so on. After 15 hours of reac...

Embodiment -2

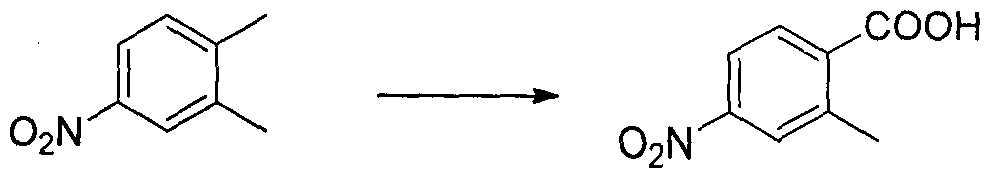

[0025] Example-2, 4-Nitro-o-xylene Oxidation Preparation of 4-Nitro-3-Methylbenzoic Acid

[0026]

[0027] Put 500 kilograms of 20% nitric acid, 25 grams of catalyst and 100 kilograms of 4-nitro-o-xylene raw materials into a 1000L reactor, heat up to 110°C-120°C, and wait until the pressure of the reactor rises to 0.3MPA, turn on the circulation pump, The mixture is poured into a 200-liter separation tank. When the liquid level in the separation tank reaches a certain height, the controller closes valve 2 and opens valve-1, so that the liquid flows back directly to the reactor, and the system forms an internal cycle. Open the gas valve-3, adjust the pressure of air or oxygen at 0.4MPA, the liquid in the separation tank and air or oxygen are slowly pressed into the reaction kettle, the excess gas is released from the pressure relief valve, and the liquid in the separation tank is discharged After emptying, the controller automatically opens valve-2 and closes valve-1, and th...

Embodiment -3

[0028] Example-3 Preparation of 3-methyl-4-nitrobenzoic acid by oxidation of 4-nitro-m-xylene

[0029]

[0030]Put 400 kilograms of 30% nitric acid, 25 grams of catalyst and 100 kilograms of 4-nitro-m-xylene raw materials into a 1000L reactor, heat up to 110°C-120°C, wait until the pressure of the reactor rises to 0.3MPA, turn on the circulation pump, The mixture is poured into the 200-liter separation tank. When the liquid level of the separation tank reaches a certain height, the controller closes the valve-2 and opens the valve-1, so that the liquid directly flows back to the reactor, and the system forms an internal cycle. Open the gas valve -3, adjust the pressure of air or oxygen at 0.4MPA, the liquid in the separation tank and air or oxygen are pressed into the reaction kettle, the excess gas is released from the pressure relief valve, and the liquid in the separation tank is emptied Finally, the controller automatically opens valve-2, closes valve-1, and so on. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com