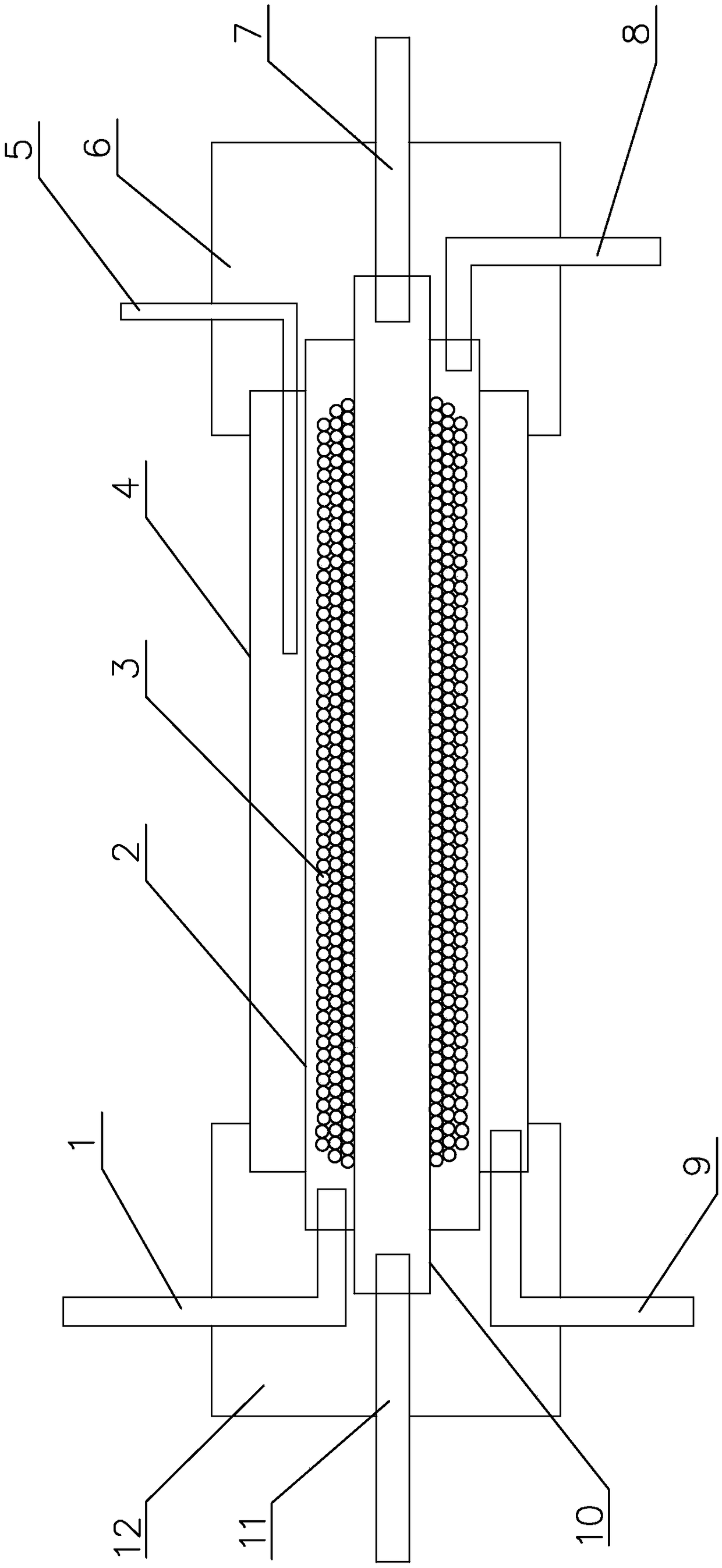

Preparation method for oxygen permeation-hydrogen permeation-reaction three-effect tubular membrane reactor for partial methane oxidation hydrogen production

A technology of reactor and oxygen-permeable membrane, which is applied in the field of preparation of oxygen-permeable-hydrogen-permeable-reaction three-effect tubular membrane reactor, which can solve the problem that product separation cannot be carried out simultaneously in the same reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

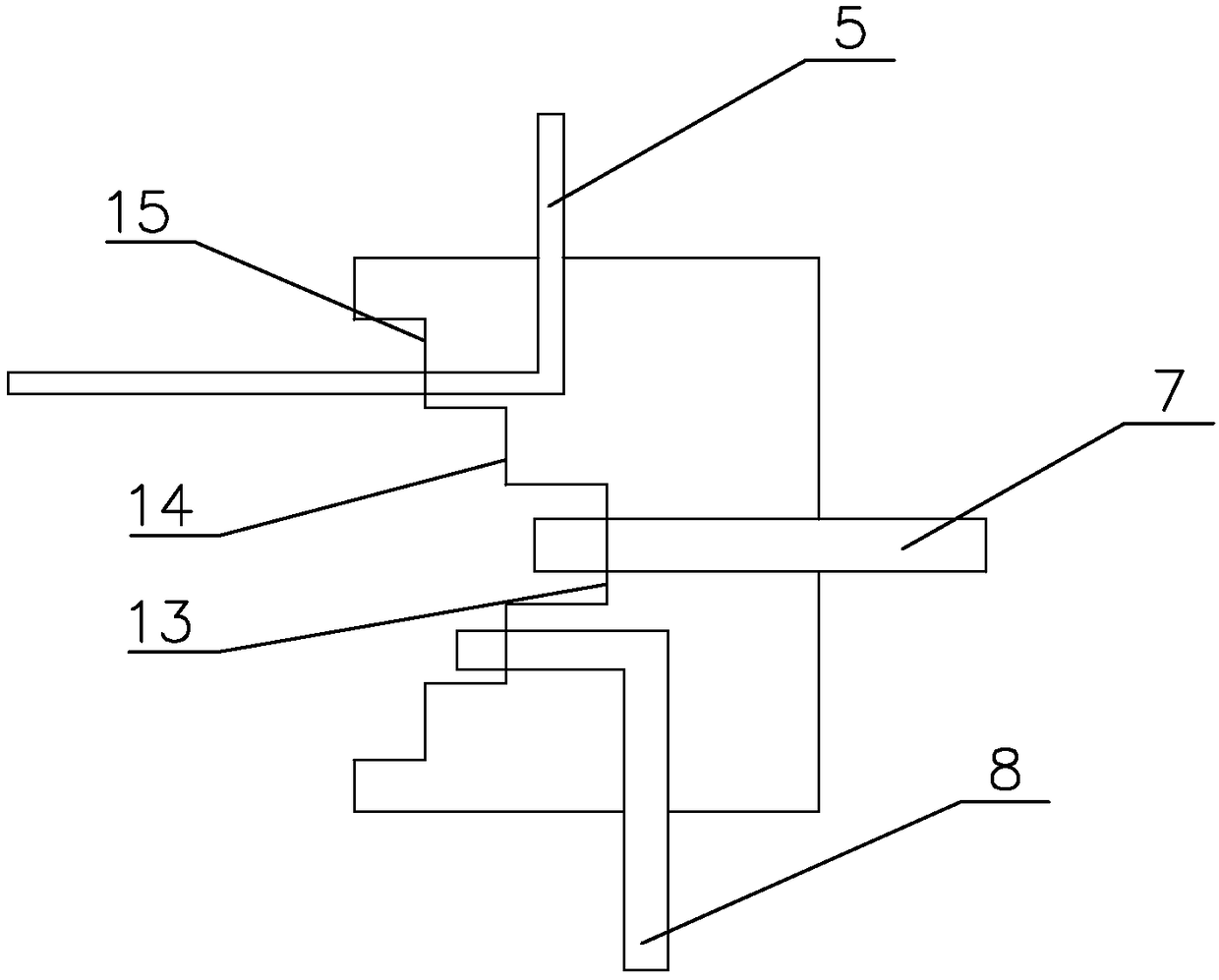

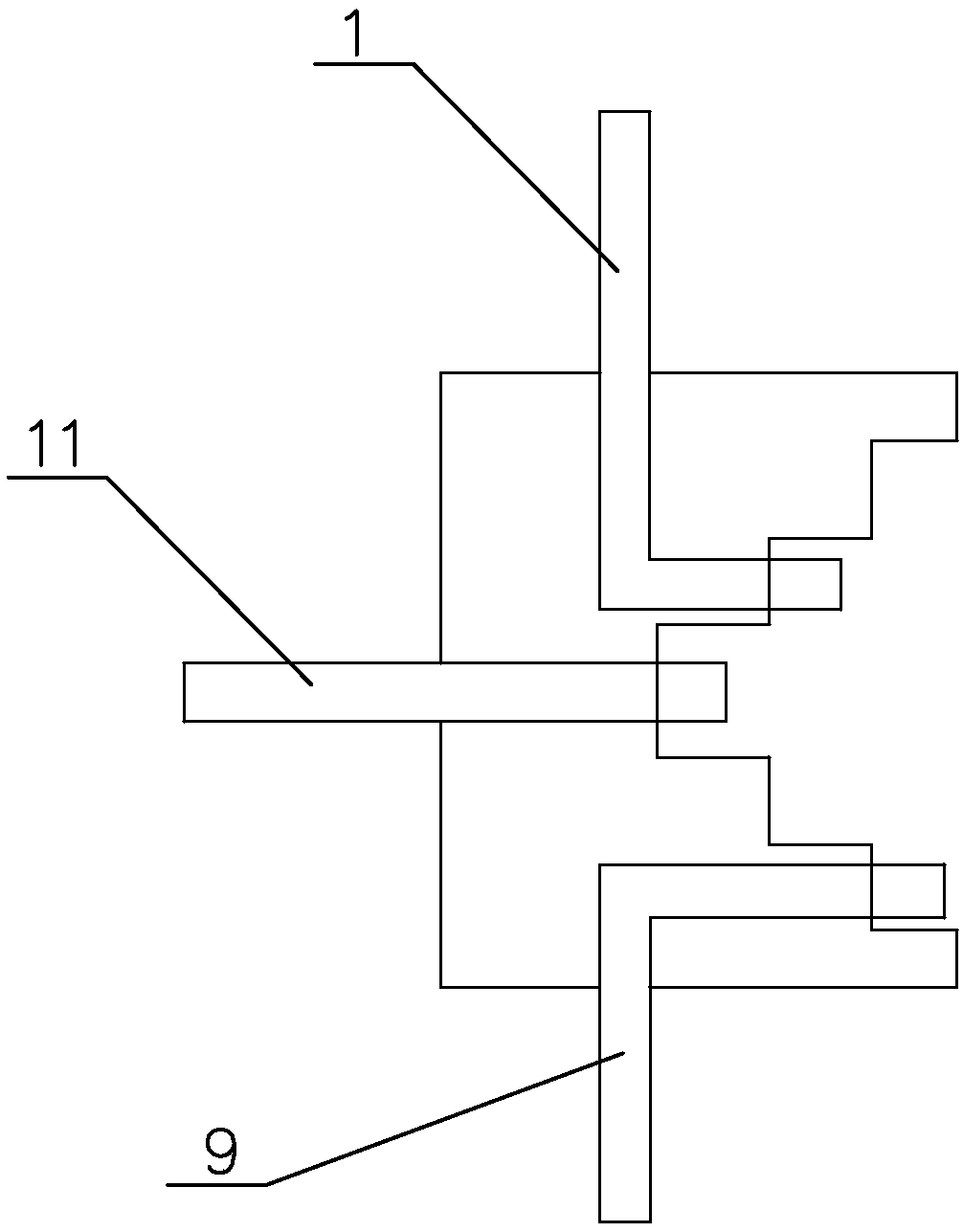

Embodiment 1

[0043] 100g La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 (LSCF) ceramic powder and 100g SrCe 0.9 Y 0.1 o 3 (SCY) ceramic powders are ball-milled and dispersed on a ball mill, passed through a 200-mesh sieve, and dried in an oven at 100°C; the dried LSCF ceramic powders and SCY ceramic powders are respectively added to 60g of 20wt.% polyethersulfone formazan In the base pyrrolidone solution, fully stir and disperse to obtain two kinds of film-forming liquids; extrude the film-forming liquids through an extruder and dry naturally to obtain LSCF tubular ceramic oxygen-permeable membrane blanks and SCY tubular ceramic hydrogen-permeable membrane blanks; and then The LSCF tubular ceramic oxygen-permeable membrane body was heated up to 1350°C at a heating rate of 5°C / min in a box-type high-temperature resistance furnace, kept for 5 hours, then cooled to 800°C at a cooling rate of 5°C / min, and then naturally cooled to room temperature , to obtain a LSCF tubular dense ceramic oxygen-permeab...

Embodiment 2

[0051] According to the method of Example 1, LSCF tubular dense ceramic oxygen permeable membrane and SCY tubular dense ceramic hydrogen permeable membrane were prepared.

[0052] The LSCF ceramic powder and the SCY ceramic powder with a mass ratio of 1:1 were used to prepare the catalyst carrier according to the method of Example 1 by physical mixing method; After calcining at 900°C for 4 hours, ball milling for 2 hours, and sieving with a 150-mesh sieve, the catalyst precursor was obtained, and then passed into H 2 The mixed gas of hydrogen and helium with a volume fraction of 5% was reduced at 800° C. for 4 hours to obtain a supported metal nickel catalyst.

[0053] The oxygen permeation-hydrogen permeation-reaction three-effect tubular membrane reactor for LSCF / SCY partial oxidation of methane to hydrogen was prepared according to the method in Example 1.

Embodiment 3

[0055] According to the method of Example 1, LSCF tubular dense ceramic oxygen permeable membrane, SCY tubular dense ceramic hydrogen permeable membrane and supported metal nickel catalyst were prepared.

[0056] Use concentrated hydrochloric acid to corrode and roughen the outer surface of the LSCF tubular dense ceramic oxygen permeable membrane and the inner surface of the SCY tubular dense ceramic hydrogen permeable membrane, increase the nickel catalyst and LSCF tubular dense ceramic oxygen permeable membrane, SCY tubular dense ceramic hydrogen permeable membrane The contact area also increases the gas transmission rate. Then, according to the method of Example 1, an oxygen permeation-hydrogen permeation-reaction three-effect tubular membrane reactor for LSCF / SCY partial oxidation of methane to hydrogen was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com