Catalytic ozonation reactor for sewage treatment and sewage circulation treatment method

A technology of ozone catalytic oxidation and sewage treatment, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problem of poor flow of sewage, affecting the efficiency of catalytic oxidation reaction, and blockage of pores at the top of the catalyst bed and other issues to achieve the effect of improving oxidation efficiency, reducing waste and speeding up the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

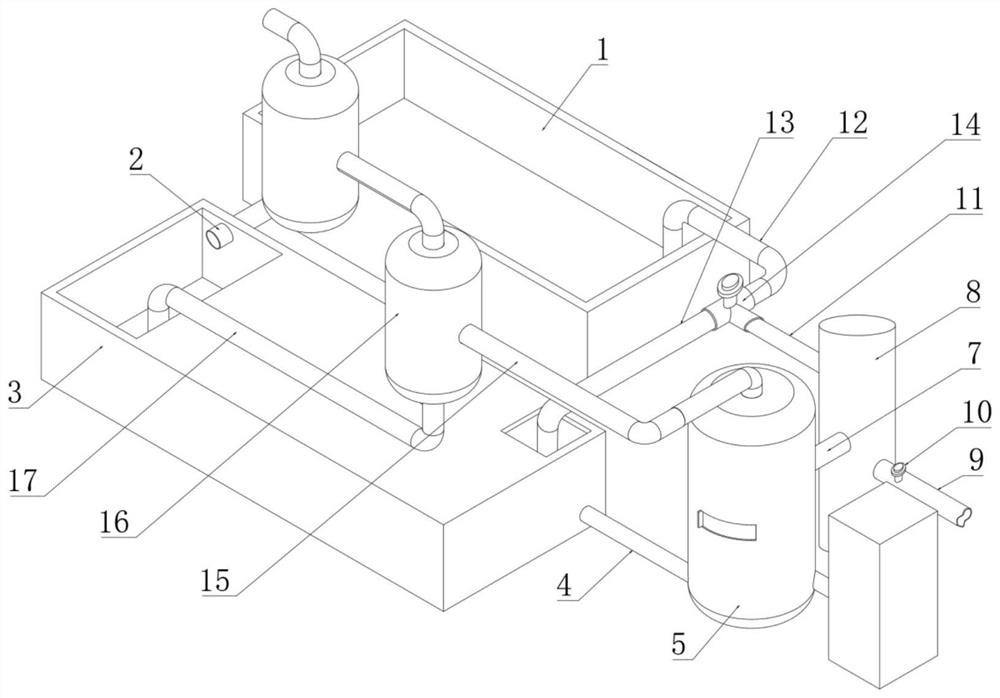

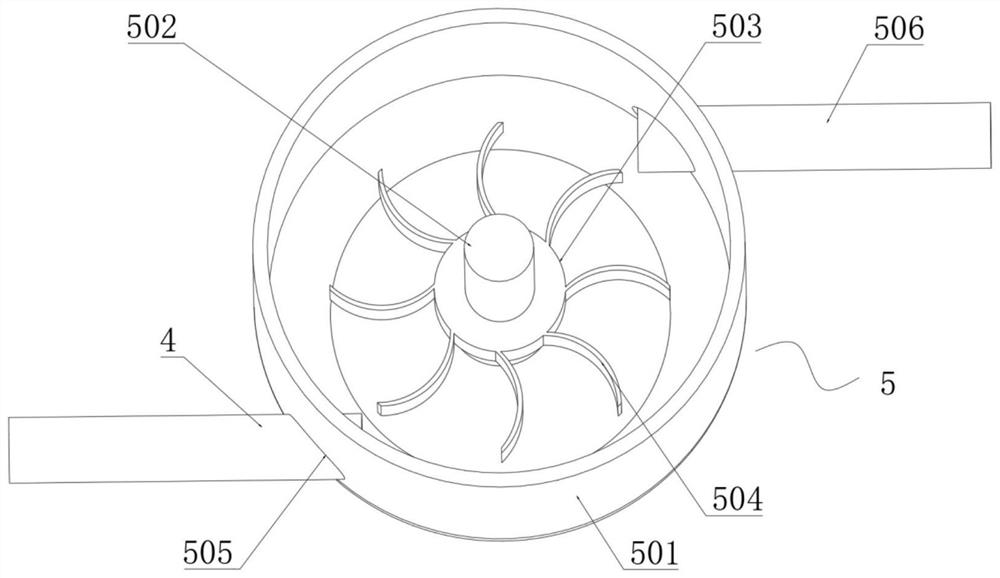

[0041] Such as Figure 1-4 As shown, the present invention provides a technical solution, an ozone catalytic oxidation reactor based on sewage treatment, including a sedimentation coagulation tank 1, the side end of the sedimentation coagulation tank 1 is embedded with a connecting pipe 2, and one end of the connecting pipe 2 is installed There is a pretreatment pool 3, a water inlet pipe 4 is installed at the side end of the pretreatment pool 3, and an ozone catalytic oxidation reaction component 5 is installed at one end of the water inlet pipe 4;

[0042] The ozone catalytic oxidation reaction assembly 5 includes a reaction cylinder 501, a rotating shaft 502, a connecting ring 503, a stirring blade 504, a connecting hole 505, an ozone inlet pipe 506, a rotating ring 507, a limiting net 508 and a dredging plate 509;

[0043]A reaction cylinder 501 is installed at one end of the water inlet pipe 4, and a rotating shaft 502 is installed inside the reaction cylinder 501 through...

Embodiment 2

[0050] The present invention provides a technical solution, a sewage circulation treatment method, the gas produced by the catalytic oxidation reaction of the reaction cylinder 501 is transported from the gas delivery pipe 15 to the inside of the gas floating sink 16, and the undissolved ozone with a large molecular weight sinks in the gas floating sink 16 bottom, and enter the pretreatment tank 3 through the gas return pipe 17, and the sewage in the pretreatment tank 3 contacts and reacts with ozone for pretreatment.

[0051] After the sewage is catalyzed and oxidized by ozone, it enters the inside of the detection cylinder 8 through the outlet pipe 7 at the top of the reaction cylinder 501. If the content of suspended solids in the detection cylinder 8 exceeds 30.0 mg / l, close the check valve 10 and turn it three times. Through the valve 14, the detection cylinder 8 is connected to the sedimentation coagulation tank 1, and the sewage enters the sedimentation coagulation tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com