Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Niter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niter, or nitre (chiefly British), is the mineral form of potassium nitrate, KNO₃, also known as saltpeter or saltpetre. Historically, the term niter was not well differentiated from natron, both of which have been very vaguely defined but generally refer to compounds of sodium or potassium joined with carbonate or nitrate ions.

Method for producing byproduct gypsum of niter-sulfur-based compound fertilizer by decomposing phosphorite with nitric acid

ActiveCN102126740ARealize comprehensive utilizationHigh removal rateCalcium/strontium/barium sulfatesFertilizer mixturesDecompositionNiter

The invention discloses a method for producing byproduct gypsum of a niter-sulfur-based compound fertilizer by decomposing phosphorite with nitric acid, which belongs to the technical field of production of compound fertilizers. The method comprises the following steps of: decomposing phosphorite with nitric acid; removing acid non-soluble substances and organic suspended matters by filtering; adding purified acid hydrolysis liquid into industrial ammonium sulfate or sulfuric acid to remove calcium; filtering to obtain a calcium-removed byproduct, namely high-purity gypsum; and producing the niter-sulfur-based compound fertilizer by using calcium-removed acid hydrolysis liquid. By adopting the method, calcium is removed from the acid hydrolysis liquid used in decomposition of the phosphorite with nitric acid by using ammonia sulfate or sulfuric acid, other impurity ions are not introduced, and ammonia in ammonia sulfate is kept in a finished product during calcium removal with the ammonia sulfate; and the removing rate of calcium in the acid hydrolysis liquid reaches above 95 percent.

Owner:KINGENTA ECOLOGICAL ENG GRP

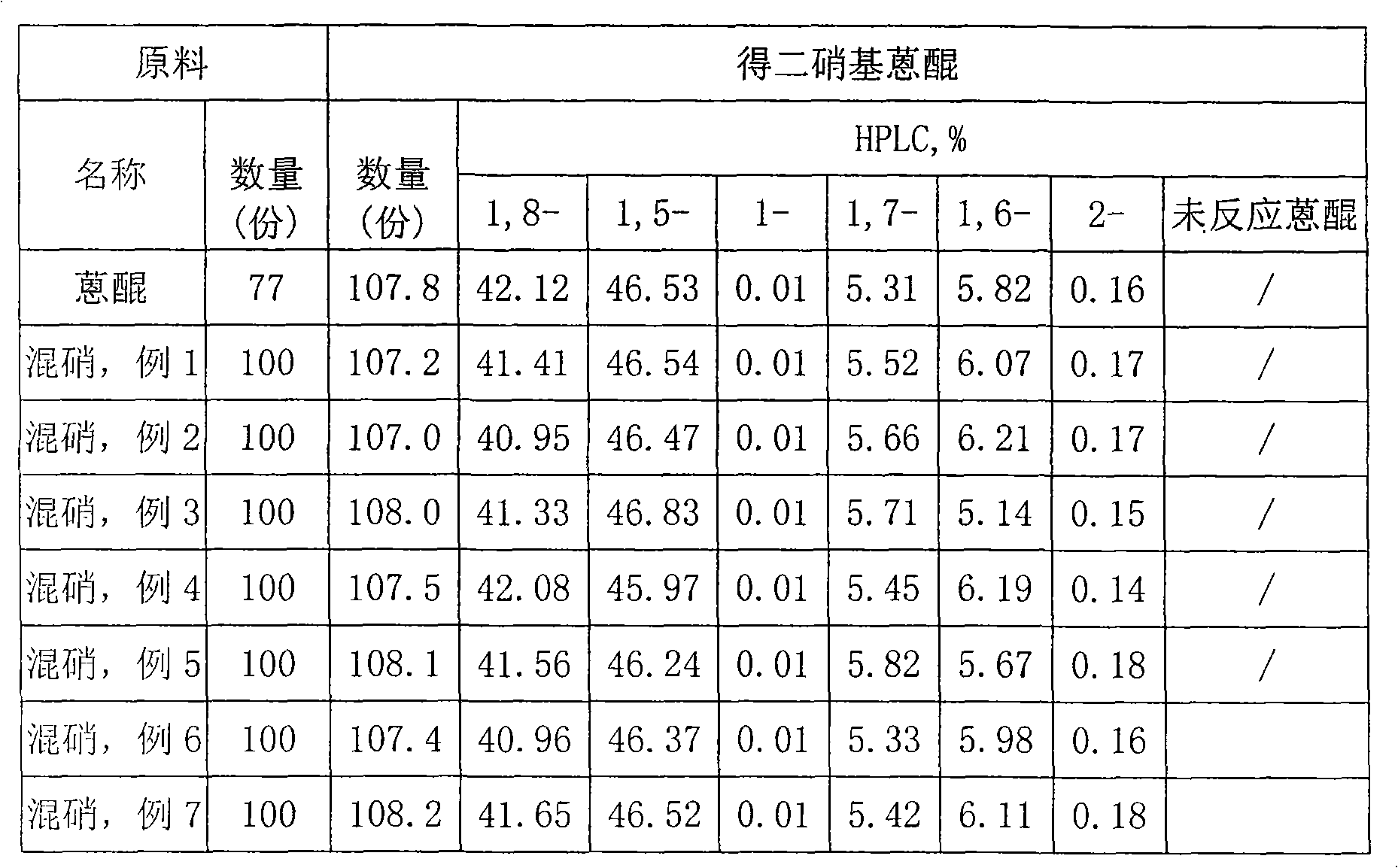

Method for treating waste residue for producing 1-aminoanthraquinone into raw material for producing 1,5(1, 8)-dinitroanthraquinone

InactiveCN101591249ASolve the problem of resource utilizationSimple processOrganic compound preparationNitro compound preparationEconomic benefitsNitration

The invention discloses a method for treating waste residue for producing 1-aminoanthraquinone into a raw material for producing 1,5(1, 8)-dinitroanthraquinone. The method treats and removes isomer containing beta-nitroanthraquinone in the waste residue for producing the 1-aminoanthraquinone to obtain mixed nitroanthraquinone (mixed niter for short), and the mixed niter mainly contains the 1,5(1, 8)-dinitroanthraquinone and the 1-aminoanthraquinone and can be used as the raw material for producing the 1,5(1, 8)-dinitroanthraquinone. The method comprises the following steps: crushing 100 portions by mass of dry waste residue for producing the 1-aminoanthraquinone into powder, adding 400 to 500 portions by mass of sulfuric acid or nitric acid into the powder, heating the mixture to between 50 and 65 DEG C, stirring the mixture for 1 to 2 hours, and filtering, washing and drying the mixture to obtain the mixed niter which can be directly used as the raw material for producing the 1,5(1, 8)-dinitroanthraquinone, wherein the 1,5(1, 8)-dinitroanthraquinone can be produced through dinitration reaction of anthraquinone according to the method of CN101423477A, and bulk commodity dye disperse blue 2BLN (C.I. disperse blue 56) is further produced. The method has simple process; and the obtained product has stable quality and obvious economic benefit.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

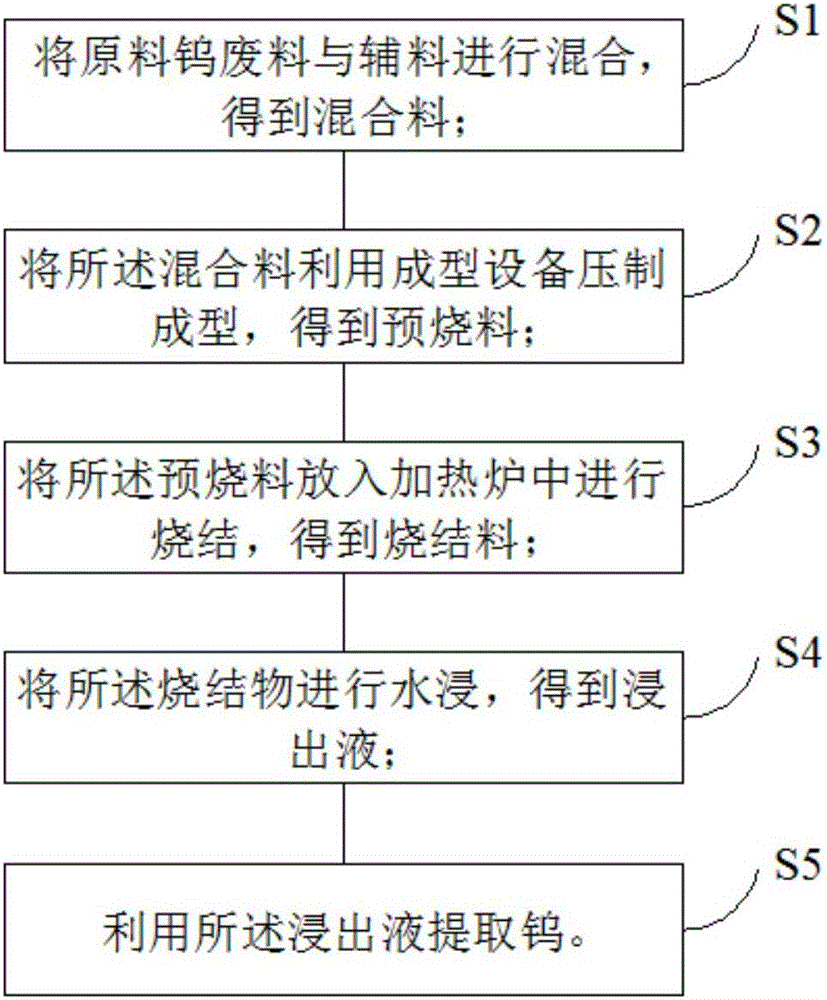

Process for extracting tungsten by tungsten wastes

InactiveCN106756032AImprove conversion rateReduce contentProcess efficiency improvementPregnant leach solutionSodium tungstate

The invention provides a process for extracting tungsten by tungsten wastes. The process comprises the following steps: raw materials-tungsten wastes are mixed with accessories to obtain a mixture; the mixture is pressed by forming equipment to obtain a pre-burnt material; the pre-burnt material is put in a heating furnace for sintering to obtain a sintered material; the sintered material is dipped in water to obtain leaching liquid; the leaching liquid is used for extracting tungsten; the method uses the tungsten wastes as the raw materials, and uses soda, caustic soda flakes and niter as the accessories; the content of the raw materials is 45-60%; and the content of the accessories is 40-55%. The process is high in generation quantity of sodium tungstate in the sintered material through the matching ratio and the chemical components of the raw materials, extracts pure compounds of tungsten to reduce the content of insoluble tungsten in the sintered material so as to improve the conversion ratio of tungsten through a sintering process, a water leaching process and an extracting process, can reach the conversion ratio of tungsten above 98%, and controls the content of insoluble tungsten within 0.5%.

Owner:HUNAN SHUNTAI TUNGSTEN IND

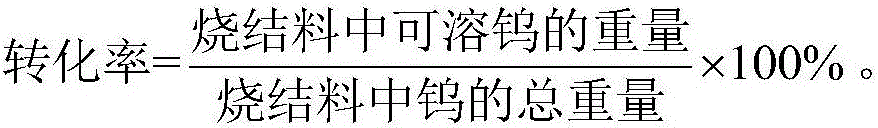

Method for preparing sodium nitrate with soda niter

ActiveCN101343072ABlocked mobilityGuaranteed liquidityEnergy inputAlkali metal nitrate preparationEvaporationNiter

The invention provides a method for using nitratine to produce sodium nitrate, which is characterized in that the method comprises the steps of: crushing a piece of nitratine raw ore, and sieving the raw ore to obtain nitratine ore and nitratine ore powder; adding water into the nitratine ore powder, and agitating and leaching the powder and then gaining a clear liquid by sedimentation and clarification; positioning the nitratine ore in a leaching pond, feeding a mother liquor for cold separation and / or a washing liquid, starting up a circulating pump to circulate the leaching solution, and leaching the ore under normal temperature; inputting the leaching solution to a solar pond after the leaching; heating the leaching solution to a temperature between 30 DEG C and 80 DEG C by utilizing the stored energy in the solar pond, and extracting high-temperature concentrated solution from the bottom of the solar pond after evaporation concentration; and separating out NaNO3 through crystallization by cooling. The method is applied to low grade nitratine resources, and locations of resources are areas short of water seriously and rich in solar energy resources, and the method has advantages of energy and water saving and easy realization.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

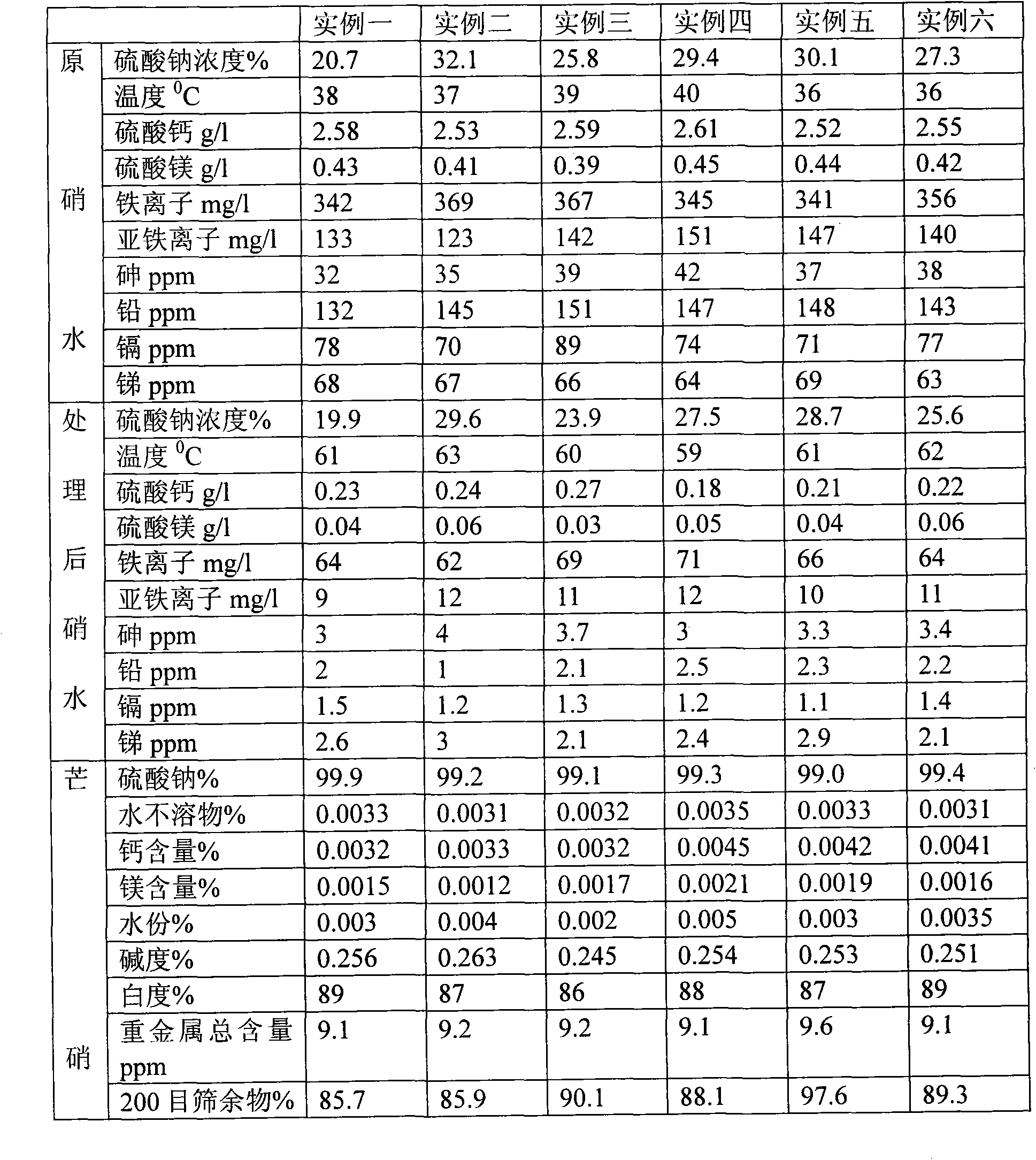

Method for preparing special mirabilite with high purity

The invention provides a method for preparing special mirabilite with high purity, which comprises the following steps: pumping hot water at 40 DEG C-70 DEG C by a pump and dissolving mirabilite in ore to form niter water containing various impurities; calculating the content of added sodium carbonate with the excess of 10 percent-20 percent according to the detected content of calcium and magnesium ions in the original niter water during chemical impurity removal processing; calculating the content of added sodium sulfide with the excess of 20 percent-30 percent according to the detected content of heavy metal ions including ferrum, arsenic, lead, cadmium, antimony, and the like in the original niter water; then adding sodium hydroxide to lead the pH value of the niter water to reach 9-11; adding 0.1-0.3 percent by weight of polyferric sulfate and polyaluminum-ferric chloride sulfate to enable various generated sediments to settle; and finally adding sulfuric acid to adjust the pH value of the niter water to reach 7-7.5. The wet niter containing crystal water is processed by a fluidized bed after standing at 45 DEG C-80 DEG C for 0.5 hour-3 hours in a heat preservation way, thereby obtaining anhydrous special mirabilite with high purity. The mirabilite can not be caked during long-term placement at room temperature and can be widely applied to industries of foods, medicines, and the like.

Owner:四川川眉特种芒硝有限公司

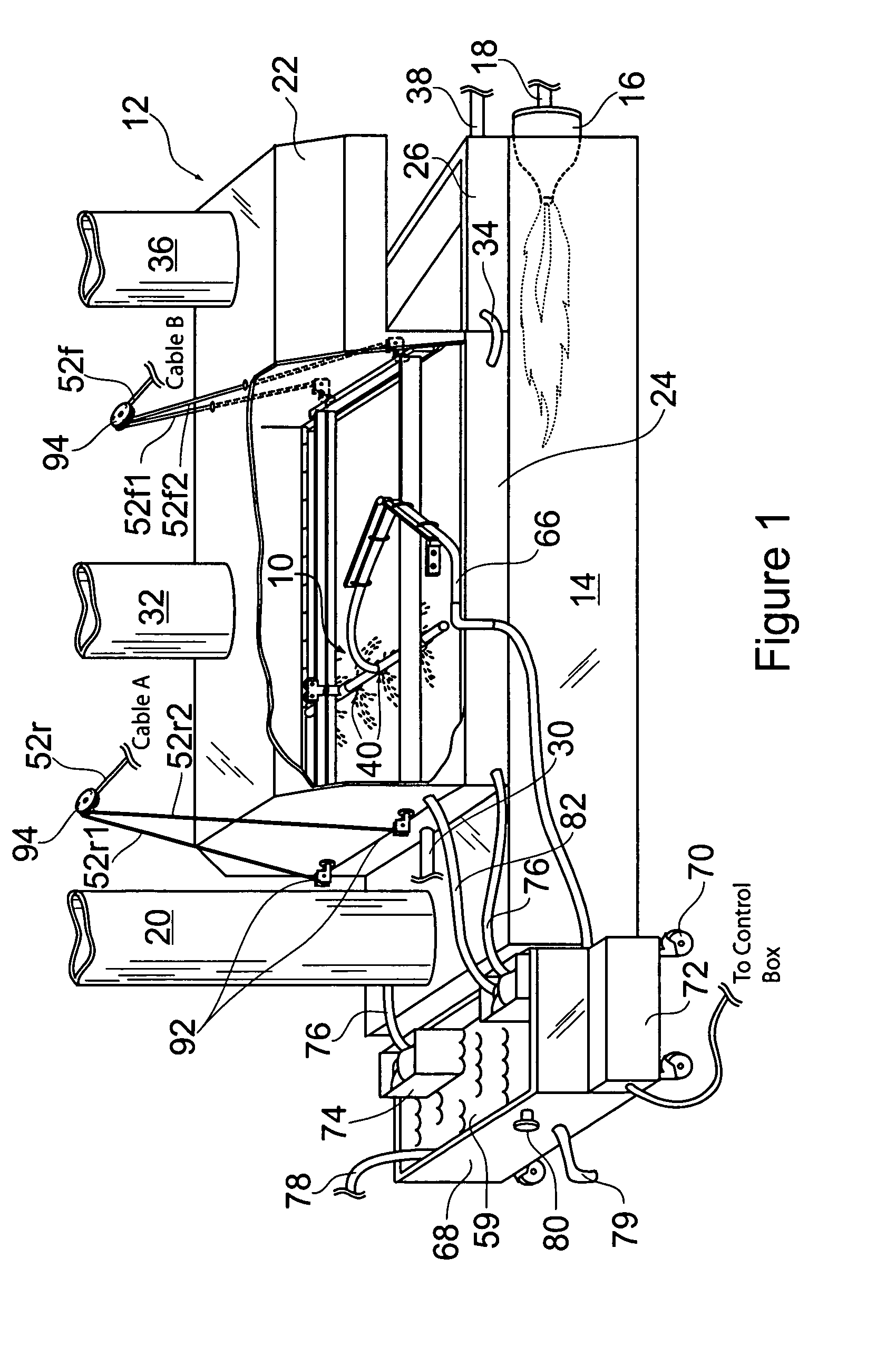

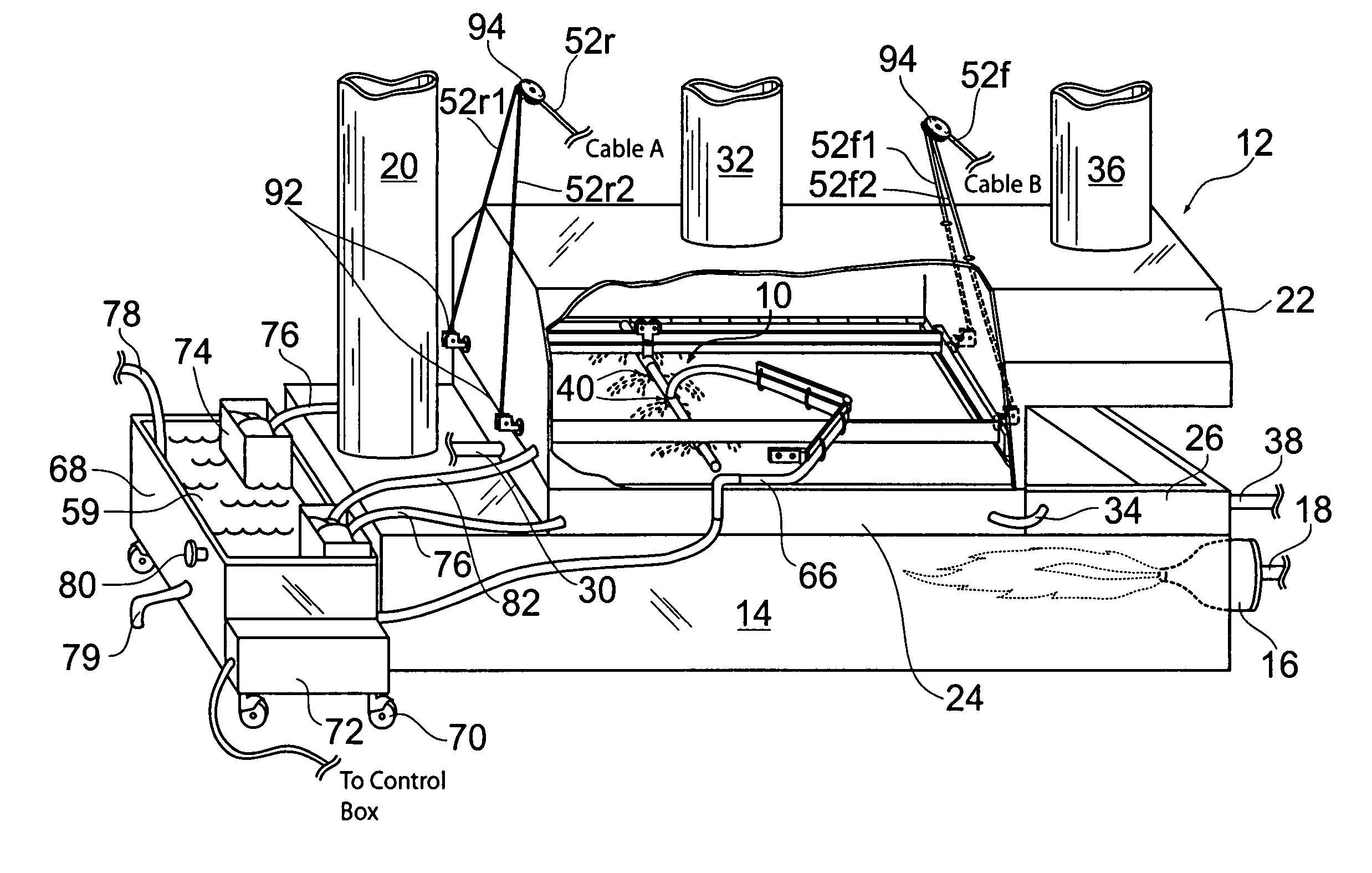

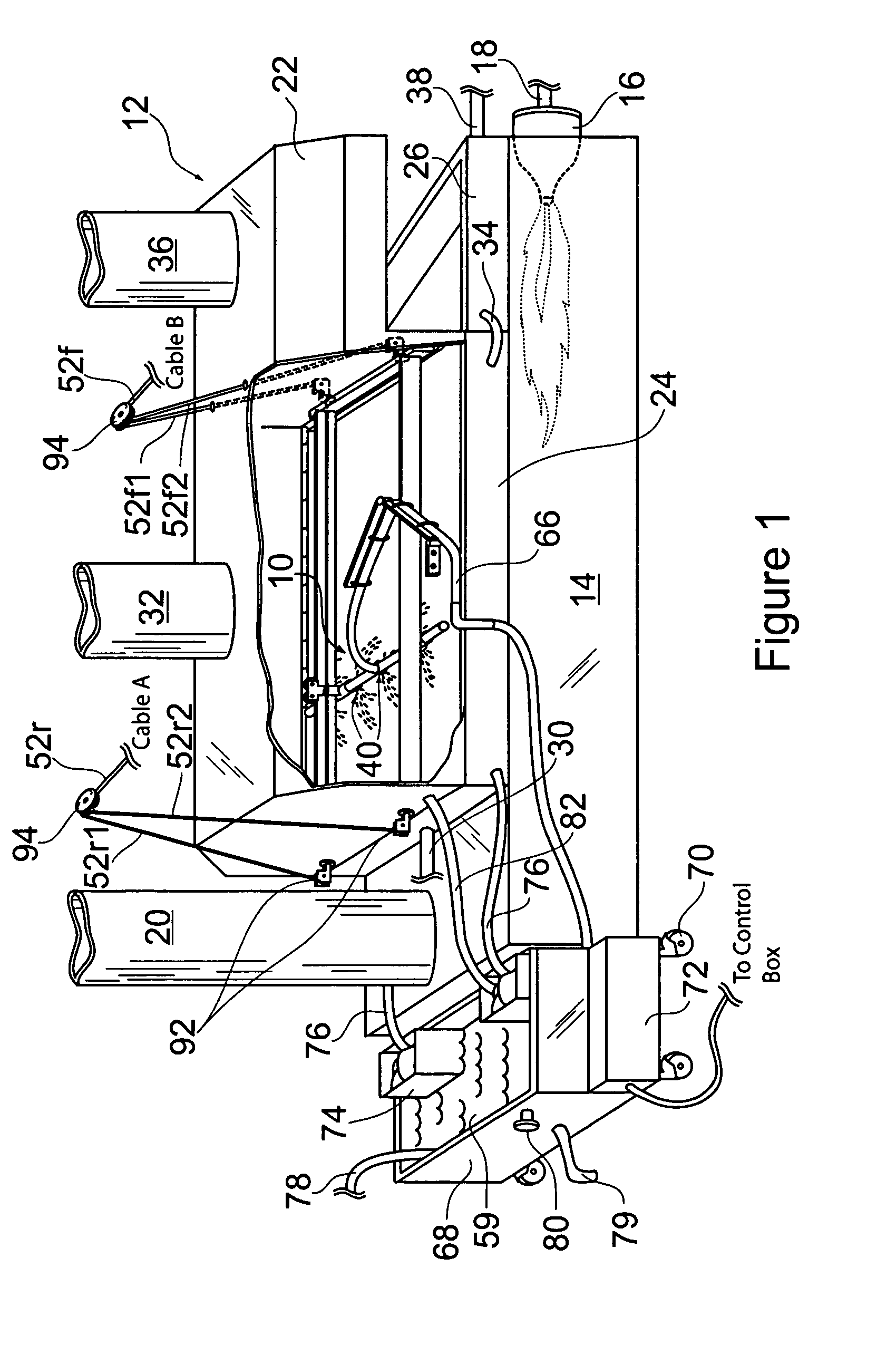

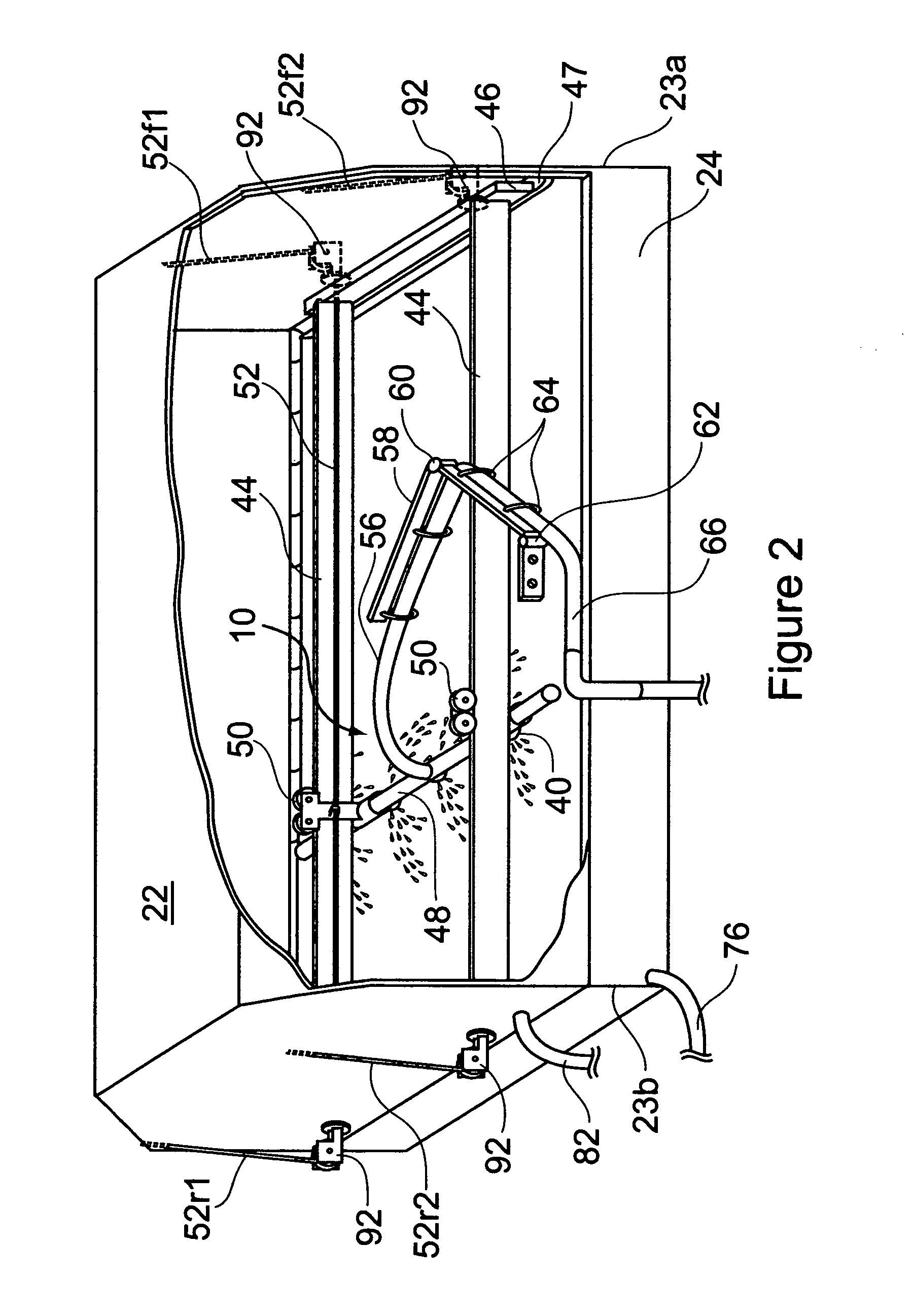

Flue pan washer for maple sugar evaporator

InactiveUS20080029129A1Pressurized chemical processBoiler cleaning apparatusSpray nozzlePulp and paper industry

The present invention is directed to an automatic washer system mounted within a maple sugar evaporator above the rear flue pan for removing niter and sediment built up during the boiling of sap. The evaporator comprises a furnace, a steam hood, a pan and a nozzle for washing the pan. The steam hood extends over the furnace. The pan is mounted to the furnace and under the steam hood. The nozzle is mounted over the pan. Cleaning fluid is sprayed from the nozzle to clean the pan by an automated process.

Owner:MANN DAVID SHRADER

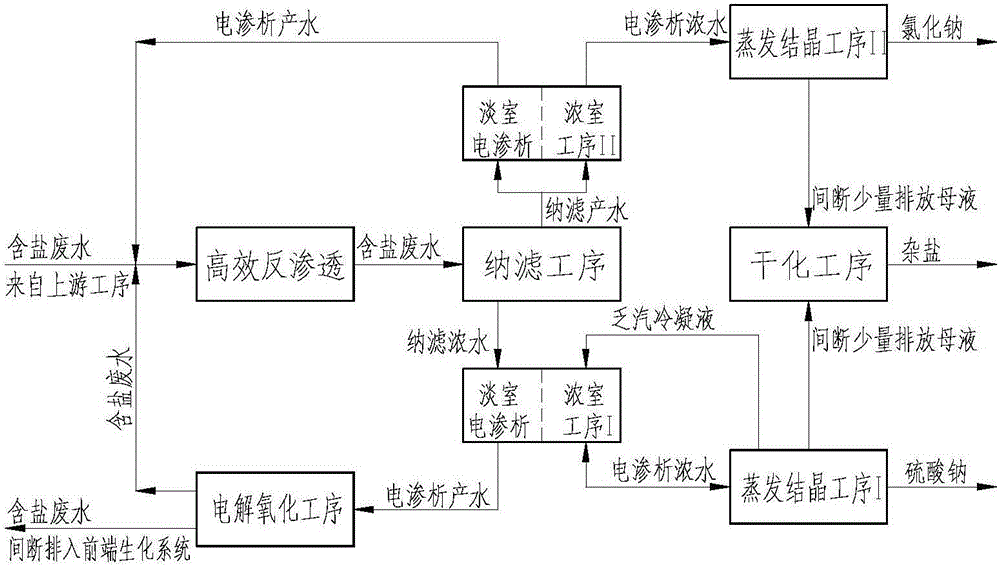

Method for separating organic matter impurities from brine waste of coal chemical industry and separating salt by utilizing membrane method

InactiveCN106830481AAchieve separationAvoid disadvantages such as low purityWater treatment parameter controlMultistage water/sewage treatmentReverse osmosisWater quality

The invention discloses a method for separating organic matter impurities from brine waste of a coal chemical industry and separating salt by utilizing a membrane method. The method comprises the following steps: (1) efficient reverse osmosis process; (2) nanofiltration process; (3) electroosmosis process I; (4) evaporative crystallization process I; (5) electrolytic oxidation process; (6) electroosmosis process II; and (7) evaporative crystallization process II. The invention abandons the traditional scheme for separating the salt in the manner of high-quality crystal separation through freezing crystallization or thermal method at the rear end and adopts a nanofiltration membrane process for separating the salt. The selective permeability of the nanofiltration membrane for ions under different valence states is utilized to separate the two main components, namely, sodium chloride and sodium sulfate in the waste water. The defects that the water quality change cannot be coped with and the product purity is low in the traditional salt niter separation hot-process crystallizing scheme can be overcome.

Owner:EAST CHINA ENG SCI & TECH

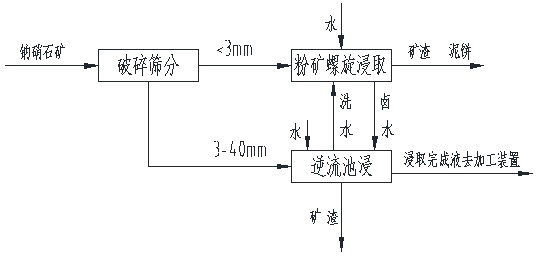

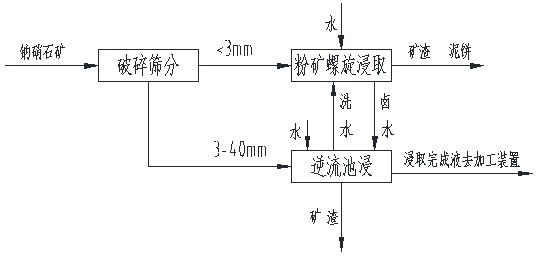

Process for producing sodium nitrate from soda niter in size-fraction leaching manner

InactiveCN102689912ASmooth circulationImprove mass transfer effectAlkali metal nitrate preparationSludgeFilter press

The invention relates to a process for producing sodium nitrate from soda niter in a size-fraction leaching manner. The process comprises the following steps of: (1) crushing and sieving ores; (2) leaching grain ores; (3) leaching ore fines; and (4) carrying out solid-liquid separation on sludge discharged by a spiral classifier of the step (3) by utilizing a plate-and-frame filter press, returning the obtained brine of 110-140g / L to an grain ore leaching pool for carrying out grain ore leaching to further concentrate; and producing mud cake and externally discharging the mud cake. The process for producing the sodium nitrate from the soda niter in the size-fraction leaching manner, disclosed by the invention, has the advantages of low water consumption, high leaching efficiency, high yield, high brine concentration and low cost, and is especially suitable for being applied to seriously hydropenic areas, such as Xinjiang.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN +1

Method for removing chromium during recycling sodium tungstate from waste tungsten

The invention discloses a method for removing chromium during recycling sodium tungstate from waste tungsten. The method comprises the following steps of: smelting the waste tungsten saltpeter with saltpeter to leach alkaline coarse sodium tungstate solution; keeping the temperature of the sodium tungstate solution between 60 and 90 DEG C under an alkaline condition; adding a proper amount of precipitating agent into the solution in a ratio of 10m<3> per 10 to 50 Kg; heating the solution and keeping the temperature under a condition of stirring for precipitation reaction; ensuring the pH of the sodium tungstate solution is more than 8.0 in the reaction process; stirring the solution and keeping the temperature for 2 to 10 hours; and finally, filtering the solution to remove chromium slag sediment generated by the reaction, and obtaining the qualified high-purity sodium tungstate solution. The method is simple in operation, large in processing capacity and simple in process flow, achieves a chromium removal rate up to 99 percent and a chromium loss rate less than 0.1 percent, is low in investment cost and suitable for industrialized production, can effectively remove impurity element chromium in the sodium tungstate solution, and meets the requirements of high-quality tungsten products.

Owner:XIAMEN TUNGSTEN

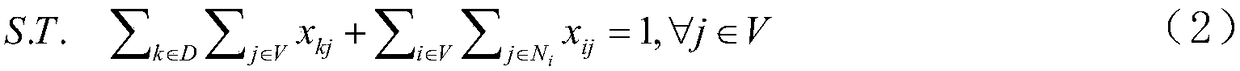

Vehicle scheduling algorithm based on human-vehicle binding mode

InactiveCN108960634AIncrease diversityAvoid the limitations of "short-sightedness"ResourcesAlgorithmReconstruction method

The invention provides a vehicle scheduling algorithm based on a human-vehicle binding mode. The vehicle scheduling algorithm is implemented by the steps of: (1) constructing a vehicle scheduling model, and solving the vehicle scheduling model to obtain a vehicle scheduling scheme; (2) regarding the vehicle scheduling scheme as an initial solution for a driver scheduling problem, and iteratively performing local search improvement; (3) introducing a destructive reconstruction method into the local search process for disturbing a current solution; (4) iteratively performing the step (2) and thestep (3) for Niter times, wherein Niter is a number of local search iterations; (5) iteratively performing the steps from (1) to (3) for Mstart times, wherein Mstart is a number of algorithm multiplestartup times; (6) improving a feasible shift chain obtained in the steps (2), establishing an SCP model, and acquiring a superior shift chain combination. The vehicle scheduling algorithm adopts theiterative local search algorithm, and introduces the destructive reconstruction method into the local search process for disturbing the current solution, thereby solving the problems of low labor efficiency of drivers, high driver cost, unbalanced driver tasks and possible increase of vehicle numbers in the traditional algorithm.

Owner:ZHENGZHOU TIAMAES TECH

Method for making covering layer of artificial stone for building

The invention is a manufacturing method of simulative stone overburden in structure, it includes producing model, confecting structure reinforcing steel bar, confecting simulative stone materials, concreting and demoulding, surface carving. It makes and fixes model according to the needed decorating sculpt, it sets reinforcing steel bar which is used as the framework of overburden, the niters are confected into concrete, the concrete are filled into model, demoulds it when it reaches the fixed intensity, then carves it according to the quality of natural stone.

Owner:凌小平

Flue pan washer for maple sugar evaporator

InactiveUS7794547B2Pressurized chemical processBoiler cleaning apparatusSpray nozzlePulp and paper industry

Owner:MANN DAVID SHRADER

Potassium nitrate preparing technology

InactiveCN101070167AWide variety of sourcesReduce manufacturing costAlkali metal nitrate purificationAlkali metal nitrate preparationSolubilityChemical reaction

The invention relates to a kind of technique field of inorganic chemical industry, which is a kind of preparation craft of niter. To solve such problems existing preparation craft of niter as that sources of raw material is restricted, production cost and energy consumption is high and quality of products is inferior, the invention uses potassium chloride and dilute nitric acid react to form potassium chloride, dilute nitric acid, niter and hydrochloric acid, take a great of hydrochloric acid and nitric acid out through distillation, then heat and concentrate them to make the mixture turn into saturated solution which becomes neutral when put into sodium carbonate and regulated, the solution reacts with surplus little hydrochloric acid and form sodium chloride at the same time. Finally, it separates niter out making use of different solubility of niter, sodium chloride and potassium chloride at the same temperature. Sources of raw material in this invention are extensive, the production cost is relatively low; Operations such as chemistry reaction, distillation and concentration are finished at the same reaction equipment, process of operation goes on under normal atmosphere and save investment of equipment; it is easy to operate and separate; get finished product using method of mechanism filter-pressing, it is simple to operate with little investment.

Owner:上海文通化工有限公司 +1

Method for preparing environment-protective acoustic-light colour firecrackers

InactiveCN101070258APromote safe productionTransportation safetyFirecrackersExplosivesHazardous substanceAcousto-optics

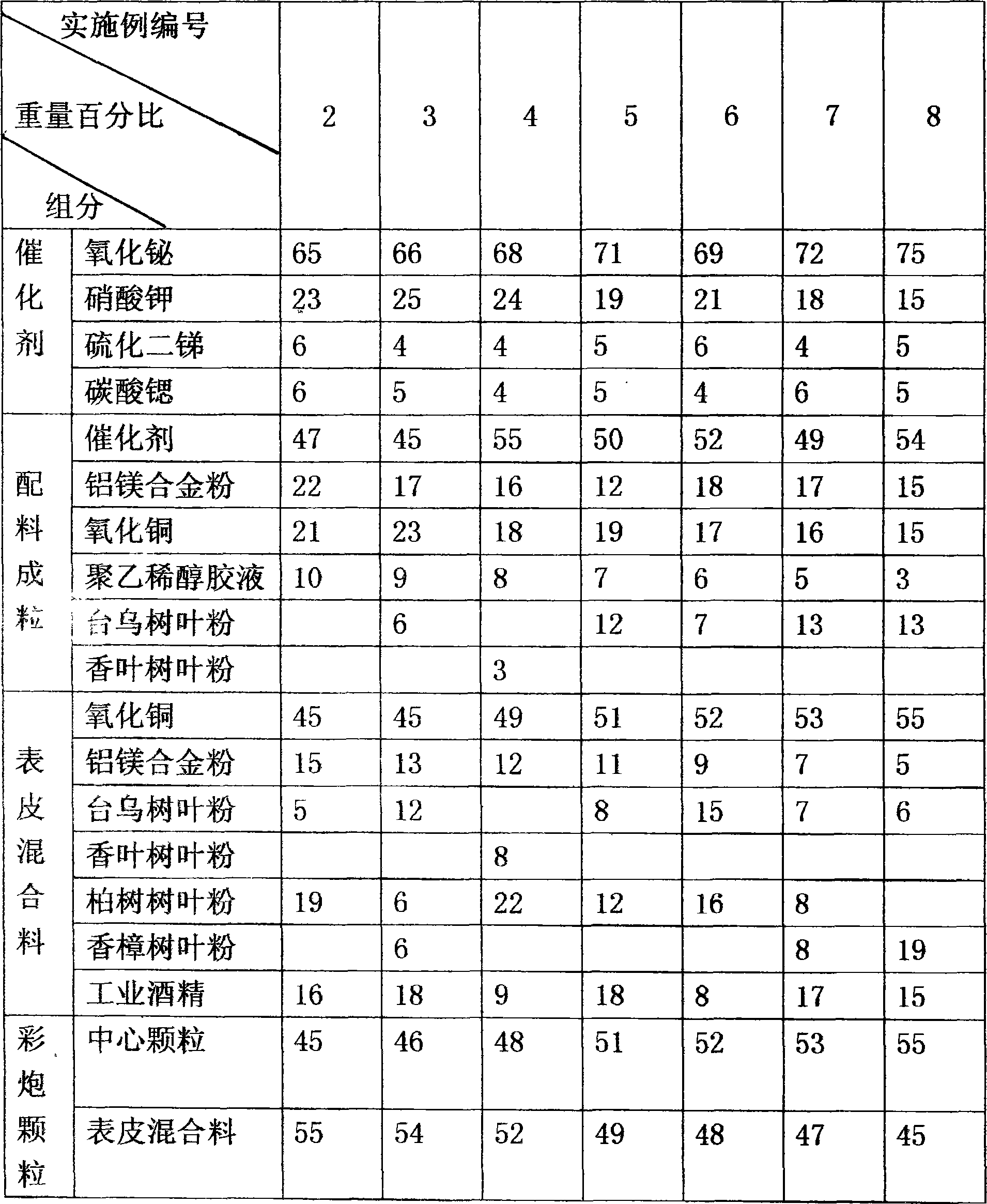

This invention relates to preparation method of a environmental-protecting acousto-optic firecrackers. The process: adopt bismuth oxide, niter, antimony sulfide, strontium carbonate, magaluma powder, PVA latices, Taiwu leaf powder or spoceleaf tree leaf powder as raw material to prepare centre particle; takes cupric oxide, magaluma powder, Taiwu leaf powder or spoceleaf tree leaf powder, cupric oxide, cypress leaf powder or yellow cinnamon leaf powder,industrial alcohol and so on as raw material to prepare coat composite; mix centre particle and coat composite to prepare color firecrackers particle; put color firecrackers in plastic film coat that has fuse to prepare product.

Owner:何明双

Alpha-biphenyl-N-alkyl nitrone compound and synthetic method thereof

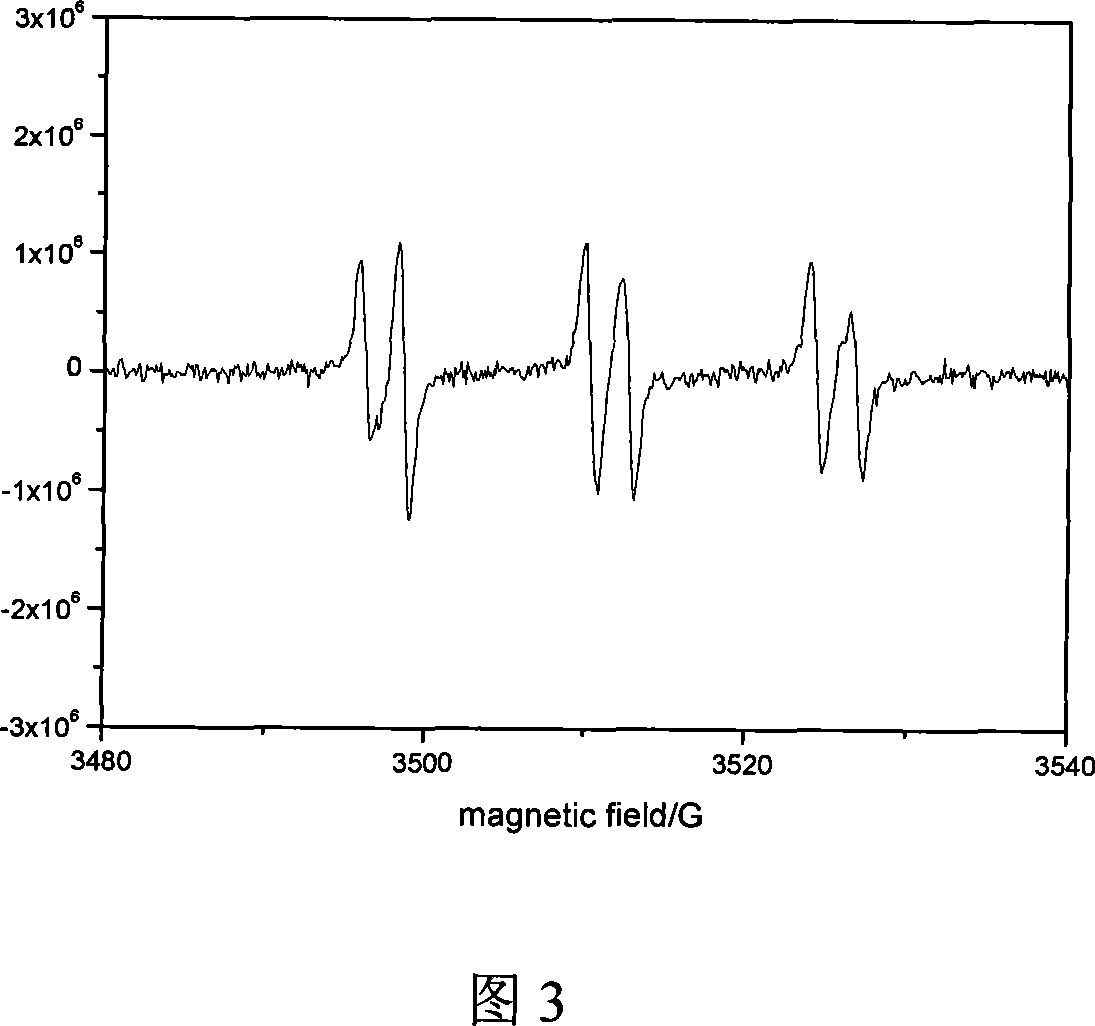

InactiveCN101225056AIncrease steric hindranceIncrease fat solubilityOximes preparationBenzaldehydeStructural formula

The invention discloses an alpha-xenyl-N-alkyl nitro ketones compound of which the structural formula is as shown in formula (I). The synthetic method is: first adding the benzene boric acid and the bromo benzaldehyde into the toluene which carry on the Suzuki coupling reaction to produce biphenyl formaldehyde under the existence of the potassium phosphate hydrate and the palladium catalyst. Then mixing the biphenyl formaldehyde, 2-nitryl-2- alkyl propane and zinc powder together in the ethyl alcohol, adding ethanoic acid, and put into the refrigerator for refrigeration, then separated for depuration. The alpha-xenyl-N-alkyl niter ketones compound connects aromatic group on the PBN benzene ring, and can increase the steric hindrance of the free radical addition atom and weaken the disproportionation extinguishment of the free radical addition compound or the enzyme catalyzed extinguishment inside the organism thus to increase the life of the free radical addition compound. The nitro alkone compound can be effective reagent for examining the free radicals in the lipin system like cell membrane.

Owner:ZHEJIANG UNIV

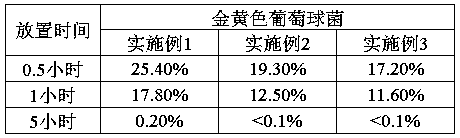

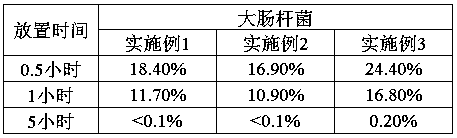

Antimicrobial red glaze and preparation and application methods thereof

The invention relates to antimicrobial red glaze used in a toilet. The antimicrobial red glaze comprises components of raw materials in parts by weight as follows: 25-30 parts of potassium feldspar, 19-24 parts of white mica, 4-7 parts of serpentine, 13-16 parts of talc, 8-11 parts of niter, 6-10 parts of manganese ore, 5-9 parts of kojic dipalmitate, 9-13 parts of kojic acid, 0.3-0.6 parts of sodium sulfite, 2-6 parts of pyroligneous acid, 2-4 parts of ferric chloride, 1-3 parts of lead oxide and 3-5 parts of copper oxide. The invention further relates to preparation and application methods of the glaze. A ceramic product which is prepared from the antimicrobial red glaze and has bright red glazing color is bright and stable in color and has an excellent decorative effect, an antimicrobial function and an inhibition effect on microbial growth and reproduction, the firing temperature is low, the energy-saving effect is good, and the production cost is greatly reduced.

Owner:潮州市乐盈弘陶瓷有限公司

Coal-burning energy releasing powder and its prepn

The present invention discloses one kind of coal-burning energy releasing powder and its preparation process. The coal-burning energy releasing powder consists of saltpeter 0.5-1.5 weight portions, ferric dicyclopentadiene or allyl cyanurate 1-2 weight portions, potassium permanganate or potassium bromide 0.3-0.7 weight portions, sodium nitrate or calcium nitrate 0.3-0.7 weight portions, potassium permanganate or potassium persulfate 1.5 -2.5 weight portions, strontium nitrate or sodium bichromate 0.5-1.5 weight portions, calcium fluoride 1.5-2.5 weight portions, coal slag or char slag 1.5-2.5 weight portions, loess or lime 1.5-2.5 weight portions, potassium chlorate or potassium persulfate 0.5-1.5 weight portions, potassium nitrate 0.5-1.5 weight portions, and sodium chloride 80-90 weight portions. It can promote combustion of coal to convert the latent energy of coal into heat completely.

Owner:张学义

Ferroniobium alloy production method

PendingCN112430756ANo pollution in the processReduce energy consumptionProcess efficiency improvementAl powderFerroniobium

The invention provides a ferroniobium alloy production method. The ferroniobium alloy production method comprises the steps of ferroniobium production through a thermite process and ferroniobium refining, wherein in the step of ferroniobium production through the thermite process, metallurgical grade niobium oxide, aluminum powder, iron oxide powder, lime, fluorite powder and saltpeter are mixed in proportion; the raw materials are put into a reactor and ignited to react to obtain ferroniobium alloy liquid, and the upper layer of the alloy liquid is a slag liquid layer; and in the refining step, an electrode is put into the slag liquid layer, the slag liquid layer is heated through an electric arc to keep flowing, aluminum powder is blown into slag liquid to promote the aluminum powder toreduce niobium elements in the slag liquid, and the niobium elements enter the alloy liquid. The thermite process and electric arc heating are used for spraying aluminum, energy consumption is low, the process is simple, the production period is short, and no pollution is caused to the environment.

Owner:CNMC NINGXIA ORIENT GRP

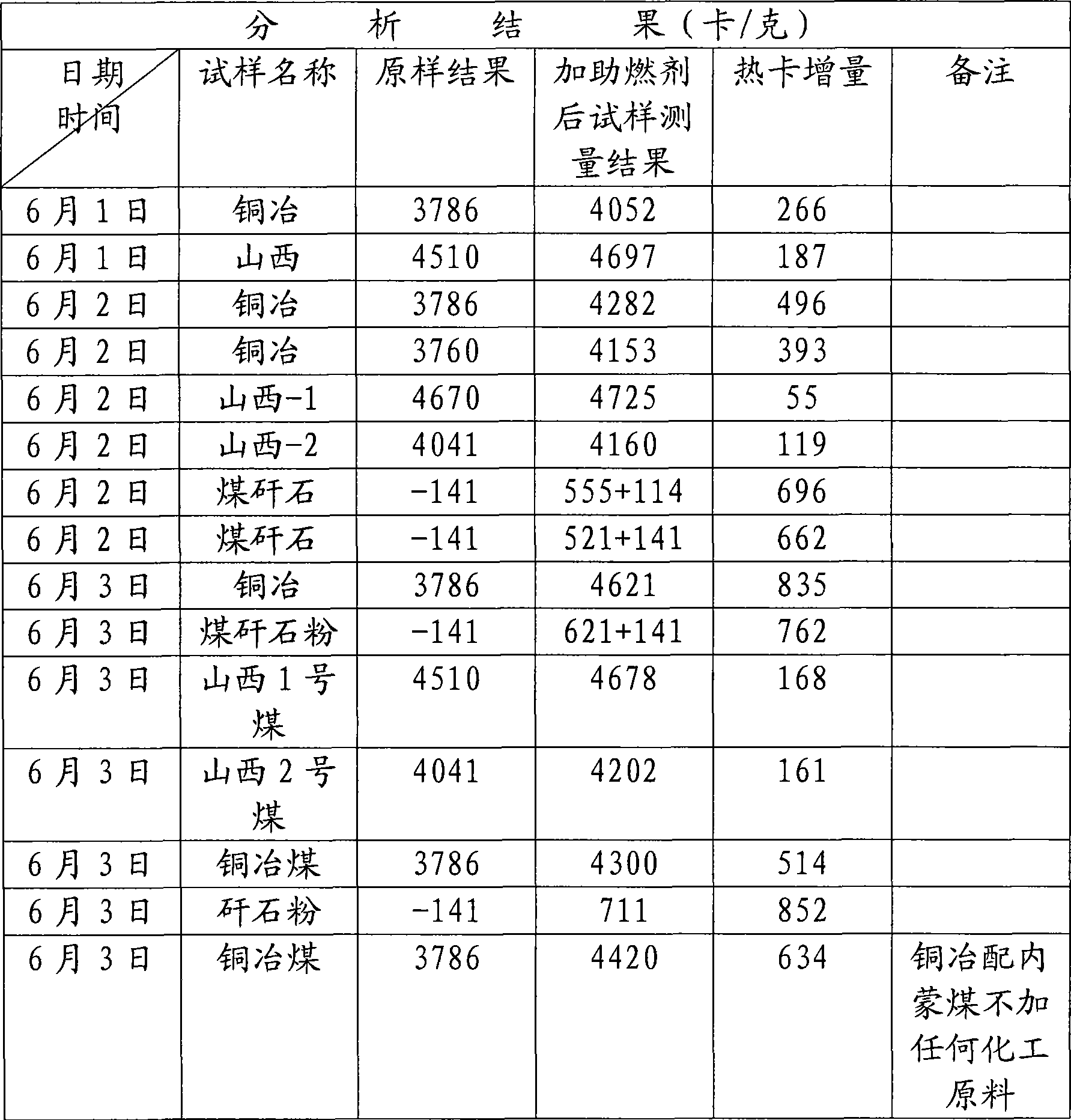

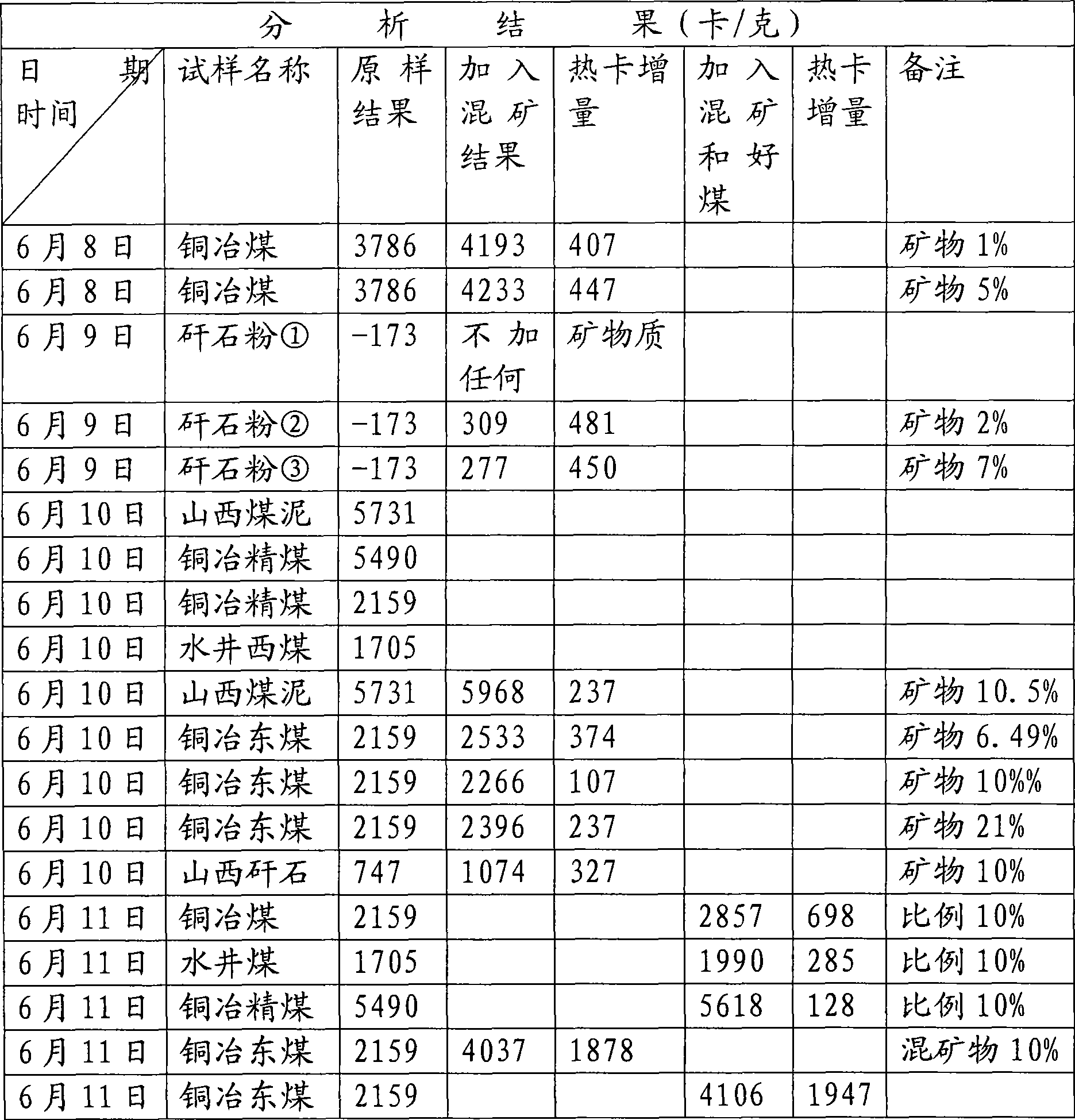

Nano ore coal combustion supporting additive, preparation and use as coal renewable energy source

The invention discloses a nanometer ore coal combustion-supporting additive, a preparation method thereof and application of the additive as renewable energy source of coal. The additive comprises the following raw material ores: 2 to 25 weight portions of saltpeter, 5 to 25 weight portions of marble, 5 to 25 weight portions of talcum, 5 to 20 weight portions of feldspar, 5 to 25 weight portions of picrite, and 1 to 10 weight portions of pyrolusite. The ores are subject to ultrafine grinding and are prepared into a coal combustion-supporting agent according to certain mixture ratio, and then the combustion-supporting agent is prepared into complex coal with coal gangue and coal according to the mixture ratio. The additive can ensure that 30 to 50 percent of standard coal is saved in the power generation industry and the cement industry, can reduce the discharge amount of sulfur dioxide and smoke dust, also reduce the environmental pollution of the coal gangue caused by land occupation spontaneous combustion at the same time, has good social benefit and economical benefit, meets the requirements of energy conservation, environmental protection and emission reduction, and is worthy to be promoted.

Owner:蒋凤亮 +2

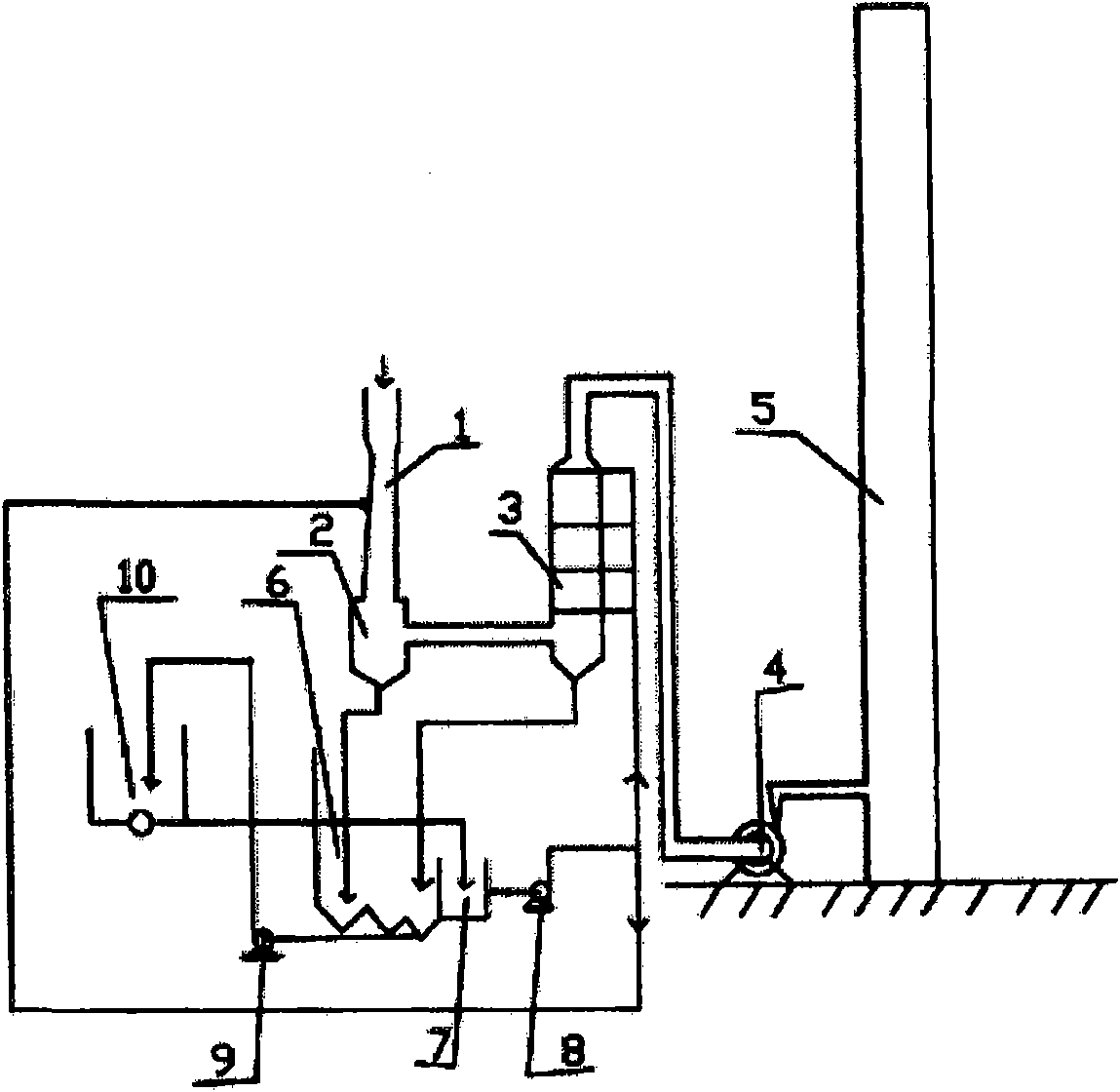

Technology for simultaneously removing dust, sulfur and niter without adding purifying agent during gas discharge of coal burning boiler

InactiveCN101539300ARaise the ratioIncrease concentrationLighting and heating apparatusPurification methodsComponents of crude oil

The invention belongs to the field of purifying the fuel gas of the coal burning boiler, and is a technology for simultaneously removing dust, sulfur and niter without adding a purifying agent during gas discharge of the coal burning boiler. The method is characterized in that: firstly, analysis of all components of the fuel coal, the burning mechanism of the coal in the boiler and the generation and physical-chemical properties of three types of pollutants shows that when the coal burns, not only the pollutants are generated, but also a key material of ferric oxide of the purification method is also generated, so the purification of the dust, sulfur and niter by the mutual reaction is realized, and at the same time, the comprehensive utilization of fuel resources is realized. The purification of the dust, sulfur and niter is achieved in the united equipment and no impurity is generated, so the technology has the characteristics of short process flow, reliable operation and convenient maintenance.

Owner:谢载衡

Medicine with acupuncture and moxibustion effect and its preparation method

InactiveCN1476866AShorten the timeReduce labor intensityHeavy metal active ingredientsInorganic boron active ingredientsCinnabarAcupuncture treatment

The present invention relates to a Chinese medicine with the action of stimulating acupoint to produce acupuncture and moxibustion effect and its preparation method. Said medicine composition includes 12 Chinese medicinal materials of mercury, cinnabar, realgar, borax, salt, alum, melanterite, niter, musk, pyrite, ampelopsis root and snail. Its preparation method includes the following steps: 1. heating earthen jar; preparing raw materials according to precription of main medicine, charging the main raw materials into the earthen jar, heating, subliming and condensing to obtain main medicine;and 2. grinding musk, pyrite, ampelopsis root and snail to obtain pink powder as auxiliary medicine; mixing main medicine and auxiliary medicine uniformly according to a certain ratio.

Owner:钱杰

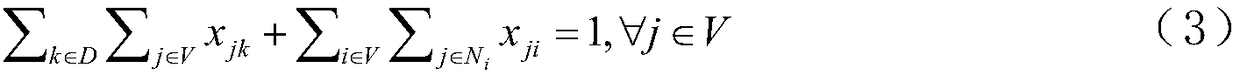

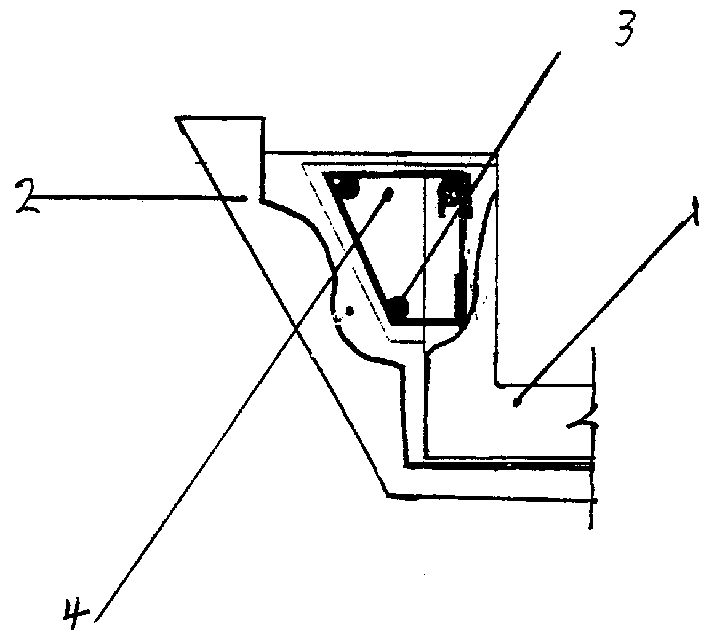

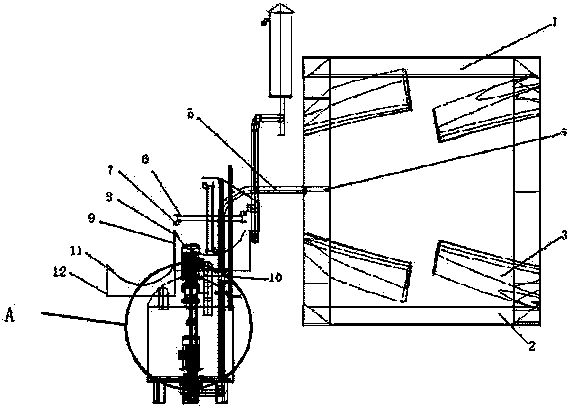

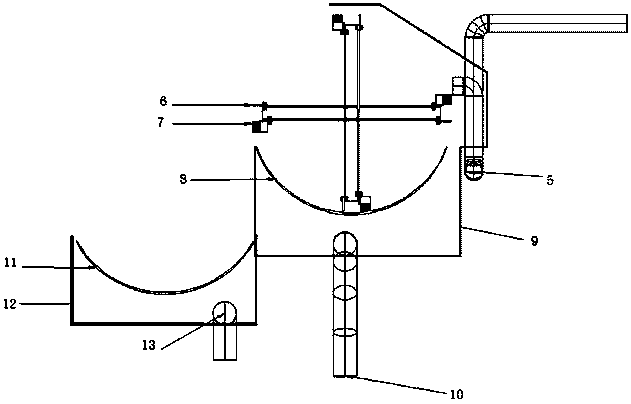

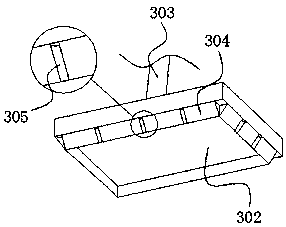

Fur niter-dyeing machine

ActiveCN104388607AIncrease heightReduce strong mechanical actionLeather/skins/hides/pelt chemical treatment apparatusTemperature controlScrub brushes

The invention discloses a fur niter-dyeing machine. The fur niter-dyeing machine comprises a rotary drum structure, a filtering device and a stirring device. The rotary drum structure comprises a flat and straight baffle plate arranged at the inner surface of the drum body along an axis direction, an inclined baffle plate structure and inlet and outlet water pipes. The filtering device comprises a liquid inlet pipe, a primary filtering device and a secondary filtering device. The opening of a liquid outlet pipe is arranged above the primary filtering device. The primary filtering device comprises a rubber scrubbing brush, a hairbrush and a primary filtering screen. The rubber scrubbing brush is located in front of the hairbrush. The secondary filtering device comprises a secondary filtering screen and a secondary liquid outlet pipe. The stirring device comprises a temperature control device, a steam heating device and an inclined stirring device arranged in the cylindrical shell of the stirring device. A water outlet of the rotary drum structure is connected to the liquid inlet pipe of the stirring device. The primary liquid outlet pipe and the secondary liquid outlet pipe of the filtering device are respectively connected to the primary liquid inlet pipe and the secondary liquid inlet pipe of the stirring device. The fur niter-dyeing machine can be used in fur niter-dyeing and guarantees finished fur quality.

Owner:桐乡市鑫诺皮草有限公司

Ceramic controllable fambe glaze

The invention relates to a ceramic controllable fambe glaze which comprises a glaze for a calving substrate, a glaze for a crystallization substrate and a glaze for a flow liner substrate. The glaze for the calving substrate is prepared from 70 parts of albite, 20 parts of spodumene, 35 parts of boric acid, 40 parts of quartz and 30 parts of heavy calcium carbonate powder. The glaze for the crystallization substrate is prepared from 150 parts of quartz sand, 30 parts of cryolite, 50 parts of anhydrous sodium carbonate, 10 parts of chalk and 5 parts of saltpetre. The glaze for the flow liner substrate is prepared from 70 parts of feldspar, 50 parts of quartz, 40 parts of limestone, 100 parts of kaolin and 12 parts of dolomite. After the glaze is printed and attached to the fired ceramic, the calving, crystallization or flow liner ceramic can be organically combined with different pictures and fired by one step, and the decorative effects, which are originally displayed on several ceramics and require different firing regimes, can be displayed on one ceramic without executing any special firing regime.

Owner:福建省德化县成艺陶瓷有限公司

Soil remediation agent and preparation method thereof

InactiveCN106635033AImprove adsorption capacityFunction increaseAgriculture tools and machinesOrganic fertilisersSodium BentoniteMicrobial agent

The invention discloses a soil remediation agent and a preparation method thereof. The soil remediation agent is prepared from the following formula components in parts by mass: 15 to 25 parts of waste clay subjected to oil extraction, 5 to 15 parts of bacillus subtilis, 6 to 8 parts of lactic acid bacteria, 3 to 5 parts of sulfur-containing compound, 4 to 8 parts of sodium-based bentonite, 14 to 18 parts of flammulina velutipes fungus chaff, 3 to 5 parts of magnesium aluminum silicate, 3 to 5 parts of niter, 3 to 5 parts of pyrethrum, 14 to 18 parts of derris trifoliate, 4 to 8 parts of humic acid, 2 to 4 parts of microbial agent and 6 to 10 parts of hydrogen peroxide. According to the soil remediation agent and the preparation method thereof disclosed by the invention, spent bleaching clay can be recycled; meanwhile, the soil remediation agent further has excellent functions of adsorbing and immobilizing heavy metal ions, and is high in added value, simple in preparation and low in cost.

Owner:钦州市星火计划办公室

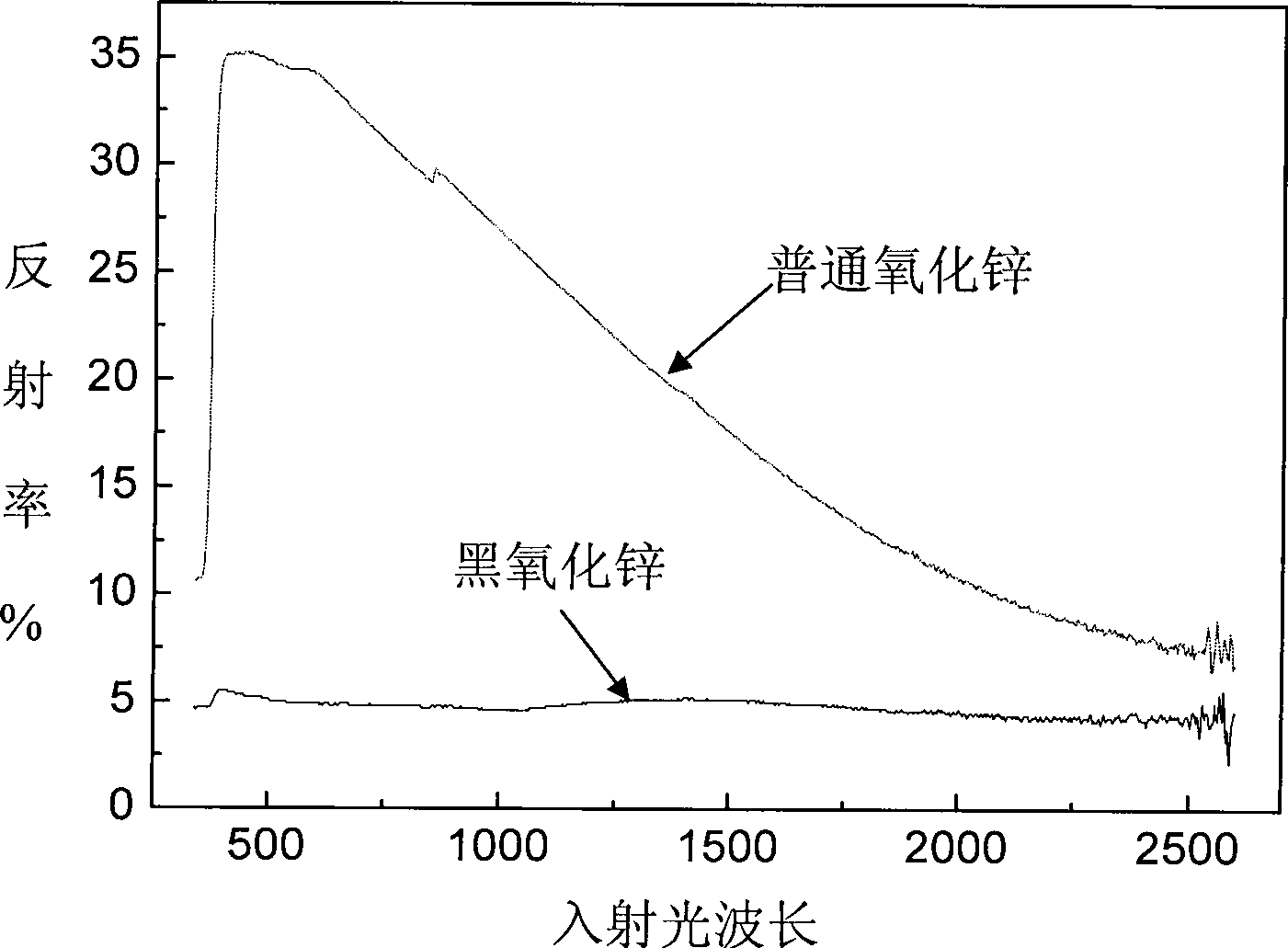

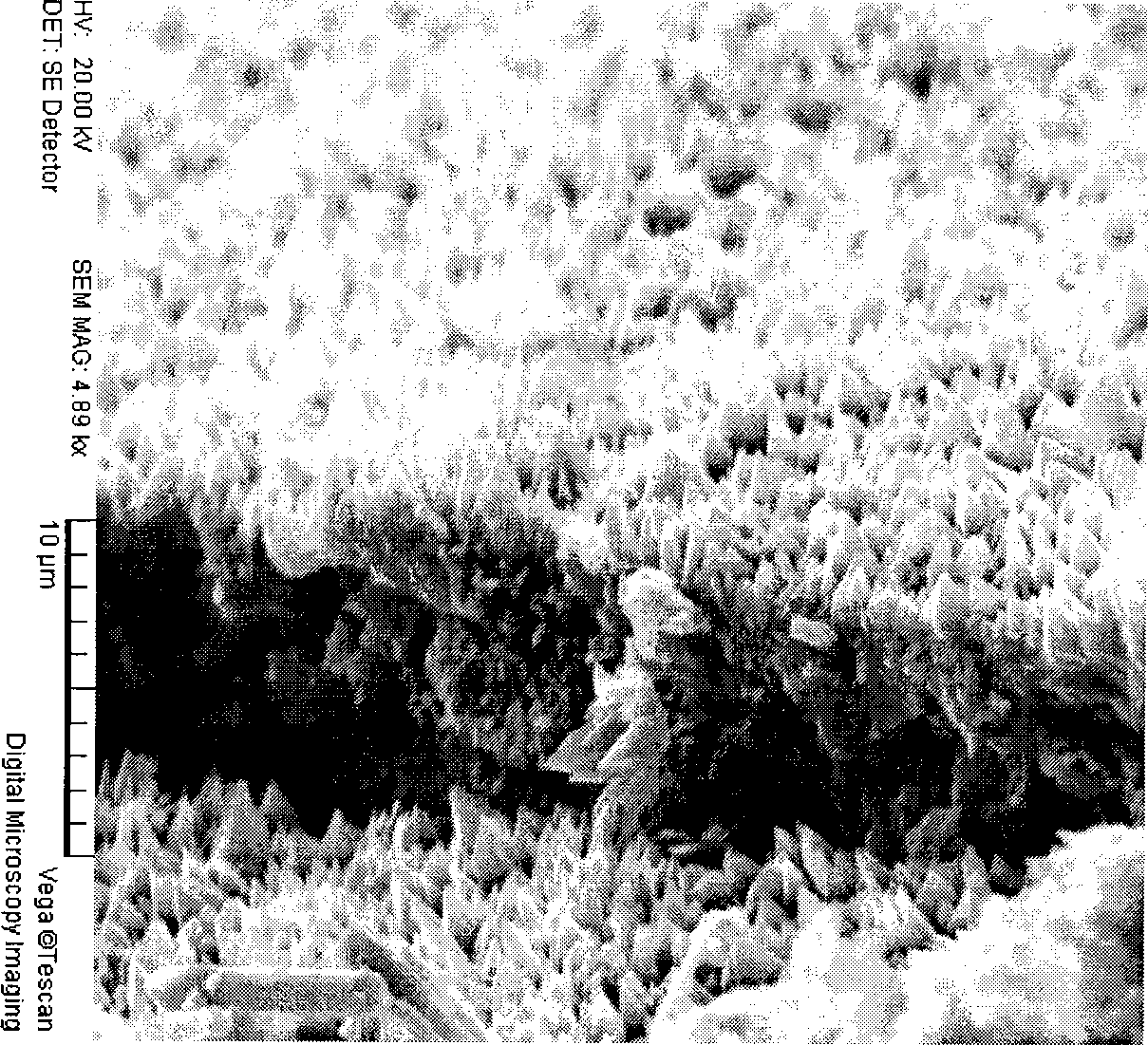

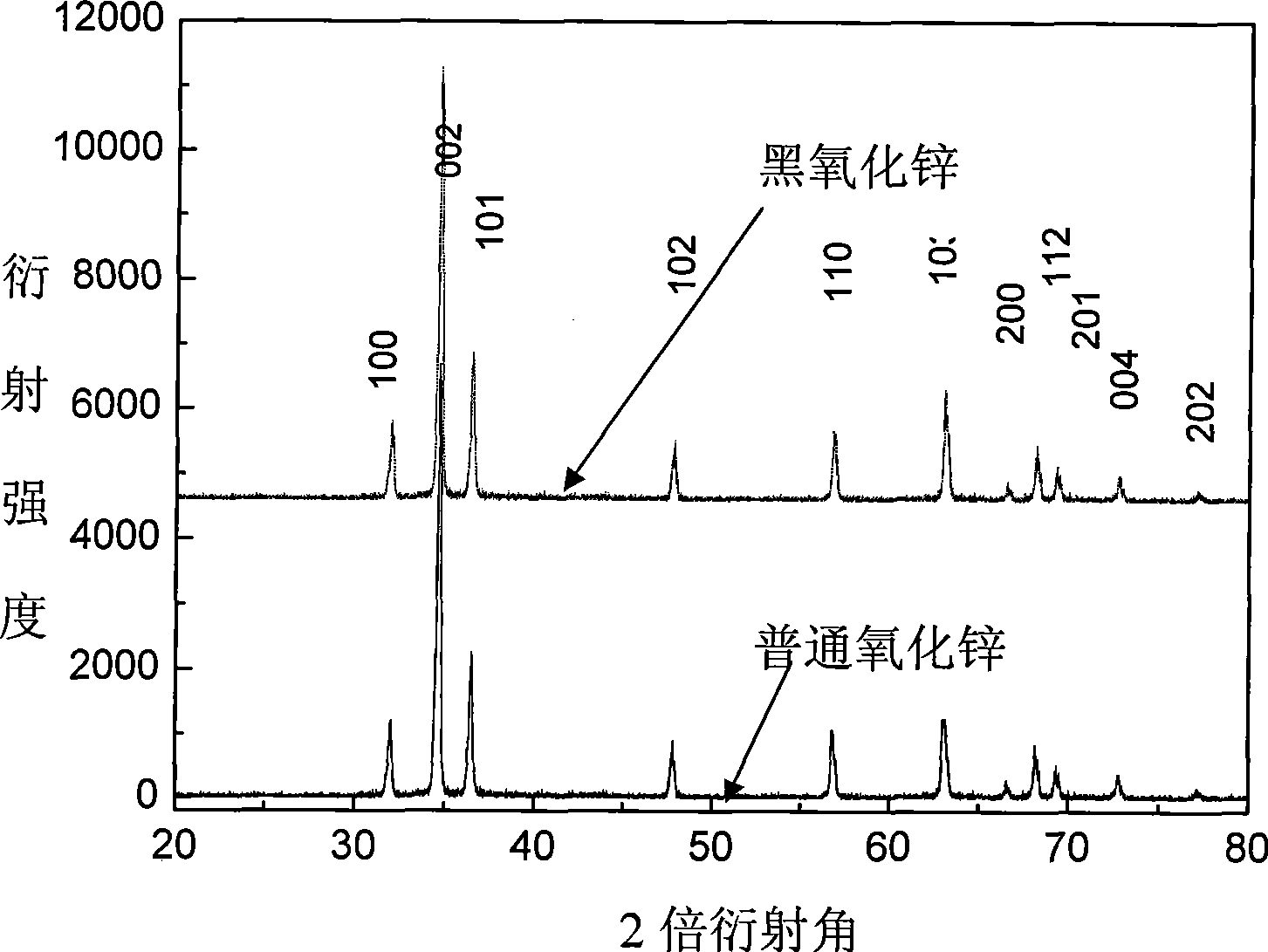

Method for Preparing black zinc oxide and application of black zinc oxide

InactiveCN101445267AEasy surface modificationFew controllable parametersZinc oxides/hydroxidesCell electrodesAluminium chlorideZinc metal

The invention discloses a method for preparing black zinc oxide and the application of black zinc oxide, the synthetic method of the invention is that zinc sheet metal or zinc metal attaching thin layer and chlorine containing salt (comprises one or more metal chlorides, the reactivity of metals of which is listed before zinc, such as sodium chloride, potassium chloride, sodium chloride, potassium chloride, rough niter, ammonium chloride, barium chloride, aluminium chloride and the like) are adopted, water or organic solvent is served as reaction solvent under various alkalinity acidities, a special reaction vessel is adopted, and reaction and production can be performed under a certain temperature and pressure. The black zinc oxide can be widely applied to technical fields of the dye-sensitized solar cells, the water photolysis, the photodegradation of organic materials, the photo sensor, the infra-red tracking, and the like. The invention has the advantages of low synthetic cost, mild reaction condition and simple operation steps.

Owner:CHONGQING UNIV

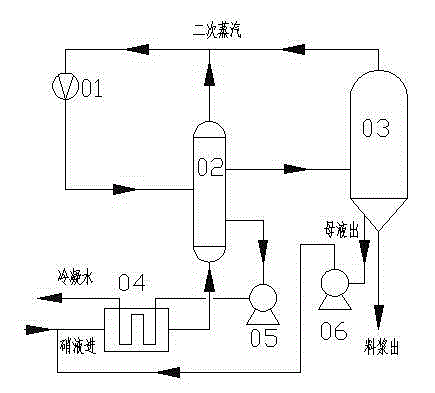

Application of MVR (Mechanical Vapor Recompression) crystallization evaporator to industrialized production of anhydrous sodium sulphate

InactiveCN103145153AImprove thermal efficiencySave energyChemical industryAlkali metal sulfites/sulfatesEvaporationWastewater

The invention discloses application of an MVR (Mechanical Vapor Recompression) crystallization evaporator to industrialized production of anhydrous sodium sulphate, relates to an improvement to an evaporation technology and aims at solving the problem of high anhydrous sodium sulphate production cost due to high evaporation cost and high water consumption of enterprises at present. The application is technically characterized in that niter solution enters the crystallization evaporator at low temperature for concentration, secondary vapor which goes out from an evaporation chamber is compressed by a compressor, the pressure and the temperature are increased, the heat content is increased, then the secondary vapor is fed into a heating chamber and is used as heating steam to keep liquid materials in a boiling state, and the heating steam is condensed into water. Therefore, steam which is abandoned in the past is fully utilized, the latent heat is recovered and the thermal efficiency is improved. The MVR crystallization evaporator can fully utilize the latent heat of secondary steam, can operate at low temperature, is energy-saving, is simple to operate, does not produce any waste residues, waste gas and waste water, and does not cause pollution to the environment.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

Fly ash non-sintered brick pressing forming process

The invention relates to a fly ash non-sintered brick pressing forming process, which comprises: a, mixing fly ash, furnace slag, niter, cement and rocky sand crystal according to a basic matching ratio (%) of the fly ash to the furnace slag to the niter to the cement to the rocky sand crystal of 25-40:25-40:20-30:5-10:0.1-0.5; b, adding water and stirring, wherein the amount of the water for stirring is 20-30%; c, forming; and d, carrying out concrete curing. According to the present invention, the brick produced through the fly ash non-sintered brick pressing forming process has characteristics of heat resistance, heat insulation and fire retardation, is the novel thermal insulation and low temperature refrigeration heat insulation material and the ultra lightweight fire resistance raw material, is firm and durable, does not easily produce the hollow cracking phenomenon, further has characteristics of high strength and good durability, and further has effects of sound absorption, vibration reducing and wear resistance; and the fly ash is recycled so as to provide advantages of environmental pollution reducing, energy saving and environmental protection.

Owner:DALIAN HENGXIANG FLY ASH INTEGRATION UTILIZATION

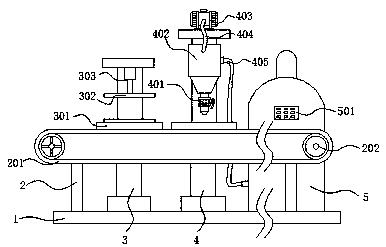

Energy-saving and environment-friendly decorative plate production device

InactiveCN109866387AReduce contact areaIncrease pressureDirt cleaningMetal working apparatusEngineeringMetal hook

The invention discloses an energy-saving and environment-friendly decorative plate production device. The energy-saving and environment-friendly decorative plate production device comprises a bottom plate and a molded plate; a motor installing rack, a first installing rack and second installing rack are fixed to the outer wall of the top of the bottom plate through bolts; and conveying motors arefixed to the outer wall of the top of the motor installing rack through bolts, a same conveying crawler belt which is horizontally placed is connected to the conveying motors in a conveying mode, an electric telescopic rod is fixed to the bottom of the outer wall of one side of the first installing rack through bolts, and a mold cutting seat is welded to the outer wall of the bottom of the electric telescopic rod. According to the energy-saving and environment-friendly decorative plate production device, air flow generated in the cutting process can be discharged though strip-shaped holes, thecutting resistance is reduced, clear water is injected into a metal frame, niter is added, the niter absorbs large quantity of heat after the niter is dissolved in the water, a metal hook surface material of a metal plate is convenient to efficiently conduct the heat out in a plastic solution, after cooling is finished, cooling liquid can perform evaporating treatment, the niter is precipitated out to be recycled, large quantity of resources are saved, and the energy-saving and environment-friendly properties of the device are greatly improved.

Owner:芮文荣

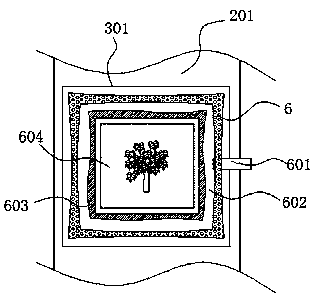

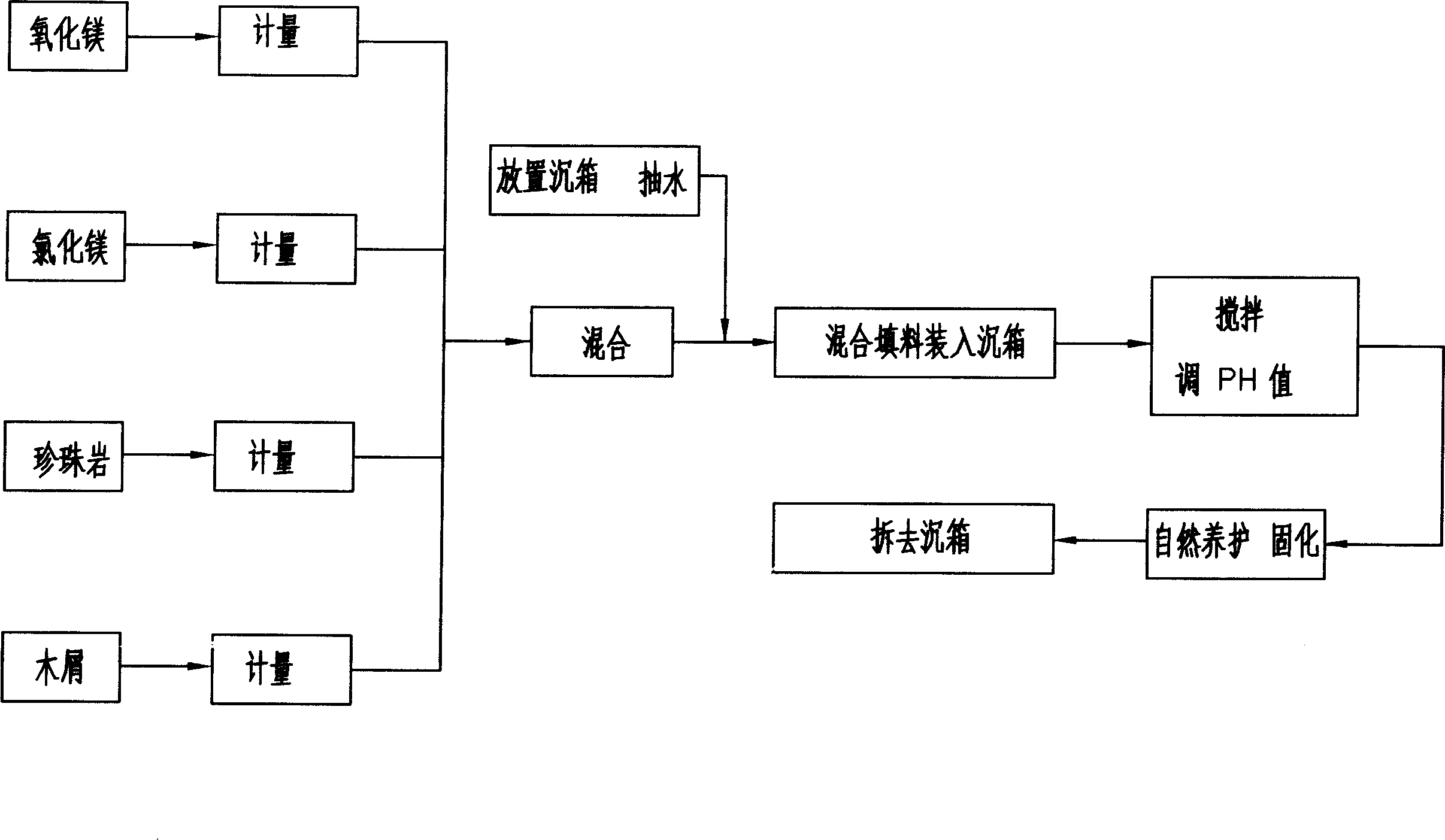

Construction method for laying permeable inverse-seepage preventing layer on bottom of river and lake

InactiveCN101139828AImprove breathabilityWon't surgeArtificial islandsClimate change adaptationSludgeNiter

An construction method of air permeable impervious liner on the bottom of rivers or lakes comprises the following steps: Arrange a plurality of square caissons in an edge-to-edge mode on the bottom of a river or lak before pumping water out of each caisson; take solid materials, such as magnesia, perlite, wood chips and rough niter solution to mix sufficiently in a proportion to form a mixed filler; add the mixed filler into each caisson to agitate, and then, adjust pH of the mixture of the mixed filler with some sludge into 7 to 8; maintain a natural solidification for the mixture of the mixed filler with some sludge in each caisson for 30 to 48 hours, until complete solidification is fulfilled; remove the caisson. The invention provides blocks to cover the bottom of a river or a lake with the construction method, so that the bottom of the river or lake has rather good air permeability, and meanwhile, sludge on the bottom of the river or lake will not upwell, for which the river and lake water can be kept rather clear. The invention provides the construction method to fulfill it not necessary to pump all water out of a river or lake during the execution, therefore, quantity of construction works and construction cost are relatively lower.

Owner:张佛西

Alkaline refining method of lead bullion

The invention discloses an alkaline refining method of lead bullion and belongs to the field of non-ferrous metals. The method comprises the following steps: (1) preparing a liquid; (2) adding saltpeter; (3) adding caustic soda; (4) controlling the temperature; and (5) deslagging, The method disclosed by the invention can be used for solving the problem that the purity of lead is reduced because impurities such as Sn, As and Sb cannot be effectively removed during the existing smelting process of the lead bullion, and has the advantages of being simple in process, low in cost and easy to process.

Owner:WUHU JINLONG MOLD FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com