Nano ore coal combustion supporting additive, preparation and use as coal renewable energy source

A technology for additives and ore, applied in the field of coal combustion-supporting additives and their preparation, can solve the problems of lack of boiler cleaning and corrosion inhibition, achieve good social and economic benefits, increase calorie value, and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

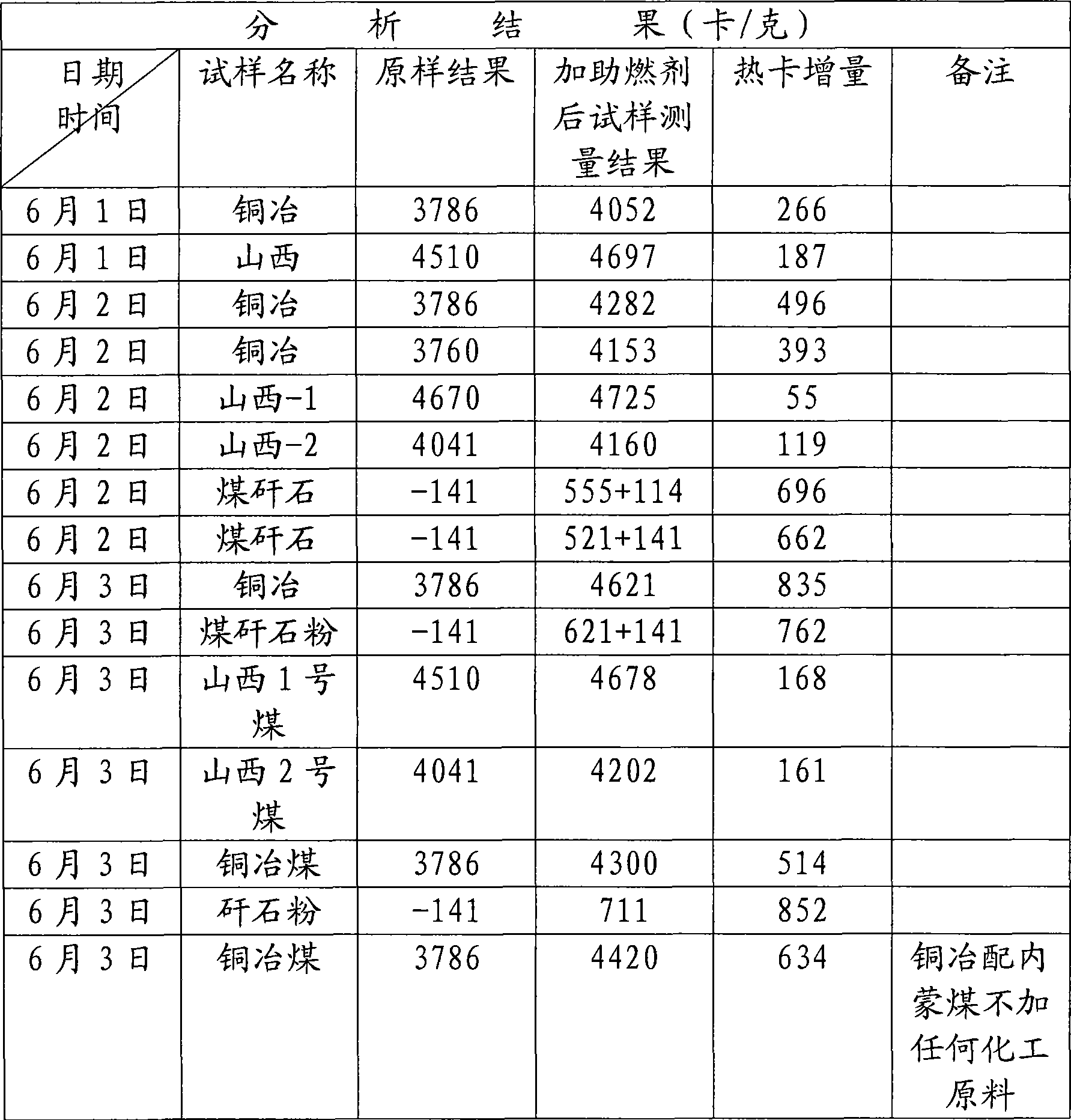

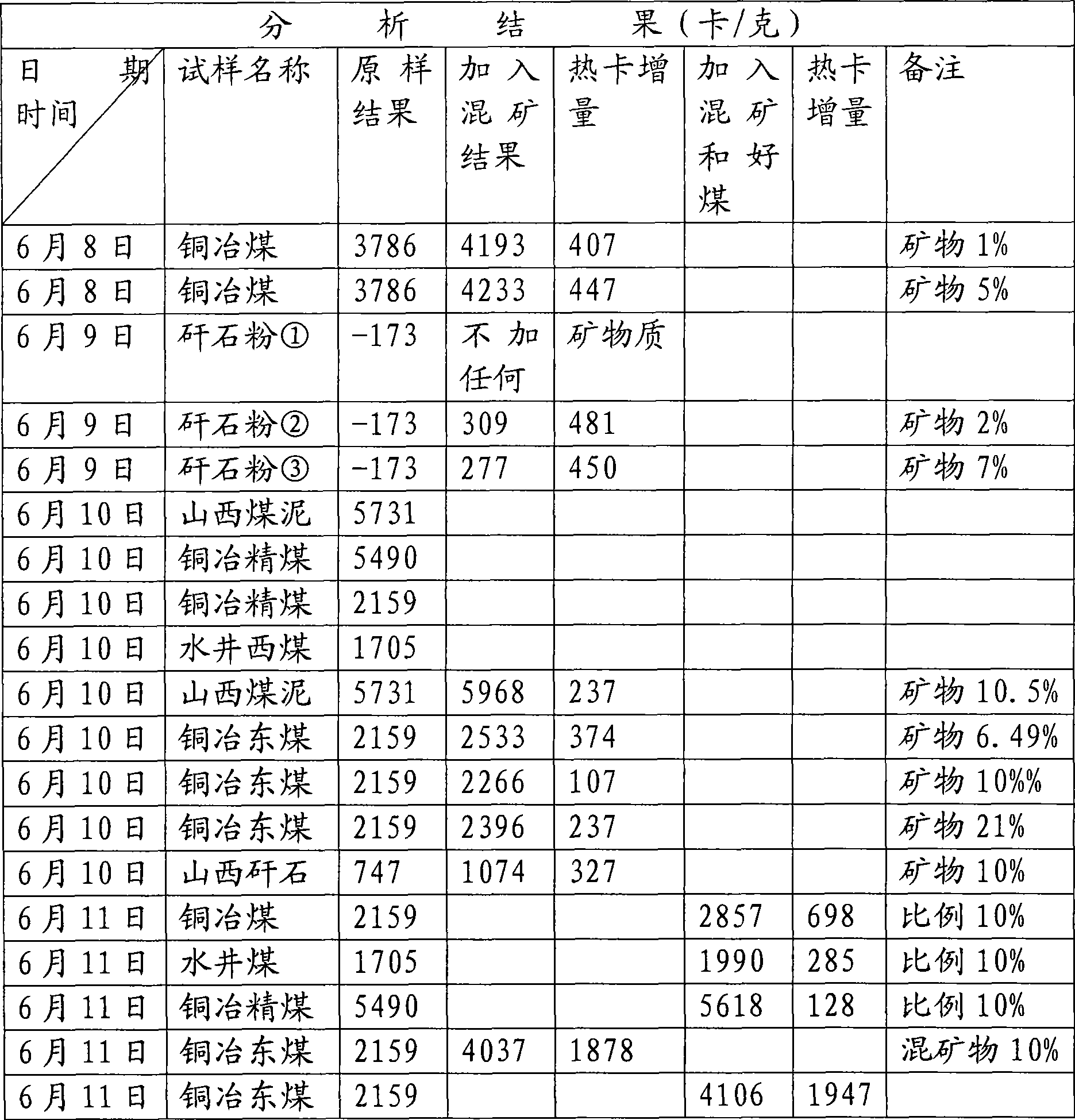

Examples

Embodiment 1

[0055] Embodiment 1: preparation coal combustion-supporting additive

[0056] 30kg of saltpeter, 10kg of marble, 10kg of talc, 10kg of feldspar,

[0057] 10 kg of pyroxene, 20 kg of pyrolusite.

[0058] Grind each of the above-mentioned ores separately to 80-120 mesh, then add them to the ball mill according to the above ratio, add water until it is wet, grind (ball mill) for 8 hours, carry out at normal temperature and normal pressure, and the speed of the ball mill is 500 rpm / min, that is to obtain coal combustion-supporting additives with particle sizes ranging from microns to nanometers.

Embodiment 2

[0059] Embodiment 2: preparation coal combustion-supporting additive

[0060] 80 kg of saltpeter, 150 kg of marble, 150 kg of talc, 130 kg of feldspar, 150 kg of pyroxene, and 30 kg of pyrolusite.

[0061] Above-mentioned each ore is pulverized separately to 150-200 order, then joins in the ball mill according to above-mentioned ratio, it is advisable to add water to wet (the amount of water is 3-5% of ore gross weight), pulverize (ball mill) 10 hours, in It is carried out under normal temperature and normal pressure, and the rotational speed of the ball mill is 600 revolutions per minute, that is, the coal combustion-supporting additive with a particle size of micron to nanometer is obtained.

Embodiment 3

[0062] Embodiment 3: preparation coal combustion-supporting additive

[0063] 50 kg of saltpeter, 120 kg of marble, 110 kg of talc, 120 kg of feldspar, 120 kg of pyroxene, and 15 kg of pyrolusite.

[0064] Grind each of the above-mentioned ores separately to 100-150 mesh, then add them to the ball mill according to the above ratio, add water until it is wet, grind (ball mill) for 7.5 hours, and carry out at normal temperature and pressure, and the speed of the ball mill is 400 rpm / min, that is to obtain coal combustion-supporting additives with particle sizes ranging from microns to nanometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com