Method for making covering layer of artificial stone for building

A manufacturing method and building technology, applied in the direction of building structure, construction, covering/lining, etc., can solve the problems of short life, poor imitation stone texture, component deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

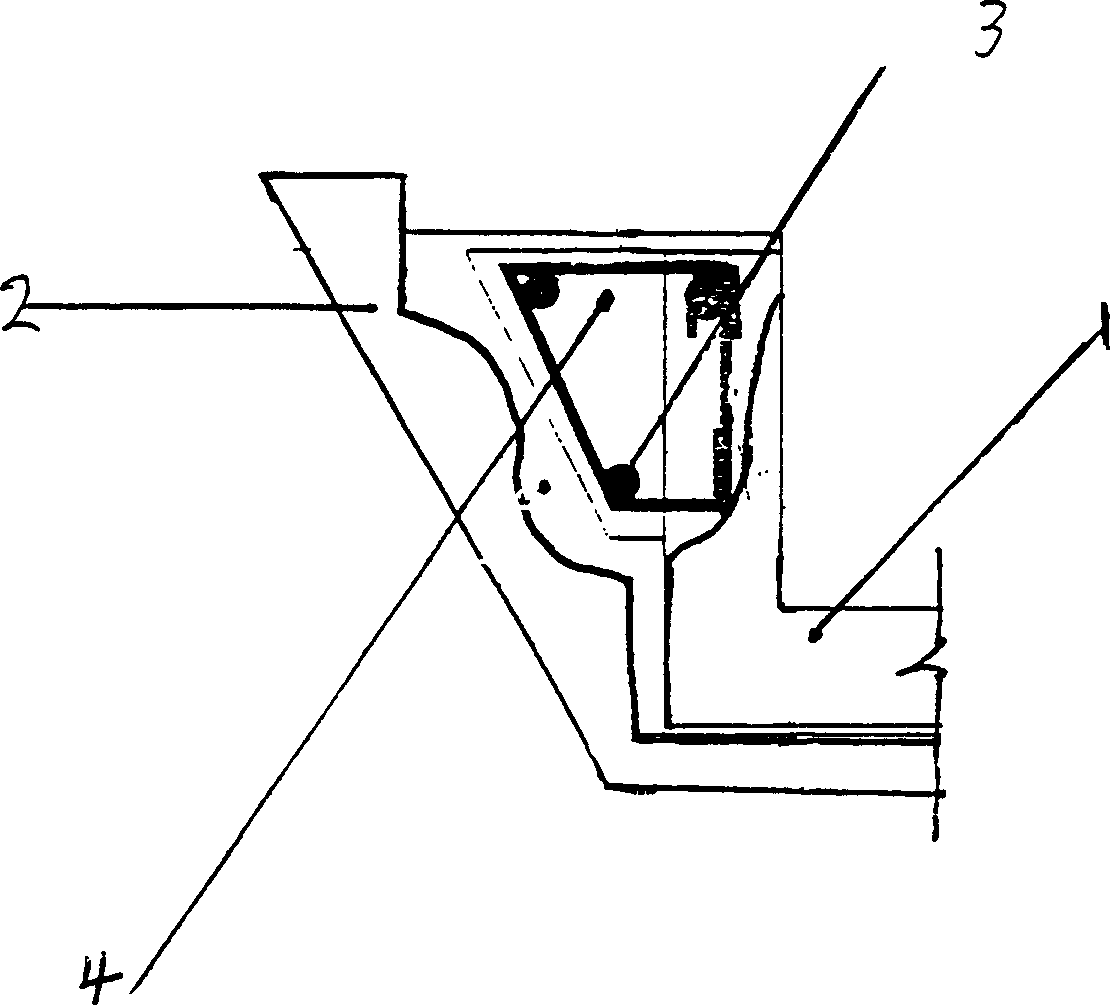

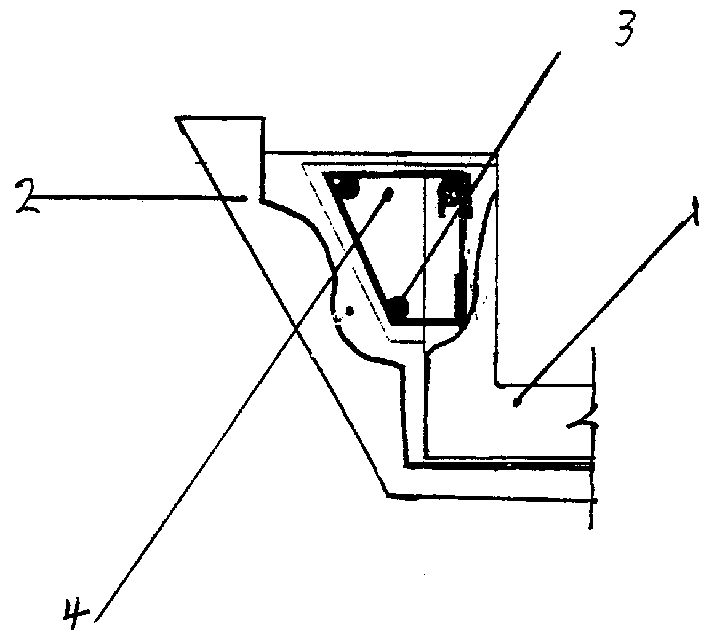

[0005] A method for making a building simulation stone covering layer of the present invention includes making molds, preparing structural steel bars, preparing imitation stone materials, pouring concrete and demoulding, wherein the process of making molds is to decorate the building according to the required decoration. Molding is made and fixed. The process of preparing structural steel bars is to set structural steel bars as the structural skeleton of the decorative covering on the building according to the required decorative modeling. The described preparation imitation stone material is to prepare stone salt Concrete, said pouring concrete and demoulding means pouring concrete into a mold, and demoulding when the concrete reaches a specified strength. Then tools can also be used to carve the imitation stone concrete after demoulding. The methods for making the mould, fixing the mould, pouring concrete and demoulding all adopt known methods in the prior art. Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com