Technology for simultaneously removing dust, sulfur and niter without adding purifying agent during gas discharge of coal burning boiler

A technology for coal-fired boilers and purifiers is applied in the field of exhaust gas purification of coal-fired boilers, which can solve the problems of large capital investment, difficult control, and long process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

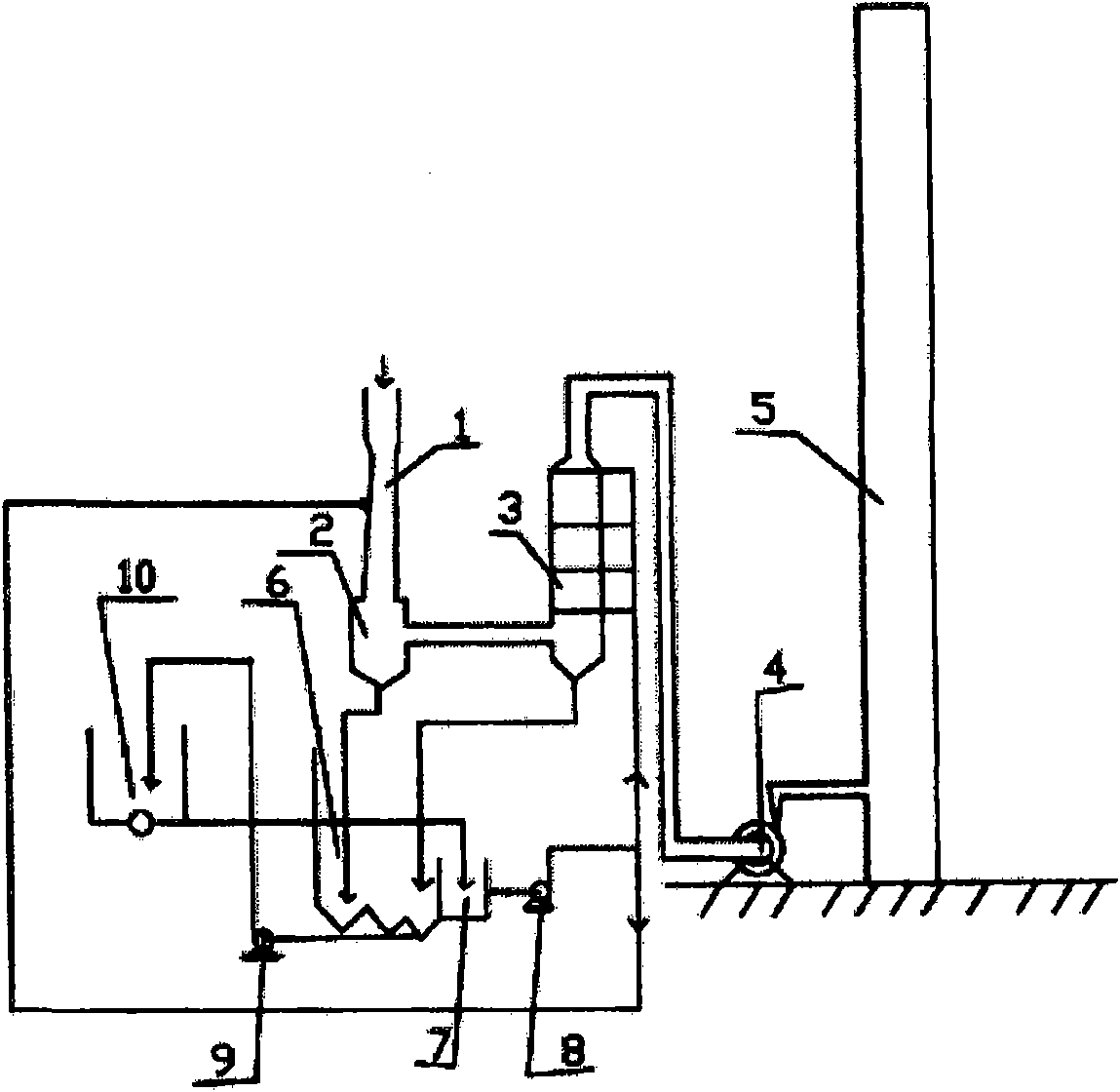

[0006] The specific implementation is shown in the accompanying drawings, which are divided into a flue gas system and a circulating washing water system. The flue gas system is: the flue gas from the boiler first enters the pretreatment vessel 1, where it is directly mixed with the circulating washing water pumped from the circulating washing water for pre-cooling and pre-dust removal, and then the gas-water separation vessel 2 is carried out, and the flue gas After removing the water, the gas enters the flue gas purification tower 3. Here, it fully contacts with the acidic washing water sent by the circulating washing water pump to carry out a series of chemical reactions, and at the same time completes the purification of various pollutants in the flue gas. The system is: the dust-containing circulating washing water flowing out from the pretreatment vessel passes through the gas-water separation vessel 2 and flows into the circulating washing water clarification tank 6 tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com