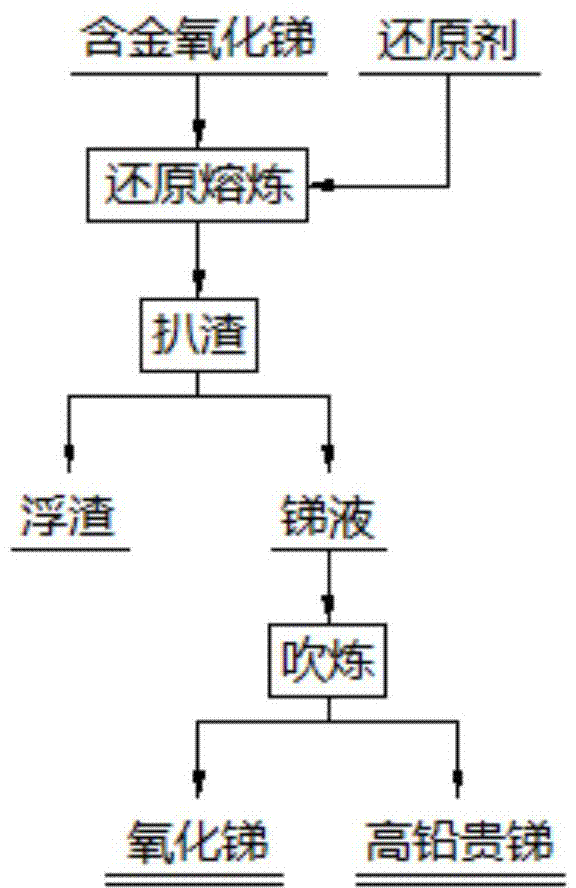

One-step technique for separating antimony from gold and lead in gold-containing antimony oxide smoke dust

An antimony oxide and process technology, applied in the field of gold smelting, can solve the problems of loss of precious metals, which have not yet appeared, and achieve the effects of efficient recovery, reduced incorporation of impurities, and good reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add anthracite with 8% soot mass to gold-containing antimony oxide fume containing 9.0g / t of gold, 1.89 mass% of lead, and 71.2 mass% of antimony to carry out reduction smelting, control the reduction smelting temperature to 1100-1150°C, Finally remove the scum, use the blower to blow air into the blowing, control the flow of blowing to 185m 3 / min, and the blowing temperature is controlled to be 700-750°C, the concentration ratio is controlled to be 7%, and the output contains 0.33g / t of gold, 0.37% by mass of lead, 74.5% by mass of antimony, and 85g / t of gold. t. High lead and noble antimony containing 11.4% by mass of lead and 85.3% by mass of antimony.

Embodiment 2

[0039] Add anthracite with a mass of soot of 11% to gold-containing antimony oxide fume containing 13.33g / t of gold, 2.93% by mass of lead, and 68.9% by mass of antimony to carry out reduction smelting, control the reduction smelting temperature to 1100-1150°C, Finally, remove the scum, use the fan to blow air into the blowing, and control the blowing flow to 155m 3 / min, and the blowing temperature is controlled to be 750-850°C, the concentration ratio is controlled to be 10%, and the output contains 0.33g / t of gold, 0.32% by mass of lead, and 73.6% by mass of antimony, and 108g / t of gold. t. High lead and noble antimony containing 13.8% by mass of lead and 84.1% by mass of antimony.

Embodiment 3

[0041] Add 10% anthracite to gold-containing antimony oxide containing 21.33g / t of gold, 1.02 mass% of lead, and 72.5 mass% of antimony for reduction smelting, control the reduction smelting temperature to 1100-1150°C, and remove scum after reduction smelting , use the blower to blow air into the blowing, control the flow of blowing to 200m 3 / min, and the blowing temperature is controlled to be 700-750°C, the concentration ratio is controlled to be 8%, and antimony oxide containing 0.50g / t of gold, 0.34% by mass of lead, and 76.8% by mass of antimony is produced, and 142g / t of gold is produced. t. High lead and noble antimony containing 9.6% by mass of lead and 87.3% by mass of antimony.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com