Easy-cutting zinc-copper-base wrought zinc alloy and preparation method thereof

A zinc alloy, easy-cutting technology, applied in the field of zinc-copper-based deformed zinc alloy and its preparation, to achieve moderate mechanical properties, good cutting performance, and improve the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

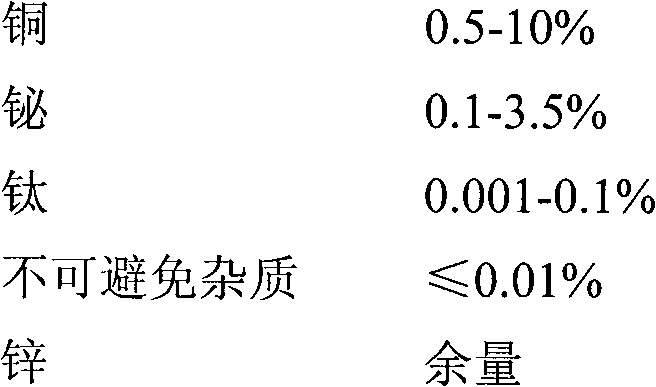

[0018] The weight composition of this zinc alloy is as follows:

[0019]

[0020] The titanium element is added in the form of a copper-titanium master alloy during alloy batching, the weight content of titanium in the copper-titanium master alloy is 30%, and the balance is copper; the remaining copper in the zinc alloy is made up with pure copper; bismuth and zinc According to the content of alloying elements, it is added in the form of pure metal.

[0021] The melting and casting process of the alloy adopts a power frequency furnace, and the master alloy blank with a diameter of 170 mm is made by semi-continuous casting, which is hot-extruded into a bar blank at a temperature of 380 ° C, and the combined drawing method is used to make the blank. rods of required diameter.

[0022] The tensile strength of the finished rod is 385MPa, the elongation is 12%, and the hardness is Hv=110.

[0023] The cam-type automatic lathe is used to drill holes to process the finished bar ...

Embodiment 2

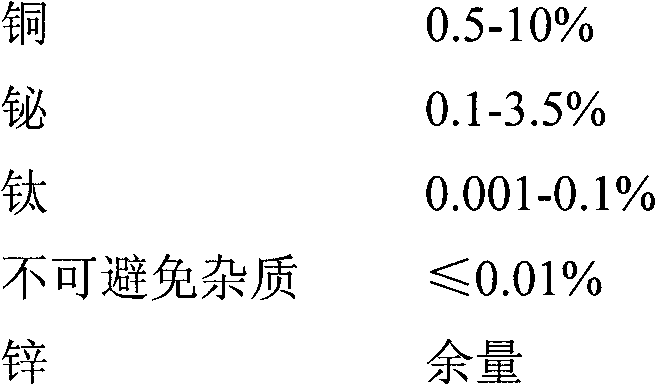

[0025] The weight composition of this zinc alloy is as follows:

[0026]

[0027] The titanium element is added in the form of a copper-titanium master alloy during alloy batching, the weight content of titanium in the copper-titanium master alloy is 25%, and the balance is copper; the remaining copper in the zinc alloy is made up with pure copper; bismuth and zinc According to the content of alloying elements, it is added in the form of pure metal.

[0028] The alloy is smelted by induction heating, and the alloy ingot is made by die casting. It is extruded into a bar blank at a temperature of 240°C, and is made into a zinc alloy bar with a crawler broaching machine. After polishing and straightening, the electronic product is processed on a CNC machine tool.

[0029] The tensile strength of the bar product is 285Mpa, and the elongation is 15%. Hardness Hv=93.

[0030] For parts with the same specifications, the machining efficiency of CNC machine tools can reach 85% of...

Embodiment 3

[0032] The weight composition of this zinc alloy is as follows:

[0033]

[0034] The titanium element is added in the form of a copper-titanium master alloy during the alloy batching, the weight content of titanium in the copper-titanium master alloy is 31%, and the balance is copper; the remaining copper in the zinc alloy is made up with pure copper; bismuth and zinc According to the content of alloying elements, it is added in the form of pure metal.

[0035] It is smelted by induction heating, and the master alloy ingot is obtained by die casting method, which is extruded into a billet of alloy rod at 180°C, passed through a multi-die wire drawing machine to the size before the finished product, and then combined drawing Reduced diameter, straightened, polished to finished product. In the dry processing of the cam type automatic lathe, the processing efficiency can reach 85% of the same specification of C3604 lead brass.

[0036] Its cutting performance comparison wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com