Method of ion liqid extraction for separating penicillin

A technology of ionic liquid and penicillin, applied in organic chemistry and other fields, can solve problems such as emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

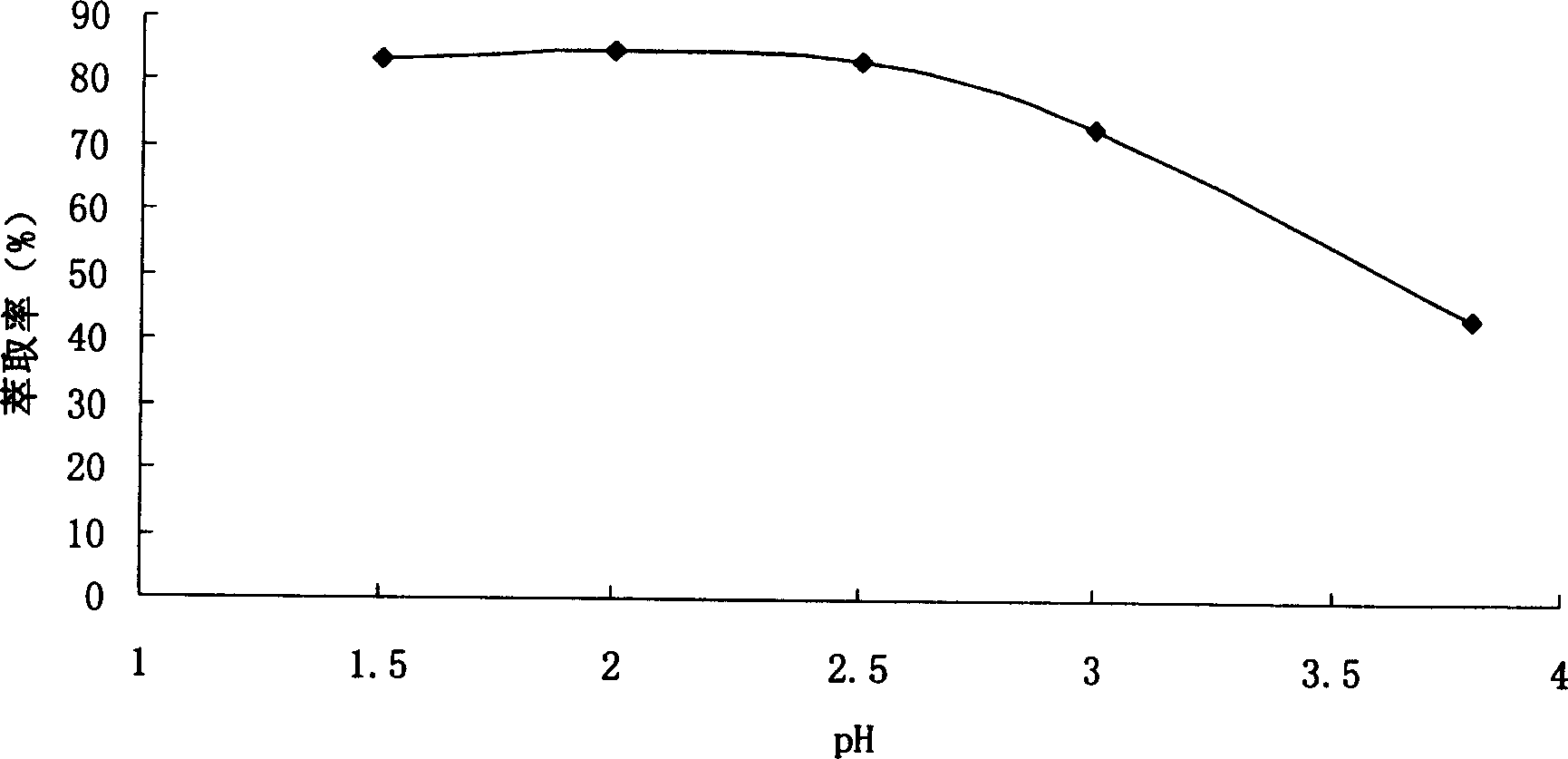

[0023] Accurately measure the penicillin G aqueous solution 350ml that concentration is 31276u / ml, the ionic liquid [Bmim]PF 6 Compared with the penicillin aqueous solution, add it into the mixing tank with a stirring device (single-stage extraction) at a ratio of 1:1.5, start the stirring, and fully mix the two phases. 2 SO 4 , control the pH value at 1.5, 2.0, 2.5, 3.0, 3.8 respectively, stir for 15 minutes, stand still and separate the phases. After the two-phase interface is clear, use a pipette to take the heavy phase ionic liquid to measure its optical rotation value. The reference penicillin in the ionic liquid The concentration of penicillin in the ionic liquid was obtained from the dissolution standard optical rotation curve in the ionic liquid, and the phase volume of the ionic liquid was accurately measured, and the calculated extraction rates were 83.46%, 84.59%, 83.44%, 73.06%, and 43.82%, respectively. Show the relationship between pH value and extraction rate. ...

Embodiment 2

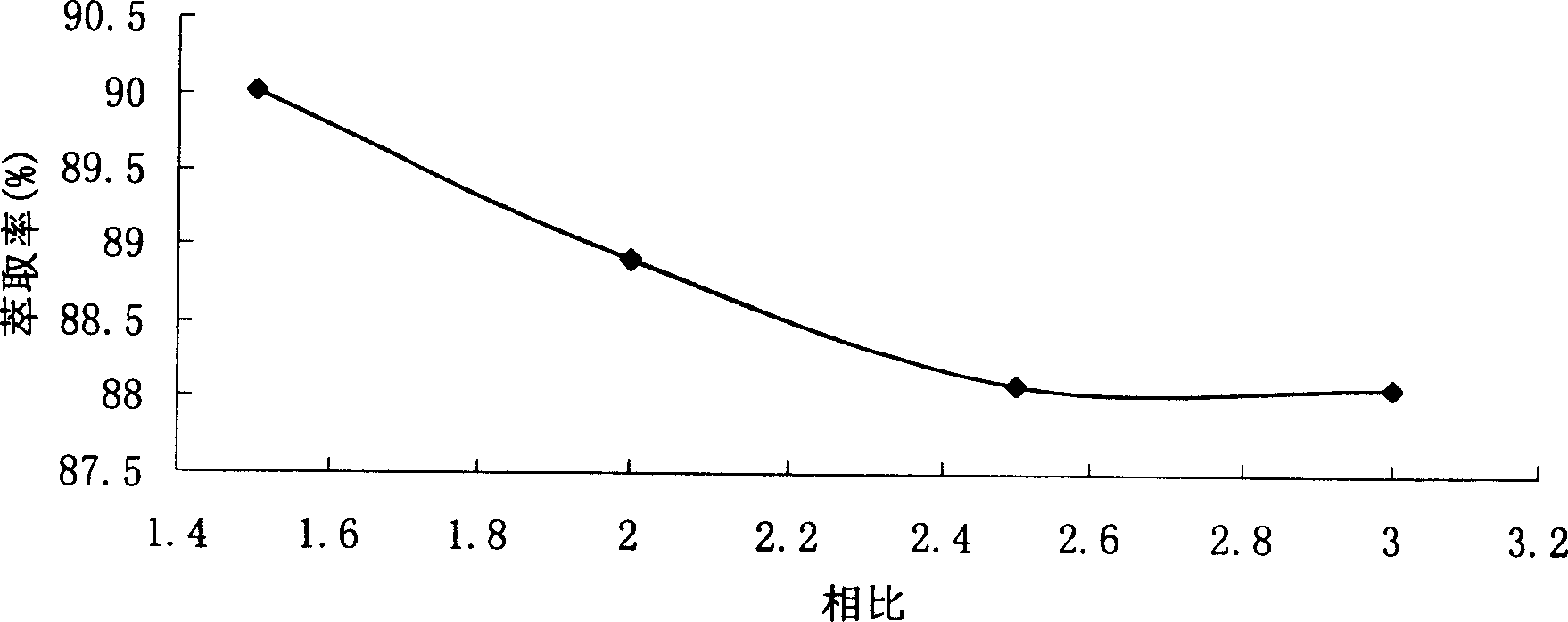

[0025] Accurately measure 350ml of penicillin G aqueous solution with a concentration of 31566u / ml, ionic liquid [Bmim]PF 6 Compared with penicillin aqueous solution, it is 1:1.5, 1:2.0, 1:2.5, 1:3.0 and added to the mixing tank with stirring device (single-stage extraction), and the stirring is started to fully mix the two phases, and the temperature is controlled at 5 ℃~10℃, slowly add 10wt% H 2 SO 4 , control the pH to 2.0, stop stirring after stirring for 15 minutes, stand still and separate the phases. After the two-phase interface is clear, use a pipette to take the heavy phase ionic liquid to measure its optical rotation value, and refer to the standard optical rotation curve of penicillin dissolved in the ionic liquid. The concentration of penicillin in the ionic liquid was obtained, and the phase volume of the ionic liquid was accurately measured. The calculated extraction rates were 91.62%, 86.07%, 85.93%, and 86.21%, respectively. Indicates the relationship betwee...

Embodiment 3

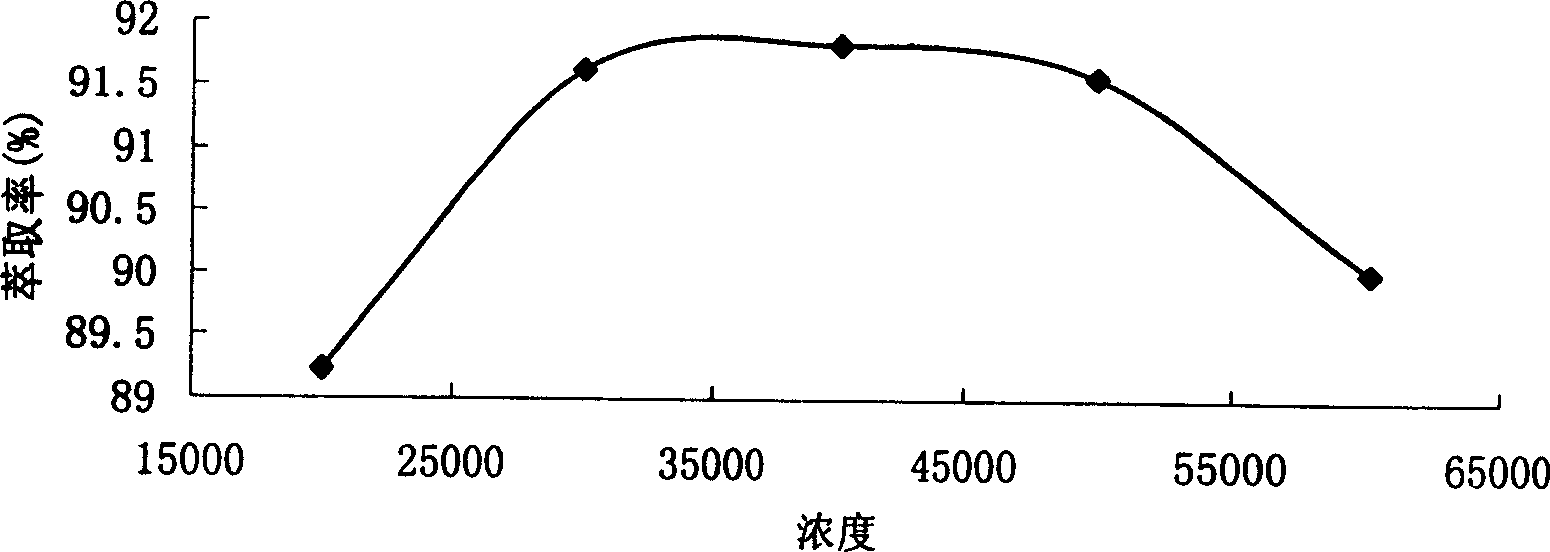

[0027] Accurately measure 350ml of penicillin G aqueous solution with a concentration of 19700u / ml, 31384u / ml, 42409u / ml, 52757u / ml, 60725u / ml and add it to a mixing tank with a stirring device. The ionic liquid [Bmim]PF 6 Compared with penicillin aqueous solution, it is 1:1.5 to add at one time, start stirring, so that the two phases are fully mixed, the temperature is controlled at 5 ° C ~ 10 ° C, slowly add 10wt% H 2 SO 4 , control the pH value to 2.0, stir for 15 minutes, stand still and separate the phases. After the two-phase interface is clear, use a pipette to take the heavy phase ionic liquid to measure its optical rotation value, and refer to the standard optical rotation curve of penicillin dissolved in the ionic liquid to obtain the ion The concentration of penicillin in the liquid, the volume of the ionic liquid phase is accurately measured, and the calculated extraction rates are 89.23%, 91.62%, 91.83%, 91.57%, and 90.02%, respectively. Show the relationship bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com