Dry and wet methods combined aluminum electrolysis flue gas deep treatment process

A dry-wet method, electrolytic aluminum technology, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., to achieve the effects of reducing emissions, solving fluorine salt recovery devices, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

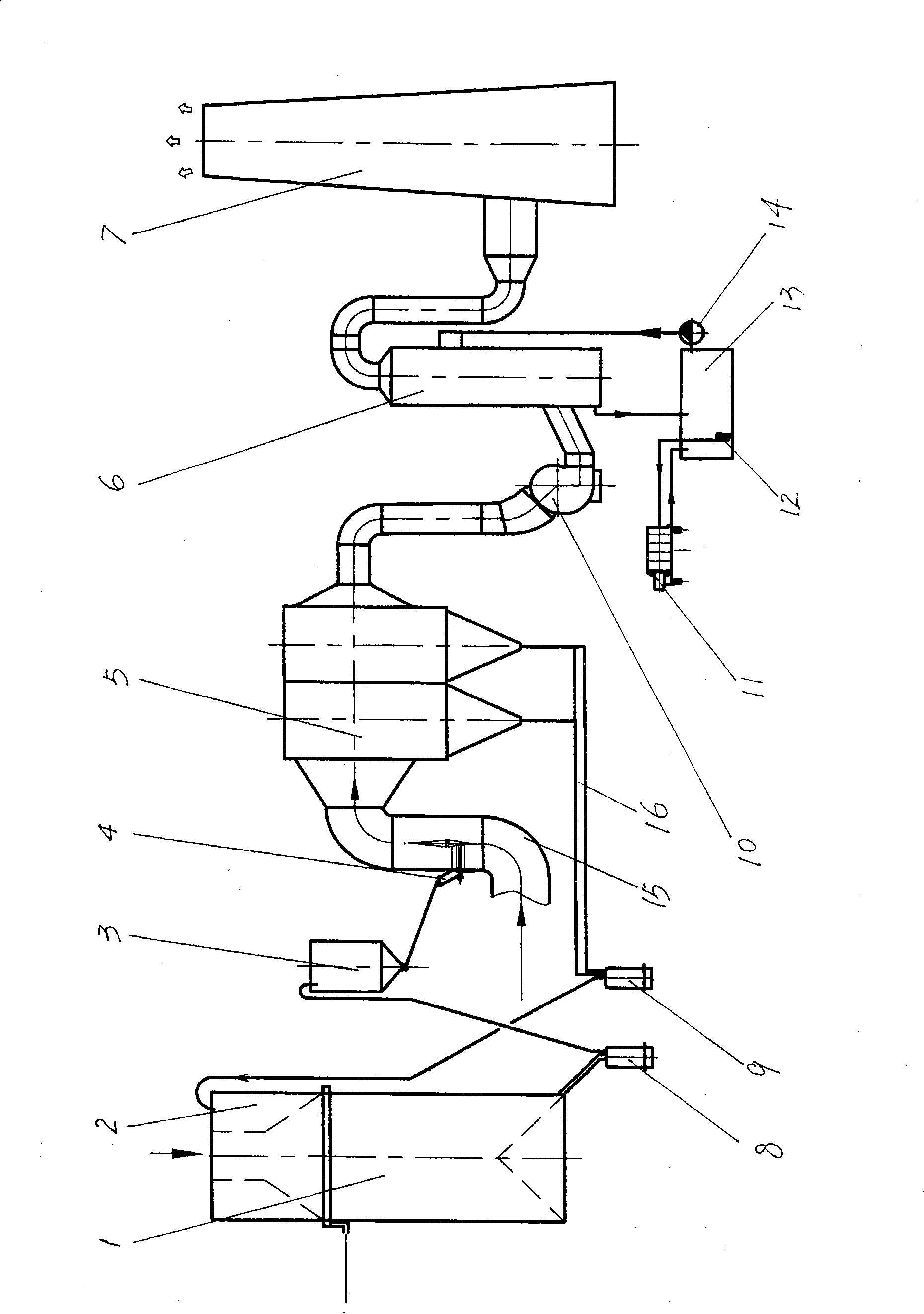

[0024] Accompanying drawing shows the flow chart of process technology of the present invention, and the electrolytic flue gas collected from electrolyzer enters waste gas flue 15, then upwards passes through VRI reactor 4, and the fresh alumina powder from fresh alumina powder storehouse 1 passes through hoist 8 is lifted to the small powder bin 3, fresh alumina powder flows into the VRI reactor 4 from the small powder bin 3 for adsorption reaction; then enters the electrostatic precipitator 5 for gas-solid separation, and the separated fluorine-loaded alumina powder goes to the material elevator 9 And be promoted to fluorine-carrying alumina powder bin 2, can go to electrolytic workshop production from fluorine-carrying alumina powder bin 2; The tail gas that goes out electrostatic precipitator 5 enters the bottom of absorption tower 6 through induced draft fan 10, and in the tower and comes from The absorption solution containing aluminum hydroxide and soda ash in the sedime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com