High-speed resin heavy-load grinding wheel

A heavy-duty, grinding wheel technology, used in grinding devices, grinding/polishing equipment, abrasives, etc., can solve the problems of harsh operating environment conditions, difficult to achieve, and many grinding wheel dressing times, and reduce environmental pollution and waste gas. Emissions, easy mass production, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

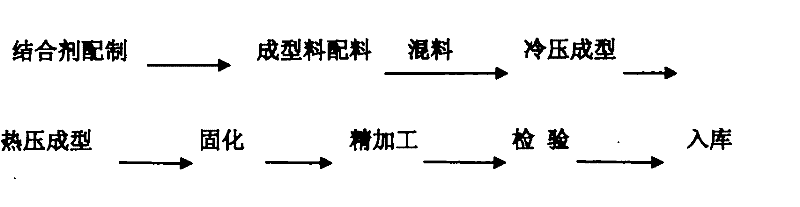

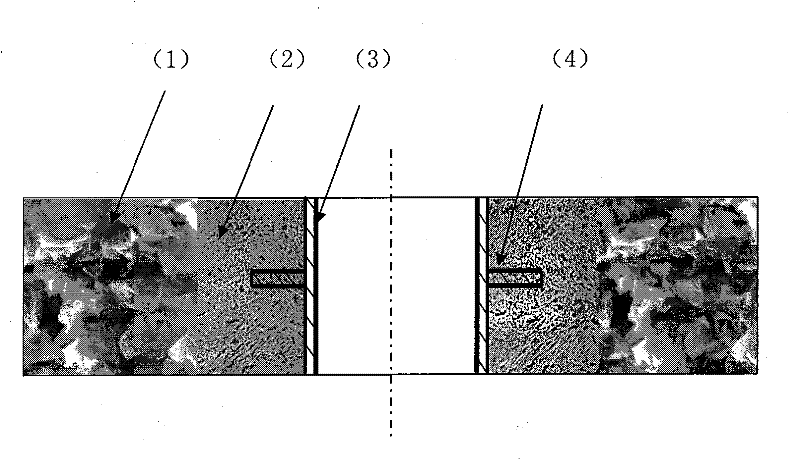

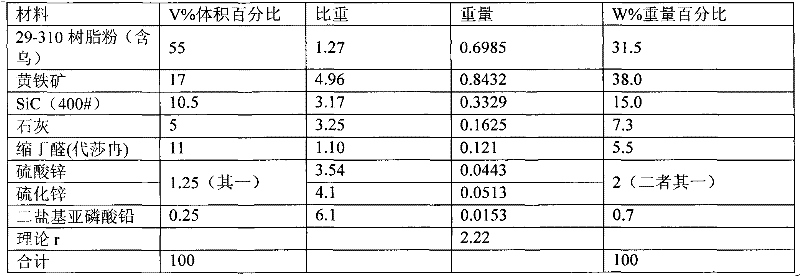

[0072] The following description is combined with the accompanying drawings: the high-speed resin heavy-duty grinding billet grinding wheel is developed by the composite technology and structural innovation of high-performance modified high-polymer-based phenolic resin grinding wheel special binder high-performance abrasives, fillers, wetting agents, and reinforcing materials. The system consists of three parts: grinding layer, core material and hole core. First, the preparation of high polymer-based modified phenolic resin and abrasive pretreatment 1 material selection (technical conditions of raw and auxiliary materials)

[0073] 1. Raw materials: zirconium corundum, alumina sintered corundum, and brown corundum meet the technical conditions set by national and industry standards.

[0074] 2. The components of the modified resin have been described above.

[0075] 3. Dibutyl fat, DBP: industrial grade, chemical name: dibutyl phthalate Appearance: transparent oily liquid, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com