Fixing method of isometric crystal and columnar crystal ceramic mold core in mold shell

A ceramic core and fixing method technology, applied in the direction of core, casting mold, casting mold composition, etc., can solve the problems of ceramic core offset, affecting the pass rate, and casting scrap, so as to improve the pass rate and reduce casting leakage. Core or wall thickness out of tolerance, effect of reducing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The blade is a ceramic core with a ceramic core rib length greater than 50mm and a width less than 10mm. figure 1 The "X" in the middle indicates the insertion point, and the serial numbers Ⅰ-Ⅶ indicate the number of insertion points. The high-temperature deformation of the ceramic core in the area of the insertion point "I" toward the leaf basin exceeds 0.3 mm, and the high-temperature deformation of the ceramic core exceeds 0.3 mm. If it is less than 10mm, insert a platinum wire; the high-temperature deformation of the ceramic core in the insertion point "II" and "III" area toward the leaf basin exceeds 0.3mm, and the length of the ceramic core with a high-temperature deformation exceeding 0.3mm is about 25mm, Insert two platinum wires; the size and high-temperature deformation of the ceramic core corresponding to the insertion point "Ⅴ" are the same as those at the insertion point "I", and the high-temperature deformation of the ceramic core in the areas "VI" and "V...

Embodiment 2

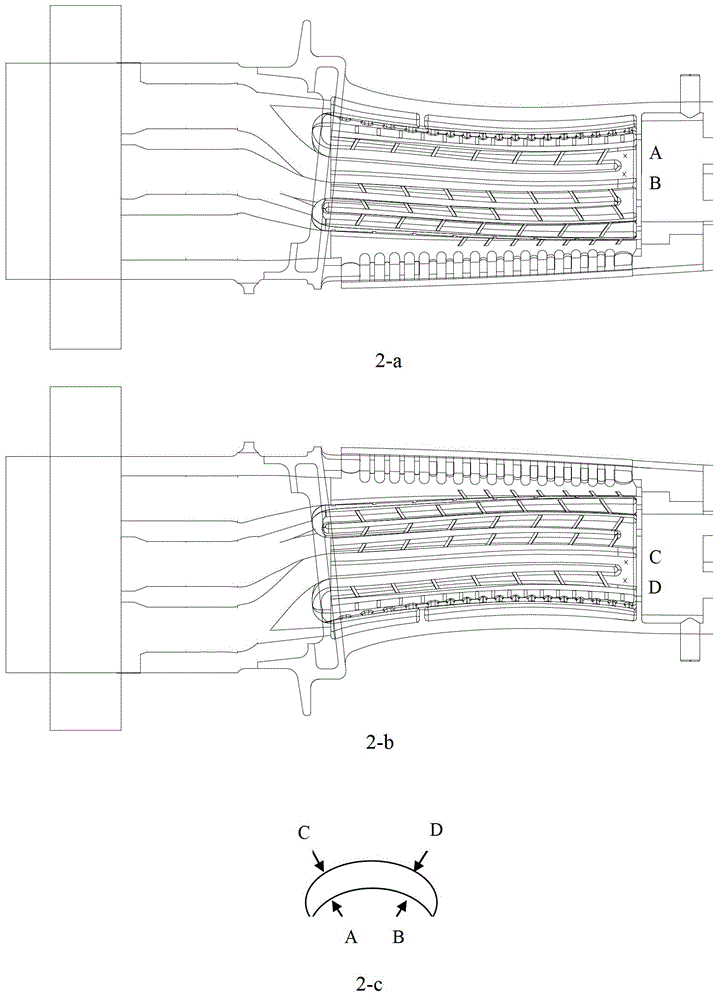

[0028] The blade is a cantilevered ceramic core, and the position of the insertion point of the platinum wire is limited, figure 2 The "X" in the middle indicates the insertion point, the serial number A-D indicates the number of insertion points, the insertion points "A" and "B" in the direction of the leaf pot and the insertion points "C" and "D" in the direction of the back of the blade, and the section of the cantilever position of the ceramic core is taken as X-Y plane, see the cross-sectional view of the cantilever position of the ceramic core. At this time, the position and quantity of the insertion point of the platinum wire should be based on the best position and minimum quantity of the cantilever position of the ceramic core when the position of the cantilever is fully constrained in the X-Y plane, that is, from the ceramic core The cantilever position section view can determine the A-D insertion point position, a total of four insertion points.

Embodiment 3

[0030] The blade is a ceramic core with a length greater than 50mm and a width greater than 10mm. image 3 The "X" in the middle indicates the insertion point, and the serial number 1-16 indicates the number of insertion points. The high-temperature deformation of the entire ceramic core exceeds 0.3mm. Insert a platinum wire every 10-15mm on the edge, such as image 3 As shown, 4 platinum wires are respectively inserted along the leaf pot and the leaf back on the side of the core head, and a total of 16 platinum wires are inserted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com