Inner layer granule reinforced cylinder sleeve and method of manufacture

A technology of particle enhancement and manufacturing method, applied in the direction of cylinder, cylinder head, machine/engine, etc., can solve the problems of affecting the service life of cylinder liner, long time for melting silicon particles, and easy peeling of reinforcement layer, saving raw materials and saving energy. The effect of eliminating the processing steps and lowering the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

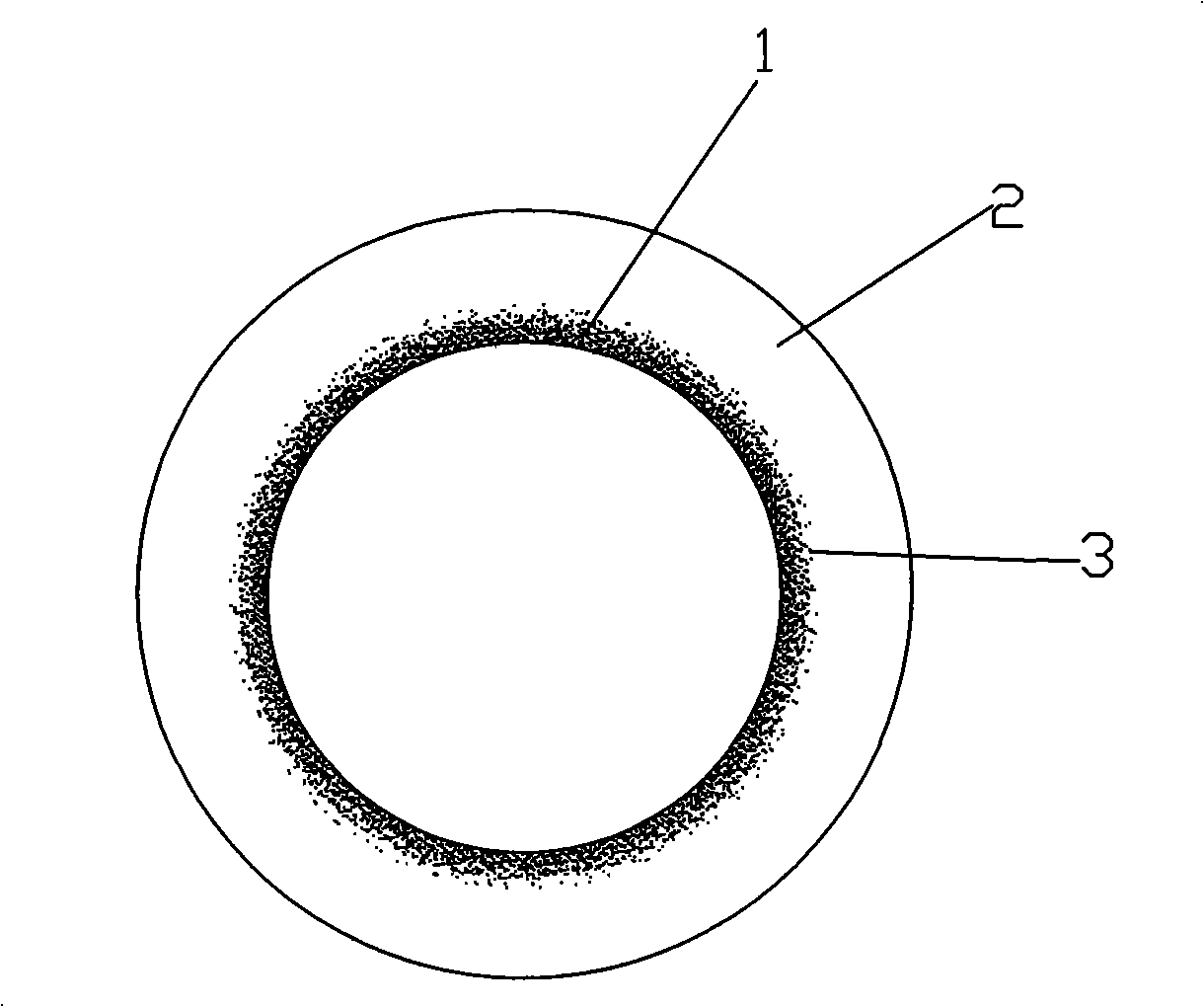

[0023] The reinforcement layer is located in the primary crystal Si and Mg on the inner surface of the cylinder liner 2 The Si reinforced particles are 10% by volume, and the primary Si and Mg 2 Among the mixed particles of Si, the primary crystal Si accounts for 20% by volume, and the particle size of the primary crystal Si is 20-120 μm, Mg 2 The particle size of Si is 20-40 μm.

Embodiment 2

[0025] The reinforcement layer is located in the primary crystal Si and Mg on the inner surface of the cylinder liner 2 The Si reinforcement particles are 20% by volume, and the volume percentage of the reinforcement particles in this embodiment makes the mechanical properties and wear resistance of the cylinder liner better than that of Embodiment 1; in primary Si and Mg 2 Among the mixed particles of Si, the primary crystal Si accounts for 50% by volume, and the particle size of the primary crystal Si is 20-120 μm, Mg 2 The particle size of Si is 20-40 μm.

Embodiment 3

[0027] The reinforcement layer is located in the primary crystal Si and Mg on the inner surface of the cylinder liner 2 The Si reinforcement particles are 35% by volume, and the volume percentage of the reinforcement particles in this embodiment makes the mechanical properties and wear resistance of the cylinder liner better than that of Example 2; in primary Si and Mg 2 Among the mixed particles of Si, primary Si accounts for 35% by volume, and the particle size of primary Si is 20-120 μm, Mg 2 The particle size of Si is 20-40 μm, and the volume percentage of primary Si in the reinforced particles of this embodiment makes the mechanical performance and wear resistance of the cylinder liner better than that of Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com