Manufacturing method of single-layer brazing diamond grinding wheel

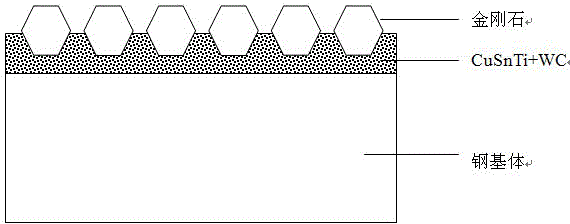

A single-layer diamond and diamond grinding wheel technology, used in the manufacture of tools, metal processing equipment, abrasives, etc., can solve the problems of reduced plasticity and toughness of welded joints, and achieve the effects of enhanced wear resistance, better mixing and lower raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for making brazed single-layer diamond grinding wheel: using TiH 2 As an active Ti source, Cu-Sn-TiH is used 2 The manufacture method of the brazing diamond tool selects Q235 steel as the grinding wheel matrix, and utilizes the method of mechanical processing to prepare the matrix of the diamond tool, degreases and derusts the processed grinding wheel matrix, selects 50 parts of Cu powder, 25 parts of Sn powder, 15 parts part TiH 2 Powder and 10 parts of WC powder are used as brazing material, among which Cu powder, Sn powder and TiH 2 The particle size of the powder is 80~200μm, and the particle size of the WC powder is 5~50μm; the solder is mechanically stirred for 25 minutes to mix evenly, and then the tool blank is prepared in the order of tool matrix / brazing material / diamond abrasive grains; diamond abrasive grains are placed on the surface 25 grains / cm 2 , the diamond particle size is 200~240μm, the abrasive particles are evenly distributed, the brazin...

Embodiment 2

[0020] A method for making brazed single-layer diamond grinding wheel: using TiH 2 As an active Ti source, Cu-Sn-TiH is used 2 The manufacture method of the brazing diamond tool selects Q235 steel as the grinding wheel substrate, and utilizes the method of mechanical processing to prepare the substrate of the diamond tool, degreases and derusts the processed grinding wheel substrate, selects 55 parts of Cu powder, 20 parts of Sn powder, 10 part TiH 2 Powder and 15 parts of WC powder are used as brazing material, among which Cu powder, Sn powder and TiH 2 The particle size of powder is 80~200μm, and the particle size of WC powder is 5~50μm; mechanically stir the solder for 30 minutes to mix evenly, and then prepare tool blanks in the order of tool matrix / brazing filler metal / diamond abrasive grains; place diamond abrasive grains on its surface 25 grains / cm 2 , the diamond particle size is 200~240μm, the abrasive particles are evenly distributed, the brazing material is place...

Embodiment 3

[0022] A method for making brazed single-layer diamond grinding wheel: using TiH 2 As an active Ti source, Cu-Sn-TiH is used 2 The manufacture method of the brazing diamond tool selects Q235 steel as the grinding wheel matrix, and utilizes the method of mechanical processing to prepare the matrix of the diamond tool, degreases and derusts the processed grinding wheel matrix, selects 50 parts of Cu powder, 30 parts of Sn powder, 15 parts part TiH 2 powder and 5 parts of WC powder as solder, including Cu powder, Sn powder and TiH 2 The particle size of the powder is 80~200μm, and the particle size of the WC powder is 5~50μm; the brazing filler metal is mechanically stirred for 20 minutes to mix evenly, and then the tool blank is prepared in the order of tool matrix / brazing filler metal / diamond abrasive grain; diamond abrasive grains are placed on the surface 25 grains / cm 2 , the diamond particle size is 200~240μm, the abrasive particles are evenly distributed, the brazing mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com