Toilet cover and surface coating technique thereof

A toilet cover and film coating technology, which is applied in the crafts, decorative arts, special patterns and other directions used to produce decorative surface effects, can solve the problems of diffuse dust in the workshop, and achieve the advantages of simplifying the production process, beautifully decorated product surfaces, and avoiding damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

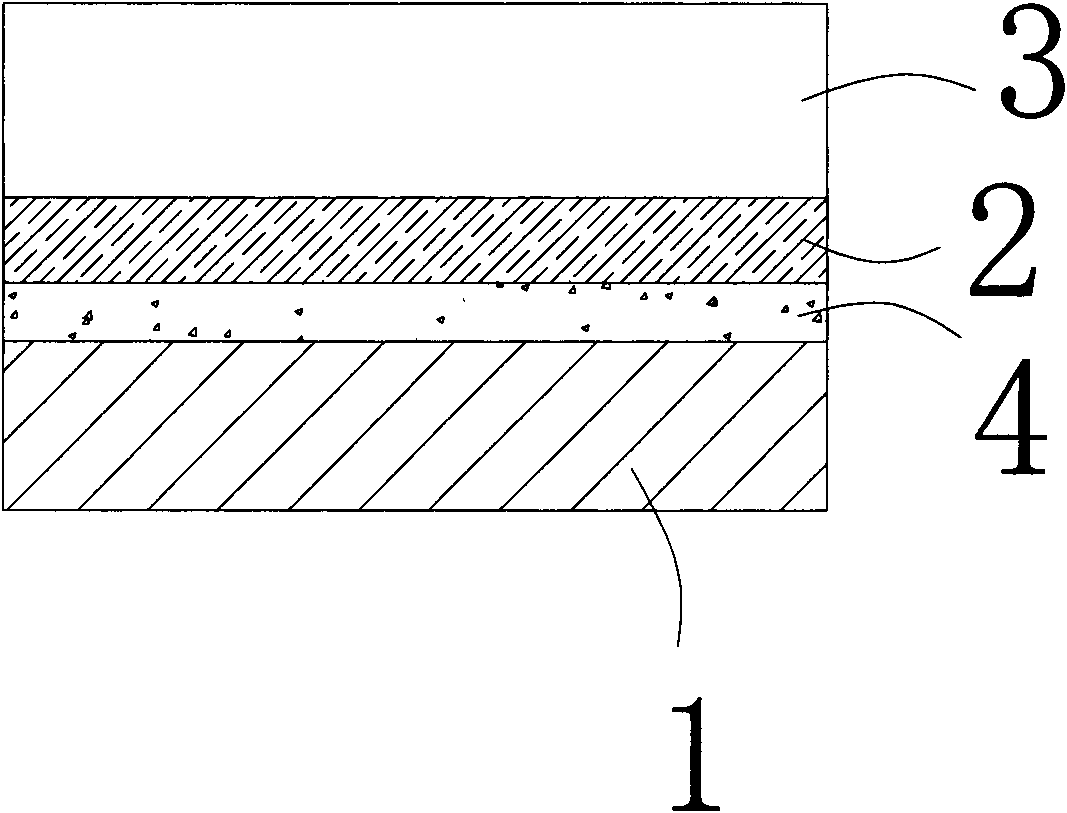

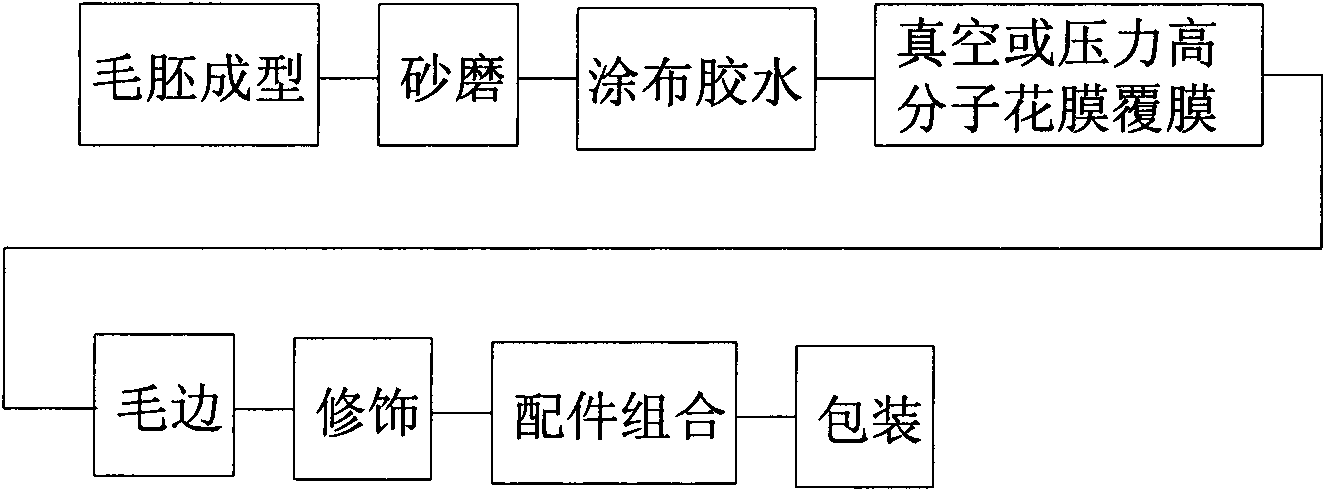

[0019] see figure 1 and figure 2 Shown, a kind of toilet lid surface coating process of the present invention, described toilet lid structure comprises toilet lid body 1, and is arranged on the toilet lid body 1, the decorative pattern pattern film 2, and is arranged on the pattern flower pattern The transparent mold 3 on the film 2 is used to protect the pattern flower film 2; the glue 4 for bonding the two is arranged between the toilet lid body 1 and the pattern flower film 2. Wherein, the pattern flower film 2 is embedded in the transparent mold 3, and no matter it is a plane or a three-dimensional pattern, it can be embedded in the mold, which can produce a relief effect, and can also change countless effects, such as metallic, three-dimensional, Multi-layered 3D sense, shiny sense, etc.; the surface decoration pattern is highly clear and processed by laser, which has a strong sense of layering and perspective three-dimensional effect, and can highlight the micro three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com