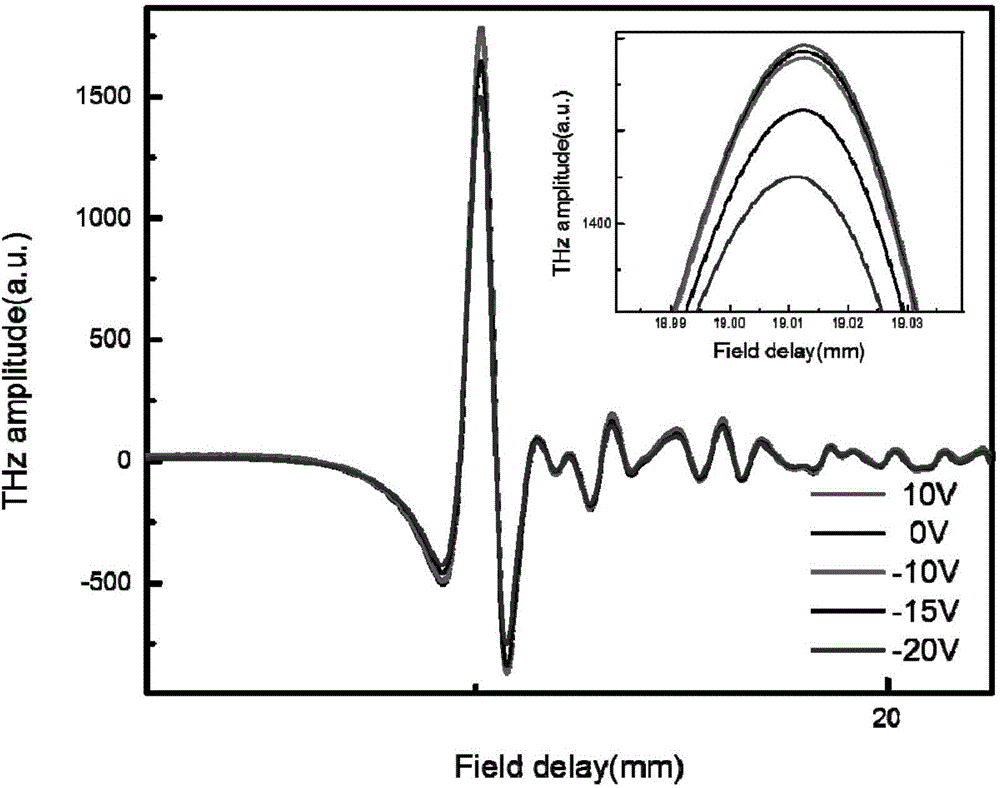

Graphene field effect transistor terahertz wave modulator and manufacture method thereof

A field effect transistor, terahertz wave technology, applied in the terahertz wave application field, can solve the problems of multiple defects, multiple pinholes, and low breakdown voltage, so as to improve the modulation rate and relative modulation depth, reduce leakage current, The effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

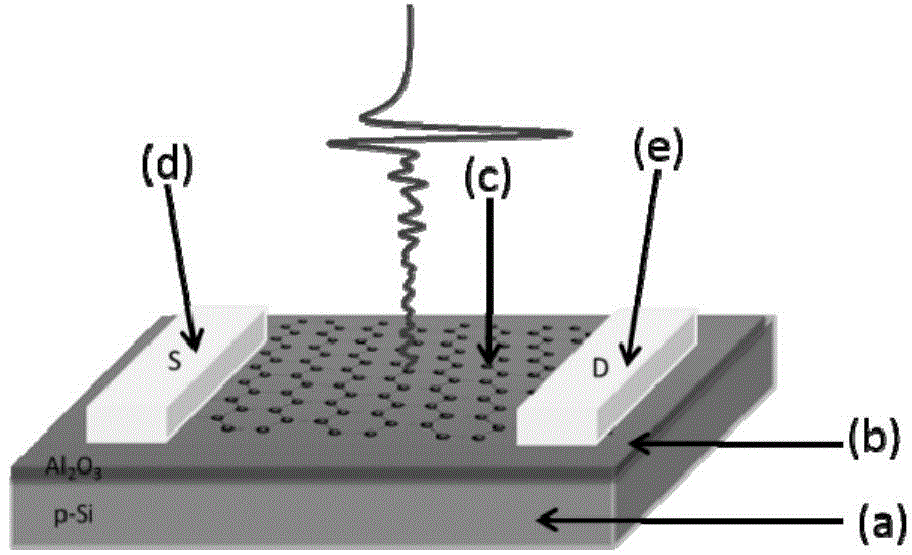

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings. It should be noted that the present invention is not limited to the embodiments.

[0030] The preparation of graphene field effect transistor terahertz wave modulator comprises the following steps:

[0031] Step 1. Cleaning the semiconductor substrate (a): first put the Si substrate into a beaker filled with acetone and perform ultrasonic cleaning for 10 minutes, then put the Si substrate into a beaker filled with alcohol for ultrasonic cleaning for 10 minutes, and finally use Rinse with deionized water, put the cleaned Si substrate into an oven and dry at 120°C for 2 hours for later use;

[0032] Step 2. Deposit dielectric layer: Deposit Al on the front side of the Si substrate by atomic layer deposition (ALD) 2 o 3For the dielectric layer, trimethylaluminum (TMA) is used as the aluminum source, oxygen is used as the reaction gas, and ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com