Quasi-TC4 titanium alloy for laser additive manufacturing application

A laser additive and titanium alloy technology, applied in additive manufacturing, additive processing, metal processing equipment, etc., can solve the problems of low plasticity, different solidification structure and original intragranular structure characteristics, high strength, etc., to achieve dense structure, The effect of excellent internal organization and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The class TC4 titanium alloy of the present embodiment is made up of the composition of following mass percent: Mo 1.05%, Al5.52%, V 3.53%, the balance is Ti and unavoidable impurity; The preparation process of this class TC4 titanium alloy comprises The following steps:

[0044] Step 1. Drying the element mixed powder of TC4-like titanium alloy at 100° C. for 4 hours; the average particle size of the element mixed powder is 100 μm to 150 μm, the mass purity is 99.8%, and the mass content of oxygen is 0.12%;

[0045] Step 2. Using the dried TC4-like titanium alloy element mixed powder in step 1 as the raw material powder, the TC4-like titanium alloy is prepared by the laser stereoforming method; the preparation process of the laser stereoforming method is as follows: The raw material powder is clad and deposited on the surface of the TC4 titanium alloy substrate to form a deposition body with a height of 20mm, and the deposition body is separated from the TC4 titanium a...

Embodiment 2

[0051] The difference between this example and Example 1 is that the TC4-like titanium alloy consists of the following components in mass percentage: Mo 1.98%, Al 6.79%, V 4.51%, and the balance is Ti and unavoidable impurities.

[0052] Figure 2a It is the macroscopic grain morphology figure of the class TC4 titanium alloy of the present embodiment, from Figure 2a It can be seen that the solidification structure of the TC4-like titanium alloy in this example presents the characteristics of a coarse columnar grain texture growing in the direction.

[0053] Figure 2b Be the optical microscope figure of the class TC4 titanium alloy of the present embodiment, from Figure 2b It can be seen that the microstructure of the TC4-like titanium alloy in this embodiment is a basket structure composed of fine α and β.

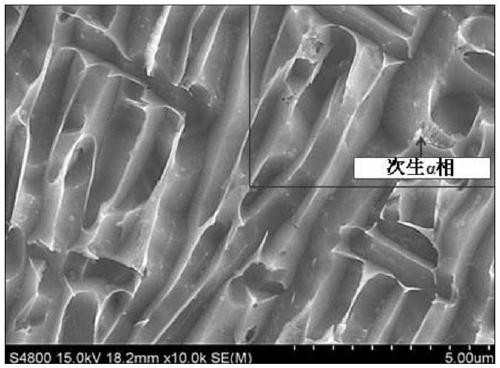

[0054] Figure 2c Be the SEM intragranular microstructure diagram (10000×) of the class TC4 titanium alloy of the present embodiment, from Figure 2c It can be se...

Embodiment 3

[0056] The difference between this example and Example 1 is that the TC4-like titanium alloy consists of the following components in mass percentage: Mo 1.49%, Al 5.94%, V 3.96%, and the balance is Ti and unavoidable impurities.

[0057] Figure 3a It is the macroscopic grain morphology figure of the class TC4 titanium alloy of the present embodiment, from Figure 3a It can be seen that the solidification structure of the TC4-like titanium alloy in this example presents the characteristics of a coarse columnar grain texture growing in the direction.

[0058] Figure 3b Be the optical microscope figure of the class TC4 titanium alloy of the present embodiment, from Figure 3b It can be seen that the microstructure of the TC4-like titanium alloy in this embodiment is acicular martensite composed of fine α and β phases.

[0059] Figure 3c Be the SEM intragranular microstructure diagram (10000×) of the class TC4 titanium alloy of the present embodiment, from Figure 3c It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com