Molding method and molding apparatus of composite material toughened thin rod

A composite material and a molding method technology are applied in the field of molding methods and devices for toughened thin rods of composite materials, which can solve the problems of large frictional resistance, complex process, fracture of toughened fibers, etc., and achieve friction reduction, cost reduction, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

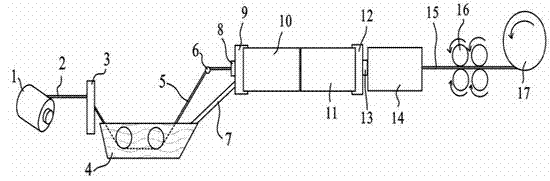

[0018] The molding method (abbreviation molding method, see Figure 1-9 ) includes the following steps: firstly, passing the resin-impregnated fiber bundle 5 through a primary forming mold 8, the inlet side 81 of the primary forming mold has a conical or parabolic profile, and the outlet side 82 is an axial section with a length of 4-18 mm. The first mold through-hole die cavity, the cross-sectional shape of the axial first mold through hole 82 of equal cross-section is the cross-sectional shape required by the product, thereby making the fiber bundle preliminary molded body consistent with the axial first mold through hole 82 cross-sectional shape; Heat or heat the preliminary molding fiber bundle 5 for the first time, and the preheating temperature is the initial reaction temperature of the resin; again, the fiber bundle 5 after the preheating is made to ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com