Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about How to "Improve thermal fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-boron low-alloy high-speed steel roll and preparation method thereof

ActiveCN101831590AReduce the amount addedReduce manufacturing costRollsElectric furnaceHardnessHigh-speed steel

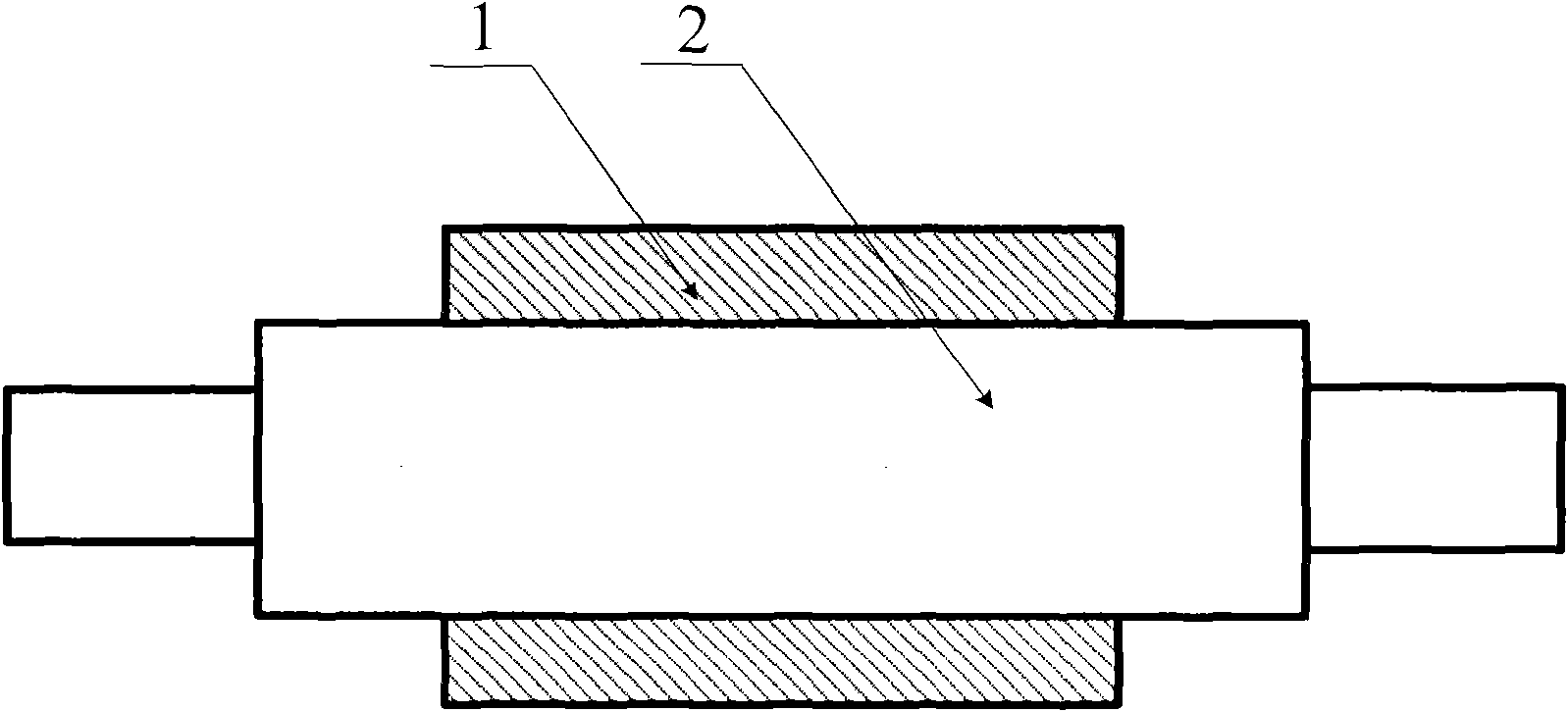

The invention relates to high-boron low-alloy high-speed steel roll and a preparation method thereof. The roll comprises two parts, namely a roll barrel (1) and a roll core (2), wherein the roll barrel comprises the following chemical components by weight percent: 0.32-0.55% of C, 1.42-2.13% of B, 5.2-6.5% of Cr, 2.5-4.5% of W, 1.6-1.8% of V, 0.5-1.0% of Nb, 0.3-1.0% of Si, 0.3-1.0% of Mn, 0.10-0.20% of Ti, 0.05-0.12% of N, 0.04-0.12% of Y, 0.08-0.15% of Mg, less than 0.04% of P, less than 0.04% of S and the balance Fe. The roll prepared by the method of the invention is characterized by high hardness, deep quenched depth and good wear resistance and thermal fatigue resistance, and has good use effect in the production of hot rolled steel.

Owner:JIANGSU DONGYE ROLL

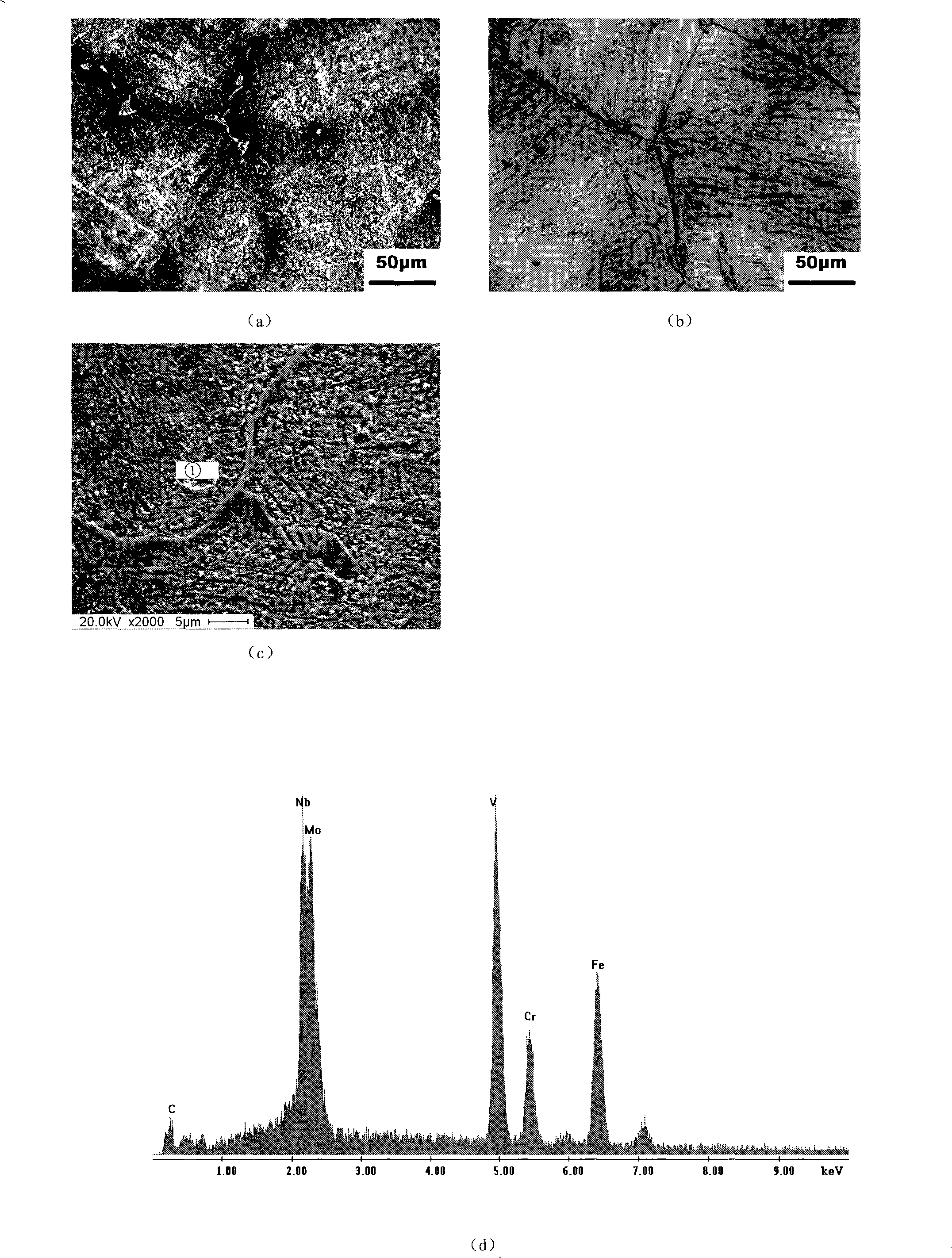

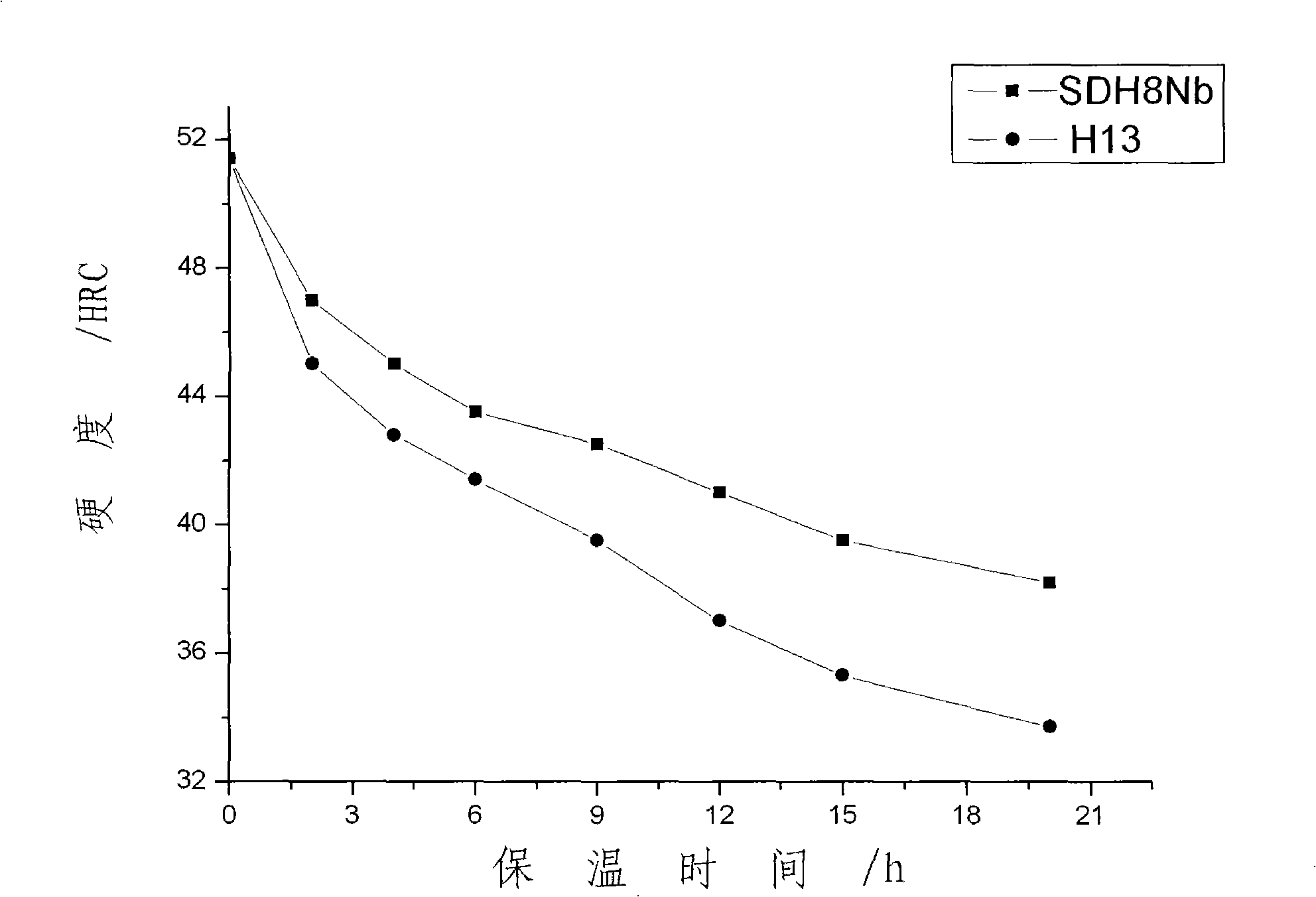

Niobium microalloyed high strength hot work die steel and preparation thereof

The invention relates to niobium microalloyed high-strength hot working die steel, belonging to the alloy steel manufacturing process technical field. The compositions by weight percentage of the steel are: 0.3 to 0.6 percent of C, 0.1 to 0.5 percent of Si, 0.1 to 0.5 percent of Mn, 4.0 to 6.5 percent of Cr, 1.0 to 3.5 percent of Mo, 0.4 to 1.4 percent of V, 0.02 to 0.10 percent of Nb, less than 0.03 percent of P, less than 0.03 percent of S, and the balance being Fe. The process for preparing the hot working die steel comprises the following steps of: batching, smelting, secondary refining and electroslag remelting; homogenizing the mixture for 5 to 10 hours at a temperature of between 1210 and 1300 DEG C, and forging, annealing, quenching and tempering the mixture; heating up the mixture to a temperature of between 1000 and 1100 DEG C for austenization, after performing 'step heating' at a temperature of 650 DEG C and at a temperature of 800 DEG C, then performing secondary tempering to the processed mixture, and finally acquiring the hot working die steel. The die steel has the advantages of good thermal resistance, good thermal stability and good thermal fatigue performance.

Owner:SHANGHAI UNIV

Compound microalloy hot die steel with high heat resistance and preparation method thereof

The invention relates to a compound microalloy hot die steel material with high heat resistance and a preparation method thereof, belonging to the technical field of the manufacture process of die steel. The invention is characterized by comprising the following components by weight percent: 0.25% to 0.4% of C, 1.0% to 1.8% of Si, 0.01% to 0.3% of Mn, 3.5% to 5.0% of Cr, 2.0% to 3.5% of Mo, 0.8% to 1.5% of V, 0.03% to 0.07% of Nb, 0.05% to 0.1% of rare earth element (Ce+La), less than 0.02% of P, less than 0.02% of S and the balance of Fe. The preparation method of the hot die steel comprises the process of: (1) adding rare earth after melting; (2) remelting electroslag; (3) homogenizing at high temperature; (4) forging and dissolving solid; (5) spheroidizing annealing; and (6) heating to finally prepare the hot die steel. The hot die steel has the advantages of high purity, high heat resistance, good heat stability and excellent heat fatigability.

Owner:SHANGHAI UNIV

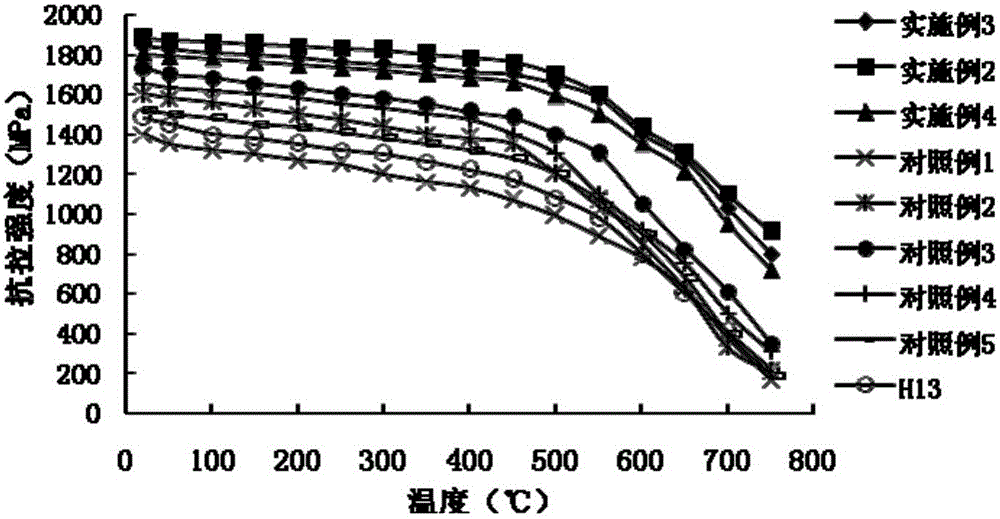

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

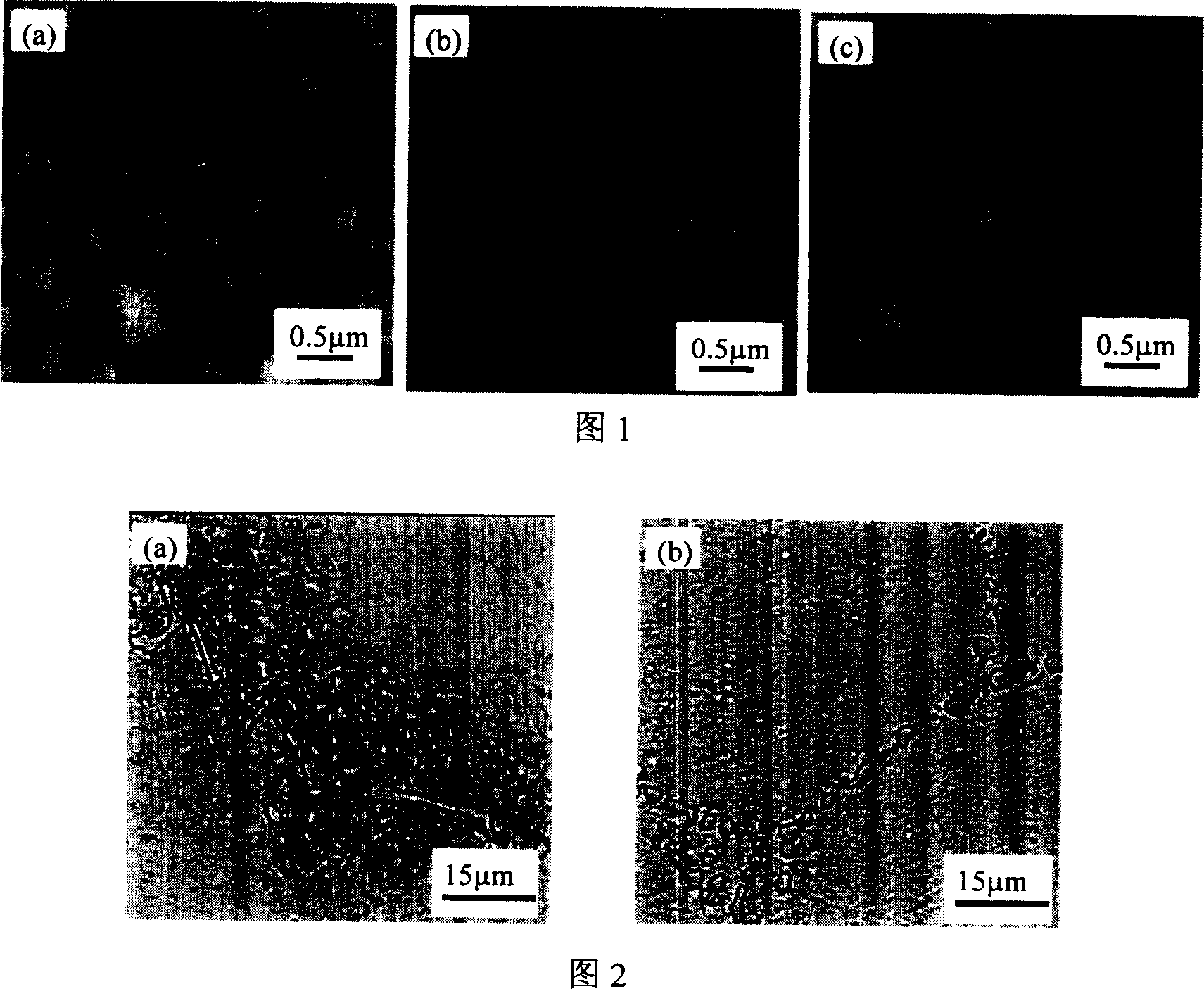

Ferritic stainless steel sheet with excellent thermal fatigue properties, and automotive exhaust-gas path member

InactiveUS20080279712A1Reasonable component designIncreased durabilityThermal fatigueLongest Diameter

Disclosed is a ferritic stainless steel sheet with excellent thermal fatigue properties, including, by mass %, 0.03% or less of C, 1.0% or less of Si, 1.5% or less of Mn, 0.6% or less of Ni, 10˜20% of Cr, 0.05˜0.30% of Ti, 0.51˜0.65% of Nb, 0˜less than 0.10% of Mo, 0.8˜2.0% of Cu, 0˜0.10% of Al, 0.0005˜0.02% of B, 0˜0.20% of V, and 0.03% or less of N, with the balance being Fe and inevitable impurities, having a composition satisfying the following equations (1) and (2) and having a structure in which ε-Cu phase grains each having a long diameter of 0.5 μm or more are present in a density of 10 or less per 25 μm2: Nb−8(C+N)≧0 . . . (1), 10 Si+20 Mo+30 Cu+20(Ti+V)+160 Nb−(Mn+Ni)≧100 . . . (2). The ferritic stainless steel sheet, having a relatively inexpensive component composition, has excellent thermal fatigue properties, and is suitable for use in an automotive exhaust-gas path member, including an exhaust manifold, a catalyst converter, a front pipe, or a center pipe.

Owner:NISSHIN STEEL CO LTD +1

Aramid fiber composite material, composite material for preparing solid tyre and manufacturing methods of two

The invention discloses an aramid fiber composite material solid tyre, a tread rubber layer composite material for preparing the solid tyre, a tread base rubber composite material and manufacturing methods of the tyre-surface rubber-layer composite material and the tread base rubber composite material. The solid tyre comprises a tread layer, a buffer layer, a tread base layer and a tyre internal steel ring; the tread layer is attached to the buffer layer, the buffer layer is attached to the tread base layer, and the tyre internal steel ring is embedded in the tread base layer; and the tread layer employs the tread rubber layer composite material, and the tread base layer employs the tread base rubber composite material. Aramid fiber possesses characteristics of high strength, good wear resistance, good temperature resistance and impact resistance, basalt fiber possesses high-temperature resistance characteristic, rubber possesses extremely good buffering performances, the above three materials are combined and the characteristics of the three materials are provided, and the solid tyre prepared from the composite material can be used on a high-temperature pavement or tropical region for a long time, is guaranteed to be uneasy to age, and is prolonged in service life.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

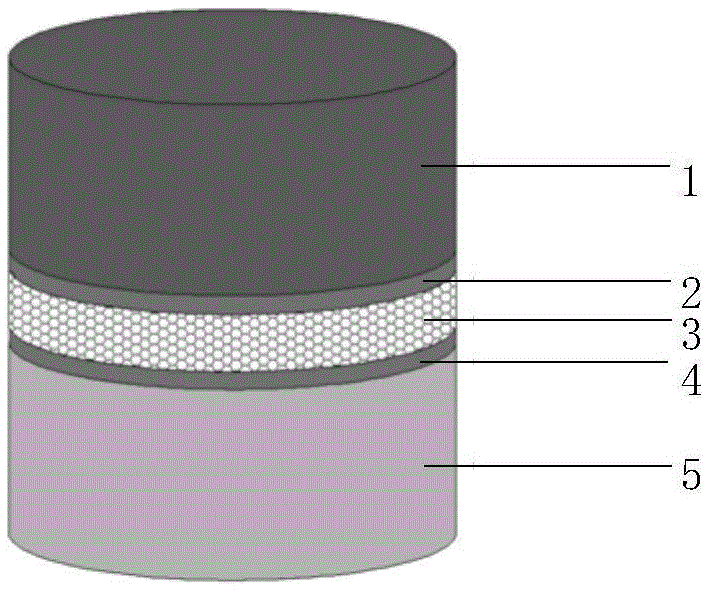

Ceramic and metal brazing composite component and preparing method thereof

InactiveCN105537712AHigh strengthImprove thermal fatigue performanceSoldering apparatusWelding/soldering/cutting articlesMetalworkingThermal fatigue

The invention provides a ceramic and metal brazing composite component. The composite component comprises metal, ceramic and a middle layer formed between to-be-welded faces of the ceramic and the metal; the middle layer comprises upper layer brazing filler metal, foam metal and lower layer brazing filler metal. The invention further provides a preparing method of the composite component. The preparing method comprises the steps that the upper layer brazing filler metal, the lower layer brazing filler metal and the foam metal are machined into an upper brazing filler metal layer, a lower brazing filler metal layer and a foam metal layer with the areas close to the area of the to-be-welded faces; the lower brazing filler metal layer, the foam metal layer, the upper brazing filler metal layer and to-be-welded metal are sequentially placed on the to-be-welded ceramic surface, and a certain pressure is applied to complete assembling; and an assembled sample is heated under the vacuum condition, is subject to heat preservation for a certain time, and then is cooled. The composite component has the excellent strength and thermal fatigue performance. According to the preparing method, existing materials can be directly used, complex pretreatment is avoided, and firm bonding between ceramic and metal can be achieved.

Owner:BEIHANG UNIV

Nickel base casting high temperature alloy for high temperature mould

ActiveCN1718803AImprove performanceImprove high temperature durabilityChemical compositionOxidation resistant

A high-temp casting Ni-base alloy for high-temp die contains proportionally Co, Al, Cr, Ti, W, Mo, No, Ta, Hf, C, B, Y and Ni. Its advantages are high high-temp strength, plasticity, anti-oxidizing, performance and stability, and better thermal fatigure nature.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

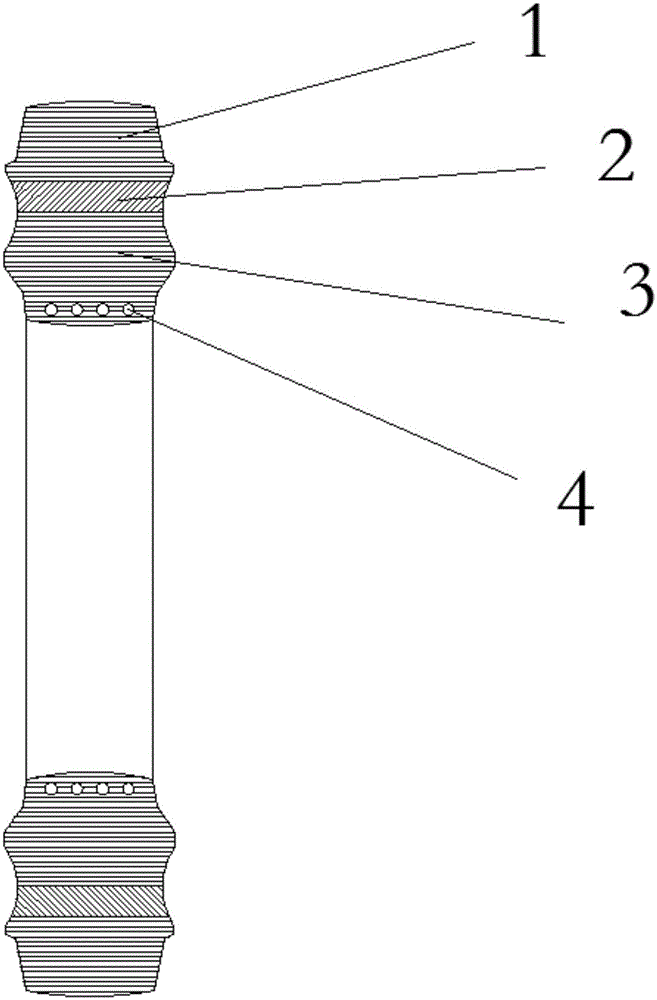

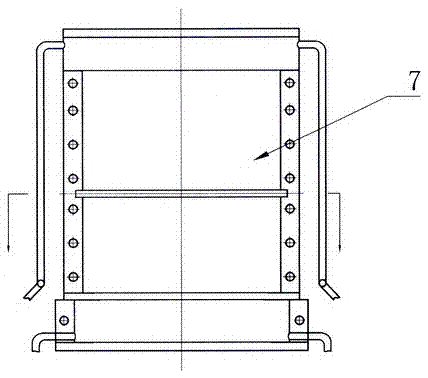

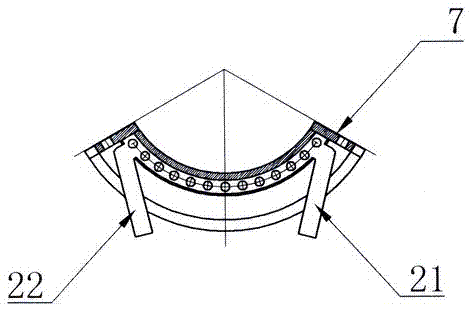

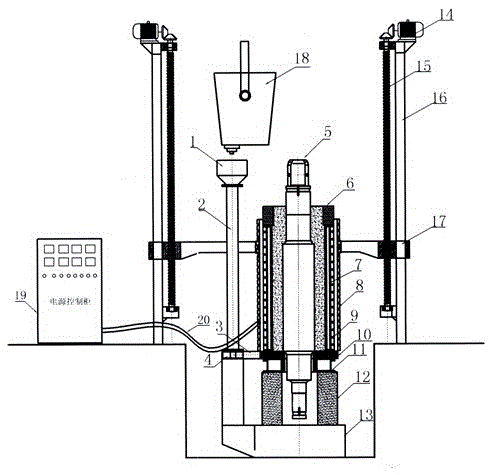

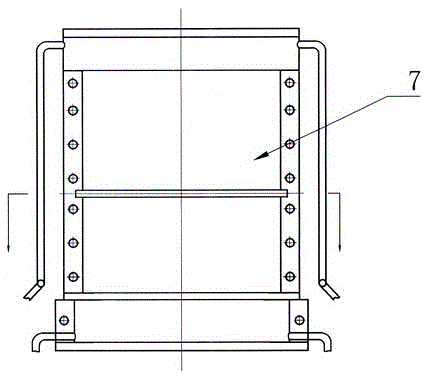

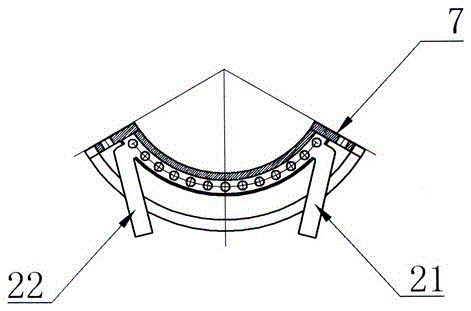

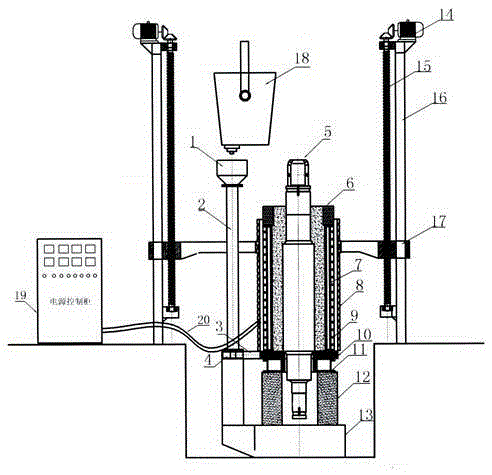

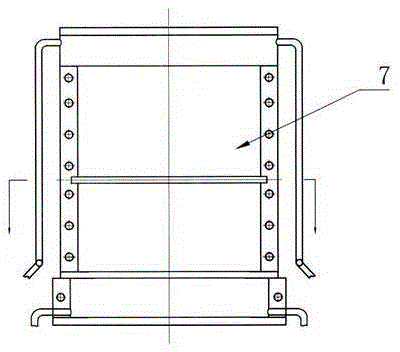

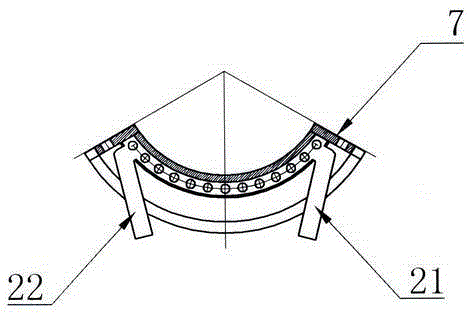

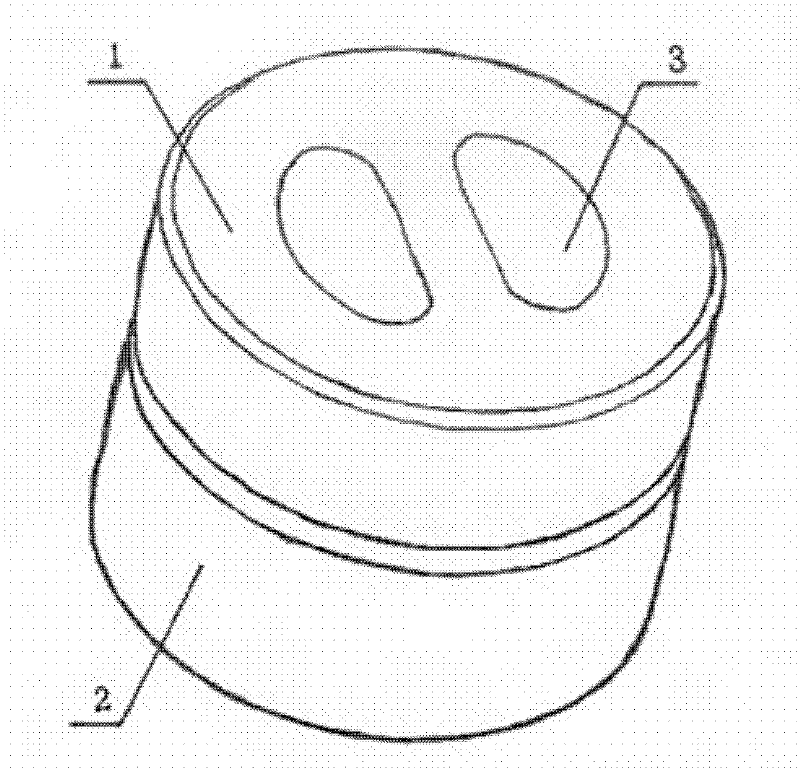

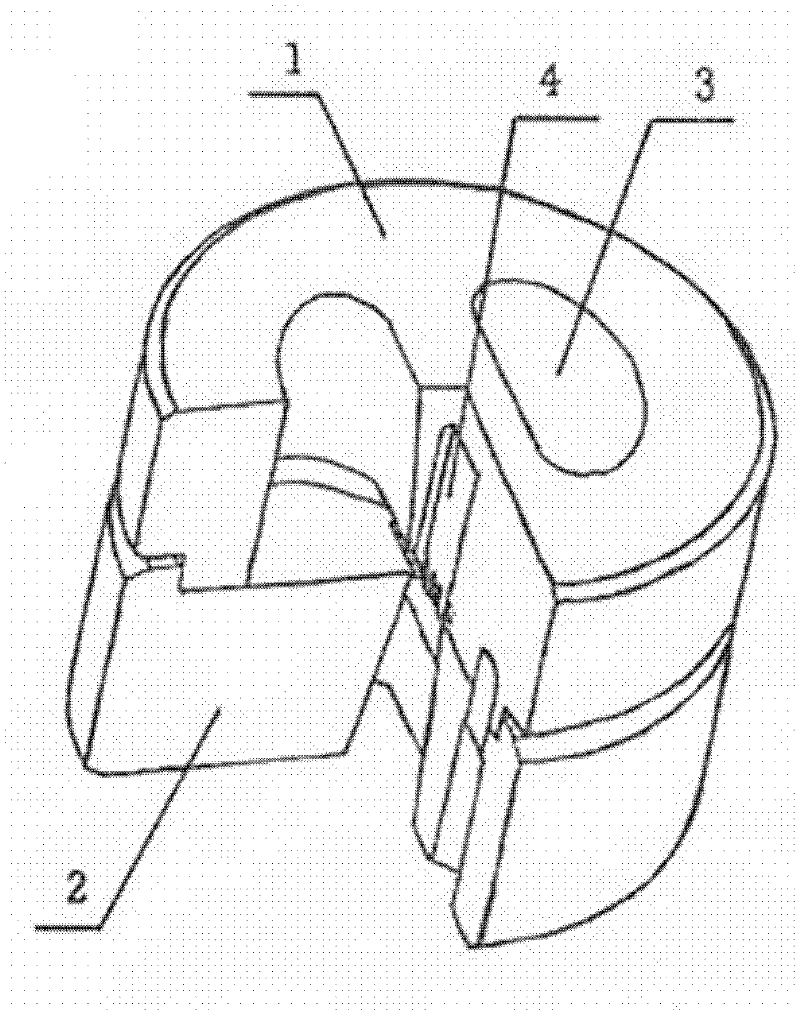

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

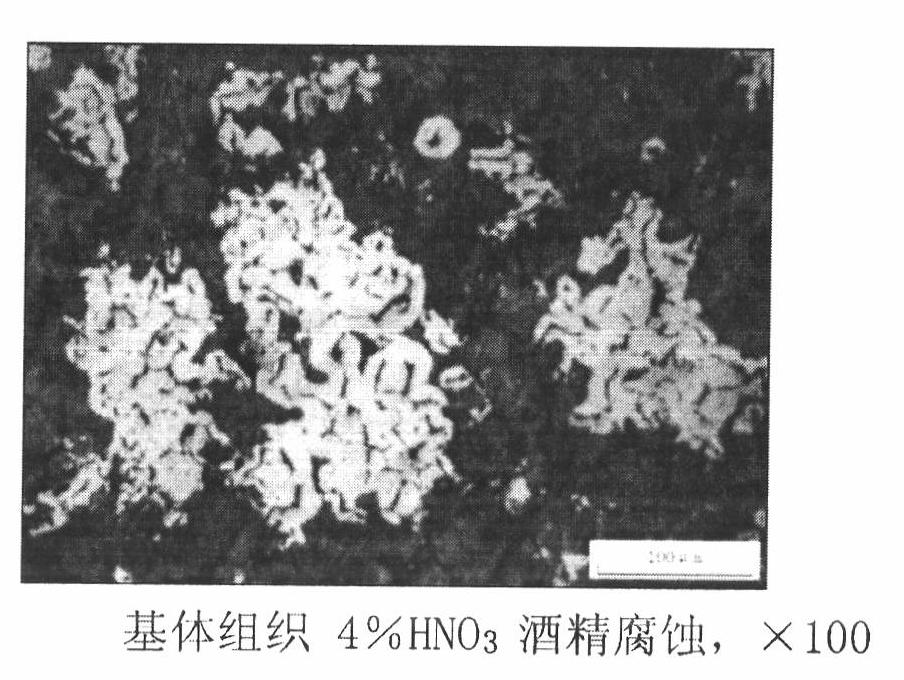

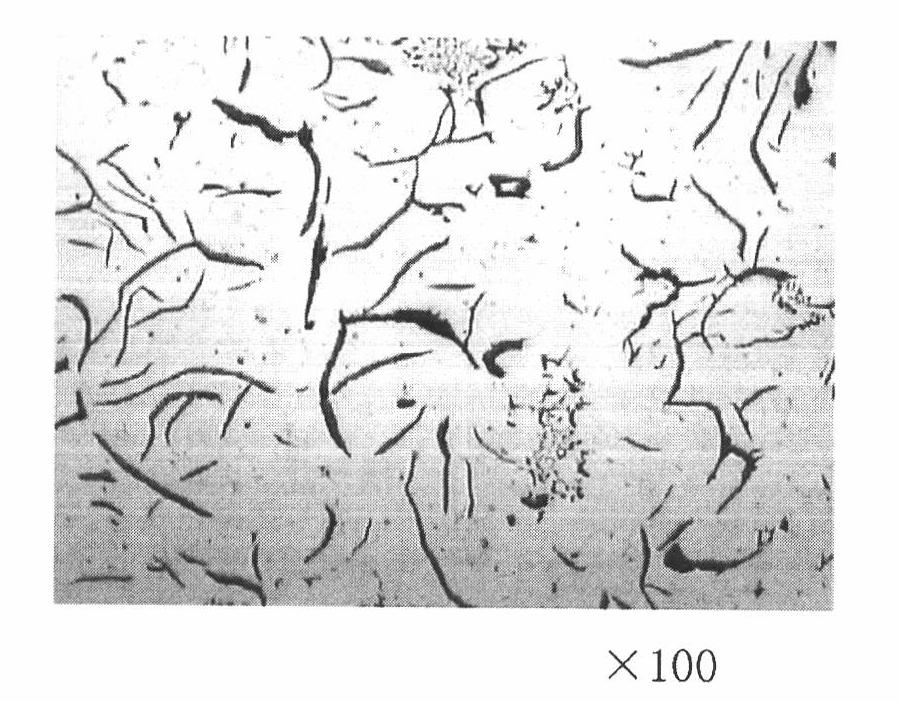

Thermal fatigue resisting and high performance hot working die steel and manufacturing process thereof

The invention relates to thermal fatigue resisting and high performance hot working die steel and a manufacturing process thereof and belongs to the technical field of alloy steel manufacturing processes. A base body of the thermal fatigue resisting and high performance hot working die steel is composed of, by mass, 0.15-0.30% of C, 0.00-0.40% of Si, 0.30-1.00% of Mn, 3.50-4.50% of Cr, 1.50-2.00% of Mo, 0.20-1.00% of W, 0.40-0.80% of V, 0.00-0.02% of P, 0.00-0.02% of S, 0.00-0.15% of Nb and the balance Fe. The manufacturing process of the thermal fatigue resisting and high performance hot working die steel comprises the steps that burdening, smelting, casting, then electroslag remelting, high temperature heat diffusion heat treatment, then multidirectional forging heat machining and post-forging control cooling are conducted; secondary carbide refining heat treatment and isothermal annealing processing are conducted; finally, quenching and tempering heat processing are conducted, the steel is heated to be 950-1100 DEG C for austenitizing, and two to three times of tempering are conducted at the temperature of 540-630 DEG C after oil cooling or mist cooling. The hot working die steel has high thermal fatigue resistance, high thermal stability and high toughness.

Owner:RUGAO HONGMAO HEAVY FORGING

Valve finisher surface modified processing method

InactiveCN1570192AHigh hardnessImprove stress resistanceMetal-working apparatusSolid state diffusion coatingThermal fatiguePlasma technology

The invention relates to a surface modification processing method for the engine critical component, which belongs to the field of the steel surface chemistry thermal treatment processing technology. The processing method comprises: nitriding for the air valve finisher by using the plasma technology, adding carbon-containing gas in the nitrogen-containing gas at the late stage of nitriding and carrying out the nitrocarburizing, and placing the mould in the steam oxidizing furnace for surface oxidizing treatment. The mould treated by said technology has excellent mechanical property, improved surface hardness, improved compression resistance, improved wear resistance and improved thermal fatigue resistance.

Owner:SHANGHAI UNIV

Vanadium-titanium vermicular graphite cast iron

The invention discloses a vanadium-titanium vermicular graphite cast iron which comprises the following compositions in percentage by weight: 3.4-3.9 percent of carbon, 2.1-2.8 percent of silicon, 0.5-0.9 percent of manganese, 0.10-0.35 percent of vanadium, 0.10-0.25 percent of titanium, 0.01-0.035 percent of residual manganese, 0.02-0.045 percent of residual rare earth, 0.1 percent of phosphorus or less, 0.07 percent of sulfur or less and the balance of iron, wherein in the vanadium-titanium vermicular graphite cast iron, the pearlite content is more than 50 percent, and the vermicular graphite rate is more than 60 percent. The vanadium-titanium vermicular graphite cast iron is used for a vehicle brake drum, is obtained with a vanadium-titanium pig iron as raw materials under the condition without singly adding other alloy elements and has the advantages of good mechanical property, high-temperature thermal fatigue resistance, hot cracking resistance, wear resistance, thermal conductivity, smaller wall thickness sensitivity and smaller vermicular fading property.

Owner:CHONGQING UNIV +1

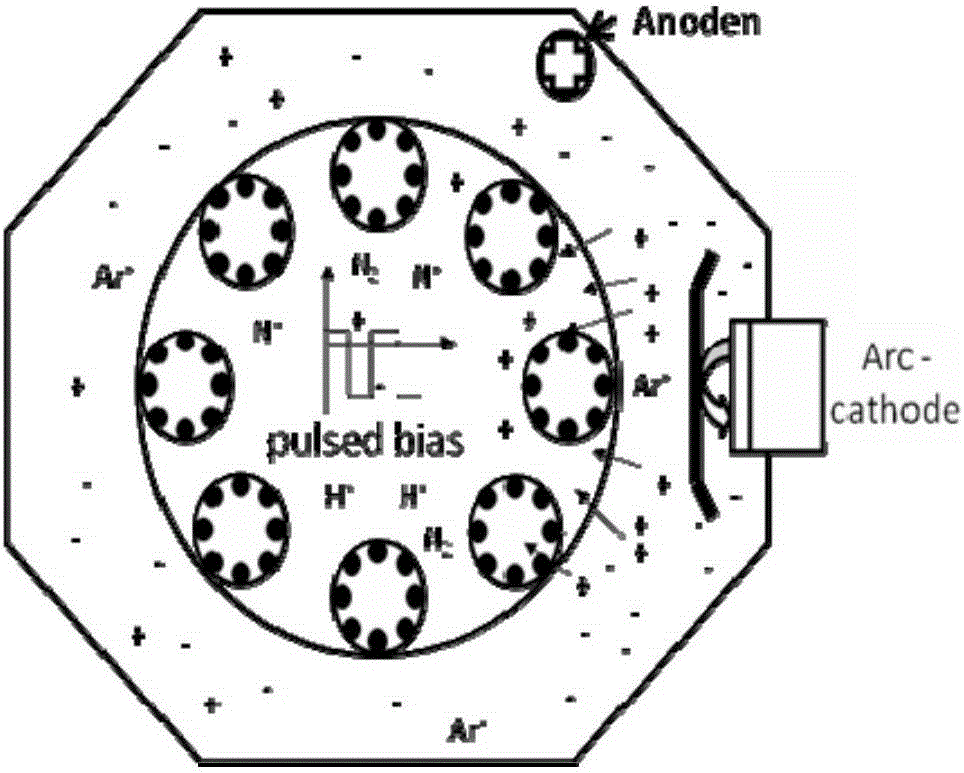

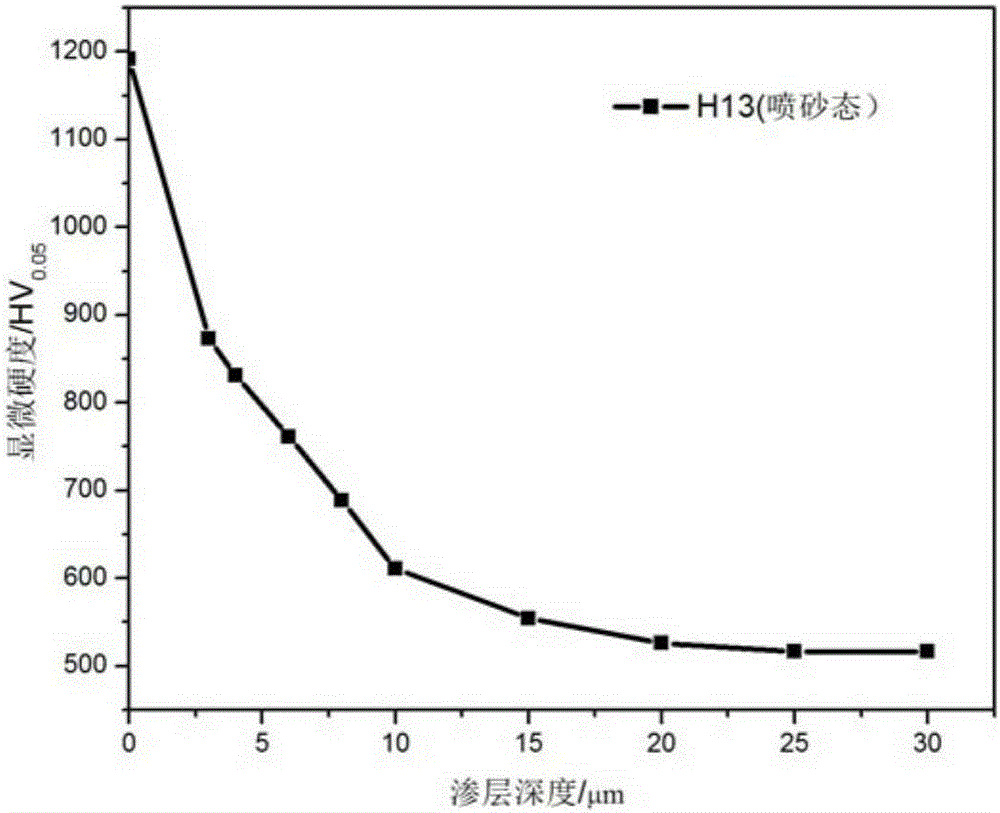

Electric arc plasma auxiliary low-voltage nitriding method for surface of hot-working die

ActiveCN105177493AImprove nitriding deficienciesIncrease plasma densitySolid state diffusion coatingEtchingPlasma nitridation

The invention discloses an electric arc plasma auxiliary low-voltage nitriding method for the surface of a hot-working die. The method includes the steps that firstly, ion etching is performed on the surface of the hot-working die through Ar+ generated by electric arc-enhanced glow discharge, so that oxide on the surface of the material is removed; then a certain flow of high-purity N2, high-purity H2 and high-purity Ar are continuously introduced to a furnace, the temperature ranging from 300 DEG C to 600 DEG C and the air pressure ranging from 0.2 Pa to 1.0 Pa in the furnace are kept constant, a workpiece rotation platform is connected with the negative electrode of a pulse power source, and plasma nitridation is performed; the depth of a nitriding layer in 2h nitridation ranges from 15 micrometers to 40 micrometers, the thickness of a compound layer in the nitriding layer ranges from 0 to 3 micrometers, the hardness ranges from 1000 HV<0.1> to 1300 HV<0.1>, and the brittleness level and the looseness level are both smaller than 1. In addition, the surface of a workpiece is effectively bombarded and activated in real time through argon ions, so that nitrogen atomic diffusion channels are increased, the nitriding process is accelerated, and finally the high-strength and high-tenacity nitriding surface layer is obtained.

Owner:SOUTH CHINA UNIV OF TECH

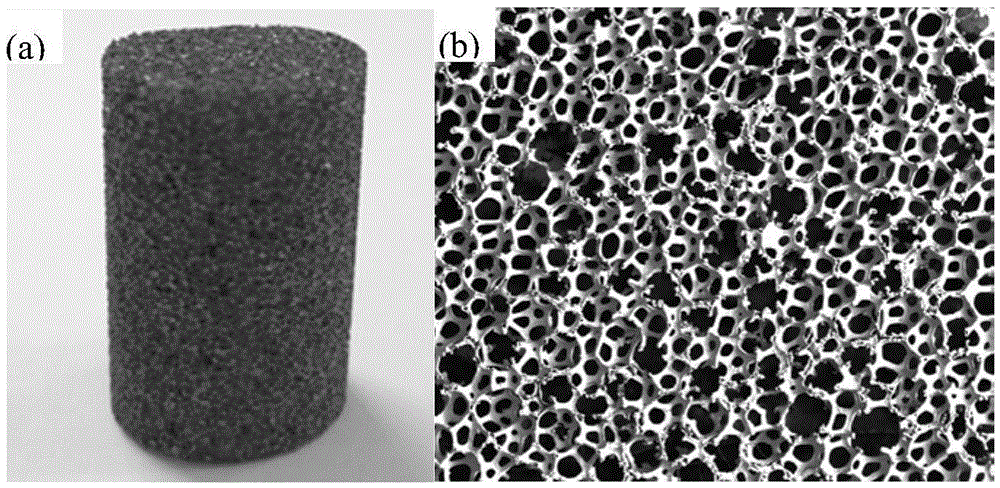

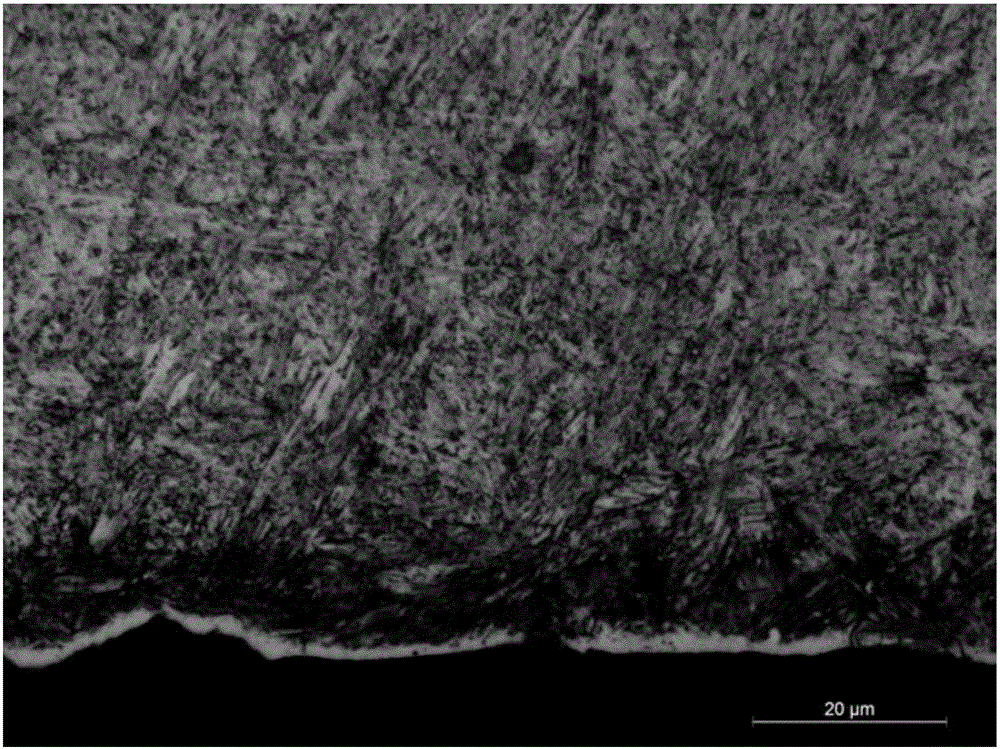

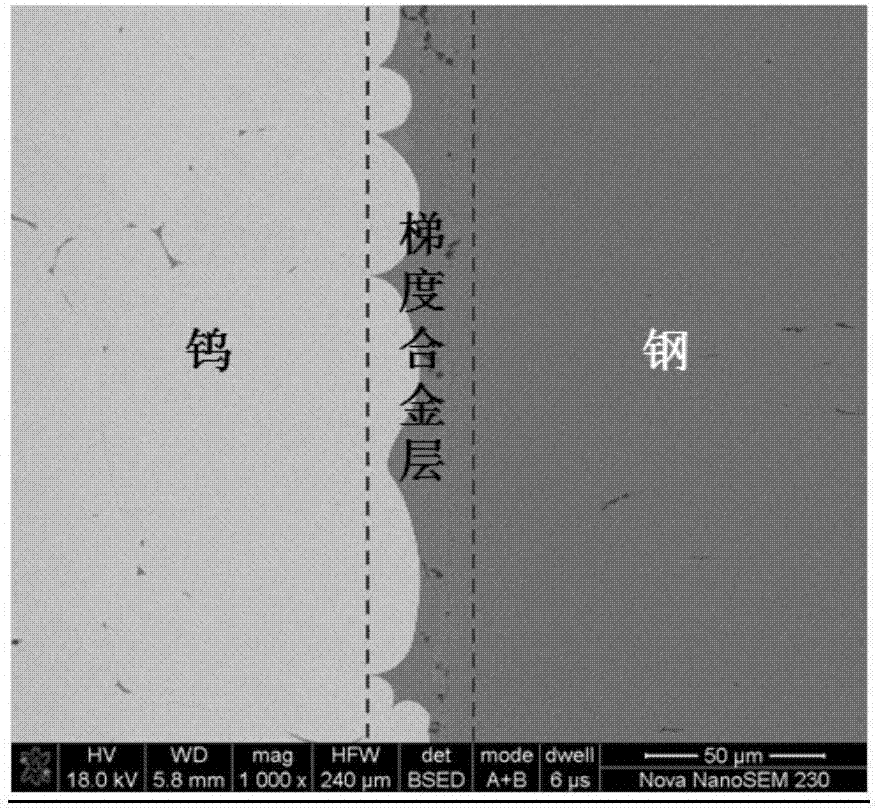

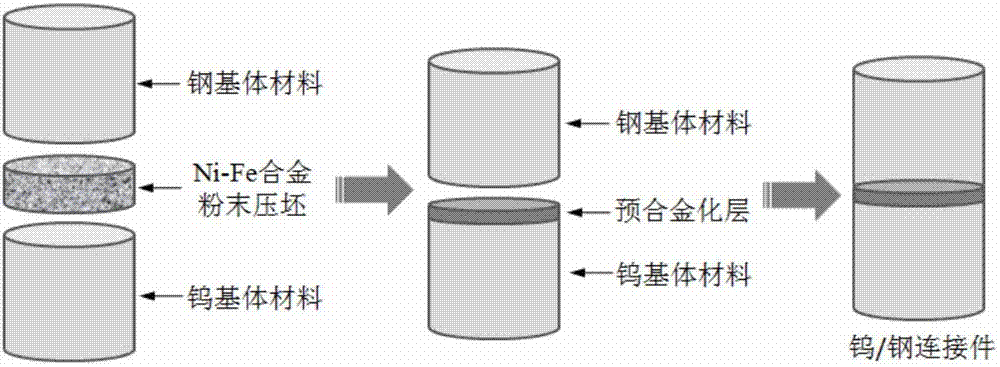

Tungsten/steel dispersion connecting method based on tungsten surface gradient alloying

InactiveCN107225249AImprove thermal fatigue performanceHigh strengthSoldering apparatusWelding/soldering/cutting articlesPowder mixtureDivertor

The invention relates to a tungsten / steel diffusion connection method based on tungsten surface gradient alloying, belonging to the technical field of composite material preparation. In the present invention, the nano-scale pre-alloyed mixed powder with a mass ratio of Ni and Fe of 7:3 is used as a raw material, and the surface of the tungsten substrate is subjected to gradient alloying treatment by high-temperature cladding and vacuum hot-pressing composite technology, and then the vacuum of tungsten and steel is carried out. Diffuse connection. The present invention forms a gradient alloy layer on the surface of the tungsten substrate through the configuration of nickel and iron components, vacuum hot pressing, high temperature cladding and vacuum diffusion and other process or parameter optimization, and obtains no defects at the interface and thermal fatigue performance Good, high interface stability of tungsten / steel composite structural parts. It can be used in the preparation of helium-cooled divertor components in magnetic confinement nuclear fusion experimental devices.

Owner:CENT SOUTH UNIV

Modified manufacturing process for high-chromium cast iron composite roll through forged steel roll neck and equipment

The invention discloses a modified manufacturing process for a high-chromium cast iron composite roll through a forged steel roll neck and equipment. The material comprises, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0%-0.05% of P, 0%-0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable microelements. Yttrium-based rare earth nodulizing and compound inoculating of Ba, Ca and silicon iron are adopted, and modification treatment is conducted by adding Nb, Ti, V, B, and Sb, so that the mechanical property of the roll is improved. The strength of the roll is improved through the forged steel roll neck. Overall in-mold heating and fusion casting are conducted on a core rod through an induction heater. Forming is conducted through a water cooled crystallizer. A composite layer interface can be dynamically controlled. The process is simple, the efficiency is high, power consumption is small, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

Austenite heat-resisting cast steel exhaust manifold and casting process thereof

ActiveCN103834876ARealize industrialized mass productionAchieve lightweightChemical compositionPressure casting

The invention discloses an austenite heat-resisting cast steel exhaust manifold which is prepared from the following chemical components in percentage by mass: 0.2-0.6% of C, less than or equal to 2.5% of Si, less than or equal to 0.2% of Mn, 24-32% of Cr, 12-24% of Ni, less than or equal to 0.5% of Mo, less than or equal to 0.5% of N, less than or equal to 2.1% of Nb, less than or equal to 0.04% of P, less than or equal to 0.15% of S and the balance of Fe. Industrial large-scale production of the austenite heat-resisting cast steel exhaust manifold is achieved by using a shell-type negative pressure casting process method, the produced austenite heat-resisting cast steel exhaust manifold has a good mechanics property, an anti-fatigue property and an anti-oxidation property, the service life of the exhaust manifold is greatly prolonged, and expense on repairing and assembling is reduced.

Owner:西峡县内燃机进排气管有限责任公司

High-grade hot work die steel with high performance and manufacturing method of high-grade hot work die steel

ActiveCN105803314AImprove high temperature strengthImprove stabilityHot workUltimate tensile strength

The invention provides high-grade hot work die steel with high performance. The die steel mainly comprises, by weight percent, 0.32%-0.41% of C, 0.2%-0.6% of Si, 0.6%-0.9% of Mn, 2.5%-4.5% of Cr, 2.5%-3.5% of Mo, 0.5%-1.1% of V, smaller than 0.02% of P, smaller than 0.0005% of S, and the balance Fe. The die steel has excellent high-temperature strength, temper resistance and heat conductivity performance, the structure AS1 grade in the NADCA#229-2011 standard can be obtained, the oxygen and sulfur content is lower than 10 ppm, and the ballistic work of the die steel is higher than H13 die steel by 30% under high hardness.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

Surface low-temperature boriding process for hot-work die steel

InactiveCN1970825AImprove wear resistanceHigh boronizing temperatureSolid state diffusion coatingBoridingHot work

The invention discloses a low-temperature boronizing method of heat mould steel surface, which comprises the following steps: a. proceeding nanometer disposal for steel mould surface; b. removing dirt on the surface of steel sample; c. boronizing in the vacuum; d. cooling to indoor temperature; coating boronizing agent with thickness at 2-5mm; drying.

Owner:HUBEI UNIV OF TECH

Method for cladding TiC enhanced Ni3Al based composite coating on surface of aluminum alloy

InactiveCN103233223AThe preparation process is stableIncrease productivityMetallic material coating processesLaser beam welding apparatusExothermic reactionAlloy surface

The invention relates to a method for cladding TiC enhanced Ni3Al based composite coating on the surface of aluminum alloy. The method comprises the following steps of: (1) cleaning the surface of aluminum alloy matrix metal and removing greasy dirt and an oxidation layer; (2) uniformly mixing a Ni-based material with TiC powder to serve as a coating material, wherein the weight content of the Ni element of the Ni-based material is over 75 percent; (3) forming a molten bath on the surface of the aluminum alloy matrix metal by using laser beams in an argon protection device; and (4) conveying the coating material into the molten bath to form metallurgical bonding with the aluminum alloy matrix metal, and performing chemical exothermic reaction between Ni and Al to form the TiC enhanced Ni3Al based composite coating. The method has the characteristics of stable preparation process, basic avoidance of sputtering or burning loss, high production efficiency and the like. The prepared TiC enhanced Ni3Al based composite coating cladded on the surface of aluminum alloy has the advantages of good surface quality, uniform TiC distribution and diffusion, tiny crystal particles, metallurgical bonding with the matrix, high wear resistance and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

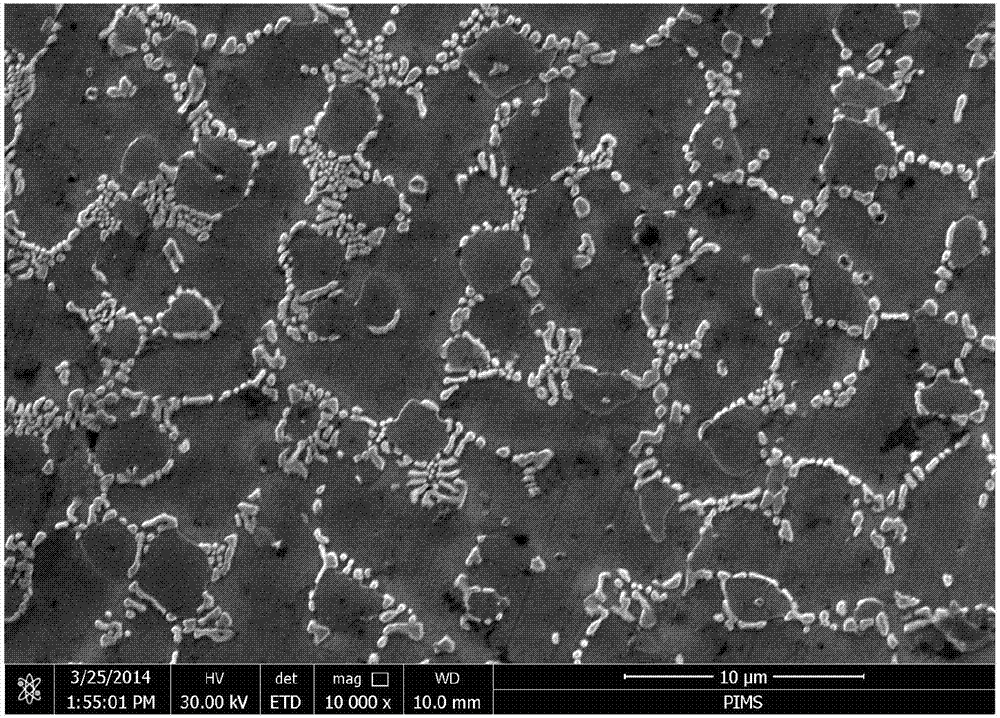

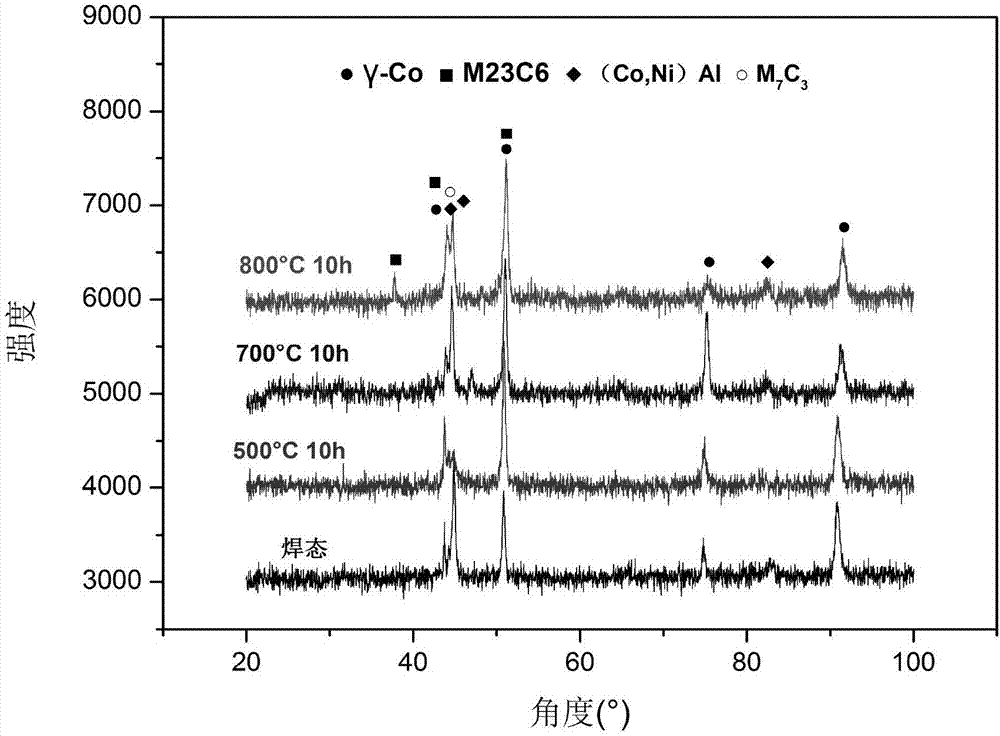

Cobalt-based alloy and cladding layer prepared from cobalt-based alloy

ActiveCN107326221AImproves abrasive wear resistanceBlock the path to rapid expansionMolten spray coatingChemical compositionMetallic materials

Provided are a cobalt-based alloy and a cladding layer prepared from the cobalt-based alloy. The cobalt-based alloy comprises Co, Ni, Cr, Fe, Si, W, C and Al. The cobalt-based alloy is specifically prepared from, by weight, 19-22.5% of Ni, 18-19.5% of Cr, 7.5-10.5% of Al, 0.8-1.1% of Fe, 0.7-1.0% of Si, 3.0-4.4% of W, 0.6-0.9% of C, and the balance Co and smaller than 0.1% of inevitable impurities, and the mass percent of Ni and Co is greater than 0.4 but smaller than 0.56, and the mass percent of Ni and Al is greater than 2 but smaller than 2.7. The cobalt-based alloy can be used for preparing the cladding layer with high abrasion resistance performance and heat fatigue resistance performance, and the cladding layer not only can be used for repairing and enhancing a friction layer of a brake disc, but also can be used as the friction layer of the brake disc and a protection layer on the surface of other metal materials needing to bear repeated heat impact and having friction abrasion in the environments like mold cavity linings, engine pistons and inner cylinders, petroleum pipeline valve inner walls.

Owner:SOUTHWEST JIAOTONG UNIV

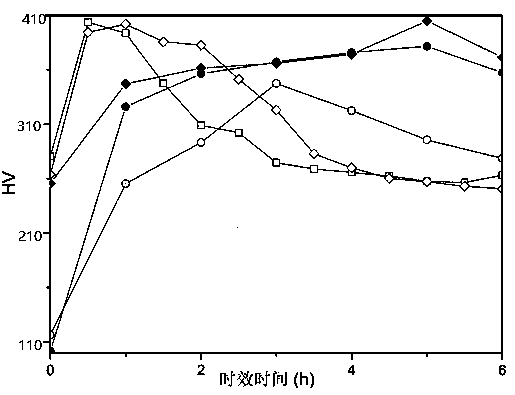

Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

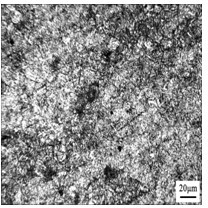

The invention relates to a preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The Cu-Ni-Sn multi-element alloy is obtained through vacuum induction melting or covering protection type non-vacuum smelting. In the casting forming process, electromagnetic stirring is applied until alloy liquid is complete solidified, and then the as-cast alloy is subjected to homogenization annealing, hot rolling and cogging, solid solution treatment, cold deformation, spinodal decomposition and other processes. The preparation method of the Cu-Ni-Sn alloy is capable ofrefining crystalline grains, reducing dendritic spacing and eliminating alloy microscopic and macroscopic structure and component segregation, provides implementation conditions for follow-up alloy plastic processing, spinodal decomposition and other processes, and has the beneficial effects that energy is saved, the production efficiency is improved, the service life of the alloy is prolonged, and the production cost is reduced.

Owner:JIANGYIN SANLING METAL PROD

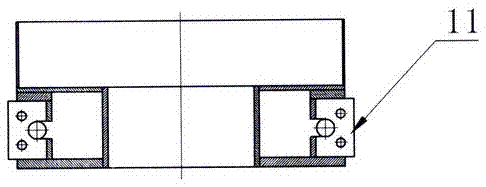

Manufacturing technique and equipment for high-performance composite roller shaft

The invention discloses a manufacturing technique and equipment for a high-performance composite roller shaft. The manufacturing technique comprises the steps that a mandril installed in a combined water-cooling crystallizer is integrally heated to 840-1100 DEG C through an induction heater; molten liquid of a working layer of the roller shaft is poured into the mandril, and then the mandril is continued to be heated for 10-50 minutes; a lifting device is stared so as to lift the heater at a certain speed for 5-15 minutes, and the heater is stopped in the position of a heat-insulating ring; and heating is continued for 10-50 minutes, feeding is conducted on a dead head, and after heating is stopped, cooling is conducted for 30 minutes to 24 hours through water. When the composite roller shaft is manufactured through the manufacturing technique, the number of controllable technological parameters is small, the interface of a composite layer is easy to control, the technique is simple, the efficiency is high, the power consumption is low, the cost is low, the composite layer is free of composition segregation, and the service life of the roller shaft is long; the defect of a centrifugation method that structure segregation is prone to occurring is overcome, and the problems of a CPC method and an ESR method that the production technique is complex, and the cost is high are solved.

Owner:丹阳恒庆复合材料科技有限公司

Copper alloy wire and copper alloy spring

ActiveCN103261460AGood strength propertiesGood electrical conductivitySingle bars/rods/wires/strips conductorsConductive materialElectricityX-ray

A high-strength and high-conductivity copper alloy wire and a copper alloy spring made from the copper alloy wire are provided. The copper alloy wire is a copper alloy filamentary material containing, in percent by mass, 3.0 to 15.0% Ni, 0.5 to 5.0% Al, and 0.1 to 3.0% Si, with the remainder being composed of Cu and incidental impurities, and is provided with a tensile strength ([sigma]B) of 900 to 1300 Mpa, and electrical conductivity of 10 to 22% IACS. In addition to the abovementioned characteristics, the copper alloy wire satisfies a strength ratio of A : B : C of 1 : 1.2 to 6.0 : 2 to 8.0 when A, B and C represent the diffraction intensities of Cu (111), Cu (200) and Cu (220) according to X-ray diffraction in a prescribed cross section. By using the copper alloy wire as a copper alloy spring that can be used for a conductive spring that can cope with heat sagging, the copper alloy spring can be incorporated in mobile phones and various electronic devices etc., and used as an operation or contact spring etc. The copper spring wire does not contain harmful elements such as Be, has excellent conductivity and spring characteristics, and is particularly excellent in resisting heat sagging due to heat generated when conducting electricity.

Owner:NIPPON SEISEN CO LTD +1

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

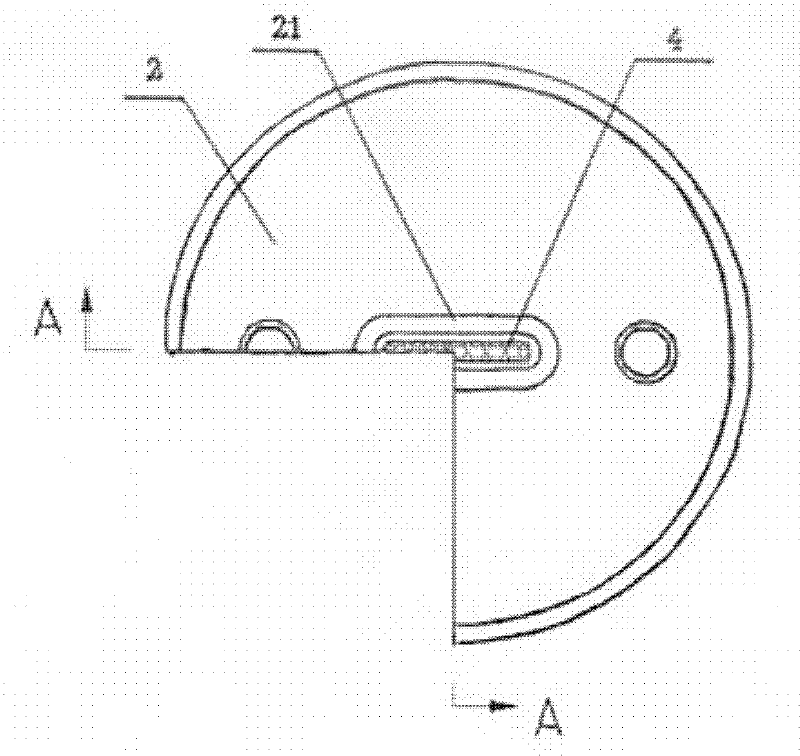

Micro channel flat pipe mould for horizontal type hot-extrusion

InactiveCN102189147AImprove wall thickness uniformityHigh dimensional accuracyExtrusion diesThermal fatigueThermal stability

The invention discloses a micro channel flat pipe mould for horizontal type hot-extrusion, relating to a mould. The mould comprises an upper mould plate and a lower mould plate, the upper mould plate and the lower mould plate are tightly matched. The module is characterized in that the upper mould plate is provided with two symmetrical flow-dividing holes, one side of each flow-dividing hole is a straight side, the other side of the flow-dividing hole is a circular arc, and two straight sides of the two flow-dividing holes are opposite to each other; the middle parts of the two flow-dividing holes in the upper mould plate are provided with module core slots; the module core slots are internally provided with module cores of the upper module plate; a welding chamber is arranged at a position corresponding to the flow-dividing holes, on the bottom of the upper module plate; a module core of the lower module plate is arranged at a position corresponding to the module core slots, on the lower module plate; the module core of the upper module plate can be concentrically matched with the module core of the lower module plate; and a plurality of uniformly-spaced module needles are arranged at the end parts of the module core of the upper module plate side by side. By adopting the micro channel flat pipe mould for horizontal type hot-extrusion, a porous high-precision micro-channel flat pipe with good uniformity of wall thickness, high precision dimension, clean surface and complicate shape can be manufactured; the service life of the module provided by the invention is 3-6 times longer than the service life of a common extrusion module; and the invention has good thermal stability, thermal fatigue, thermal wear resistance and toughness.

Owner:LIAOCHENG WANBANG NEW METAL MATERIAL

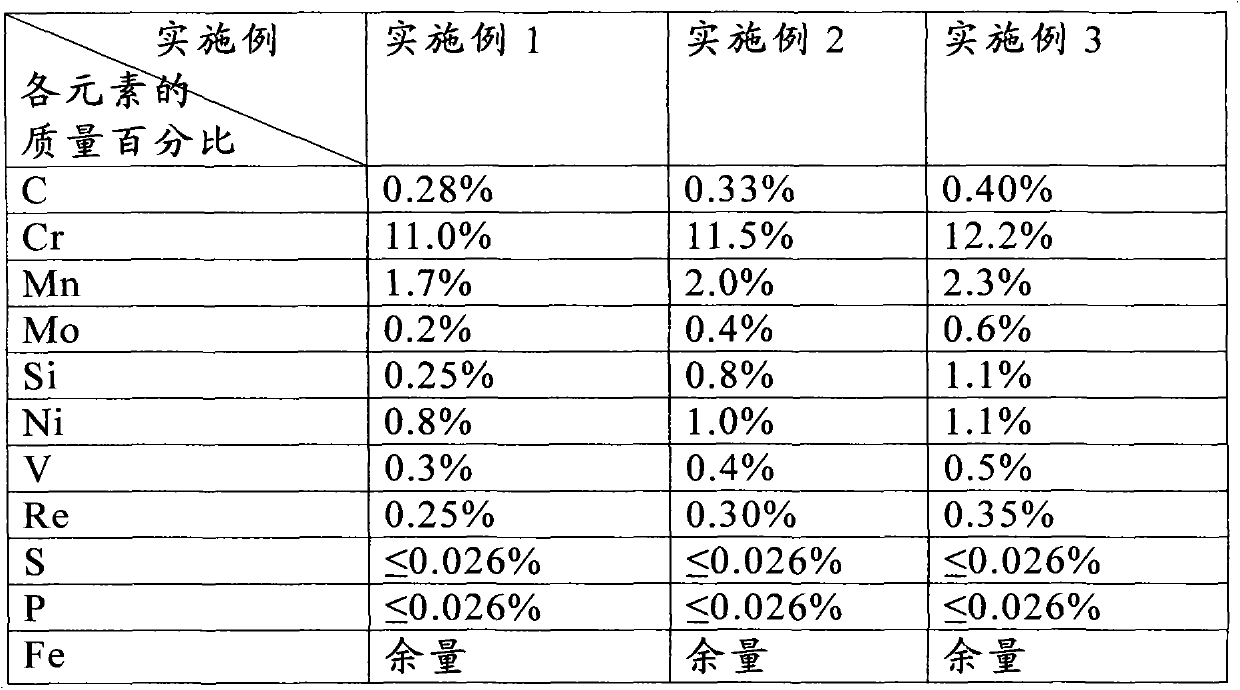

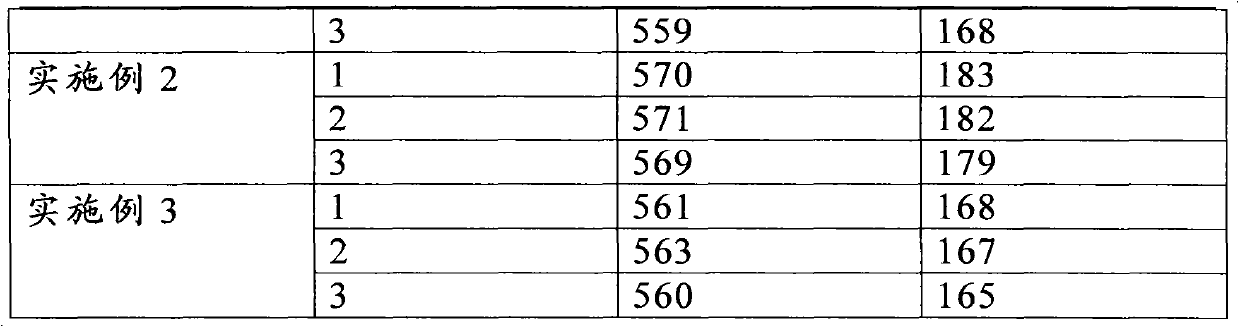

Steel tube piercing point and preparation method thereof

ActiveCN103131966AImprove wear resistanceExtended service lifeMandrelsMetal rolling arrangementsRheniumSurface oxidation

The invention discloses a steel tube piercing point and a preparation method thereof. The invention solves the problems of insufficient wear resistance, short service life and the like in the steel tube piercing point in the prior art. The steel tube piercing point disclosed by the invention comprises the following component elements in percentage by mass: 0.28%-0.40% of carbon (C), 11.0%-12.2% of chromium (Cr), 1.7%-2.3% of manganese (Mn), 0.2%-0.6% of molybdenum (Mo), 0.25%-1.10% of silicon (Si), 0.8%-1.1% of nickel (Ni), 0.3%-0.5% of vanadium (V), 0.25%-0.35% of rhenium(Re) and the balance of iron (Fe) and inevitable impurities. The invention also provides a preparation method of the steel tube piercing point, which comprises the following steps: proportioning, forging, annealing heat treatment and surface oxidation treatment. The steel tube piercing point disclosed by the invention has the advantages of favorable wear resistance and long service life.

Owner:宁波文而昌新材料科技有限公司

Directional solidification nickel-base high-temperature alloy and heat treatment process thereof

The invention relates to a directionally solidified nickel-based superalloy and a heat treatment process thereof. In particular, it provides a guide vane material with low density, low cost, high initial melting temperature, good oxidation corrosion resistance and thermal fatigue performance. And a heat treatment process to improve the alloy's tensile properties, durability and thermal fatigue properties. Alloy composition (percentage by weight) of the present invention: B 0.003~0.03, C 0.02~0.2, Cr 8.0~10.0, Al 4.5~6.5, Co 4.0~12.0, Nb 1.8~2.5, W 2.5~4.5, Mo 2.5~4.5, Y 0.005~0.05, more than Ni. The heat treatment process of the present invention: (1) at a temperature of 1210°C to 1240°C, heat preservation for 3h to 5h, and air-cool to room temperature; (2) at a temperature of 1040°C to 1080°C, heat preservation for 3h to 5h, and air cooling to room temperature; ( 3) At a temperature of 850°C to 900°C, keep warm for 16h to 32h, and air cool to room temperature. The alloy of the invention has the characteristics of low density, low cost, high initial melting temperature, good oxidation corrosion resistance and thermal fatigue performance, and is suitable for directional nickel-based guide vane materials.

Owner:辽宁红银金属有限公司

Method for prolonging fatigue life of metal material

InactiveCN105200226AImprove thermal fatigue performanceImprove fretting fatigue lifeDislocationCorrosion

Owner:JIANGSU UNIV

High-temperature alloy material and preparation method thereof

The invention discloses a high-temperature alloy material and a preparation method thereof, comprising C: 0.05-0.15%, Cr: 20.5-23.00%, Mo: 8.00-10.00%, Co: 0.50-2.50%, W: 0.20 to 1.00%, Fe, 17.00 to 20.00%, B: 0.001 to 0.010%, the balance being Ni and unavoidable impurities. The high-temperature alloy prepared by the invention has a uniform structure, and the slag material used for electroslag remelting is processed with a reasonable ratio to improve the purity of the material, so that the plasticity and impact toughness of the alloy material are enhanced at low temperature, room temperature and high temperature. The amount of deformation and the method of multiple fires are forged into materials, so that the structure of the turbine blade is uniform and has excellent fracture toughness. The alloy material produced by the present invention has a tensile strength σb≥700N / mm at room temperature. 2 ; Yield strength σ0.2≥320N / mm 2 ; Elongation δ5≥50%; High temperature (816±3℃) creep rupture test ≥103N / mm 2 , breaking time ≥ 25h, elongation δ5 ≥ 60%, meeting the performance requirements of turbine blades.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

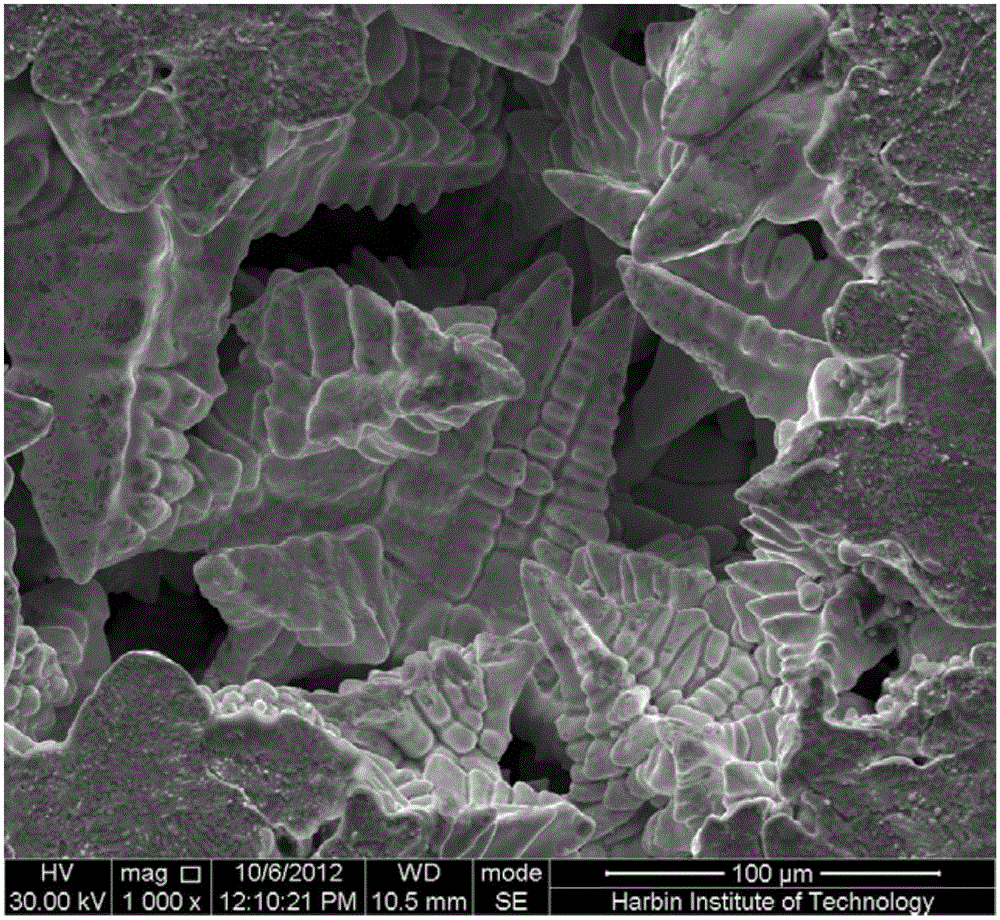

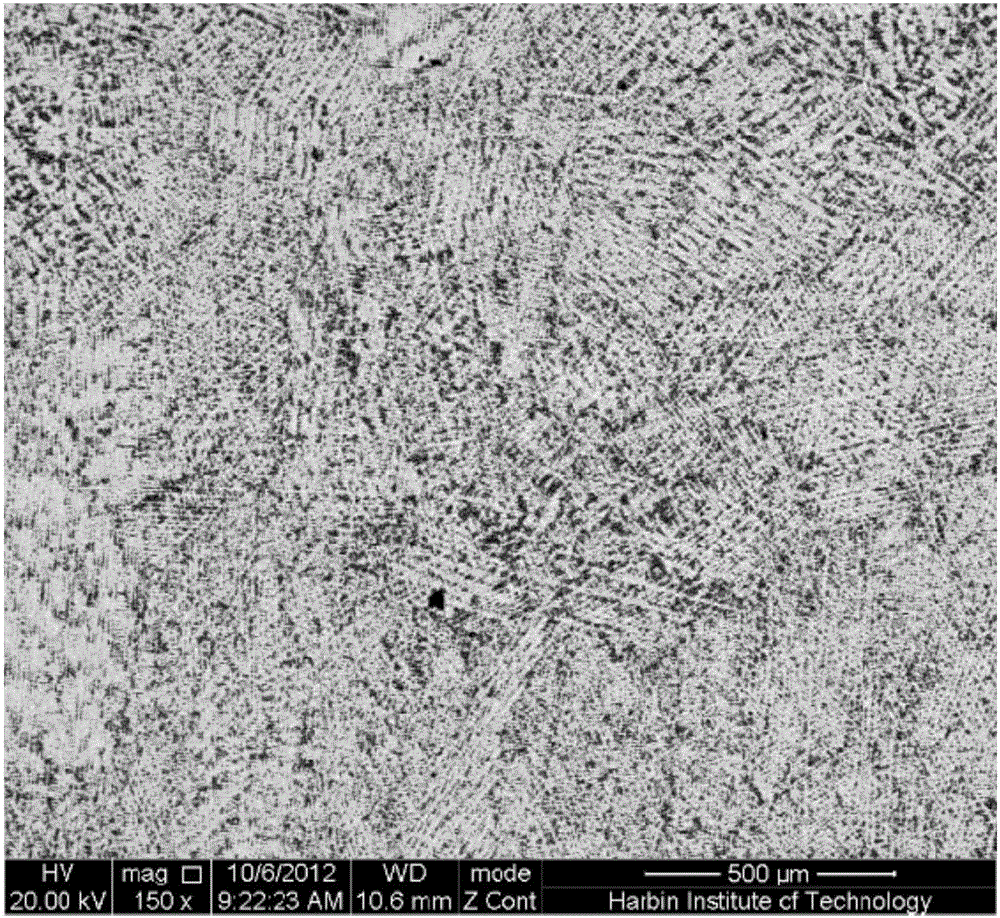

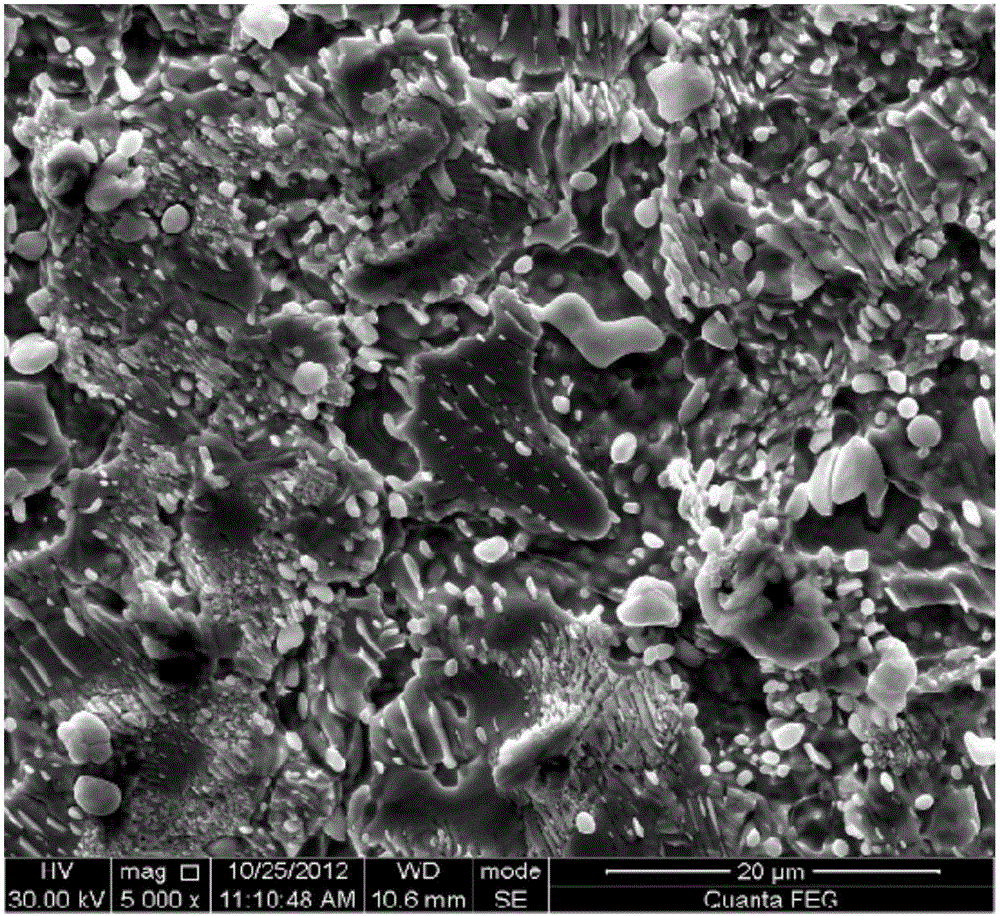

Method for refining grains of lead-tin alloy cast structure

ActiveCN105219989AUniform vibrationAvoid attenuationProcess efficiency improvementHigh energyMicrometer

The invention provides a method for refining grains of a lead-tin alloy cast structure, and relates to a method for refining grains of an alloy cast structure. The method aims at solving the problems that a method for chemically refining the lead-tin alloy cast structure easily causes composition segregation and affects electrical properties of the lead-tin alloy, and a method for physically refining the lead-tin alloy cast structure has the disadvantages of equipment complexity, high energy consumption, high cost and poor grain refinement effect. The method for refining the grains of the lead-tin alloy cast structure is characterized in that ultrasonic treatment is applied to the lead-tin alloy only in a lead-tin alloy melt preparation process, ultrasonic treatment is applied to the lead-tin alloy only in a lead-tin alloy melt pouring process, or ultrasonic treatment is applied to the lead-tin alloy only both in the lead-tin alloy melt preparation process and in the lead-tin alloy melt pouring process. The grain size of the lead-tin alloy cast structure treated by the method is 20 micrometers to 50 micrometers. The method for refining the grains of the lead-tin alloy cast structure can be obtained.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com