Steel tube piercing point and preparation method thereof

A technology for perforating plugs and steel pipes, which is used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of wear resistance and temperature resistance not being significantly improved, and the service life of hot perforating plugs is not long. Good wearability, improved wear resistance, and the effect of increasing chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

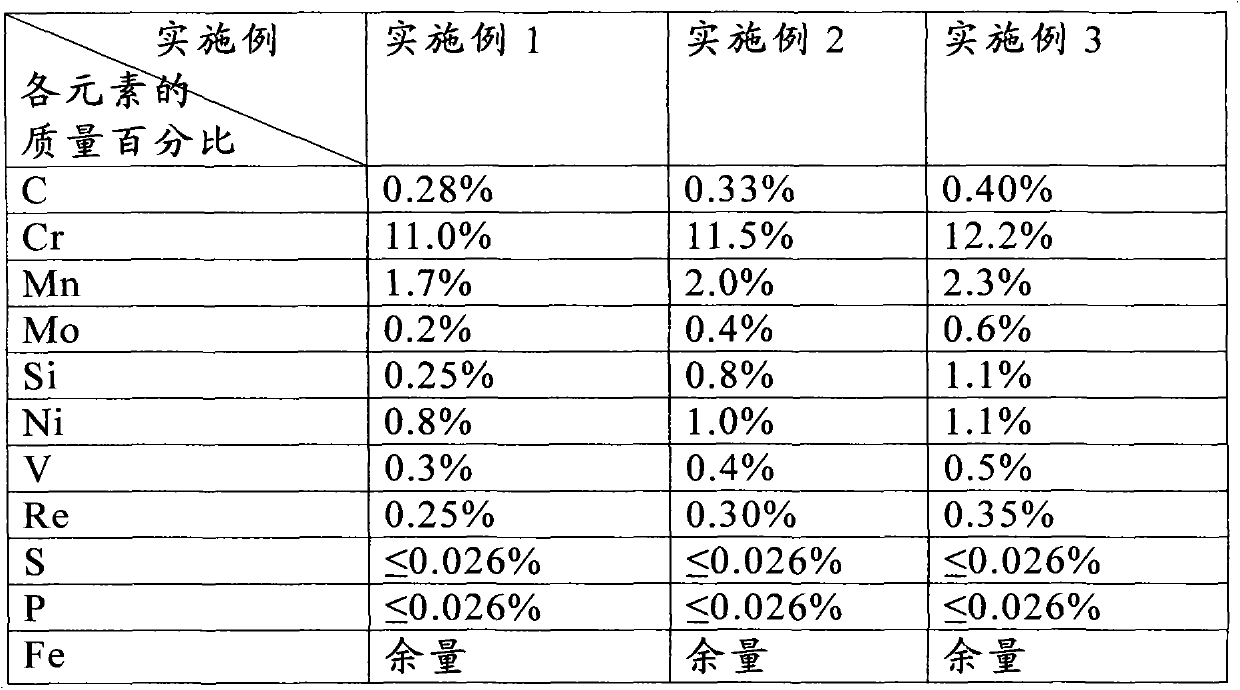

[0036] According to Table 1, Example 1, the composition elements and mass percentages of steel pipe perforated plugs are determined. The composition elements and mass percentages of steel pipe perforated plugs have certain influence on the mechanical properties of the plugs, and the preparation process has a great influence on the mechanical properties of the finally formed perforated plugs. also have a greater impact.

[0037] Prepare steel pipe piercing plugs as follows:

[0038] Raw material preparation: The raw materials were prepared according to the composition elements and mass percentages of the steel pipe perforated plug described in Example 1 in Table 1.

[0039] Forging: smelting, pouring and processing the prepared raw materials into the desired shape.

[0040] Annealing heat treatment: heat the processed steel pipe perforated plug to 880°C for annealing, keep it warm for 2 hours after annealing, and then take it out of the furnace at 350°C and air cool to obtain ...

Embodiment 2

[0043] Prepare steel pipe piercing plugs as follows:

[0044] Raw material preparation: prepare raw materials according to the composition elements and mass percentages of the steel pipe perforated plug described in Example 2 in Table 1.

[0045] Forging: smelting, pouring and processing the prepared raw materials into the desired shape.

[0046] Annealing heat treatment: heat the processed steel pipe perforated plug to 930°C for annealing, keep it warm for 3 hours after annealing, and then take it out of the furnace at 360°C and air cool to obtain the preliminary steel pipe perforated plug.

[0047] Surface oxidation treatment: first micro-processing the assembly surface of the finished steel pipe perforated plug, then heating to 980°C for high-temperature oxidation, and then holding the temperature at 580°C for 4 hours to obtain the finished steel pipe perforated plug.

Embodiment 3

[0049] Prepare steel pipe piercing plugs as follows:

[0050] Raw material preparation: The raw materials were prepared according to the composition elements and mass percentages of the steel pipe perforated plug described in Example 3 in Table 1.

[0051] Forging: smelting, pouring and processing the prepared raw materials into the desired shape.

[0052] Annealing heat treatment: heat the processed steel pipe perforated plug to 950°C for annealing, keep it warm for 4 hours after annealing, and then take it out of the furnace at 370°C and air cool to obtain the finished product of steel pipe perforated plug.

[0053] Surface oxidation treatment: first micro-process the assembly surface of the finished steel pipe perforated plug, then heat it to 1100°C for high-temperature oxidation, and then hold it at 610°C for 5 hours to obtain the finished steel pipe perforated plug.

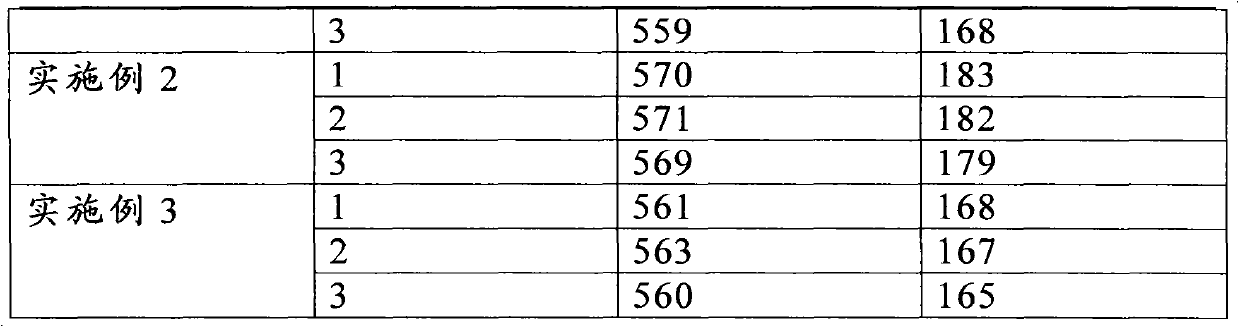

[0054] Immediately, the steel pipe piercing plug samples prepared in Examples 1-3 of the invention were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com