Compound microalloy hot die steel with high heat resistance and preparation method thereof

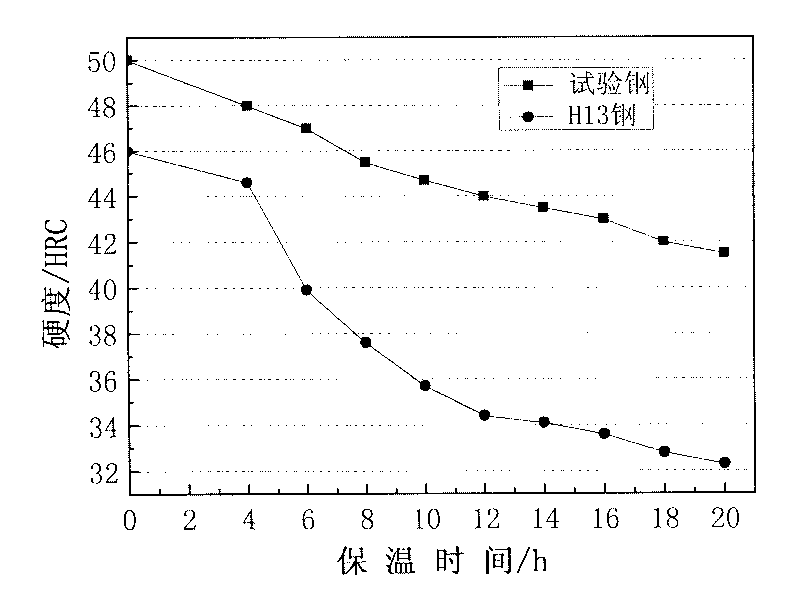

A technology of hot work die steel and microalloying, which is applied in the field of die steel manufacturing technology, can solve the problems of low comprehensive performance level of hot work die steel, low quality of domestic alloy die steel, easy cavity collapse or deformation, etc., to achieve High hardness, strong market adaptability, and excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In the present embodiment, the composition and weight percentage of the hot work die steel are as follows: C 0.32%, Si 1.53%, Mn 0.23%, Cr 4.25%, Mo 2.92%, V 0.99%, Nb 0.06%, rare earth elements ( Ce+La) 0.086, P 0.011%, S<0.016%, Fe balance.

[0034] In the present embodiment, the technical process and steps of hot work die steel are as follows:

[0035] (1) Induction smelting: Induction smelting is carried out according to the designed ratio of alloy elements, rare earth is added, and then cast into a φ80mm electrode rod;

[0036] (2) Electroslag remelting: put the smelted and cast electrode rod into the electroslag remelting device for secondary refining; use electric current to generate resistance heat through the electroslag layer to melt the consumable electrode alloy steel base material, liquid The metal falls through the slag layer of the slag pool in the form of molten droplets to the water-cooled crystallizer below, and then re-solidifies into a steel ingot o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature impact toughness | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com