Ceramic and metal brazing composite component and preparing method thereof

A technology for metal brazing and composite components, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of limited energy absorption of the intermediate layer, ineffective crack arrest, and limited ability of the intermediate layer to relieve residual stress, etc. Achieve the effect of improving strength and thermal fatigue properties, excellent compressive stress-strain characteristics, and relieving residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The accessories used in this example are as follows:

[0038] Ceramics to be welded: Al 2 o 3 ceramics.

[0039] Metal to be welded: 1Cr18Ni9Ti stainless steel.

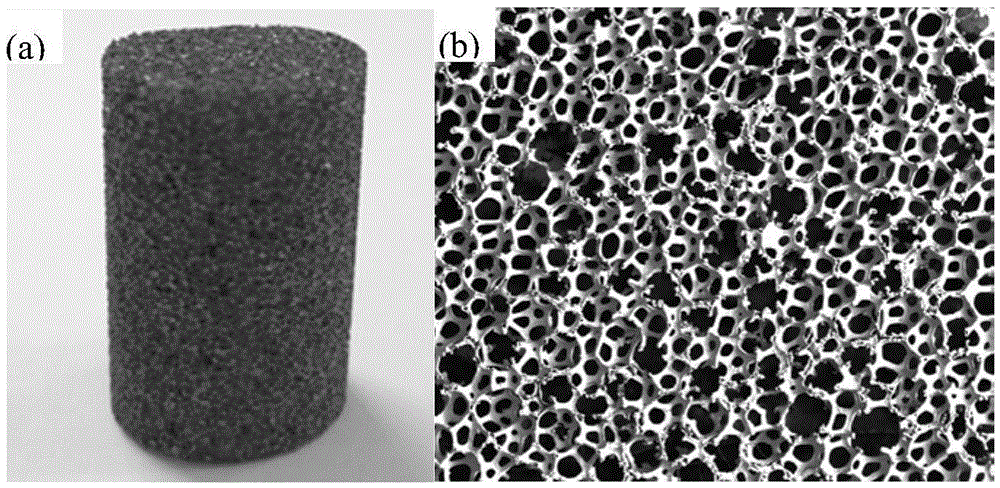

[0040] Foam metal: Ni foam metal with a pore size of 0.1mm and a porosity of 90%. figure 2 shown.

[0041] Brazing filler metal: Ag-Cu-Ti filler metal, the proportion of which is Ag: 26.77wt%, Cu: 68.83wt%, Ti: 4.4wt%.

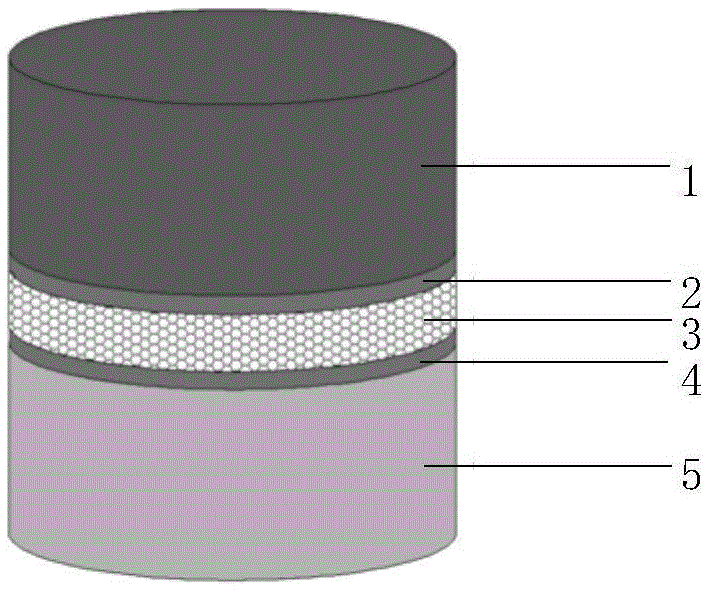

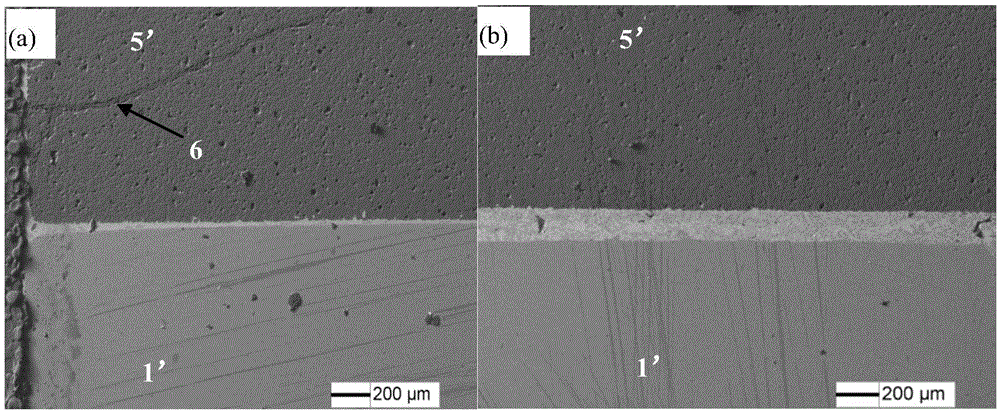

[0042] 1) Process the metal foam above into a disc of Φ10mm×0.2mm (that is, the diameter of the disc is 10mm and the thickness is 0.2mm) as the metal foam layer; process the above-mentioned solder into two discs of Φ10mm×0.1mm , respectively as the upper solder layer and the lower solder layer.

[0043] 2) Process the above-mentioned ceramics and metal to be welded into a size of Φ10mm×5mm, and use 400#, 600#, 800#, 1000# water sandpaper to polish the surface to be welded step by step to remove burrs and oxide films on the processed surface.

[0044] 3) Put the ceramics to be welded, t...

Embodiment 2

[0048] The accessories used in this example are as follows:

[0049] Ceramics to be welded: Si 3 N 4 ceramics.

[0050] Metal to be welded: Invar alloy.

[0051] Metal foam: Ni foam with a pore diameter of 0.15mm and a porosity of 80%.

[0052] Brazing filler metal: Ag-Cu-Ti filler metal, its proportion is Ag: 23wt%, Cu: 73wt%, Ti: 4wt%.

[0053] 1) Process the metal foam above into a disc of Φ10mm×0.15mm as the metal foam layer; process the above-mentioned solder into two discs of Φ10mm×0.1mm as the upper solder layer and the lower solder layer respectively.

[0054] 2) Process the above-mentioned ceramics and metal to be welded into a size of Φ10mm×5mm, and use 400#, 600#, 800#, 1000# water sandpaper to polish the surface to be welded step by step to remove burrs and oxide films on the processed surface.

[0055] 3) Put the ceramics to be welded, the metal to be welded, the solder layer and the foamed metal layer processed in the above steps 1) and 2) into acetone, ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com