Electric arc plasma auxiliary low-voltage nitriding method for surface of hot-working die

A surface arc and plasma technology, applied in metal material coating process, coating, solid-state diffusion coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

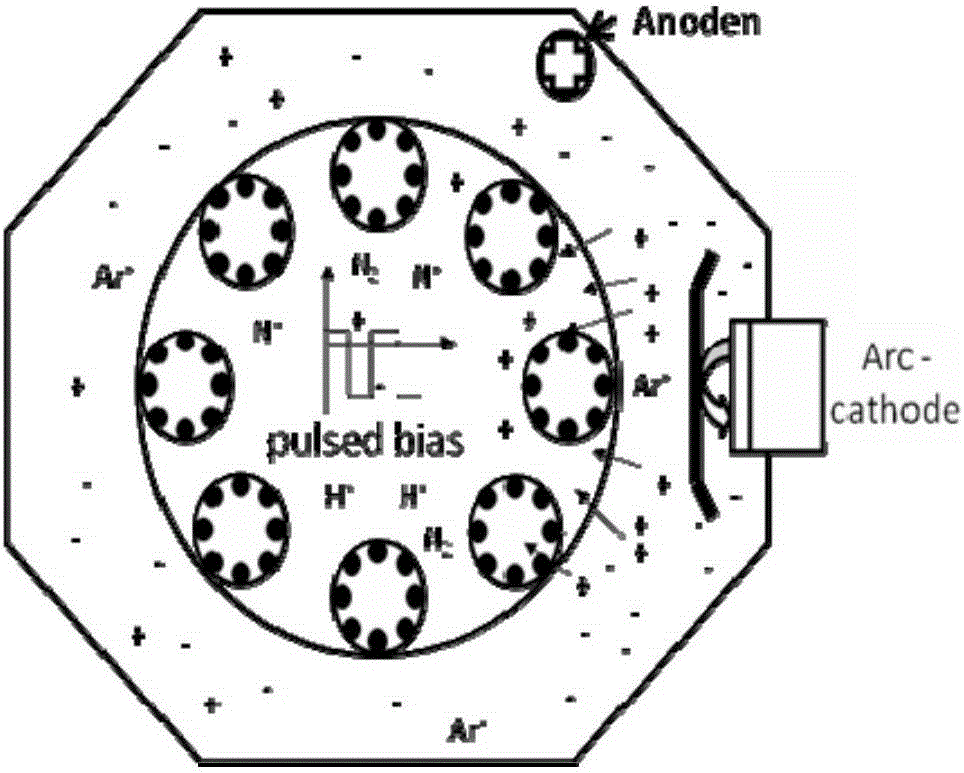

Method used

Image

Examples

Embodiment 1

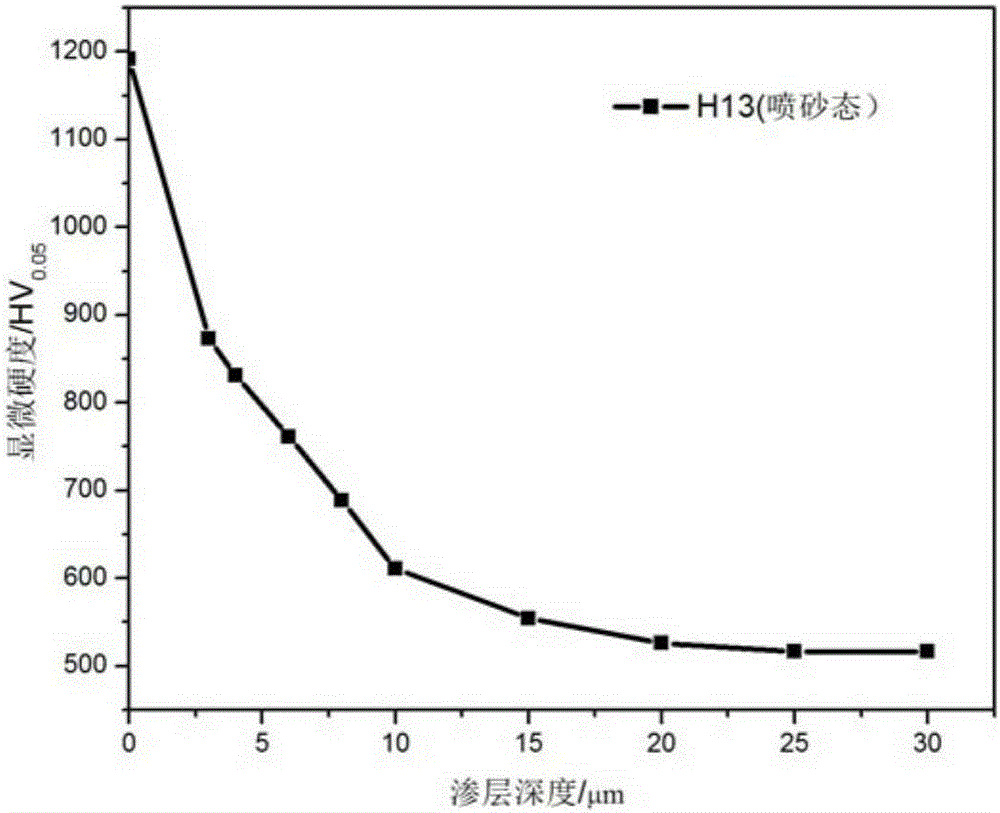

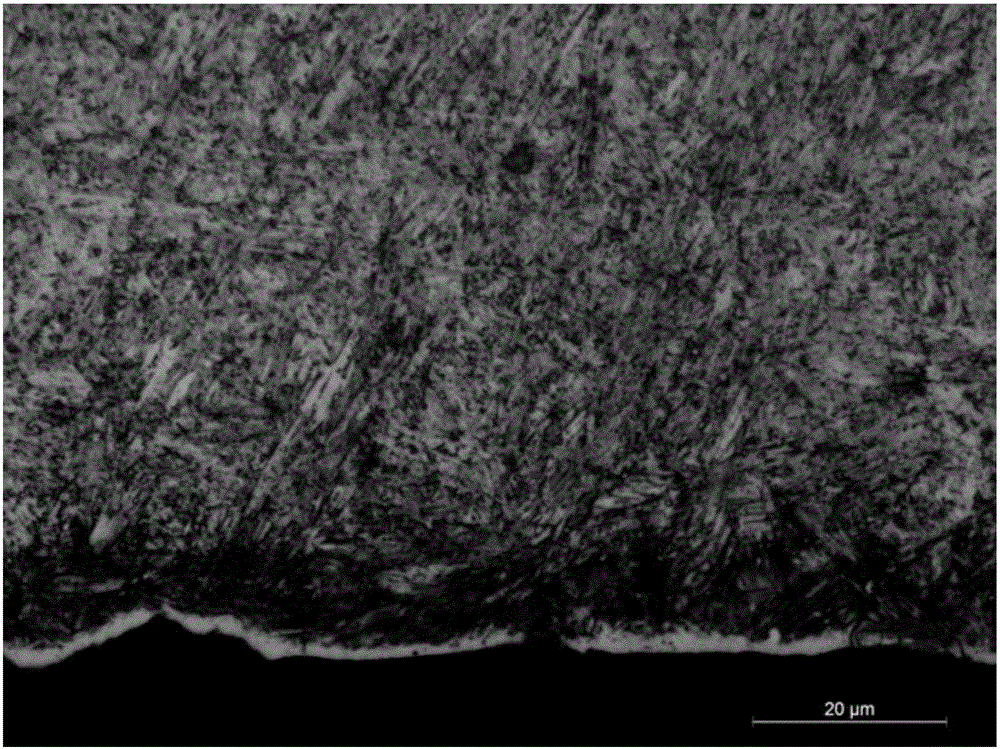

[0057] Example 1— Sand blasting on workpiece surface

[0058] (1) The workpiece is H13 steel that has been sandblasted, with a sandblasting particle size of 80 mesh and a roughness of Ra1.4μm. The workpiece is ultrasonically cleaned with acetone solution for 20 minutes, taken out and dried with a hair dryer, and placed in an arc plasma assisted nitriding device Carry out nitriding treatment in the vacuum chamber, turn on the mechanical pump and the molecular turbo pump in turn to evacuate to the background vacuum, heat to 600°C, and remove the residue in the vacuum chamber.

[0059] (2) Keep the temperature in the furnace at 500°C, and the air pressure in the vacuum chamber is 4.0×10 -3 Pa, the workpiece transfer platform is connected to the negative pole of the pulse power supply, the negative bias voltage is 300V, the pulse frequency is 20kHz, and the duty cycle is 0.8. The arc is struck by an arc target. The arc target uses a Ti target. The target current is 85A. There i...

Embodiment 2

[0064] Example 2— Workpiece surface grinding wheel grinding

[0065] (1) The workpiece is H13 steel in the grinding state of the grinding wheel, the roughness is Ra0.8μm, the workpiece is ultrasonically cleaned with acetone solution for 20 minutes, after taking it out, it is dried with a hair dryer, and placed in an arc plasma assisted nitriding device for nitriding treatment, followed by Turn on the mechanical pump and the molecular turbo pump to evacuate to the background vacuum, heat to 600°C, and remove the residue in the vacuum chamber.

[0066] (2) Keep the temperature in the furnace at 500°C, and the air pressure in the vacuum chamber is 4.0×10 -3 Pa, the workpiece transfer platform is connected to the negative pole of the pulse power supply, the negative bias voltage is 300V, the pulse frequency is 20kHz, and the duty cycle is 0.8. The arc is struck by an arc target. The arc target uses a Ti target. The target current is 85A. There is a baffle in front of the target...

Embodiment 3

[0071] Example 3— Sandpaper grinding of workpiece surface

[0072] (1) The workpiece is sandpaper-polished (1000#) H13 steel, with a roughness of Ra0.35μm. The workpiece is ultrasonically cleaned with acetone solution for 20 minutes. After taking it out, it is dried with a hair dryer and placed in an arc plasma assisted nitriding device for nitriding For nitrogen treatment, turn on the mechanical pump and molecular turbo pump in turn to evacuate to the background vacuum, heat to 600°C, and remove the residue in the vacuum chamber.

[0073] (2) Keep the temperature in the furnace at 500°C, and the air pressure in the vacuum chamber is 4.0×10 -3 Pa, the workpiece transfer platform is connected to the negative pole of the pulse power supply, the negative bias voltage is 300V, the pulse frequency is 20kHz, and the duty cycle is 0.8. The arc is struck by an arc target. The arc target uses a Ti target. The target current is 85A. There is a baffle in front of the target, and the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com