Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Reduce overheating sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Low temperature resistant wind power flange steel with high welding performance and high strength

The invention discloses a low temperature resistant wind power flange steel with high welding performance and high strength, comprising the following chemical components in percentage by weight: 0.13-0.18% of C, 0.17-0.40% of Si, 1.30-1.45% of Mn, 0.035-0.060 of V, 0.03-0.05% of Nb, 0.015-0.030% of Al, 0.010-0.020% of Ti, not more than 0.005% of S, not more than 0.015% of P, not more than 0.04% of As, not more than 0.0020% of [O], 0.0060-0.0110% of [N], not more than 0.0002% of [H] and the balance of Fe; meanwhile, the required carbon equivalent (CEV) of the material is 0.40-0.43%. After the normalizing treatment, a flange made of the steel of the invention has the following performances: 500-570 MPa of tensile strength Rm, 325-360 MPa of yield strength Re1, 28-39% of elongation A5 and 76-85% of reduction rate of cross section; at the temperature of -50 DEG C, the impact energy AKv of the V-shaped nick is 110-180 Joules. The invention has the advantages of good welding performance, stable low temperature impact performance and higher strength.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

Anticorrosion coating for metal surface and preparation method of anticorrosion coating

InactiveCN104789958AHigh strengthImprove corrosion resistanceHeat inorganic powder coatingNiobiumManganese

The invention discloses an anticorrosion coating for a metal surface and a preparation method of the anticorrosion coating. The anticorrosion coating comprises the following components in mass percent: 0.23-0.25% of carbon, 4.62-4.65% of manganese, 7.52-7.58% of chromium, 6.43-6.45% of vanadium, 8.52-8.55% of nickel, 0.51-0.55% of strontium, 1.24-1.27% of niobium, 1.42-1.45% of molybdenum, 2.22-2.24% of zirconium, 0.25-0.29% of tungsten, 4.32-4.35% of zinc, 3.45-3.48% of lanthanum, 12.27-12.29% of neodymium, 5.43-5.45% of promethium, 2.2-2.4% of gadolinium, 3.62-3.65% of terbium, 3.5-3.8% of an auxiliary, and the balance of iron.

Owner:SUZHOU TONGMING MACHINERY

High temperature-resistant coating for metal surfaces and preparation method of coating

InactiveCN104878378AHigh strengthImprove corrosion resistanceAnti-corrosive paintsPressure inorganic powder coatingNiobiumLanthanum

The invention discloses a high temperature-resistant coating for metal surfaces and a preparation method of the coating. The high temperature-resistant coating is prepared from the following components in percentage by mass: 0.4-0.6% of carbon, 2.6-2.8% of magnesium, 6.5-6.8% of chromium, 3.0-3.2% of vanadium, 12.5-12.8% of nickel, 0.3-0.5% of calcium, 0.2-0.5% of niobium, 2.4-2.6% of molybdenum, 2.7-2.9% of barium, 0.2-0.4% of tungsten, 3.2-3.5% of titanium, 0.2-0.5% of aluminum, 3.5-3.8% of lanthanum, 4.8-5.1% of neodymium, 2.3-2.5% of promethium, 1.2-1.4% of europium, 4.2-4.5% of dysprosium and the balance of iron; the high temperature-resistant coating is further coated with an anti-corrosion oil paint.

Owner:SUZHOU TONGMING MACHINERY

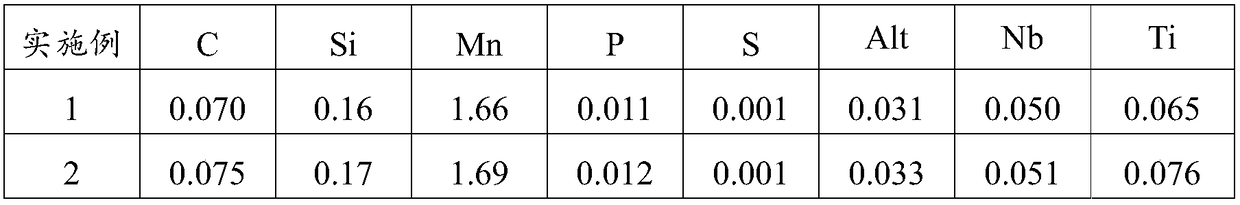

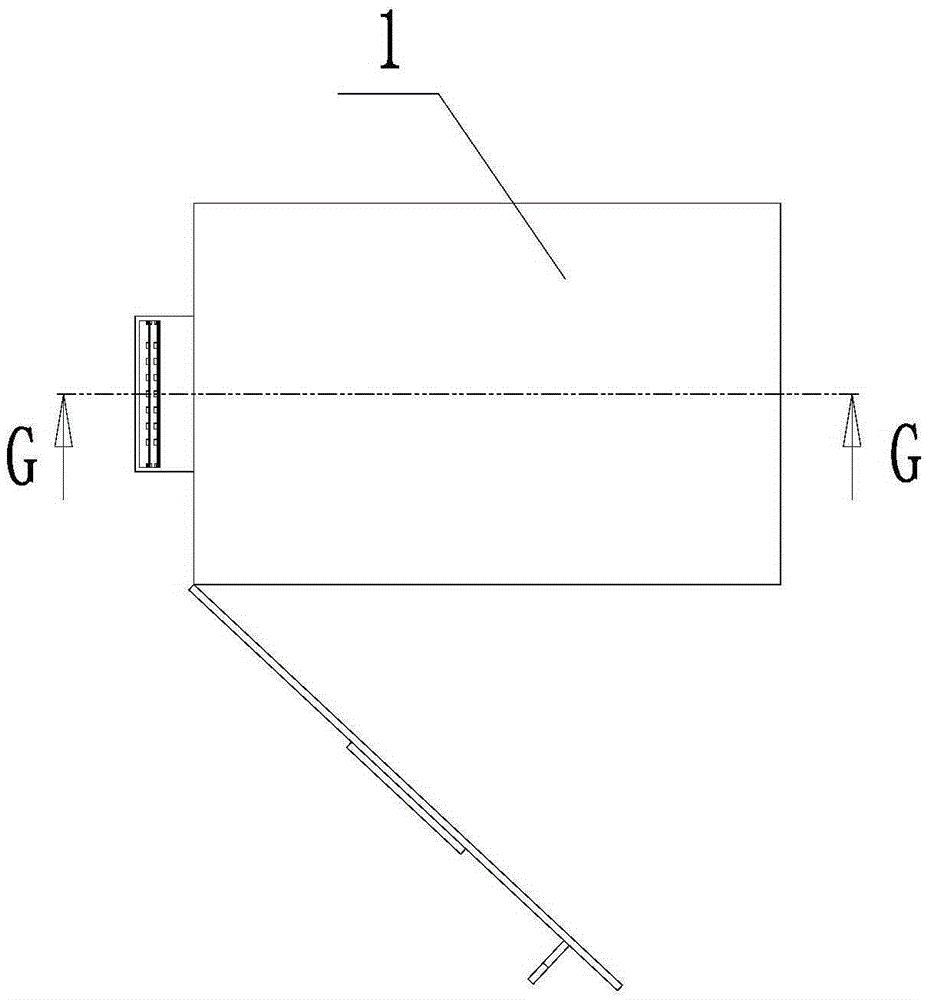

700 MPa level automobile beam steel belt and preparation method thereof

The invention provides a 700 MPa level automobile beam steel belt and a preparation method thereof. The beam steel belt comprises the following chemical components in percentages by weight: 0.06% to 0.08% of C, 0.10% to 0.20% of Si, 1.60% to 1.80% of Mn, 0 to 0.017% of P, 0 to 0.002% of S, 0.020% to 0.050% of Alt, 0.065% to 0.085% of Ti, 0.045% to 0.055% of Nb and the balance of Fe and unavoidableimpurities. The 700 MPa level automobile beam steel belt provided by the invention has an excellent mechanical property, particularly low-temperature toughness, simultaneously has good welding performance, and can be used for automobile structural parts such as automobile cross beams and longitudinal beams with good forming processability and high strength requirement.

Owner:BAOTOU IRON & STEEL GRP

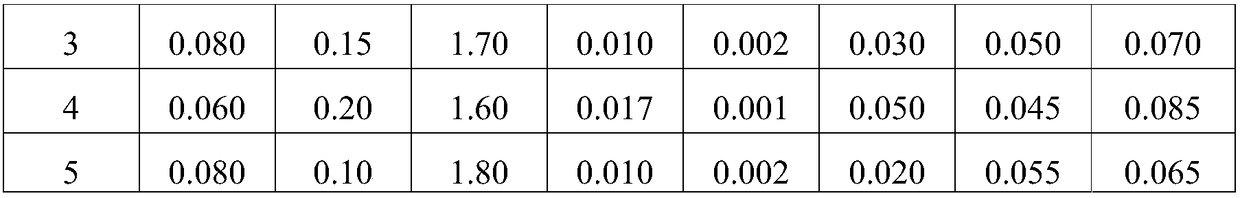

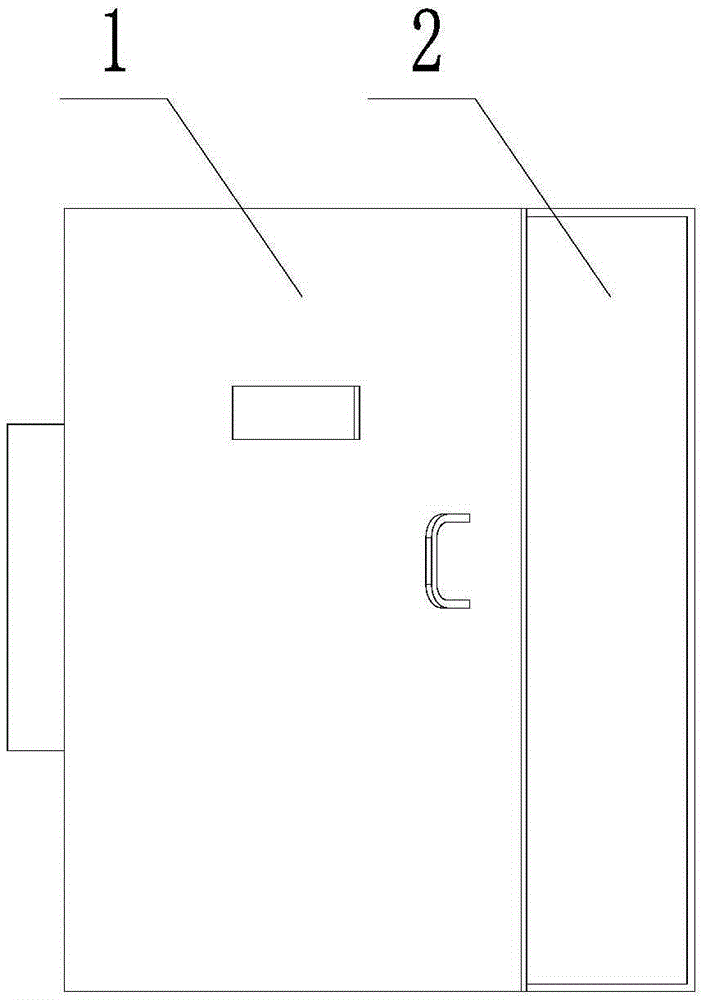

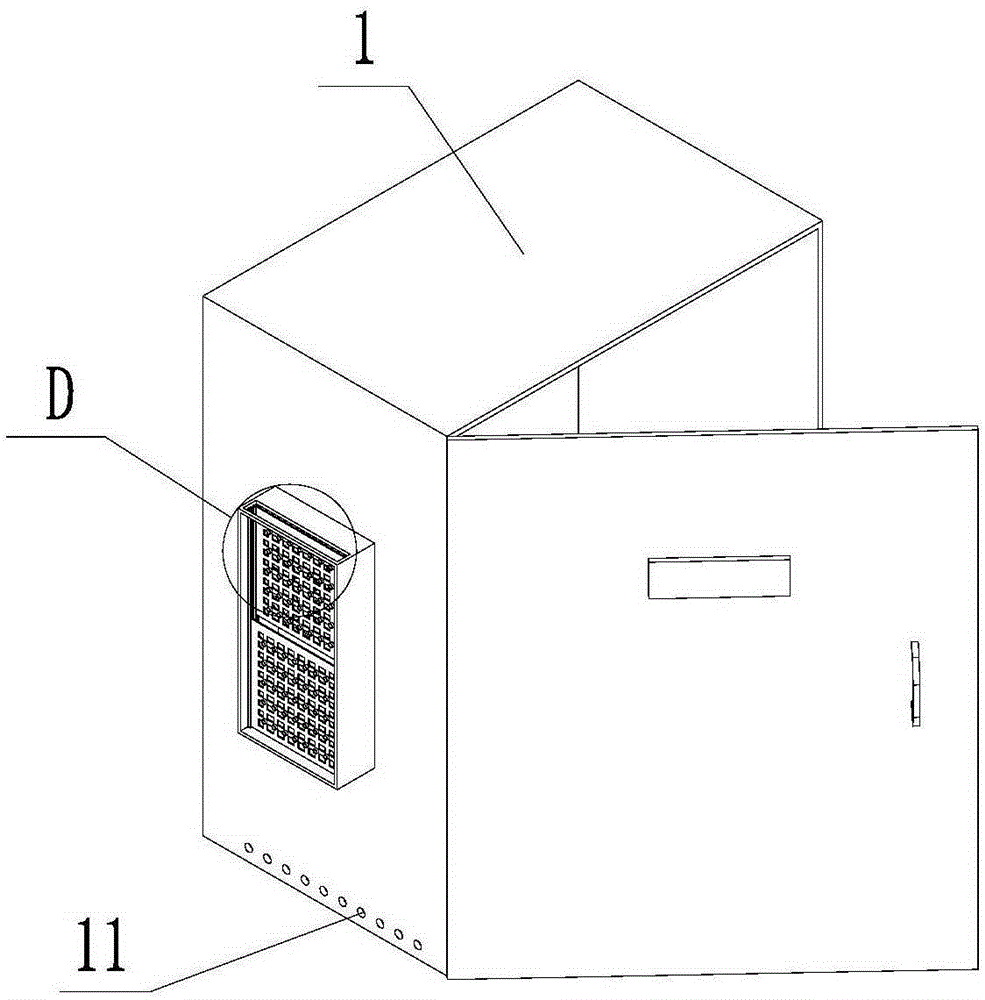

High-low-voltage switch cabinet having dust removing function

InactiveCN105244784AImprove securityImprove reliabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlStructural engineering

The invention discloses a high-low-voltage switch cabinet having a dust removing function. The high-low-voltage switch cabinet comprises a switch cabinet body which is horizontally arranged, wherein an installation empty cavity is formed inside the switch cabinet body, a bracket is arranged on a side wall of the switch cabinet body, a support is arranged inside the bracket, an axial flow fan is arranged on the support, the bracket is provided with a ventilation net on the outer side of the axial flow fan, the surface of the ventilation net is provided with a plurality of magnets, and a plurality of air outlets are formed in the switch cabinet body. the high-low-voltage switch cabinet is simple in structure and convenient in operation, can reduce temperature inside the switch cabinet, prolongs the service life of the switch cabinet, has a function of absorbing metal dust, greatly reduces the metal dust entering into the switch cabinet, ensures the normal operation of internal electrical components, avoids safety problems of causing short circuit and the like, is stable and reliable in operation, and reduces costs.

Owner:鼎圣集团有限公司

Bronze alloy material for valve casting and treatment process thereof

The invention discloses a bronze alloy material for valve casting. The alloy material contains the chemical ingredients in percentage by mass: 0.55-0.58% of C, 0.33-0.36% of Mn, 2.25-2.45% of Cr, 4.35-4.55% of Ni, 0.52-0.55% of Mo, 0.38-0.40% of W, 0.12-0.15% of V, 0.11-0.13% of Nb, 22.3-22.5% of Zn, 0.25-0.28% of rare earth and the balance of Cu and trace impurities. The invention further discloses a treatment process of the bronze alloy material for valve casting. According to the bronze alloy material for valve casting and the treatment process thereof, the corrosion resistance, wear resistance and oxidation resistance of valves are improved, the valves can adapt to various harsh environments and are high in strength and long in service lives, the cost is reduced, and the high-temperature resistance is improved.

Owner:盐城市大丰区亿然阀门有限公司

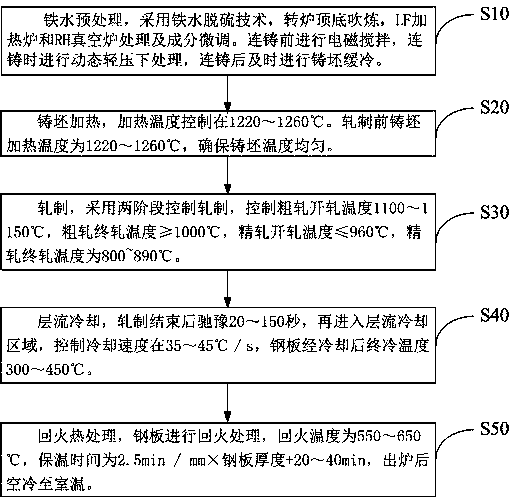

Ultrahigh steel Q960E thick plate and manufacturing method

The invention discloses an ultrahigh steel Q960E thick plate, and relates to the field of ultrahigh-strength steel thick plate producing and manufacturing. The ultrahigh steel Q960E thick plate comprises chemical components including, by mass percent, 0.15%-0.18% of C, 0.20%-0.50% of Si, 0.80%-1.30% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.003% of S, 0.30%-0.50% of Cr, 0.40%-0.60% of Mo, 0.80%-1.0% of Ni, 0.008%-0.030% of Ti, 0.015%-0.050% of Nb, 0.0008%-0.0025% of B and the balance Fe and inevitable impurities. The medium-high carbon and alloying component design is adopted, controlled rolling and offline heat treatment methods are adopted for assistance, and the ultrahigh-strength steel thick plate with the thickness being 90 mm is provided.

Owner:NANJING IRON & STEEL CO LTD

Alloy steel, retained mandrel and production method of retained mandrel

InactiveCN104998905AImprove purityImprove wear resistanceMandrelsMetal rolling arrangementsAlloy steelHeat treated

The invention discloses alloy steel and belongs to the technical field of continuous rolling units. The alloy steel comprises components in percentage by mass as follows: 0.27%-0.31% of C, 0.60%-0.80% of Si, 0.7%-0.9% of Mn, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, 3.50%-3.70% of Cr, 0.20%-0.30% of Ni, 0.40%-0.50% of V, 0.50%-0.58% of Mo, smaller than or equal to 0.025% of Al and the balance of iron and impurity elements. The invention discloses a retained mandrel adopting the alloy steel. The retained mandrel comprises a plug, a connecting rod and a hollow cylindrical retained mandrel body. The invention further discloses a production process for manufacturing the retained mandrel. The process comprises steps of steel making, rolling, heat treatment, machining and assembling. On the premise that the use requirements are met and the product quality is guaranteed, the cost is reduced.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

Anti-corrosion steel plate for shuttle type storage rack and thermal treatment process thereof

The invention discloses an anti-corrosion steel plate for a shuttle type storage rack and a thermal treatment process thereof. The steel plate comprises the following components by weight percentage: 0.12-0.14% of carbon, 2.32-2.38% of manganese, 0.54-0.56% of gallium, 0.02-0.04% of calcium, 0.01-0.03% of sodium, 1.23-1.25% of cobalt, 2.16-2.18% of vanadium, 3.36-3.39% of titanium, 2.63-2.67% of copper, 0.57-0.59% of tin, 12.7-12.9% of chromium, 0.06-0.08% of molybdenum, 5.11-5.13% of nickel, 0.36-0.38% of zirconium, 2.42-2.44% of magnesium and the balance of Fe and unavoidable impurities; and an anti-corrosion coating is sprayed on the surface of the steel plate.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

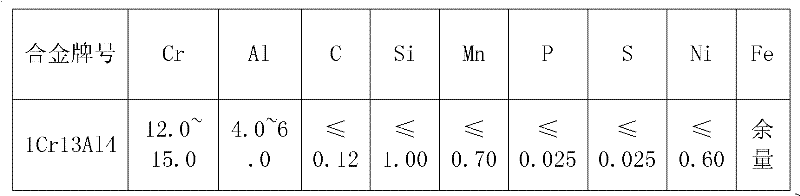

Iron-chromium-aluminum alloy with high plasticity and long service life

The invention relates to an iron-chromium-aluminum alloy with high plasticity and long service life. The iron-chromium-aluminum alloy comprises the following components in percentage by weight: 13.5-14.5 percent of chromium, 3.5-4.5 percent of aluminum, less than or equal to 0.03 percent of carbon, less than 0.24 percent of silicon, 0.3-0.5 percent of titanium, 0.25-0.35 percent of vanadium and the balance of iron. In the invention, the carbon content of the alloy is controlled: carbon plays a harmful role in the inoxidability of the iron-chromium-aluminum alloy, and the formation of harmful carbonates and nitrides can be avoided by lowering the carbon content, so that the plasticity of the alloy is improved. A reasonable aluminum-chromium content ratio is selected: the oxidizing speed of the iron-chromium-aluminum alloy is lowered along with the increase in the aluminum and chromium content, but the plasticity is lowered along with the increase in the aluminum and chromium content. Titanium is doped: the nitriding resistance and corrosion resistance of the alloy are improved. Vanadium is added: tissue product grains of the alloy can be fined, the grain coarsening temperature is raised, the overheat sensitivity of the alloy is lowered, and high hardness and chemical stability with a silicide formed by silicon are realized.

Owner:DANYANG HUALONG SUPERIOR STEEL

Gear production process facilitating improvement of production efficiency and product quality

InactiveCN104128775ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesAdditive ingredientSlow cooling

The invention discloses a gear production process facilitating the improvement of production efficiency and product quality. The gear production process includes the steps of blank casting, cutting, heat treatment, finishing cutting and ground finish, wherein blank casting, cutting, heat treatment, finishing cutting and ground finish are sequentially conducted. Raw materials for blank casting are 20CrMnTiH, a continuous casting machine is adopted in the blank casting process, the pulling rate of the continuous casting machine ranges from 0.6 m / min to 0.72 m / min, electromagnetic stirring of a crystallizer is adopted in the blank casting process, electromagnetic stirring currents are 400 A, and electromagnetic stirring frequency is 2.5 Hz. The heat treatment step includes the procedures that a cut blank is heated and carburized, heating in stages, namely, preheating at the first stage, carburization at the second stage, diffusion for 1 h to 1.2 h at the third stage and slow cooling at the fourth stage is adopted, the blank is slowly cooled to the temperature ranging from 500 DEG C to 600 DEG C and then quenched, the quenched blank is heated to the temperature ranging from 170 DEG C to 200 DEG C and then tempered after heat is preserved for not less than 3 h. The gear production process is simple in steps and short in process time, and product ingredients are even.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

High-strength valve for steam

InactiveCN105506612APrevent leakageReduce leakageValve housingsPressure inorganic powder coatingThermodynamicsEngineering

The invention discloses a high-strength valve for steam. The high-strength valve comprises a main valve body, and the upper end of the main valve body is provided with a valve flange used for controlling connection and disconnection of the main valve body; the portion, located under the valve flange, of the main valve body is provided with a first installing flange, the upper end face of the first installing flange is provided with a positioning boss in an upwards extending mode, a seal sleeve is arranged over the first installing flange, the lower end of the sealing sleeve is provided with a second installing flange matched with the first installing flange, and a seal ring is arranged between the first installing flange and the second installing flange; the positioning boss is slidably matched with an inner hole of the seal sleeve, the first installing flange and the second installing flange are both provided with corresponding connecting holes, and the first installing flange is provided with an installing groove used for installing the seal ring. According to the high-strength valve for the steam, the structure is simple, the cost is low, the safety and reliability are achieved, the service life is long, stopping is not needed for replacing, only a secondary seal structure needs to be utilized to seal the overall valve again, therefore, the production persistence and stability are facilitated, and the production efficiency is improved.

Owner:YANCHENG FAIR TRUEMARK VALVES

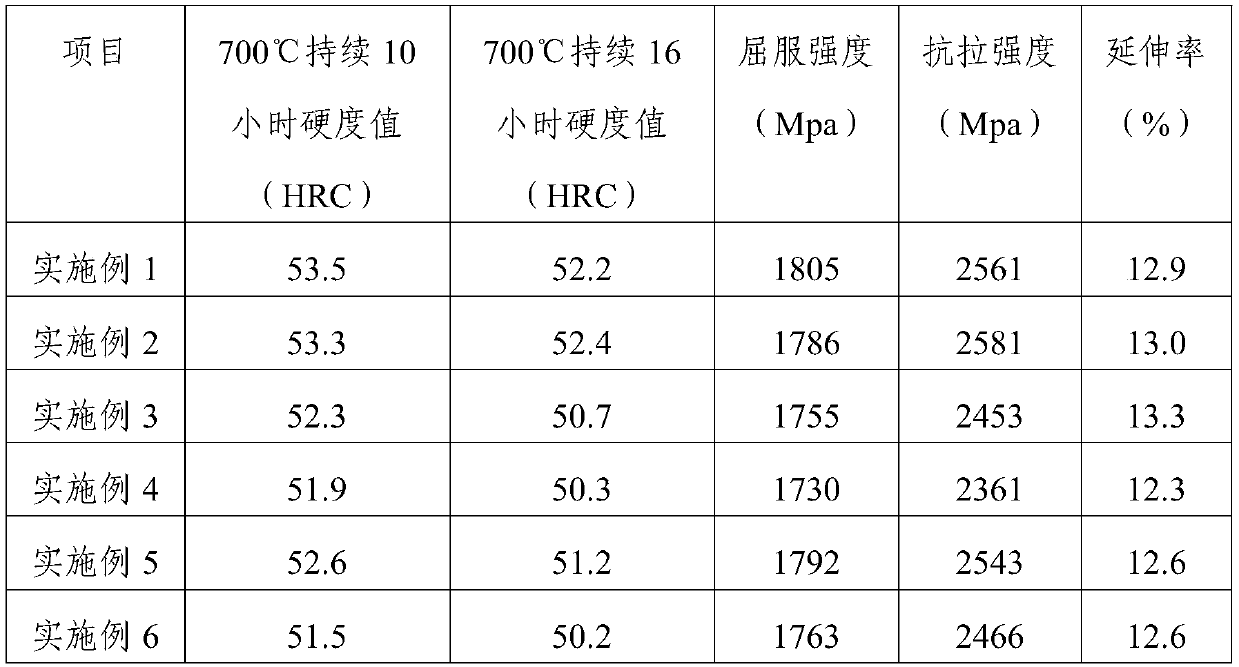

Manufacturing process of hot work die steel for high performance die-casting die

InactiveCN111057933ATissue uniform refinementHigh strengthSolid state diffusion coatingFurnace typesTemperingManufacturing technology

The invention provides a manufacturing process of hot work die steel for a high performance die-casting die and relates to the technical field of die steel. The manufacturing process of the hot work die steel comprises the following steps of (1) smelting; (2) high-temperature homogenization treatment; (3) forging; (4) annealing treatment; (5) quenching and tempering treatment; (6) nitriding treatment; and (7) tempering treatment. The hot work die steel is prepared from the following components in percent by weight: 0.33-0.46% of C, 1.5-2.3% of Si, 0.32-0.45% of Mn, 1.6-2.3% of Mo, 2.6-3.6% ofW, 0.16-0.27% of Nb, 2.8-3.7% of Cr, 0.21-0.53% of Sr, 0.16-0.31% of Ti, 0.05-0.09% of Ce, less than or equal to 0.003% of S, less than or equal to 0.03% of P and the balance Fe. The hot work die steel prepared by the manufacturing process has relatively high surface hardness and wear resistance, relatively good impact toughness and excellent fatigue resistance and strength, so that the service life of the hot work die steel for the die-casting die is prolonged effectively.

Owner:宁波海琰伟业金属制品有限公司

Steel material and processing technology for ball screw

The invention discloses a steel material and a processing technology for a ball screw. The steel material comprises the following elements by weight: 0.58% of carbon, 0.25% of silicon, 0.86% of manganese, 0.035% of phosphorus, 0.029% of sulphur, 0.90% of chromium, 0.25% of molybdenum, 0.10% of vanadium, 0.27% of nickel and 0.25% of copper, with the balance being iron and impurities. The invention has the following beneficial effects: the invention provides a novel material and processing technology for the ball screw, the processed ball screw can totally overcome disadvantages of the GCr15 material during processing, heat treatment distortion and grinding cracks are reduced, processing efficiency is improved, wear resistance, contact fatigue strength and service life of the ball screw are enhanced, and good economic benefits and social benefits are obtained.

Owner:SHANDONG BEST PRECISION

Wear-resisting steel plate for extremely cold area and manufacturing method

The invention discloses a wear-resisting steel plate for an extremely cold area. Thechemical components comprise, by mass percent, 0.18 to 0.23% of C, 0.20 to 0.50% of Si, 1.0 to 1.50% of Mn, not larger than 0.010% of P, not larger than 0.002% of S, 0.10 to 0.30% of Cr, 0.10 to 0.30% of Mo, 0.30 to 0.8% of Ni, 0.008 to 0.030% of Ti, 0.012 to 0.040% of Nb, 0.0008 to 0.0025% of B, and the balance Feand inevitable impurities. Medium and high carbon and alloying component design is adopted, an auxiliary rolling and offline heat treatment method is adopted, the obtained steel plate has the Brinellhardness being 450 HBW level, and -60 DEG C low temperature impact toughness is larger than or equal to 34 J.

Owner:NANJING IRON & STEEL CO LTD

High-temperature-resisting high-strength spring hanger

InactiveCN105039872AHigh strengthImprove corrosion resistancePressure inorganic powder coatingMetal coatingThulium

The invention discloses a high-temperature-resisting high-strength spring hanger. The surface of the spring hanger is provided with a high-strength metal coating. The high-strength metal coating comprises, by mass percent, 0.06%-0.08% of carbon, 0.06%-0.08% of magnesium, 0.15%-0.18% of silicon, 0.45%-0.48% of vanadium, 7.52%-7.55% of nickel, 2.73%-2.75% of titanium, 0.02%-0.05% of copper, 1.84%-1.86% of polonium, 0.24%-0.26% of cobalt, 0.52%-0.56% of tungsten, 0.32%-0.35% of antimony, 2.62%-2.65% of aluminum, 4.45%-4.48% of lanthanum, 3.54%-3.56% of neodymium, 4.36%-4.38% of thulium, 1.22%-1.24% of europium, 13.42%-13.46% of an auxiliary and the balanced ferrum.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

Corrosion resistant coating layer for surface of hydraulic cylinder and preparation method thereof

InactiveCN104862686AHigh strengthImprove toughnessPressure inorganic powder coatingNichromeLanthanum

The invention discloses a corrosion resistant coating layer for a surface of a hydraulic cylinder and a preparation method thereof. The corrosion resistant coating layer for the surface of the hydraulic cylinder comprises the following components in percentage by mass: 0.75-0.77% of carbon, 3.26-3.28% of aluminum, 0.25-0.28% of silicon, 2.23-2.25% of vanadium, 14.23-14.25% of nickel, 0.13-0.15% of chromium, 0.62-0.65% of scandium, 2.44-2.46% of molybdenum, 2.56-2.58% of boron, 0.62-0.64% of tungsten, 2.52-2.55% of titanium, 0.62-0.65% of barium, 3.45-3.48% of lanthanum, 3.54-3.56% of neodymium, 2.63-2.65% of promethium, 1.22-1.24% of lutecium, 4.42-4.45% of terbium, 5.63-5.65% of assistant, and the balance of iron.

Owner:SUZHOU JIN YUAN OIL MACHINERY

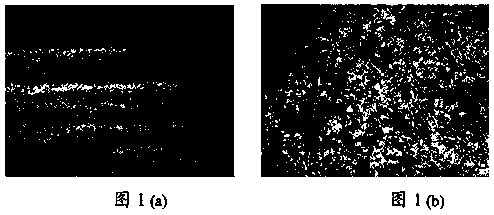

Low-cost high-speed tool steel for cutting drill bit and preparation process of low-cost high-speed tool steel

InactiveCN104195440AEvenly distributedFine particle sizeIncreasing energy efficiencyCeriumElectro-slag remelting

The invention discloses low-cost high-speed tool steel for a cutting drill bit and a preparation process of the low-cost high-speed tool steel. The low-cost high-speed tool steel for the cutting drill bit is characterized by comprising the following components in percentage by weight: 0.88-0.99% of C, 4.80-5.60% of W, 3.8-4.50% of Mo, 3.80-4.80% of Cr, 1.80-2.25% of V, 0.25-0.45% of Mn, 0.20-0.40% of Si, 0.70-1.30% of Al, 0.10-0.30% of Nb, 0.03-0.06% of La, 0.03-0.06% of Ce, 0.10-0.20% of Ti, 0-0.03% of P, 0-0.03% of S, the balance of Fe and inevitable trace impurities. High-speed steel bars are prepared by a medium frequency induction furnace and an electroslag remelting process. Compared with the prior art, the low-cost high-speed tool steel for the cutting drill bit has the advantages as follows: the using amount of tungsten, molybdenum and other valuable alloys is reduced, aluminum is added and titanium-niobium-lanthanum-cerium mixed rare earth is used for inoculation, so that austenite grains and an eutectic structure of the high-speed steel are obviously refined, most of eutectic carbides are spheroidized and uniformly distributed, the hardness, the red hardness, the impact toughness and the stickness resistance are improved, the cutting service life is prolonged, and the cost is reduced.

Owner:丹阳惠达模具材料科技有限公司

Antifriction coating for metal surface and preparation method of antifriction coating

InactiveCN104789907AHigh strengthImprove antioxidant capacityPretreated surfacesCoatingsManganesePotassium

The invention discloses an antifriction coating for a metal surface and a preparation method thereof. The antifriction coating comprises the following components in mass percent: 0.02-0.05% of carbon, 0.6-0.8% of silicon, 2.5-2.8% of scandium, 3.7-3.9% of vanadium, 9.5-9.8% of nickel, 0.5-0.8% of manganese, 1.2-1.5% of cobalt, 1.4-1.6% of rhodium, 2.2-2.4% of lead, 0.7-0.9% of tungsten, 4.2-4.5% of aluminum, 2.5-2.7% of potassium, 0.85-0.88% of copper, 4.52-4.56% of zinc, 2.57-2.59% of rare earth, 1.24-1.26% of an auxiliary, and the balance of iron.

Owner:SUZHOU TONGMING MACHINERY

Railway steel plate with high strength and low yield ratio and good toughness and manufacturing method thereof

The invention discloses a railway steel plate with high strength and low yield ratio and good toughness and a manufacturing method thereof. The steel plate is prepared from the following components: C, Si, Mn, P, S, Ni, V, Nb, Ti, N and the balance of Fe and impurities, wherein the element contents of the components satisfy the following relation: Nb+V+Ti is less than or equal to 0.11%. Accordingto the manufacturing method, the adding variety and the adding content of alloy elements are reasonably set, the intensifying effect of V and Ti elements and the grain refining effect of Ni and Nb elements are fully achieved, and then a tempering heat treatment process is added after a TMCP (Thermal Mechanical Control Processing) technique, so that steel structures include ferrite, pearlite and asmall quantity of bainite structures so as to enhance the low-temperature toughness of steel. The thickness of the steel plate provided by the invention is 10 to 30 mm, the yield strength ReL of the steel plate at room temperature is greater than or equal to 420 MPa, the tensile strength is 600 to 720 MPa, the low yield ratio is less than or equal to 0.75%, the elongation A is greater than or equal to 20%, the impact work KV2 at the temperature of -46 DEG C is greater than or equal to 130 J, the alloy variety is small, the alloy dosage is low, the production cost is low, and economic benefitsand social benefits are good.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Steel plate with high outdoor oxidation resistance and heat treatment technology thereof

InactiveCN106756550AHigh strengthImprove friction resistanceAnti-corrosive paintsThermal treatmentCobalt

The invention discloses a steel plate with high outdoor oxidation resistance. The steel plate comprises the following components in a percent by mass: 0.06-0.08% of C, 0.04-0.06% of Mn, 0.21-0.23% of Ti, 0.001-0.003% of Co, 0.022-0.025% of Na, 0.24-0.26% of Sc, 0.17-0.19% of Nb, 2.72-2.79% of Cr, 0.123-0.125% of Ca, 0.23-0.25% of V, 0.43-0.47% of Ba, 0.27-0.29% of Cs, 0.23-0.25% of Ta, 6.11-6.13% of Bi, 1.16-1.18% of W and the balance of Fe and unavoidable impurities.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

Gear production technology facilitating reducing composition segregation in gear thickness

InactiveCN104128768ASimple processAppropriate impact resistanceSolid state diffusion coatingFurnace typesCase hardeningSlow cooling

The invention discloses a gear production technology facilitating reducing composition segregation in gear thickness. The technology comprises the steps of blank casting, cutting, heat treatment, finish cutting and grinding in sequence. A raw material for blank casting is 20CrMnTiH. A continuous caster is adopted in the blank casting process, and the pulling rate of the continuous caster is 0.6 m / min-0.72 m / min. The heat treatment comprises the steps that blanks obtained through cutting are heated to 600 DEG C-920 DEG C for carburizing, wherein during carburizing, the hold time of the temperature is not less than 3 h, heating is staged heating composed of first-stage preheating, second-stage carburizing, third-stage diffusing for 1 h-1.2 h and fourth-stage slow cooling; the blanks are quenched after slow cooling and tempered after quenching. The technology is simple in step, the composition segregation in gear thickness is small, technology time is short, and gears which have the advantages that surface hardening layers do not easily come off, and impact resistance, abrasion resistance and intensity are suitable are convenient to obtain.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Alloy steel used for high-temperature electric resistance furnace

The invention provides an alloy steel used for high-temperature electric resistance furnace. The alloy steel is composed of the following components in percentage by weight: 0.25 to 0.68% of C, 2.4 to 5.6% of Mn, 0.40 to 0.65% of Si, not more than 0.03% of P, not more than 0.025% of S, not more than 0.12% of N, 12.3 to 13.1% of Cr, 1.4 to 2.7% of Ni, 0.25 to 0.30% of V, 0.9 to 1.2% of Mo, 2.5 to 3.2% of W, and the balance being Fe. The alloy steel used for high-temperature electric resistance furnace has a good high-temperature antioxidant performance and oxidant resistant performance, excellent wear resistant property, heat resistance, and antioxidant property, and a high corrosion fatigue resistant performance. Moreover the thermal conductivity, conductivity, and overheating sensitivity of the alloy steel are all reduced.

Owner:扬州市金阳光铸造有限公司

High-strength fiber cable and processing process thereof

InactiveCN104867623AHigh strengthImprove corrosion resistanceCommunication cablesInsulated cablesFiberLutetium

The invention discloses a high-strength fiber cable and a processing process thereof. The surface of the fiber cable is coated with a metal coating layer. The metal coating layer comprises, by mass percentage, 0.13 to 0.15% of carbon, 0.12 to 0.15% of silicon, 2.5 to 2.8% of titanium, 4.2 to 4.5% of manganese, 2.65 to 2.68% of sodium, 1.5 to 1.8% of magnesium, 4.32 to 4.35% of cobalt, 2.25 to 2.28% of vanadium, 3.4 to 3.6% of cadmium, 0.52 to 0.54% of tin, 0.46 to 0.48% of tungsten, 1.2 to 1.5% of rhodium, 2.54 to 2.56% of cerium, 3.12 to 3.17% of neodymium, 0.73 to 0.75% of thulium, 0.62 to 0.64% of lutetium, 9.2 to 9.5% of erbium, 7.4 to 7.6 % of a promoter, and the rest being iron.

Owner:JIANGSU JINDI ELECTRONICS TECH

06Cr19Ni10N austenite stainless steel tube and production process

The invention discloses a 06Cr19Ni10N austenite stainless steel tube, which comprises the following components in percentage by weight: 0.04-0.06% of C, 0.010-0.015% of S, 0.020-0.024% of P, 0.35-0.38% of Si, 1.85-1.90% of Mn, 8.2-8.5% of Ni, 19.5-19.8% of Cr, 0.63-0.65% of Ti, 0.02-0.04% of Cu, 0.05-0.08% of B, 0.02-0.04% of Co, 3.2-3.5% of Mo, 2.85-2.90% of V, 4.6-4.8% of composite rare earth, and the balance of Fe. The 06Cr19Ni10N austenite stainless steel tube disclosed by the invention is good in anti-oxidation property, high in tensile strength and yield strength, smooth in surface, good in abrasive resistance and attractive in appearance.

Owner:WUXI XINCHANG STEEL PIPE

High temperature resistant alloy coating for cutter and preparation method high temperature resistant alloy coating

InactiveCN105154792AReduce overheating sensitivityReduce temper brittlenessMolten spray coatingLutetiumNiobium

The invention discloses a high temperature resistant alloy coating for a cutter. The alloy coating comprises the following components in percentage by weight: 0.03-0.05% of carbon,0.52-0.55% of magnesium,1.54-1.56% of chromium,0.25-0.28% of silicon,4.24-4.26% of nickel,0.32-0.35% of vanadium,0.12-0.14% of niobium, 0.52-0.55% of titanium,0.24-0.26% of manganese,3.55-3.57% of molybdenum,1.32-1.35% of selenium,0.23-0.25% of potassium,2.21-2.23% of copper,1.52-1.55% of composite rare earth, and the balance being iron, wherein the composite rare earth comprises the following components in percentage by weight:12-14% of erbium,5-7% of cerium,3-5% of ytterbium,30-35% of neodymium,3-5% of promethium, 8-10% of samarium,8-12% of thulium and the balance being lutetium. The invention further provides a preparation method of the high temperature resistant alloy coating for the cutter.

Owner:南京腾达五金制品有限公司

Cold-pressed steel plate for automotive axle housing and production method thereof

The invention relates to a steel and iron smelting technology, in particular to a cold-pressed steel plate for an automotive axle housing and a production method of the cold-pressed steel plate. The cold-pressed steel plate for the automotive axle housing comprises, by mass percentage, 0.10%-0.16% of C, 0.30%-0.45% of Si, 1.45%-1.60% of Mn, smaller than or equal to 0.15% of P, smaller than or equal to 0.005% of S, 0.045%-0.060% of V, 0.015%-0.030% of Nb, 0.025%-0.050% of Als and the balance Fe. According to the cold-pressed steel plate for the automotive axle housing and the production method, a trace of V elements and a trace of Nb elements are added to ordinary carbon structural steel, and the content of P elements and the content of S elements are reduced, so that the rolling and cooling technology is appropriately changed to improve the strength of the steel plate, and the cold forming performance of the steel plate is improved. By means of the element design and the design of the production technology process, various performance indexes of the steel plate are guaranteed, and the indexes, such as mechanical properties including the stretching property and the impact property, and the ultrasonic flaw detection index, of the steel plate are better than those of similar products.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Vanadium-containing hot-based galvanized sheet and preparation method thereof

PendingCN113957337AIncrease nucleation rateHigh strengthHot-dipping/immersion processesChemical compositionStrip steel

The invention belongs to the technical field of metallurgy, and particularly relates to a vanadium-containing hot-based galvanized sheet and a preparation method thereof, and a base plate of the vanadium-containing hot-based galvanized sheet comprises the following chemical components in percentage by weight: 0.15-0.20% of C, 0.10-0.15% of Si, 0.25-0.29% of Mn, less than or equal to 0.02% of P, 0.03-0.06% of V, less than or equal to 0.01% of S, less than or equal to 0.02% of Cu, less than or equal to 0.03% of Ni, less than or equal to 0.03% of Cr and the balance of Fe and inevitable impurities. The preparation method of the base plate conforming to the components comprises the processes of three-stage acid pickling, five-stage rinsing and the like, and specific acid pickling parameters are adopted. The vanadium-containing hot-based galvanized plate obtained by combining the strip steel with the components and the preparation method has excellent surface quality and high tensile strength, yield strength and corrosion resistance, and the high-strength use requirement of the hot-based galvanized plate is completely met.

Owner:HEBEI IRON AND STEEL +1

Preparation method of brake hose joint

ActiveCN106282764AImprove mechanical propertiesHigh strengthSleeve/socket jointsFurnace typesAcid washingAlloy

The invention relates to a preparation method of a brake hose joint, belonging to the technical field of alloy material processing. The preparation method comprises the following steps: proportioning, smelting, smelting, casting and rolling to obtain a steel plate; sequentially carrying out surface acid washing derusting, limestone coating and phosphating on the steel, and carrying out cold extrusion forming to obtain a brake hose joint blank; heating the brake hose joint blank to 520-540 DEG C, heating to 780-860 DEG C, heating to 980-1050 DEG C, carrying out quenching treatment with quenching oil, keeping the temperature for 1-3 hours, tempering at 350-420 DEG C, and keeping the temperature for 1-2 hours, thereby obtaining a brake hose joint semifinished product; and carrying out pulse electroplating on the brake hose joint semifinished product to obtain the brake hose joint of which the surface is plated with a chromium coating. The brake hose joint is prepared from cold forging steel; and the cold forging steel is subjected to quenching+high temperature tempering dual heat treatment and then subjected to pulse electroplating to enhance the hardness, strength, corrosion resistance, temperature resistance and other properties of the brake hose joint.

Owner:NINGBO YINZHOU CHINAUST AUTOMOBILE FITTINGS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com