High-strength and high-toughness metal powder flux-cored wire

A technology of metal powder core and flux cored wire, applied in metal processing equipment, welding medium, welding equipment, etc., to achieve good anti-knock performance, stable mechanical properties, and excellent seawater corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

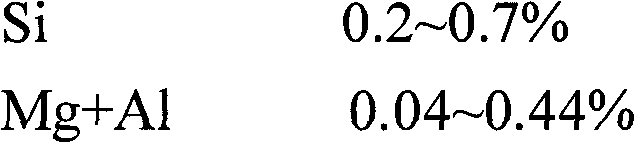

Method used

Image

Examples

Embodiment 1

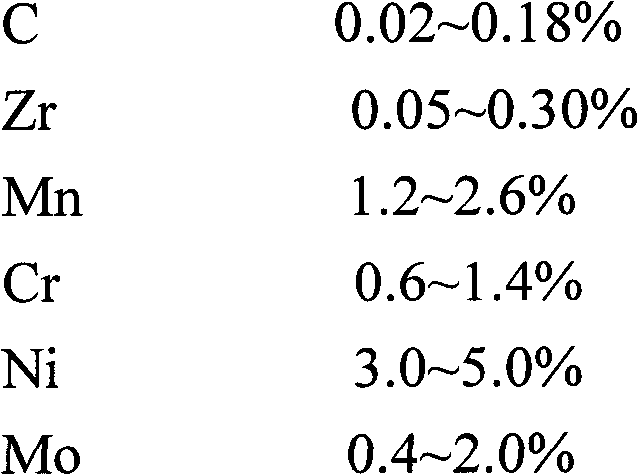

[0055] The steel sheath of the flux-cored wire is made of low-carbon steel strip, and its chemical composition and content in % by weight of the steel strip are shown in Table 2.

[0056] Chemical composition of table 2 steel strip

[0057]

Embodiment 2

[0059] The chemical composition and raw material composition of the drug core powder are shown in Table 3.

Embodiment 3

[0061] The low-carbon steel strip (14X9mm) is filled with core powder, the filling rate is 16-22%, and the diameter is reduced by drawing to form a finished welding wire with a diameter of 1.2-1.6mm.

[0062] According to the content ratio of each component of the flux core, different diameters of flux-cored wires were drawn by different filling ratios for testing. The composition ratio, flux core diameter and filling ratio are shown in Table 4.

[0063] Table 3 Composition of drug core powder

[0064]

[0065] Table 4 Composition ratio, drug core diameter, filling rate test

[0066] serial number

[0067] Ni

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com