Welding robot device for welding of plunger pump power end shell

A welding robot and power end technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of ensuring welding quality and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

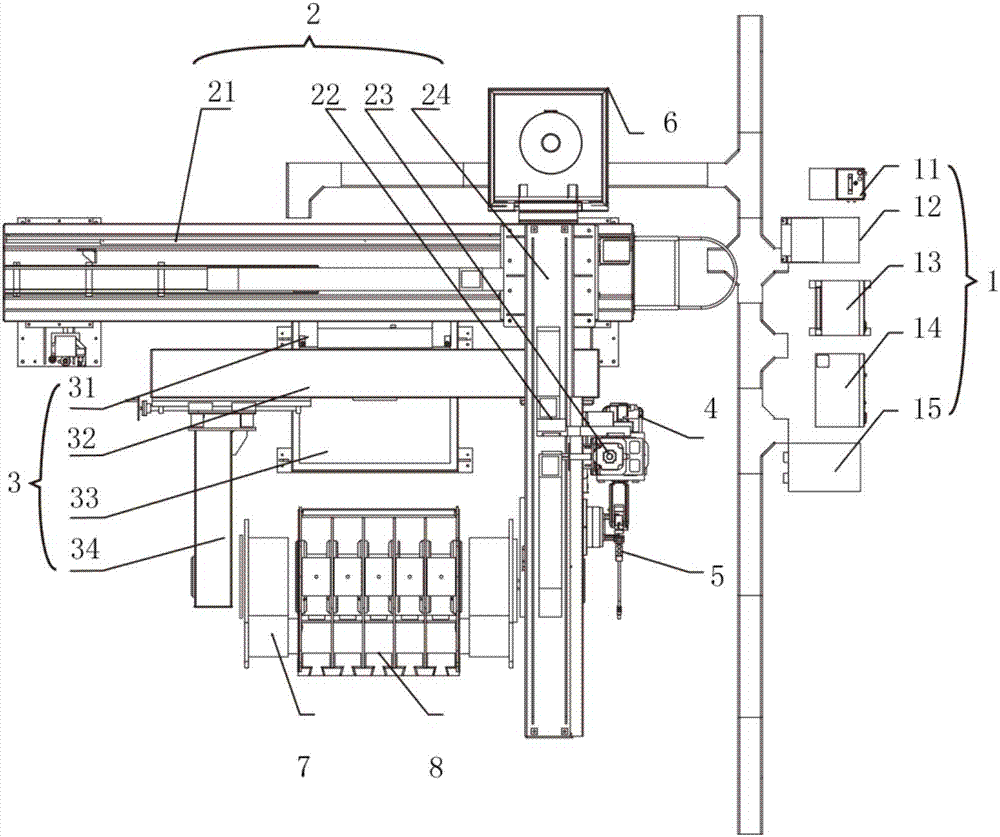

[0020] Such as figure 1 As shown, a welding robot equipment for welding the power end shell of a plunger pump, including: a control system 1, a gantry X-Y-Z coordinate system 2, a space positioner 3, a welding robot arm 4, a welding torch 5, and barreled welding wire Frame 6, rotary shaft 7 and fixture 8. Control system 1 includes control switch 11, welding machine 12, control box 13, peripheral control box 14, transformer 15; gantry X-Y-Z coordinate system 2 consists of gantry 21, coordinate system X-axis 22, coordinate system Y-axis 24 and coordinate system Z The coordinate system Y axis 24 is located above the beam of the gantry 21 and is perpendicular to the vertical plane of the beam, the coordinate system Z axis 23 is connected with the coordinate system X axis 22 through a rotating bearing, and can rotate 360° along the coordinate system X axis The welding torch 5 is installed on the front end of the welding mechanical arm 4, the welding mechanical arm 4 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com