Field welding method of domestic A335 P91 high-pressure thick-wall pipe

A technology of A335P91 and welding method, which is applied to welding equipment, tubular objects, arc welding equipment, etc., can solve the problems of low efficiency of manual welding, affect the construction period, and restrict the progress of piping, so as to shorten the heat treatment and welding period and reduce labor intensity , Improve the quality of weld seam and the effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, with domestic A335P91 pipeline DN350 As the base metal, the following welding methods are adopted:

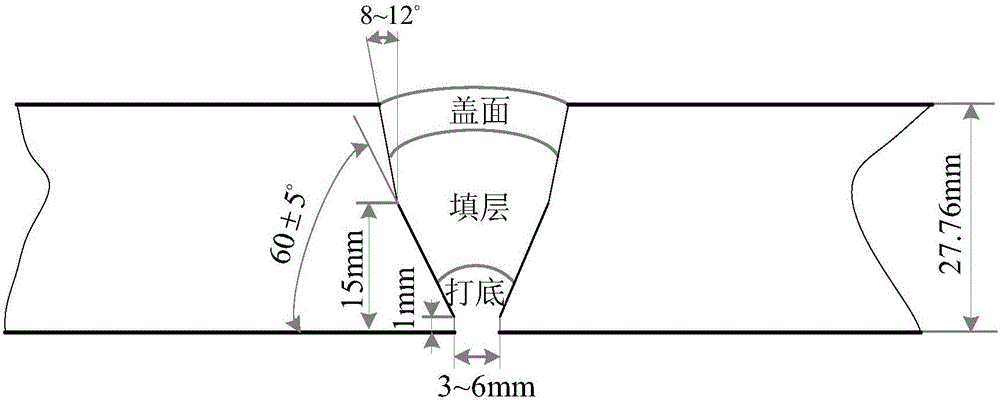

[0025] (1) Put the welding part of the pipe to be welded according to the attached figure 1 As shown, it is processed into a double V-shaped groove, the height of the blunt side is 1mm, the angle between the bottom of the groove and the length direction of the pipe is 60±5°, the height is 15mm, the angle between the upper part of the groove and the length direction of the pipe is 78-82°, and Carry out coloring inspection on the groove surface to ensure that the groove has no surface cracks, and clean the surface rust, oil stains, oxides, etc. on the surface of the groove and the 20mm areas on both sides;

[0026] (2) Assemble the two sections of welded pipes to ensure that the gap between the end faces of the butt joints is 3 to 6 mm, the height is flat, and the amount of misalignment is not greater than 1 mm;

[0027] (3) Manual argon arc welding GTAW is u...

Embodiment 2

[0045] Example 2, with domestic A335P91 pipeline DN600 As the base metal, the following welding methods are adopted:

[0046](1) Put the welding part of the pipe to be welded according to the attached figure 1 As shown, it is processed into a double V-shaped groove, the height of the blunt side is 1mm, the angle between the bottom of the groove and the length direction of the pipe is 60±5°, the height is 15mm, the angle between the upper part of the groove and the length direction of the pipe is 78-82°, and Carry out coloring inspection on the groove surface to ensure that the groove has no surface cracks, and clean the surface rust, oil stains, oxides, etc. on the surface of the groove and the 20mm areas on both sides;

[0047] (2) Assemble the two sections of welded pipes to ensure that the gap between the end faces of the butt joints is 3 to 6 mm, the height is flat, and the amount of misalignment is not greater than 1 mm;

[0048] (3) Manual argon arc welding GTAW is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com