Iron-based powder metallurgy friction material and preparation method thereof

A technology of iron-based powder metallurgy and friction materials, which is applied in the field of materials, can solve problems such as use and description of test working conditions, and achieve the effects of small deformation, low density, and low expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

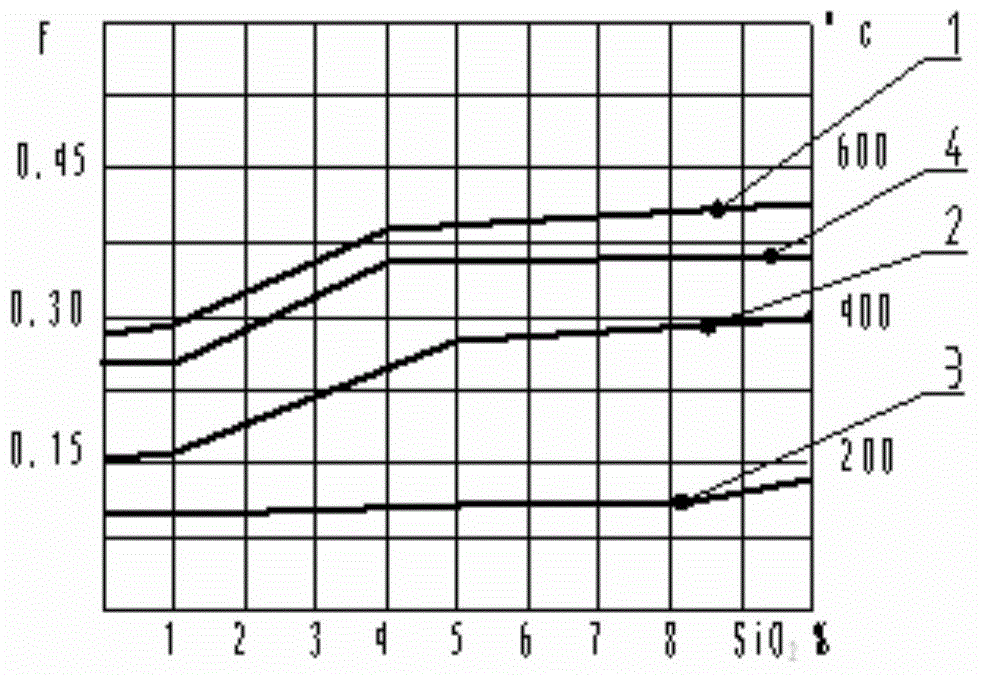

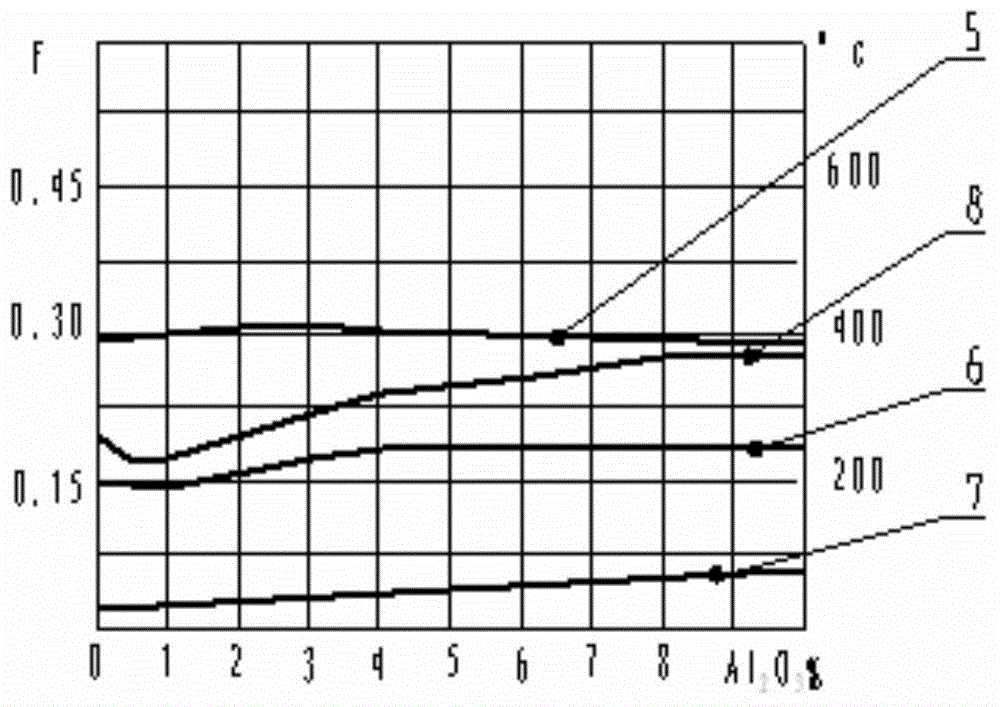

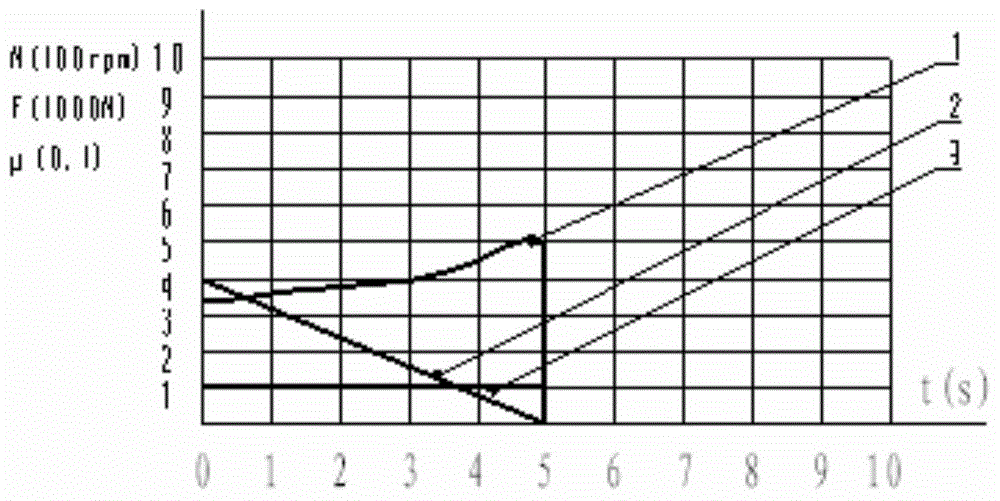

Image

Examples

Embodiment Construction

[0069] This embodiment is an iron-based powder metallurgy friction material. The iron-based powder metallurgy friction material consists of 64% iron powder, 9% copper powder, 3% manganese powder, 10% graphite powder, 3% silicon carbide powder, 2% molybdenum disulfide powder, 4% Silica powder, 3% aluminum oxide powder and 2% precipitated barium sulfate powder, the percentages are all mass percentages. The iron powder is FHY200, Fe≥98%, and the standard GB / T4136-94 is implemented. The copper powder is FTD1, Cu≥99.8%, and the standard GB / T5246-2007 is implemented. The manganese powder is -100~+300 mesh DJMnD, Mn≥99.7%, and implements the standard YB / T051-2003. The graphite powder is +80 mesh scale-like, with a content of C ≥ 99.99%, and the standard GB / T3518-95 is implemented. The silicon dioxide powder is -100 to +200 mesh, and the aluminum oxide powder is -100 to +250 mesh calcined α type. The silicon carbide powder is green silicon carbide of -120 mesh, and the standard GB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com