Fully automatic drilling anchor work vehicle

A fully automated, working vehicle technology, applied in drill pipe, drill pipe, installation of anchor rods, etc., can solve the problems of long occupation time, unbalanced driving support, low support efficiency, etc., to reduce offset and improve installation efficiency. , the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is attached figure 1 , 2 And embodiment the present invention is described further. This example should not be used to explain the limitation of the protection scope of the present invention.

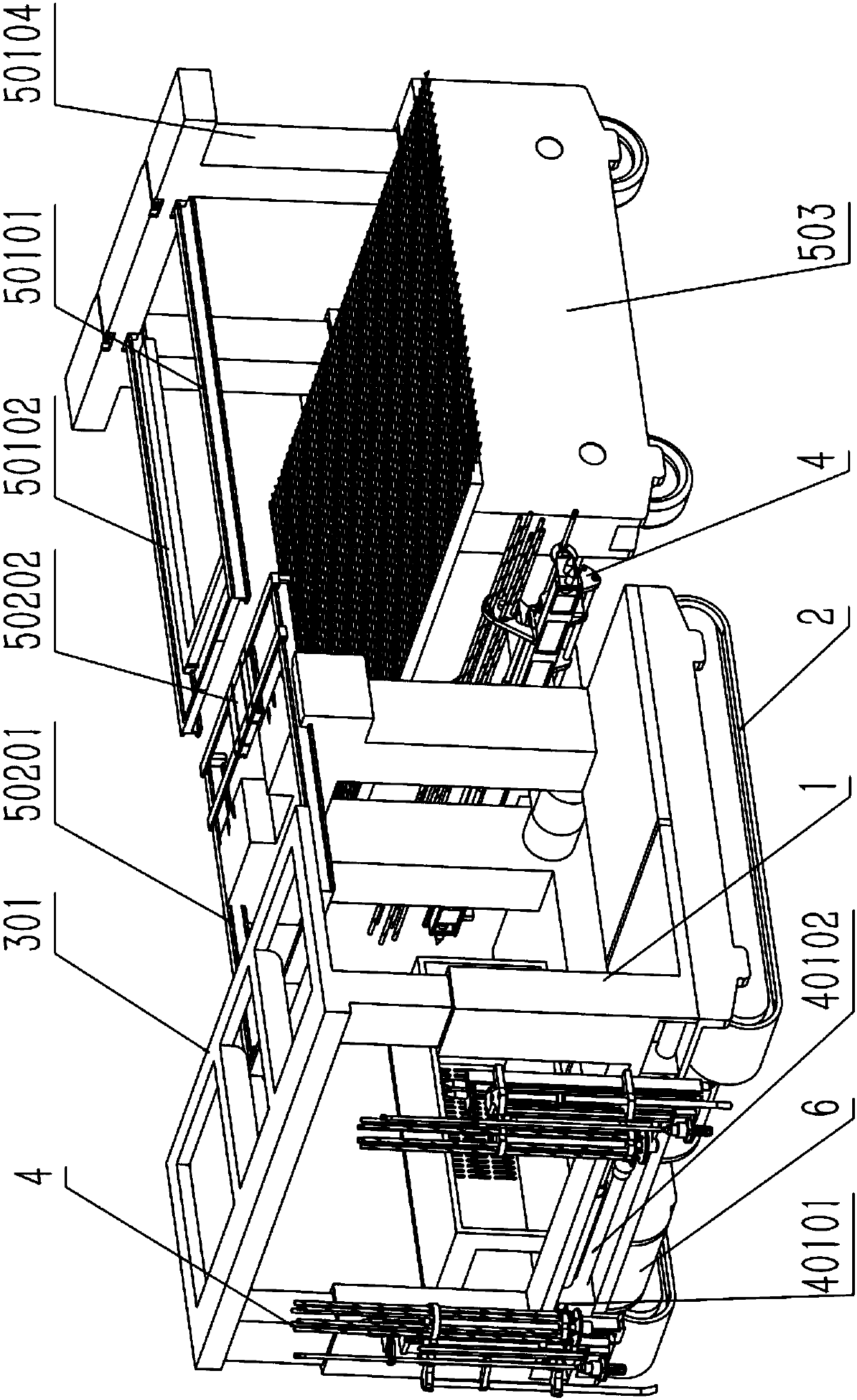

[0025] According to an embodiment of the present invention, the fully automatic drilling and anchoring operation vehicle is suitable for rapid support of roadways in excavation working faces, such as figure 1 The fully automatic drilling and anchoring operation vehicle shown includes: a vehicle body 1, a self-propelled mechanism 2, a temporary support mechanism 3, an automatic drilling and anchoring device 4, and an anchor net storage and delivery mechanism 5.

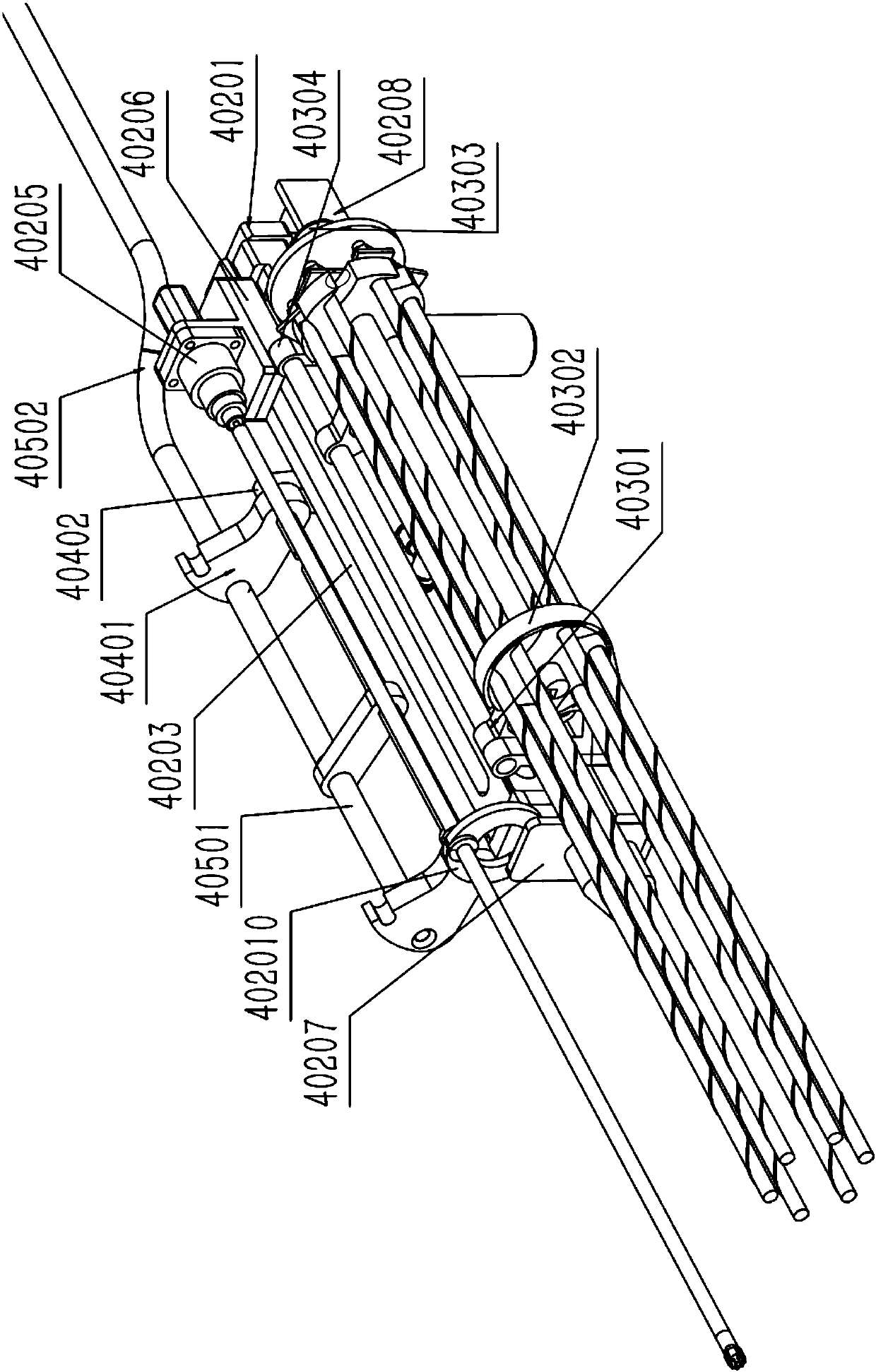

[0026] The drilling and anchor automation device 4 is as figure 2 Shown includes: drill rack pose conversion mechanism 401 , drill rack mechanism 402 , anchor rod storage and replacement mechanism 403 , drill rod loading and unloading mechanism 404 , and anchoring agent injection mechanism 405 . The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com