Composite support device of dynamic pressure softrock tunnel based on steel pipe concrete bracket

A technology of steel pipe concrete and composite support, which is applied in the directions of pillars/supports, earthwork drilling, temporary shields, etc., which can solve the problems of large roadway deformation, high support investment, insufficient support resistance, etc., and achieve control of roadway deformation , strong support resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

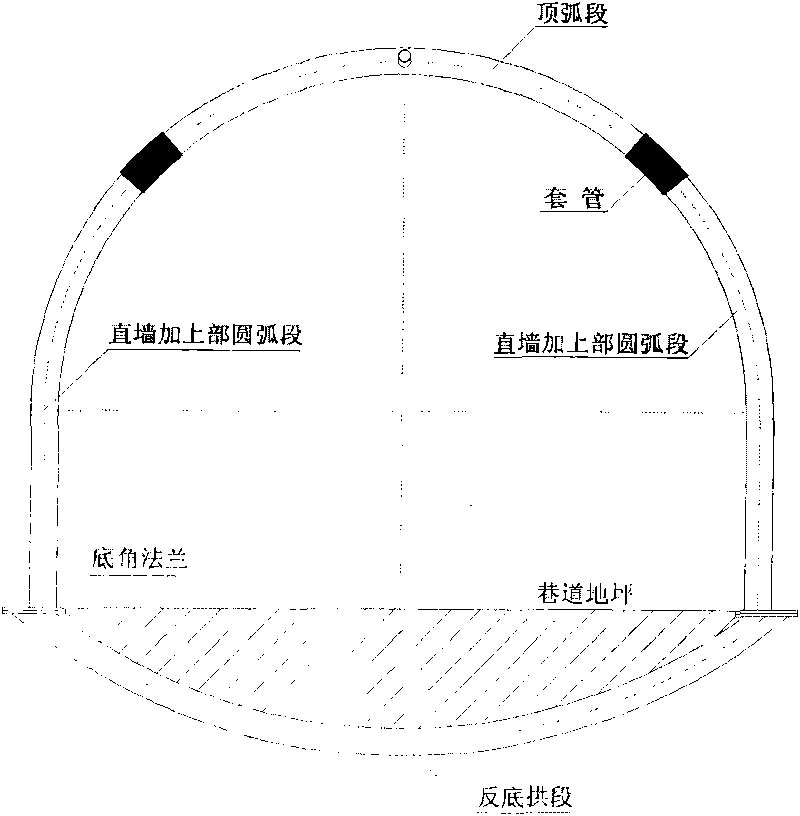

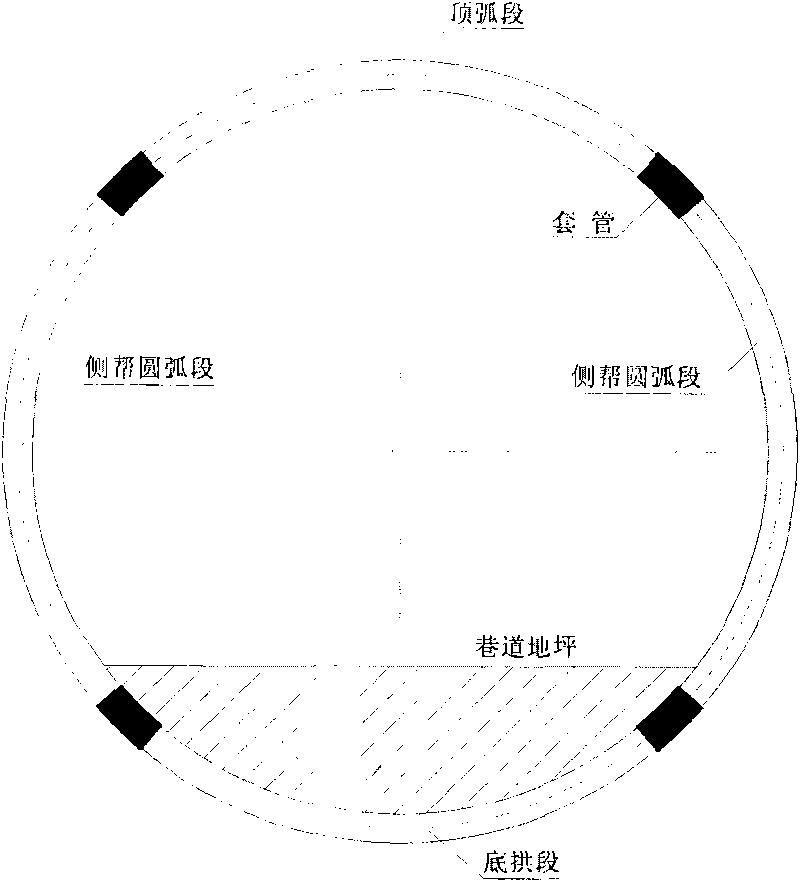

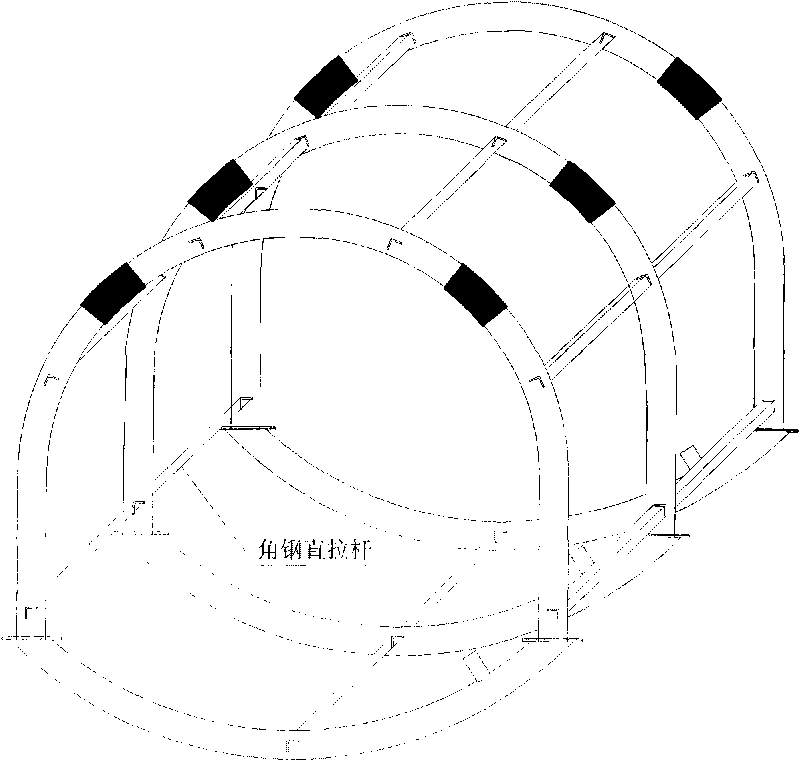

[0020] The composite supporting device of the dynamic pressure soft rock roadway of the present invention based on the steel pipe concrete support, its preferred specific implementation mode is:

[0021] The steel pipe concrete support is included, and a flexible pressure equalization and pressure relief layer is arranged between the steel pipe concrete support and the supported surrounding rock.

[0022] It can also include a surrounding rock grouting reinforcement device. The surrounding rock grouting reinforcement device includes a plurality of hollow surrounding rock grouting anchors. , the outer end of the bolt is integrated with the shotcrete layer on the surface of the surrounding rock.

[0023] The shotcrete layer is covered with a flexible sealing layer, or a flexible sealing layer can also be provided between the surrounding rock surface and the shotcrete layer.

[0024] The steel tube concrete support can be provided with a support column, and the support column ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com