Crawler-type walking rockbolt drilling carriages

A rock bolt drilling rig and walking technology, which is applied in the installation of bolts, drilling equipment, earthwork drilling, etc., can solve the problems of complex structure, high price and high failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

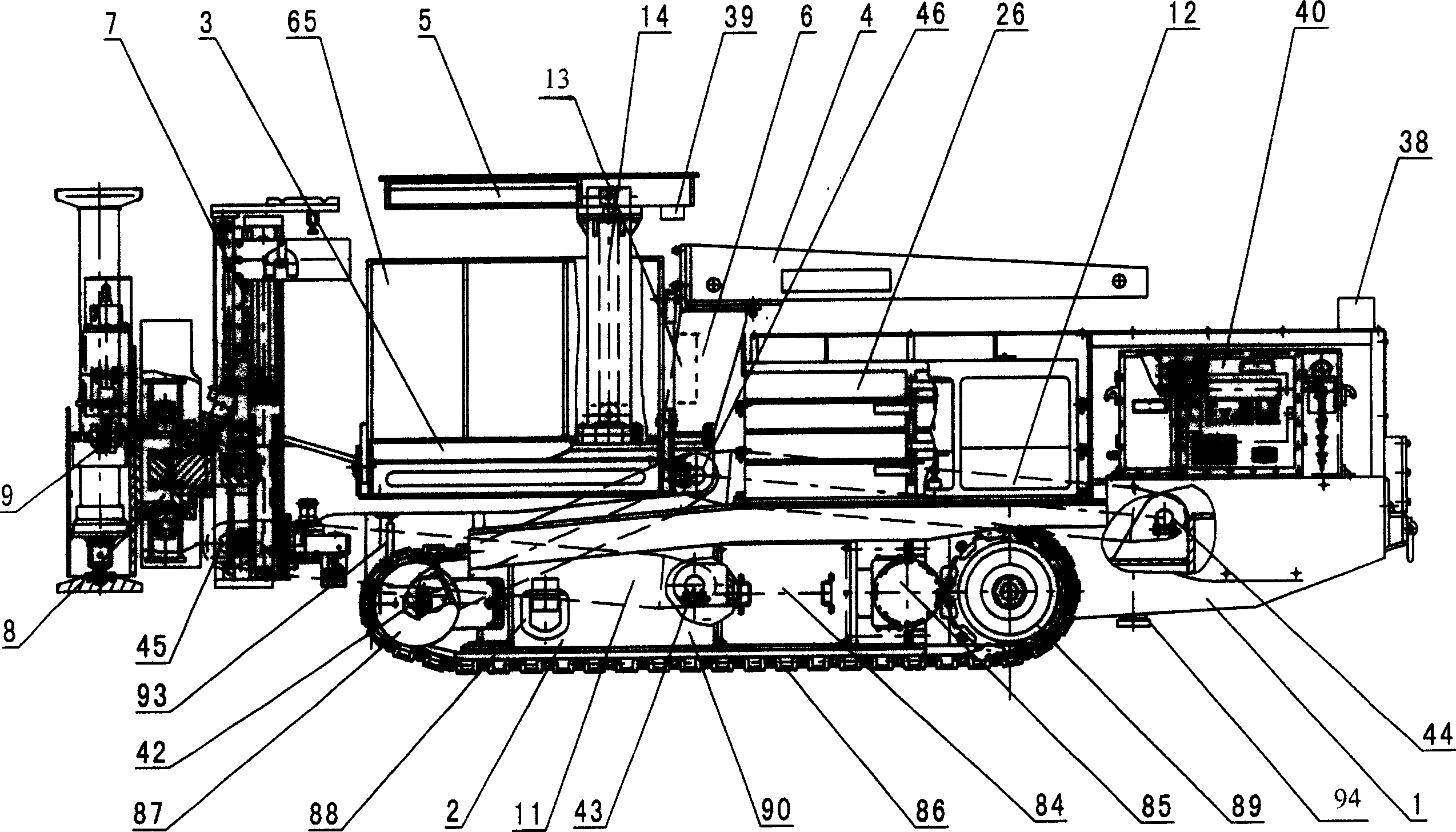

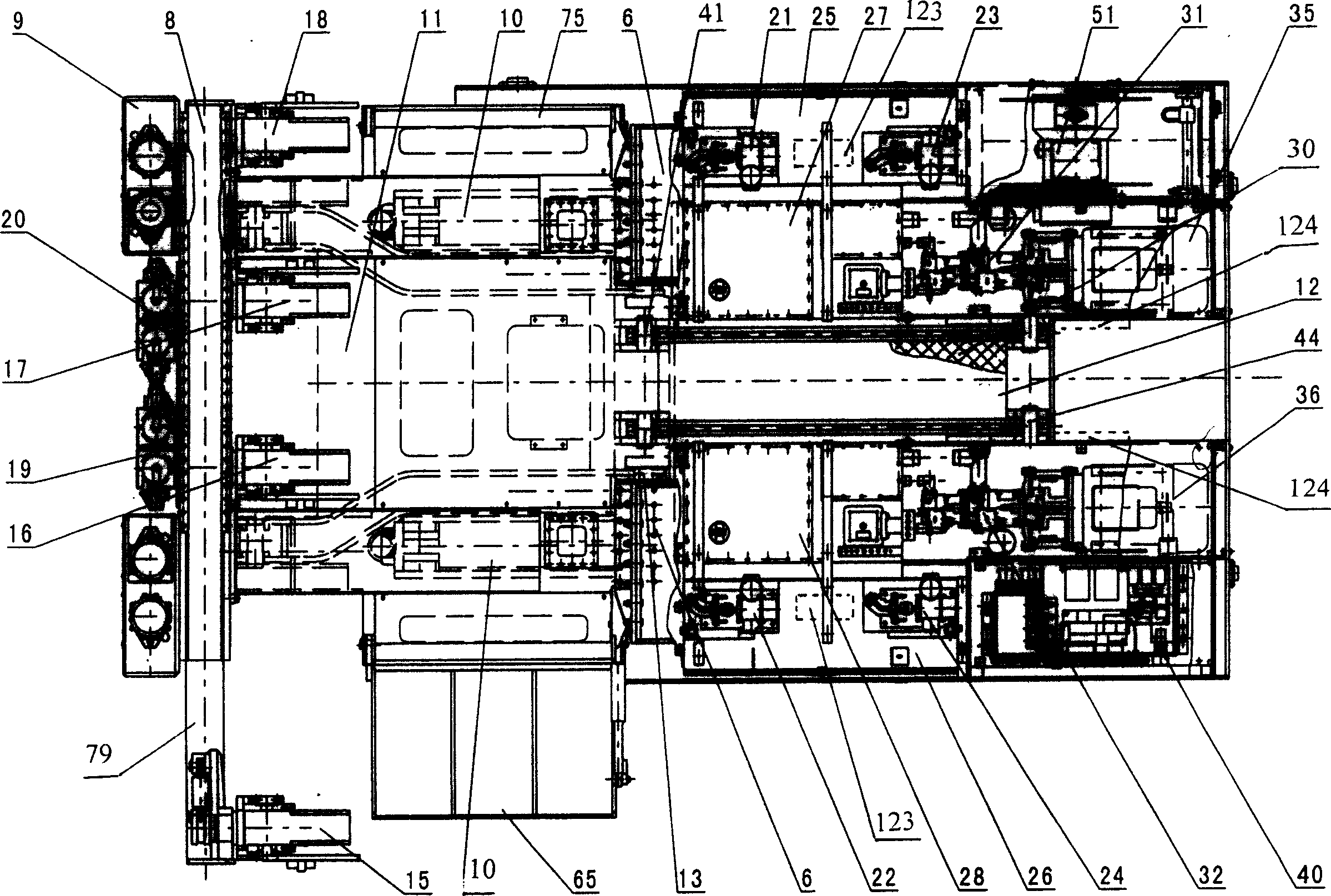

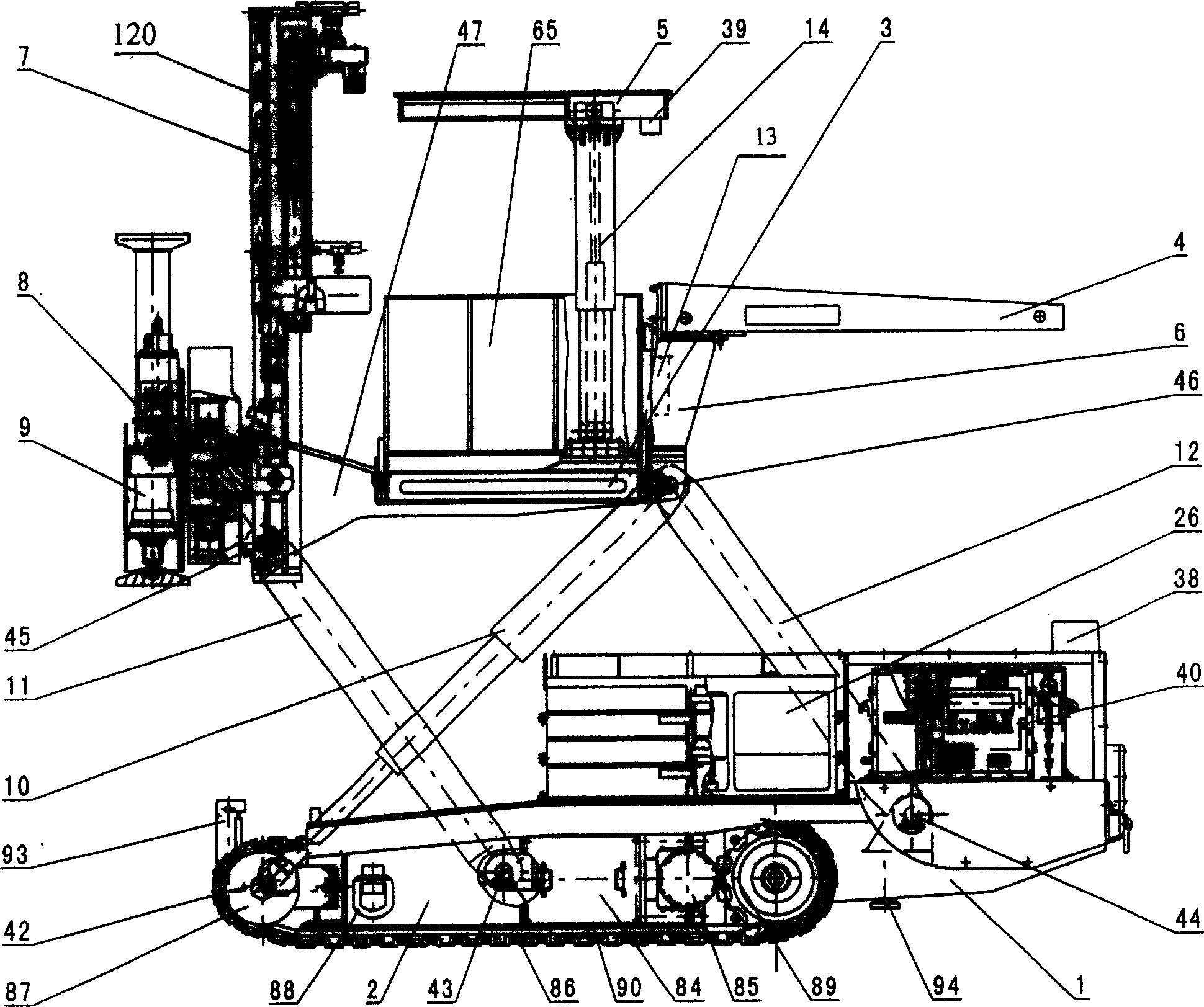

[0038] figure 1 , 2 As shown in , 3, this drilling rig is a large and heavy machinery with a dead weight of more than 40 tons. Since it works in the harsh environment of the underground, all electrical components have been designed for explosion-proof; machine base 1, traveling mechanism 2, workbench 3. Drill frame assembly 7, slide rail assembly 8, support assembly 9 and lifting mechanism form a complete machine model; , support assembly 9, hopper 4, material rack 6, ceiling 5, lifting frame oil cylinder 14 and the lifting mechanism fall, the height is reduced, the center of gravity is balanced, the machine base 1 and each mechanism are placed on the walking mechanism 2 on both sides, The machine is also in this state when it travels for a long distance, so the two traveling mechanisms 2 on the left and right are the load-bearing support center of gravity of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com