Yielding strata bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

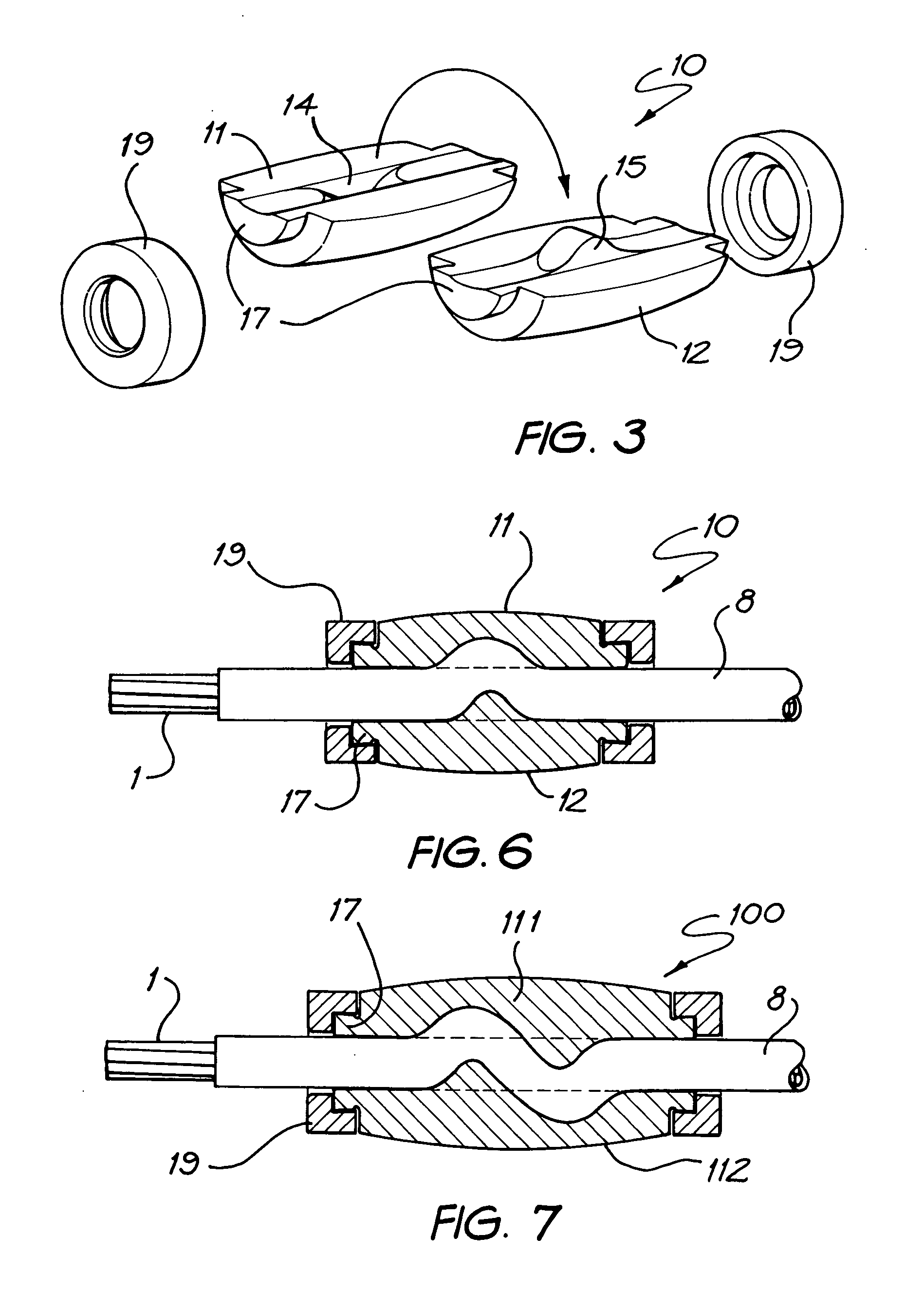

[0033]FIG. 7 illustrates the anchor 100 in which the keeper rings 19 are as before but each of the shells 111 and 112 is provided with a recess 114 and a protrusion 115. As will become apparent hereafter, the purpose of the anchor 100 of FIG. 7 is to provide a greater degree of work before the cable 1 can be passed there through.

first embodiment

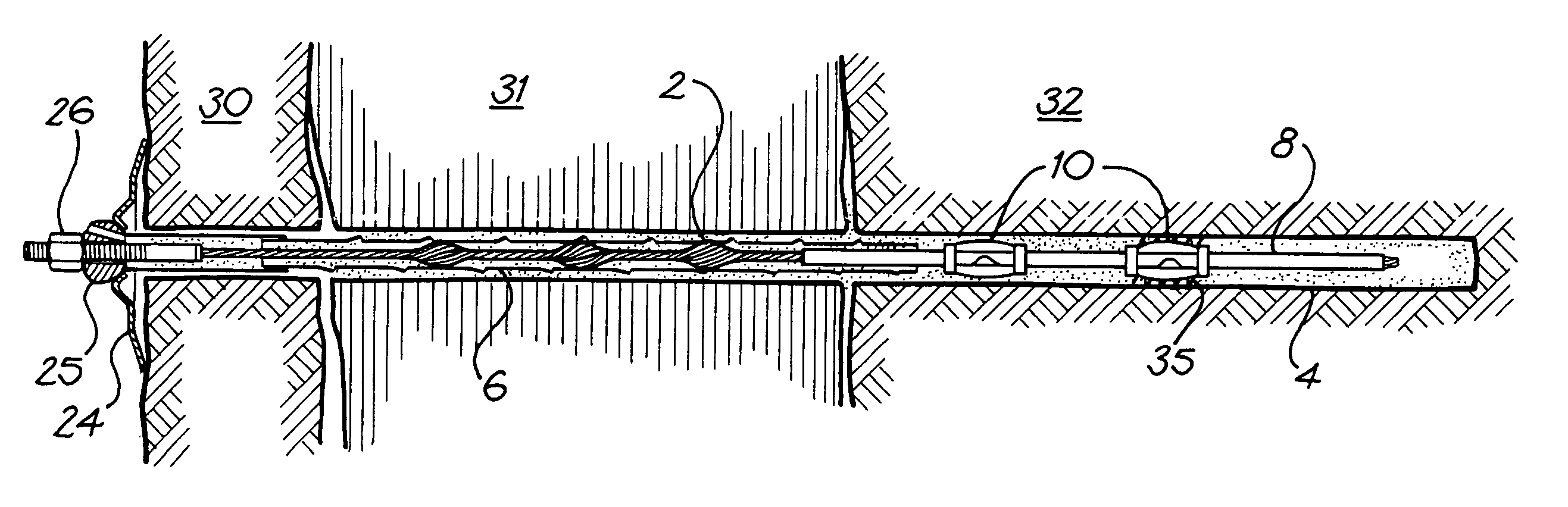

[0034] Turning now to FIG. 8, a yielding cable bolt 21 is illustrated. The tendon 22 of the bolt 21 is fabricated from the multi-strand steel cable 1 and the near end is provided with the threaded end fitting 23 which cooperates with a load plate 24, grout injector 25 and nut 26. The grout injector 25 works in the general manner described in the abovementioned Australian Patent No. 669,393 (WO 94 / 05900). In the embodiment illustrated in FIG. 8, a single anchor 10 is secured adjacent the free end of the bolt 21, however, in the embodiment illustrated in FIG. 9 a pair of spaced apart anchors 10 are so secured.

[0035] In the particular embodiment illustrated in FIG. 9, three strata 30, 31 and 32 are illustrated and strata 30 and 32 are relatively strong whereas stratum 31 is relatively weak and liable to movement. The tube 8 covers the cable 1 essentially throughout the stratum 32 but does not cover the cable 1 essentially throughout the strata 30 and 31. As a consequence, there is good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com