Construction technology for allowing tunnel to pass through ultra-large karst cave

A kind of construction technology and super-large technology, which is applied in the construction technology field of tunnel passing through karst caves, can solve problems such as lack of technical means and measures, and achieve the effect of eliminating potential safety hazards, controlling construction costs and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

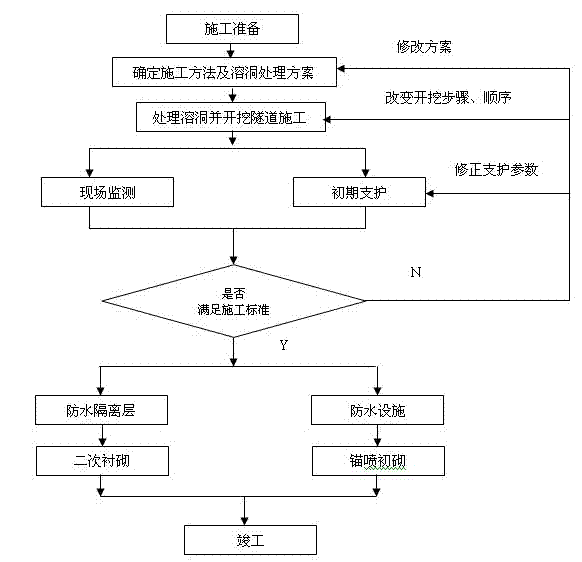

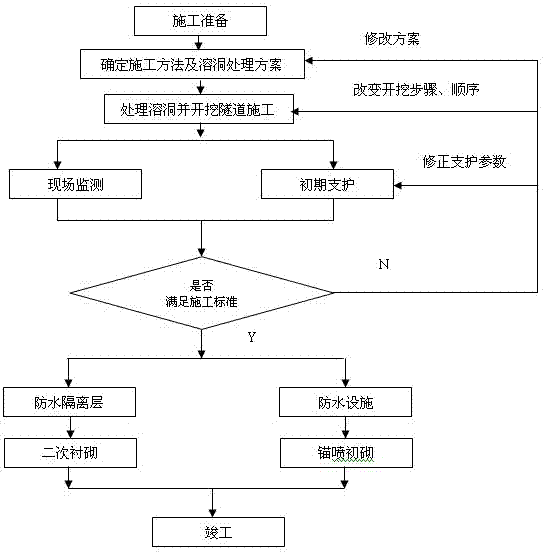

[0030] Such as figure 1 As shown in the figure, the construction process of the tunnel passing through the super-large karst cave includes the following steps:

[0031] 1) The underground part of the karst cave is treated with a simple bridge: the tunnel passes through the karst cave, and a simple bridge is built in the karst cave, which is treated with a pile foundation; and a steel-concrete structure cap is poured on the pile foundation as a whole, so that the lower part forms a whole; digging piles into holes;

[0032] 2) Initial support, support wall is set on one side of the karst cave: the support wall is fully penetrated into the upper rock mass on the side of the karst cave. The initial support forms an integral support structure; the part above the tunnel outline is constructed with anchor rods on the wall of the cave, and 1m is reserved to connect with the support wall as a whole;

[0033] 3) Set up parallel pilot tunnels: Excavate the main tunnel while processing ...

Embodiment 2

[0041] 1) Determine the treatment plan for tunnels passing through super-large karst caves.

[0042] A. The underground part of the cave is treated with a simple bridge.

[0043] The tunnel passes through the karst cave, and a simple bridge is built in the karst cave, which is treated with pile foundation. Due to the limited terrain, the pile foundation can only be excavated manually to form holes, and the steel-concrete structure cap is poured on the pile foundation as a whole, so that the lower part forms a whole, the structure is firm and reasonable, and the stability of the lower structure is ensured.

[0044] B. Improve the initial support, and set up a supporting wall on one side of the cave.

[0045] The design and construction of the karst cave treatment adopt the principle of the new Austrian method, and give full play to the role of the supporting wall: on the one hand, the supporting wall is fully penetrated into the upper rock mass on the side of the karst cave, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com