A pin timbering process and sectionalized hollow mud injecting stay bolt thereof

A technology of bolt support and grouting bolt, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of affecting the service life, small anchoring force, and not suitable for strata that need rapid support. , to improve the reliability and durability, the grouting body is full and uniform, and the effect of avoiding single applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

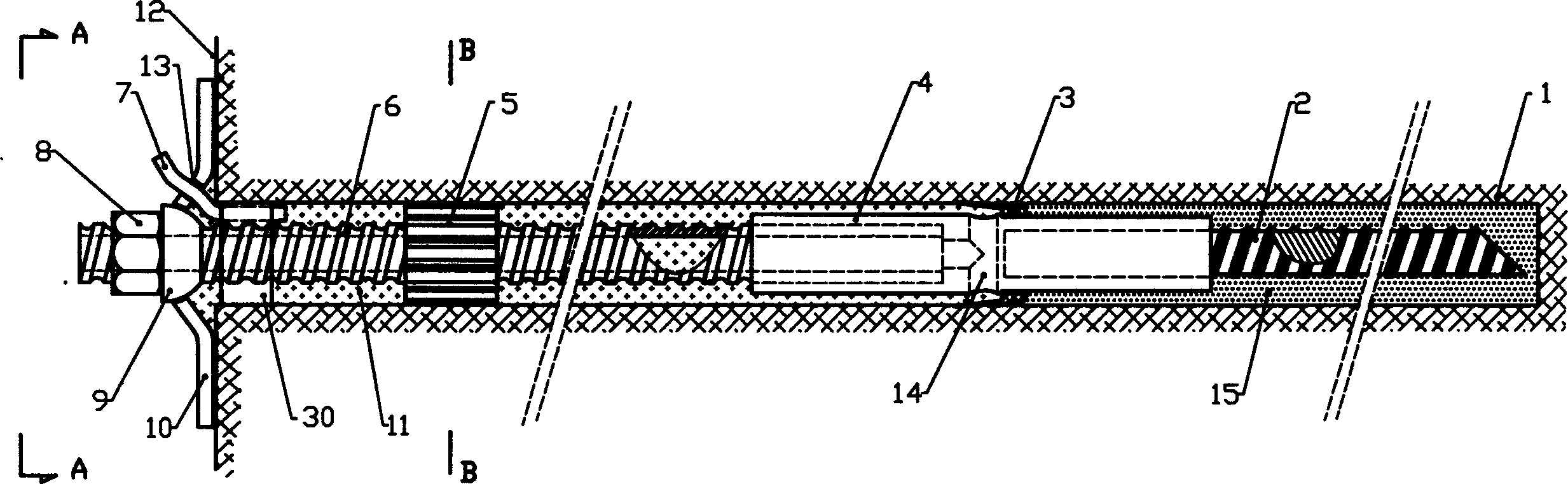

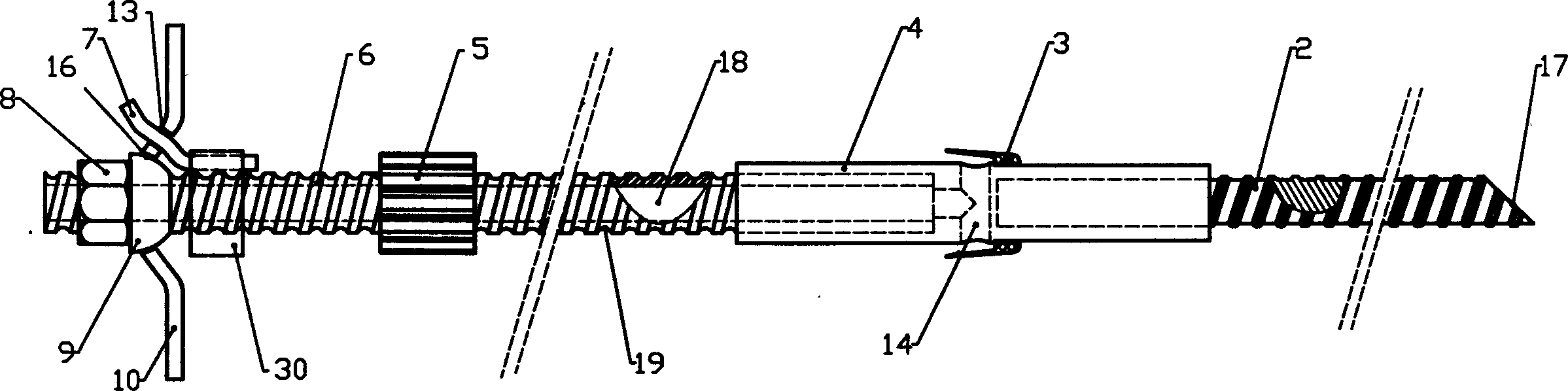

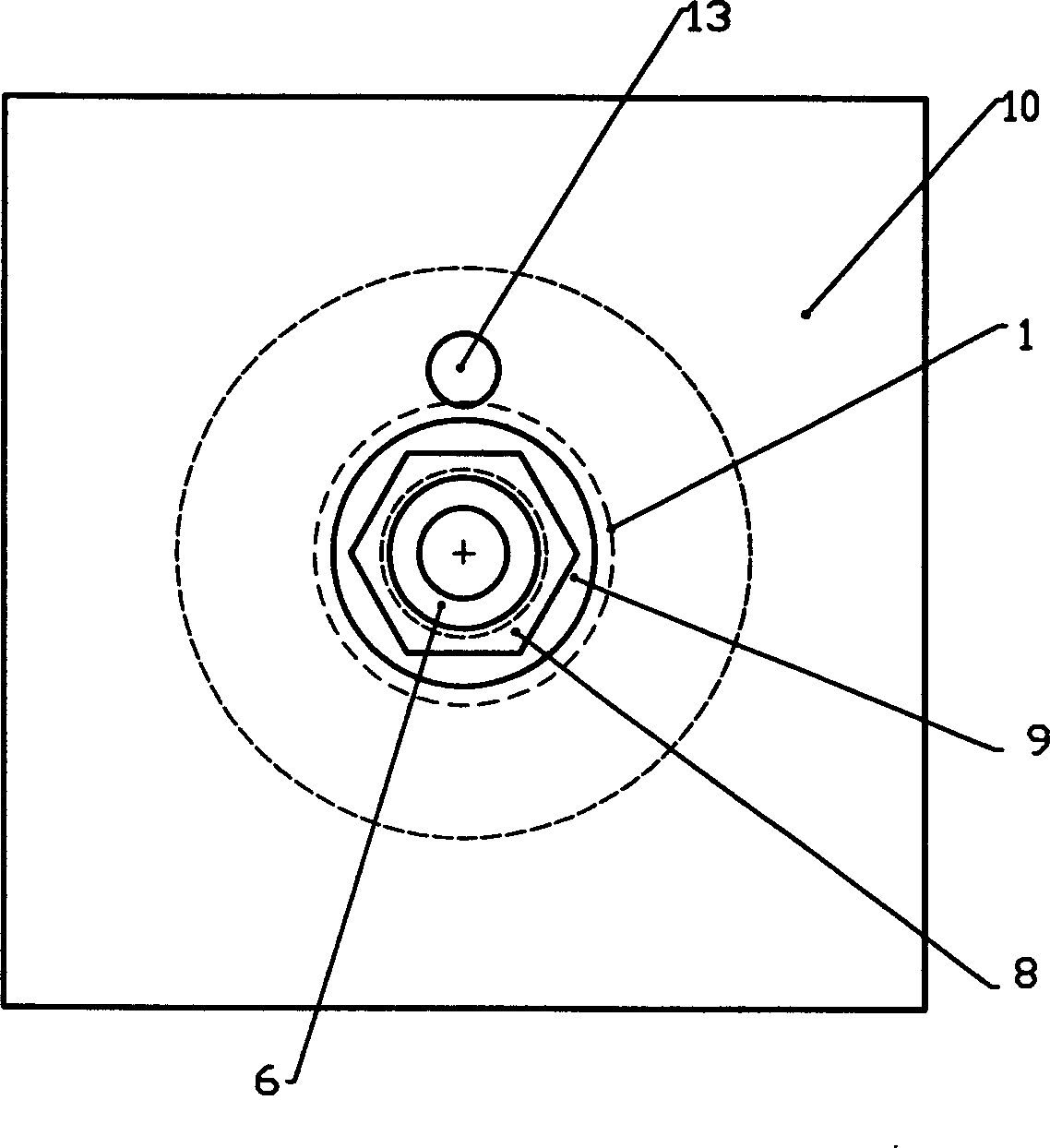

[0037] Such as figure 1 It is an elevation view of the bolt installed in the stratum after adopting the bolt support method of the present invention. figure 2 The utility model relates to a segmented hollow grouting anchor adopted in the bolt support method of the present invention. The anchor rod of the present invention is composed of a solid rod body 2 at the front end and a hollow rod body 6 at the rear. The hollow rod body 6 and the solid rod body 2 are combined through a connecting sleeve 4 . There are several centering devices 5; the connecting sleeve 4 and the cavity 18 of the hollow rod body 6 are provided with a lateral channel 14; the support plate 10, the nut 8, the washer 9 are matched with the end of the hollow rod body 6; A hole 13 is provided on the supporting backing plate 10, and the pipeline 7 passes through the hole 13.

[0038] The bolting method adopted in the present invention: drill a hole 1 in the stratum with a drilling machine and clean the drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com